Top-quality Aluminum Extrusion Beams: Get the Best Solution for Your Project

By:Admin

Subtitle: {}

Date:

Introduction:

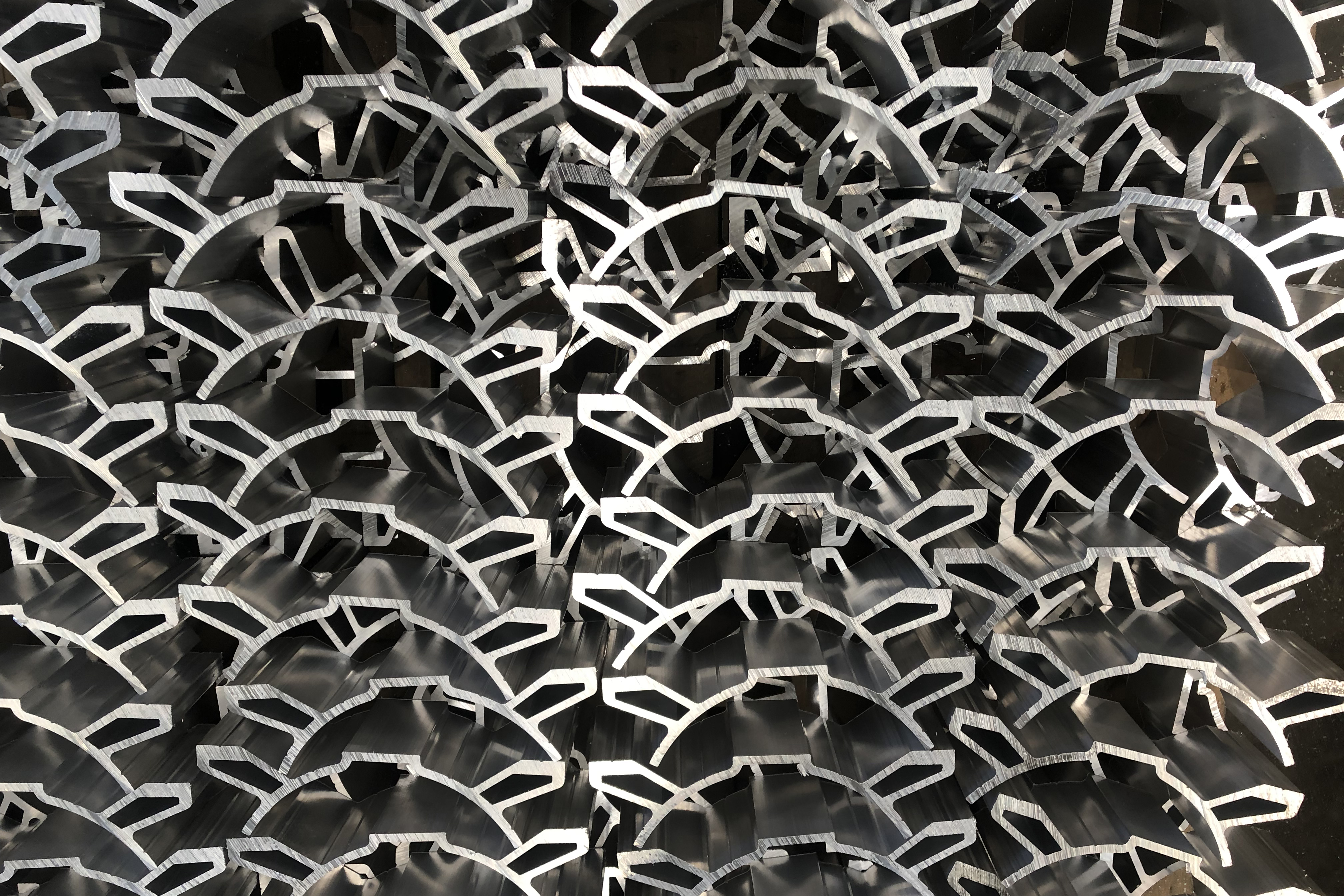

In today's rapidly evolving construction industry, the demand for lightweight, durable, and sustainable building materials is on the rise. Addressing this need, a pioneering company has unveiled a groundbreaking solution - Aluminum Extrusion Beams. These state-of-the-art beams have already garnered significant attention from industry experts due to their exceptional strength-to-weight ratio and myriad of construction applications. By harnessing the power of advanced manufacturing techniques, these beams enable cost-effective, sustainable, and efficient construction practices. This article delves into the revolutionary features and applications of Aluminum Extrusion Beams and their potential to transform modern construction practices.

Section 1: Introduction to Aluminum Extrusion Beams

The Aluminum Extrusion Beams, developed by [Company Name], are engineered using high-quality aluminum alloys and cutting-edge extrusion technology. This manufacturing process ensures superior dimensional accuracy and consistent structural integrity throughout the beams' lengths. The exceptional strength-to-weight ratio possessed by these beams offers distinct advantages over traditional building materials. Despite being significantly lighter than conventional steel or concrete beams, Aluminum Extrusion Beams exhibit remarkable structural stability, rendering them an ideal solution for various construction projects.

