High-quality Aluminium Profile For CNC: Everything You Need to Know

By:Admin