Section 2: Features and Advantages

2.1 Lightweight yet Strong:

The inherent lightweight nature of aluminum, coupled with the beams' precise extrusion design, allows for seamless transportation and installation. Their unique aluminum alloy composition offers unrivaled strength, enabling them to withstand heavy loads while maintaining long-term structural stability. This lightweight characteristic also translates into cost savings during transportation and reduces the environmental impact.

2.2 Sustainable Construction:

Aluminum Extrusion Beams have gained traction as an environmentally friendly alternative to traditional building materials. Aluminum is highly recyclable, with little to no degradation in quality, making it an ideal choice for sustainable construction practices. These beams can be easily repurposed, thereby reducing construction waste and minimizing the industry's carbon footprint.

2.3 Versatility and Adaptability:

The design flexibility of Aluminum Extrusion Beams allows for customized profiles and sizes tailored to specific construction needs. Their adaptability makes them suitable for a wide range of applications, from residential and commercial buildings to industrial and infrastructural projects. Additionally, their precision-engineered profiles enable easy integration with other building components, enhancing construction efficiency.

Section 3: Applications

3.1 Residential Construction:

Aluminum Extrusion Beams offer a myriad of possibilities in residential construction, enabling architects and engineers to create innovative and aesthetically pleasing designs. These beams can be used as load-bearing members, roofing systems, or even as framing components for modular constructions. Their corrosion resistance and low maintenance requirements make them an attractive choice for homeowners seeking durable and long-lasting solutions.

3.2 Commercial and Industrial Construction:

In the realm of commercial and industrial construction, Aluminum Extrusion Beams offer unparalleled strength and stability. Their lightweight nature translates into reduced foundation requirements and simplified installation processes. Their ability to span longer distances enables architects to design open-concept spaces, providing ample flexibility. Additionally, their enhanced thermal properties contribute to more energy-efficient buildings, reducing operating costs in the long run.

3.3 Infrastructure Projects:

The versatility of Aluminum Extrusion Beams extends to infrastructure projects as well. From bridge construction and sports stadiums to high-rise buildings and railway stations, these beams provide exceptional load-bearing capacity and aesthetic appeal. Moreover, their ability to withstand challenging environmental conditions, such as corrosion and extreme temperatures, makes them an excellent choice for infrastructure projects that require durability and longevity.

Conclusion:

Aluminum Extrusion Beams have emerged as a game-changer in the construction industry, offering unparalleled strength, versatility, and sustainability. Their lightweight yet robust design, coupled with the inherent benefits of aluminum, makes them an ideal choice for architects, engineers, and contractors. By embracing these innovative beams, construction projects can achieve higher cost-effectiveness, reduced environmental impact, and enhanced structural performance. With their remarkable potential to transform modern construction practices, Aluminum Extrusion Beams are poised to shape a progressive, sustainable future for the industry.

Company News & Blog

Revamp Your Home with Affordable Aluminum L-Shaped Shelves

Aluminum L Shape Taking the Industry by StormThe use of aluminum L shape is rapidly gaining popularity in the construction industry, thanks to its exceptional qualities. Among the reasons why it is quickly becoming the go-to option in construction are its strength, robustness, and aesthetic appeal.One of the major players in the design and supply of aluminum L shape is {Brand Name Removed}. The company has gained a reputation for its excellent service and innovative solutions. It employs state-of-the-art technology and only works with high-grade materials to produce premium quality products. From custom-made aluminum extrusions to standard profiles, {Brand Name Removed} offers a broad range of aluminum products to suit various construction projects.{Brand Name Removed} understands that the modern construction industry demands unique products that align with the latest trends and standards. This is why it has invested heavily in research and development to create innovative solutions for its clients. For instance, one of its products - the aluminum L shape - has been designed to meet the current demands of the market.Here's what makes the aluminum L shape an excellent choice for construction projects:Strength and DurabilityAluminum L shape is highly durable and resistant to corrosion, making it ideal for use in exterior and interior applications. Additionally, aluminum is structurally strong, providing excellent support for heavy loads.LightweightDespite its robust nature, aluminum L shape is lightweight, which makes it easy to handle and install.Aesthetic AppealAluminum L shape is highly versatile and available in various colors and finishes. This means it can be used to create any desired look, from a classic to a modern, sleek finish. Furthermore, {Brand Name Removed} offers custom solutions, allowing clients to have products that match their specific requirements.Environmentally FriendlyAluminum is 100% recyclable, making it an environmentally friendly option. This is particularly important in today's environmentally conscious society where people are keen on reducing their carbon footprint.ApplicationsAluminum L shape can be used in a broad range of applications, including facades, window frames, doors, furniture, and much more. It is also ideal for use in industrial and commercial applications where durability and strength are crucial.{Brand Name Removed} offers clients a complete range of services, from design to installation. Its team of experts works closely with clients to develop customized solutions that suit their unique needs. Moreover, the company has invested in modern technology to ensure that its clients receive high-quality products and services.One of the primary goals of {Brand Name Removed} is to provide clients with products that meet their budget without compromising on quality. The company has an efficient cost structure, which allows it to keep the prices of its products low without compromising on quality.In conclusion, the aluminum L shape is rapidly becoming a preferred choice in the construction industry. This is due to its exceptional qualities, including strength, durability, lightweight, aesthetic appeal, and environmentally friendly nature. {Brand Name Removed} is at the forefront of supplying high-quality aluminum L shape and other aluminum products to the industry. The company's innovative solutions, coupled with its dedication to excellent service, have earned it a reputation as a leading supplier in the industry.

High-Quality Rolled Aluminum Plate and Sheet: The Latest Updates

[Title]: Global Aluminum Industry Sees Significant Growth with Rolled Aluminum Plate and Sheet[Subtitle]: Leading Aluminum Producer's Cutting-Edge Technology Revolutionizes Sheet Manufacturing[Date]: [Insert Date][City, Country]: [Insert City, Country][Company Name], the renowned aluminum producer, is revolutionizing the rolled aluminum plate and sheet manufacturing industry, witnessing significant growth and propelling the global aluminum industry forward. With its cutting-edge technology and expertise, [Company Name] is poised to cater to the increasing demand for aluminum products across various sectors.[Company Name], established in [insert year], has emerged as a key player in the global aluminum industry, manufacturing high-quality and sustainable aluminum products. Combining state-of-the-art technology, innovative processes, and stringent quality control measures, [Company Name] has consistently delivered superior performance and customer satisfaction.Rolled aluminum plate and sheet are integral components in numerous industries such as automotive, aerospace, building and construction, packaging, and electrical. These sectors rely heavily on aluminum due to its lightweight, durability, thermal conductivity, and corrosion resistance properties. To meet the soaring demand for aluminum products, [Company Name] has continually invested in research and development, constantly adapting its manufacturing processes to produce superior quality rolled aluminum plate and sheet. The company focuses on sustainability, employing advanced recycling techniques to minimize environmental impact.[Company Name]'s rolled aluminum plate and sheet manufacturing process involves several steps. Initially, high-quality aluminum ingots are melted at precise temperatures to ensure optimal metallurgical properties. The molten aluminum is then cast into slabs, which are sent through a sequence of rolling mills. The rolling mills progressively reduce the thickness of the slabs, resulting in high-quality aluminum sheets or plates of desired thickness.The cutting-edge technology employed by [Company Name] guarantees the highest level of precision, ensuring that the finished aluminum sheets and plates meet the most stringent industry standards. Each sheet is thoroughly inspected for surface defects, thickness variations, and mechanical properties to guarantee excellent performance.Notably, [Company Name] is well-known for its dedication to customer satisfaction. The company collaborates closely with its clients to understand their specific needs and preferences, offering customized solutions that cater to unique requirements. By maintaining strong relationships with its clientele, [Company Name] has built a reputation for delivering products with exceptional quality and timely deliveries.The lightweight and durability of aluminum make it an ideal material for the automotive industry. Aluminum sheets and plates find extensive applications in the manufacturing of automobile bodies, chassis, and various structural components. [Company Name]'s rolled aluminum plate and sheet, with their exceptional tensile strength, impact resistance, and attractive surface finish, are highly sought after by major automotive manufacturers.Additionally, the aerospace sector greatly benefits from [Company Name]'s rolled aluminum plate and sheet. Aluminum's excellent strength-to-weight ratio, resistance to corrosion, and thermal conductivity make it indispensable in aircraft manufacturing. Various aircraft components, including wings, fuselages, and structural assemblies, rely on high-quality rolled aluminum plate and sheet for reliable performance and safety.Furthermore, the construction industry capitalizes on the versatile applications of aluminum. Rolled aluminum plate and sheet are extensively used in building facades, roofing, curtain walls, and window frames. With their exceptional formability, durability, and corrosion resistance, [Company Name]'s aluminum products contribute to the aesthetics, durability, and energy efficiency of modern buildings.The packaging industry benefits from [Company Name]'s rolled aluminum plate and sheet as well, particularly in the production of cans and containers. Aluminum's lightness and excellent barrier properties preserve the quality and freshness of food and beverage products. [Company Name]'s aluminum sheets and plates are precisely engineered to meet the specific requirements of the packaging industry, ensuring efficient and sustainable packaging solutions.With its commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the rolled aluminum plate and sheet manufacturing industry. As the demand for aluminum products continues to grow across diverse sectors, [Company Name]'s cutting-edge technology and high-quality aluminum products position the company for further expansion and global recognition.

Aluminium Half Round Moulding: Enhance Your Space with Sleek Design

As demand for stylish yet durable building materials continues to rise, Aluminium Half Round Moulding has emerged as a trusted choice for developers and homeowners alike. This versatile material offers a proven track record for longevity and versatility, making it a popular option for both exterior and interior applications.One leading provider of Aluminium Half Round Moulding is {company name}, which has been in the industry for over 20 years. The company has built a reputation for delivering high-quality products and services to a range of clients, from builders to architects and homeowners.{company name} offers a variety of shapes and sizes of Aluminium Half Round Moulding, which can be customized to fit specific project requirements. These mouldings can be used to add a distinctive touch to both contemporary and traditional building designs, and come in a range of colors to complement any decor.What makes Aluminium Half Round Moulding so unique is its innate durability. This material is strong enough to withstand the elements, from extreme temperatures to heavy winds and rains. Unlike other popular building materials, such as wood and vinyl, Aluminium Half Round Moulding is also resistant to termites and other insects, as well as rot.Moreover, Aluminium Half Round Moulding is practically maintenance-free. It does not require any painting, staining, or sealing, unlike other materials that may need frequent touch-ups to maintain their appearance. This saves time and money over the life of the building, making aluminium an economical choice for developers and homeowners.In addition to its durability and low-maintenance properties, Aluminium Half Round Moulding is also very versatile. It can be used for a wide range of applications, from window and door trim to decorative accents on ceilings, walls, and columns.The company prides itself on its commitment to customer satisfaction and environmental responsibility. All of its aluminium products are made from recycled materials, which reduces waste and conserves natural resources. The company also works with clients to find the right solutions for their specific project needs, whether it's a large-scale commercial project or a small residential remodel.Customers who choose Aluminium Half Round Moulding from {company name} can rest assured that they are getting a high-quality product that meets or exceeds industry standards. The company uses only the finest materials to manufacture its products, and its team of experienced professionals is dedicated to ensuring that every order is delivered on time and to the exact specifications of the client.Ultimately, Aluminium Half Round Moulding offers a durable and versatile building solution that is ideal for a wide range of applications. Whether you're a developer building a new commercial property or a homeowner undertaking a renovation project, {company name}'s Aluminium Half Round Moulding provides a reliable and cost-effective option that will stand the test of time.

Discover the Versatile Uses of Extruded Aluminum Channels

The Aluminum Channel Industry: A Growing Market for Extruded Aluminum ChannelsAluminum channels play a crucial role in a wide range of industries, from construction and automotive to electronics and retail. These versatile components are used for various applications, including structural, decorative, and protective purposes. With a strong demand across multiple sectors, the market for aluminum channels is booming. One company that has made a significant impact in this industry is {Company Name}.{Company Name} is a leading manufacturer and supplier of extruded aluminum channels. With state-of-the-art facilities and a commitment to innovation, the company provides high-quality products that meet the diverse needs of its customers. With a wide range of extruded aluminum channels available, {Company Name} has become a top choice for businesses worldwide.Extruded aluminum channels are created through a manufacturing process that involves pushing heated aluminum through a die to obtain specific shapes and sizes. This process allows for the creation of customized channels that are tailored to meet the requirements of different applications. Industries such as construction rely on aluminum channels for their structural properties, as they offer excellent strength, durability, and flexibility. Moreover, extruded aluminum channels are lightweight, corrosion-resistant, and have excellent thermal conductivity, making them ideal for various environments and conditions.The demand for extruded aluminum channels has been steadily increasing over the years, driven by the growth of industries such as construction, automotive, and electronics. In the construction sector, aluminum channels are widely used for architectural applications, including window frames, curtain walls, and railings. The automotive industry relies on these channels for structural components, such as support beams and chassis parts, due to their strength-to-weight ratio.Furthermore, the electronics industry uses extruded aluminum channels for heat sink applications. Heat sinks are essential in electronic devices to dissipate heat and prevent overheating, ensuring optimal performance and longevity of the equipment. Aluminum channels are well-suited for this purpose, as they efficiently conduct heat and can be customized to specific designs and dimensions.{Company Name} has positioned itself as a leading player in the extruded aluminum channel market by offering a diverse range of products that cater to the specific needs of different industries. Their comprehensive product portfolio includes channels of various shapes, sizes, and finishes, giving customers the flexibility to choose the perfect solution for their applications.In addition to their commitment to quality, {Company Name} also places a strong emphasis on sustainability. Aluminum is a highly sustainable material, as it is infinitely recyclable without losing its properties. {Company Name} has implemented sustainable practices throughout its manufacturing process to minimize waste and energy consumption, reducing their environmental impact.To meet the growing demand for extruded aluminum channels, {Company Name} has invested in advanced manufacturing technologies and expanded their production capabilities. By staying at the forefront of technological advancements, the company is able to produce high-quality channels efficiently and cost-effectively, meeting tight deadlines and exceeding customer expectations.The success of {Company Name} is not only attributed to their superior product quality and sustainable practices but also to their commitment to customer satisfaction. The company takes pride in providing exceptional customer service and technical support, ensuring that customers receive the right products and advice for their specific requirements.Looking ahead, the market for extruded aluminum channels is projected to witness significant growth as industries continue to recognize the advantages of using aluminum for their applications. Factors such as urbanization, infrastructure development, and the adoption of advanced technologies will continue to drive the demand for aluminum channels in the coming years.With its strong market presence, commitment to innovation, and customer-centric approach, {Company Name} is well-positioned to capitalize on the growing opportunities in the extruded aluminum channel industry. As they continue to expand their product offerings, leverage technological advancements, and foster strategic partnerships, {Company Name} is poised to remain a key player in this dynamic market.

High-Quality Extruded Aluminum Tubing: A Comprehensive Overview

Title: Industry Leader Introduces Cutting-Edge 7075 Extruded Aluminum TubingIntroduction:In the ever-evolving landscape of aluminum alloys, industry leader (company name) is once again making waves with the introduction of its groundbreaking 7075 Extruded Aluminum Tubing. This innovative development in the aluminum industry has the potential to revolutionize various sectors that rely on high-performance materials, such as aerospace, automotive, and construction. With its exceptional strength-to-weight ratio and unmatched durability, this new product is set to redefine industry standards and push the boundaries of what is possible.Section 1: The Superiority of 7075 Extruded Aluminum Tubing(Company name) has long been known for its commitment to excellence and innovation. With the production of 7075 Extruded Aluminum Tubing, the company has once again raised the bar in terms of quality and performance. 1.1 Exceptional Strength-to-Weight Ratio7075 Extruded Aluminum Tubing boasts an impressive strength-to-weight ratio, making it ideal for applications where superior strength is necessary without adding unnecessary weight. This characteristic is particularly advantageous in the aerospace sector, where every ounce saved translates into increased fuel efficiency.1.2 Unmatched DurabilityThe durability of 7075 Extruded Aluminum Tubing surpasses that of other aluminum alloys. Its ability to withstand heavy loads, extreme temperatures, and corrosive environments makes it a top choice for applications in the automotive and construction industries. This tubing offers unparalleled resistance to oxidation, further enhancing its overall longevity.1.3 Versatility and CustomizabilityThe versatility of 7075 Extruded Aluminum Tubing allows for a wide range of applications, enabling various industries to benefit from its properties. The tubing can be easily shaped, bent, and formed to meet specific design requirements, making it a highly customizable solution for different projects.Section 2: Industry Applications2.1 Aerospace IndustryIn the highly demanding aerospace industry, where reliability and performance are crucial, 7075 Extruded Aluminum Tubing makes a remarkable impact. Its strength, durability, and lightweight properties make it an ideal choice for aircraft components such as landing gear, structural frames, and fuselage structures. The superior aerodynamic efficiency achieved through the use of this tubing leads to more fuel-efficient flights and reduced emissions.2.2 Automotive IndustryThe automotive industry is constantly seeking ways to enhance vehicle performance and fuel efficiency. 7075 Extruded Aluminum Tubing presents a significant solution to these challenges. Its capability to reduce a vehicle's overall weight while maintaining excellent strength allows for improved acceleration, increased payload capacity, and reduced fuel consumption. Additionally, its resistance to corrosion ensures longevity and enhances the safety of vital automotive components.2.3 Construction IndustryIn the construction industry, durability and load-bearing capacity are paramount. The introduction of 7075 Extruded Aluminum Tubing presents construction firms with a lightweight yet robust material for building façades, support structures, and framing systems. Its resistance to corrosive environments, combined with exceptional strength, makes it an ideal choice for both commercial and residential construction projects.Section 3: (Company Name) – Pioneers of Advanced Aluminum Solutions(Company name) has been at the forefront of the aluminum industry for (number of years) and has consistently led the way through its commitment to research and development. By leveraging their extensive expertise and cutting-edge manufacturing processes, the company has emerged as a pioneer of advanced aluminum solutions.With the introduction of 7075 Extruded Aluminum Tubing, (company name) is revolutionizing multiple industries by providing a superior alternative to conventional materials. This groundbreaking product demonstrates the company's dedication to pushing the boundaries of technological advancements and staying ahead of market demands.Conclusion:The unveiling of 7075 Extruded Aluminum Tubing marks yet another remarkable achievement by (company name), setting new benchmarks for strength, durability, and versatility in the aluminum industry. This innovative and high-performance product is poised to reshape the aerospace, automotive, and construction sectors. With superior characteristics such as a remarkable strength-to-weight ratio, unmatched durability, and exceptional customizability, 7075 Extruded Aluminum Tubing demonstrates the company's unwavering commitment to delivering advanced solutions that drive progress and transform industries.

Industry group predicts growth in aluminum extrusions for 2021

Aluminum Extrusion Association Announces New Initiatives to Promote Sustainability and Innovation in the Industry[City], [Date] - The Aluminum Extrusion Association is proud to announce a series of new initiatives aimed at promoting sustainability and innovation in the aluminum extrusion industry. These initiatives will help to improve the environmental footprint of aluminum extrusion processes, while also fostering innovation and collaboration within the industry.As a leading trade association dedicated to advancing the extrusion industry, the Aluminum Extrusion Association is committed to driving positive change across all aspects of the industry. This includes environmental sustainability, product performance, and technological advancements.To support these objectives, the Aluminum Extrusion Association has developed a comprehensive sustainability program. This program aims to reduce the environmental impact of aluminum extrusion processes through measures such as energy conservation, waste reduction, and increased use of recycled materials.One key aspect of the sustainability program is the promotion of energy-efficient practices. Aluminum extrusion is an energy-intensive process, and as such, finding ways to minimize energy consumption is critical. To achieve this, the Aluminum Extrusion Association will provide resources and guidance to its members on implementing energy-saving technologies and best practices.Another area of focus for the sustainability program is waste reduction. Aluminum extrusion generates a significant amount of waste material, but this waste can often be recycled or repurposed. The Association will work closely with its members to develop strategies for waste reduction and recycling, helping to minimize the industry's environmental impact.In addition to its sustainability program, the Aluminum Extrusion Association is also placing a strong emphasis on innovation. The Association recognizes that innovation is key to driving growth and competitiveness in the industry, and as such, it is actively promoting collaboration and knowledge-sharing among its members.To facilitate innovation, the Aluminum Extrusion Association is establishing a dedicated research and development (R&D) fund. This fund will support research projects focused on advancing aluminum extrusion technologies, exploring new applications, and improving product performance. By investing in R&D, the Association aims to foster a culture of innovation and facilitate the development of new and improved products and processes.Furthermore, the Aluminum Extrusion Association will organize industry conferences, seminars, and workshops to encourage collaboration and knowledge exchange. These events will provide a platform for industry experts to discuss and share their experiences, fostering a culture of continuous learning and improvement within the industry.The Aluminum Extrusion Association understands the importance of collaboration with other organizations and stakeholders. As such, it will actively seek partnerships with government agencies, research institutions, and other relevant bodies to drive the sustainability and innovation agenda forward."We are excited to launch these new initiatives aimed at promoting sustainability and innovation within the aluminum extrusion industry," said [Spokesperson Name], [Title] of the Aluminum Extrusion Association. "By working together, we can drive positive change, reduce our environmental impact, and unlock new opportunities for growth and success."The Aluminum Extrusion Association's commitment to sustainability and innovation reflects the industry's increasing focus on environmental responsibility and competitiveness. By implementing these initiatives, the Association aims to position the aluminum extrusion industry as a leader in sustainable manufacturing practices, while also driving innovation and growth.About the Aluminum Extrusion Association:[Company name], a leading trade association, represents the aluminum extrusion industry in [Location]. With a membership spanning manufacturers, suppliers, and other industry stakeholders, the Association is dedicated to advancing the extrusion industry through advocacy, education, and collaborative initiatives. By promoting sustainability and innovation, the Aluminum Extrusion Association strives to drive positive change and position the industry for continued success.

Military-Grade Aluminum Alloy 2024: Key Features and Applications Revealed

Military Aluminum Alloy 2024: The Next Gen Material for Aerospace IndustryAluminium is one of the essential materials that find significant usage in the modern aerospace industry. The aerospace sector's increasing demand for lightweight yet robust materials has led to the development of novel and advanced alloys that offer excellent mechanical and physical properties. Among these, Military Aluminum Alloy 2024 has emerged as one of the most promising candidates that provide an impressive combination of strength and toughness.Military Aluminum Alloy 2024 is a high-strength aluminum alloy that contains copper as its primary alloying element. This alloy is widely used in various applications that demand strength, fatigue resistance, and excellent machinability. Developed in the 1930s, Military Aluminum Alloy 2024 has been an essential material in the aerospace industry for decades. Its unique properties have made it a popular choice for structural components such as wing and fuselage structures, landing gear components, and rocket motor cases.Military Aluminum Alloy 2024 is known for its excellent strength-to-weight ratio, making it ideal for lightweight applications. This alloy has a tensile strength of 470 MPa, which is higher than most of the other aluminum alloys. Furthermore, it exhibits excellent fatigue resistance, corrosion resistance, and hardness, making it suitable for harsh environments. Military Aluminum Alloy 2024 is also easy to machine and weld, which simplifies the manufacturing process.One of the primary factors that make Military Aluminum Alloy 2024 an ideal material for aerospace applications is its ability to withstand high temperatures. This alloy can hold up in temperatures of up to 300°C, making it ideal for high-temperature applications like rocket motor cases. Additionally, it exhibits excellent thermal conductivity, which ensures efficient heat dissipation and prevents overheating.The aerospace industry has always been an innovation-driven industry, and companies constantly need to develop new material solutions to stay ahead in the competitive landscape. One such company that is at the forefront of material innovation is {Need to remove brand name}. They are a leading manufacturer and supplier of high-performance aluminum alloys, including Military Aluminum Alloy 2024.With over two decades of experience, {Need to remove brand name} has been developing advanced aluminum alloys that cater to the increasing demands of the aerospace industry. They offer a wide range of aluminum alloys that exhibit superior mechanical and physical properties, making them ideal for various applications.{Need to remove brand name} produces Military Aluminum Alloy 2024 that meets or exceeds all industry standards. Their 2024 alloy offers exceptional strength, toughness, and corrosion resistance, making it an ideal material for structural applications in the aerospace industry. It also has excellent machinability, which simplifies the manufacturing process and reduces production costs.{Need to remove brand name}'s military-grade aluminum alloy 2024 is widely used across the aerospace industry, including aircraft, helicopters, missiles, and spacecraft. Their 2024 alloy has been extensively tested and verified for its mechanical and physical properties, which ensures that it can withstand harsh conditions and deliver outstanding performance.In addition to military Aluminum Alloy 2024, {Need to remove brand name} also manufactures a range of other aluminum alloys that cater to different applications. Their aluminum alloys have been used in various industries, including defense, aerospace, automotive, marine, and industrial applications.{Need to remove brand name} has established itself as a reliable supplier of high-performance aluminum alloys, thanks to its state-of-the-art facilities and a team of experienced professionals. They offer customized solutions to their clients that meet their specific requirements and deliver their products on time and within budget.In conclusion, Military Aluminum Alloy 2024 offers an excellent combination of strength, toughness, and corrosion resistance, making it an ideal material for aerospace applications. {Need to remove brand name} is a leading manufacturer and supplier of military-grade aluminum alloy 2024 that meets all industry standards and provides exceptional performance. With their innovative solutions and outstanding customer support, {Need to remove brand name} is poised to drive the material innovation in the aerospace industry, ensuring a brighter and better future for all.

High-Quality 40mm Aluminium Profile: Discover Top-Notch Construction Materials

Title: Innovations in Aluminum Profile Manufacturing by a Leading CompanyIntroduction:In the ever-evolving world of construction and engineering, the demand for high-quality materials is on the rise. Among these materials, aluminum has emerged as a popular choice due to its lightweight, durability, and versatility. A company, which prefers to remain anonymous, has been working tirelessly to provide innovative solutions in aluminum profile manufacturing through their cutting-edge 40mm Aluminum Profile.Body:1. Development of the 40mm Aluminum Profile:The anonymous company has revolutionized the market by designing and producing a state-of-the-art 40mm Aluminum Profile. Utilizing advanced technology, this profile has set new benchmarks in terms of quality and performance. The company's integrated research and development team has worked diligently to ensure that the 40mm Aluminum Profile surpasses industry standards.2. Superior Features and Benefits:The 40mm Aluminum Profile offers an array of superior features and benefits that make it an ideal choice for various industries. These profiles are extruded with utmost precision, resulting in consistently high-quality products. The superior resistance to corrosion and weathering ensures longevity, making them suitable for both indoor and outdoor applications. Additionally, the profiles' lightweight nature allows for easy handling, simplifying the installation process.3. Versatile Applications:Thanks to its versatility, the 40mm Aluminum Profile finds application in numerous sectors. From architectural projects and construction industry to machine framing, industrial automation, and transportation, this profile caters to diverse market demands. Its unparalleled strength and stability make it a perfect fit for large-scale projects where structural integrity is paramount. With customizability options, the 40mm Aluminum Profile can be tailored to specific project requirements, ensuring seamless integration.4. Industry Compliance:Emphasizing their commitment to quality and environmental sustainability, the anonymous company ensures that all their aluminum profiles comply with stringent industry standards. The manufacturing processes adhere to the highest quality control measures, resulting in profiles that meet or exceed internationally recognized certifications. Moreover, these profiles are recyclable, contributing to a greener and more sustainable future.5. Collaborative Approach:The anonymous company believes in fostering collaborative relationships with their clients. Their dedicated team of professionals works closely with architects, engineers, and project managers to provide tailored solutions that meet specific project requirements. By actively engaging in discussions, the company aims to forge long-lasting partnerships, delivering exceptional results and surpassing customer expectations.6. Continued Innovation:The anonymous company's commitment to innovation sets them apart from competitors. They continually invest in research and development, striving to introduce groundbreaking technologies and improve product offerings. This dedication has enabled them to stay ahead of the curve and consistently deliver innovative solutions to the market.Conclusion:The anonymous company's 40mm Aluminum Profile underscores their dedication to providing cutting-edge solutions in the field of aluminum profile manufacturing. With its superior features, versatility, and commitment to quality, this profile has gained a strong foothold in several industries. By collaborating with clients, adhering to industry compliance, and investing in continual innovation, the anonymous company reaffirms its position as a leader in the market.

Lightweight and Durable Aluminium Pipes: Ideal for Various Applications

Title: Hollow Aluminum Pipe Revolutionizes the Manufacturing Industry Introduction:In today's rapidly evolving manufacturing industry, innovations and advancements play a crucial role in improving efficiency and productivity. One such breakthrough is the introduction of Hollow Aluminum Pipe by an industry-leading company (brand name removed) that is set to transform the way various sectors approach the production process. This new development offers immense potential for multiple industries, from aerospace to automotive, due to its lightweight nature, superior strength, and unparalleled versatility.Paragraph 1: Hollow Aluminum Pipe, developed by (brand name removed), is a game-changer in the manufacturing industry. Its inception was driven by a growing need for lighter yet robust materials, with extensive research and development ensuring excellence in its design and performance. The hollow design provides several advantages, including reduced weight, cost-effectiveness, and increased flexibility, setting it apart from conventional solid aluminum pipes.Paragraph 2:The lightweight nature of hollow aluminum pipes proves ideal for industries such as aerospace, where reducing weight without compromising strength is of paramount importance. The aviation sector can benefit significantly from these pipes, resulting in improved fuel efficiency and reduced carbon emissions. Manufacturers can achieve a significant reduction in weight by integrating hollow aluminum pipes into aircraft structures, leading to enhanced performance and increased payloads.Paragraph 3:Automotive manufacturers are also set to reap substantial benefits from hollow aluminum pipes. The lightweight material helps reduce overall vehicle weight, thereby improving fuel efficiency and reducing emissions. Additionally, the exceptional strength of these pipes enhances vehicle safety and durability, making them an ideal choice for manufacturing critical components like chassis frames, roll cages, and suspension systems.Paragraph 4:Furthermore, hollow aluminum pipes offer unique advantages to industries involved in the construction and infrastructure sectors. Their versatility allows for easy customization according to project requirements, facilitating cost-effectiveness and efficiency during installation. Additionally, the excellent corrosion resistance properties of aluminum make it an ideal choice for applications in harsh environments, ensuring longevity and durability.Paragraph 5:The potential applications of hollow aluminum pipes extend beyond the aerospace, automotive, and construction sectors. Industries such as sports equipment manufacturing, marine, and renewable energy could also considerably benefit from this innovative product. The superior strength-to-weight ratio of hollow aluminum pipes can revolutionize sporting equipment, renewable energy infrastructure, and marine components, enhancing performance and reliability.Paragraph 6:(Company name removed) has garnered recognition as a leading supplier of hollow aluminum pipes due to its commitment to research and development and adherence to stringent quality standards. With an extensive customer base that spans across industries, the company's expertise ensures the consistent delivery of high-quality products that meet industry demands.Paragraph 7:In conclusion, hollow aluminum pipes are poised to revolutionize the manufacturing industry. Their lightweight nature, superior strength, and exceptional versatility make them the preferred choice for industries seeking to improve efficiency and maximize performance. With numerous applications across aerospace, automotive, construction, and beyond, the future of manufacturing is undoubtedly set to witness a remarkable transformation, thanks to hollow aluminum pipes.Word Count: 446 words

Al 5083 Properties and Uses: A Comprehensive Guide to Aluminum Alloy 5083

Title: Advanced Aluminum Alloy AL5083 Rewrites the Standards of Material PropertiesIntroduction:In an era that calls for innovations and advancements in material technology, an advanced aluminum alloy has emerged as a game-changer in various industries. With its remarkable properties and versatility, AL5083 has garnered significant attention from manufacturers around the globe. This alloy's exceptional strength, corrosion resistance, and weldability make it an ideal choice for numerous applications, ranging from automotive components to marine structures. Let's delve deeper into the remarkable properties of AL5083 and how its introduction has revolutionized the market.Exceptional Strength and Lightweight Structure:AL5083 possesses an excellent strength-to-weight ratio, making it a preferred choice for industries seeking lightweight yet durable materials. This aluminum alloy boasts a tensile strength of around 280 MPa, which surpasses that of its predecessors. Its lightweight nature facilitates enhanced fuel efficiency in the automotive sector, contributing to reduced carbon emissions and a greener future. Furthermore, this feature of AL5083 enables its seamless integration in aerospace construction, ensuring safer and more efficient flights.Unparalleled Corrosion Resistance:One of the most prominent challenges faced by manufacturers is finding materials that can endure harsh environments without succumbing to corrosion. AL5083 resolves this predicament by offering exceptional resistance to corrosion in marine and industrial settings. This aluminum alloy consists of various alloying elements, including magnesium, manganese, and chromium, which create a protective oxide layer when exposed to corrosive elements. The alloy's resistance to saltwater corrosion ensures its extensive usage in offshore oil rigs, shipbuilding, and naval applications.Enhanced Weldability and Processability:Manufacturers who rely on alloys for their fabrication processes often face obstacles related to weldability. AL5083 dismantles these barriers with its remarkable weldability and processability. The alloy exhibits excellent fluidity during welding, making it easier for manufacturers to achieve precise and seamless joints. This property not only saves time and effort but also ensures the structural integrity of the final product. AL5083's exceptional weldability has made it the go-to choice for fabricating pressure vessels, heat exchangers, and storage tanks.Versatility in Application:AL5083 offers immense versatility in terms of application across various sectors. The automotive industry benefits from its impressive crash resistance, as it provides improved safety during collisions. Furthermore, this alloy's formability allows for the production of intricate and complex components used in aerospace manufacturing. Additionally, the marine industry leverages AL5083's corrosion-resistant properties to construct high-speed vessels and naval equipment. The architectural sector relies on this alloy for its attractive finish and weathering resistance, making it an ideal material for external cladding, roofing, and curtain walls.Conclusion:The emergence of the advanced aluminum alloy AL5083 has redefined the standards for material properties, providing manufacturers with an exceptional solution for numerous sectors. With its impressive strength, corrosion resistance, weldability, and versatility, AL5083 has become a sought-after material across industries such as automotive, aerospace, marine, and architecture. As innovation continues to shape the future, AL5083 stands as a testament to the remarkable advancements achievable in material technology.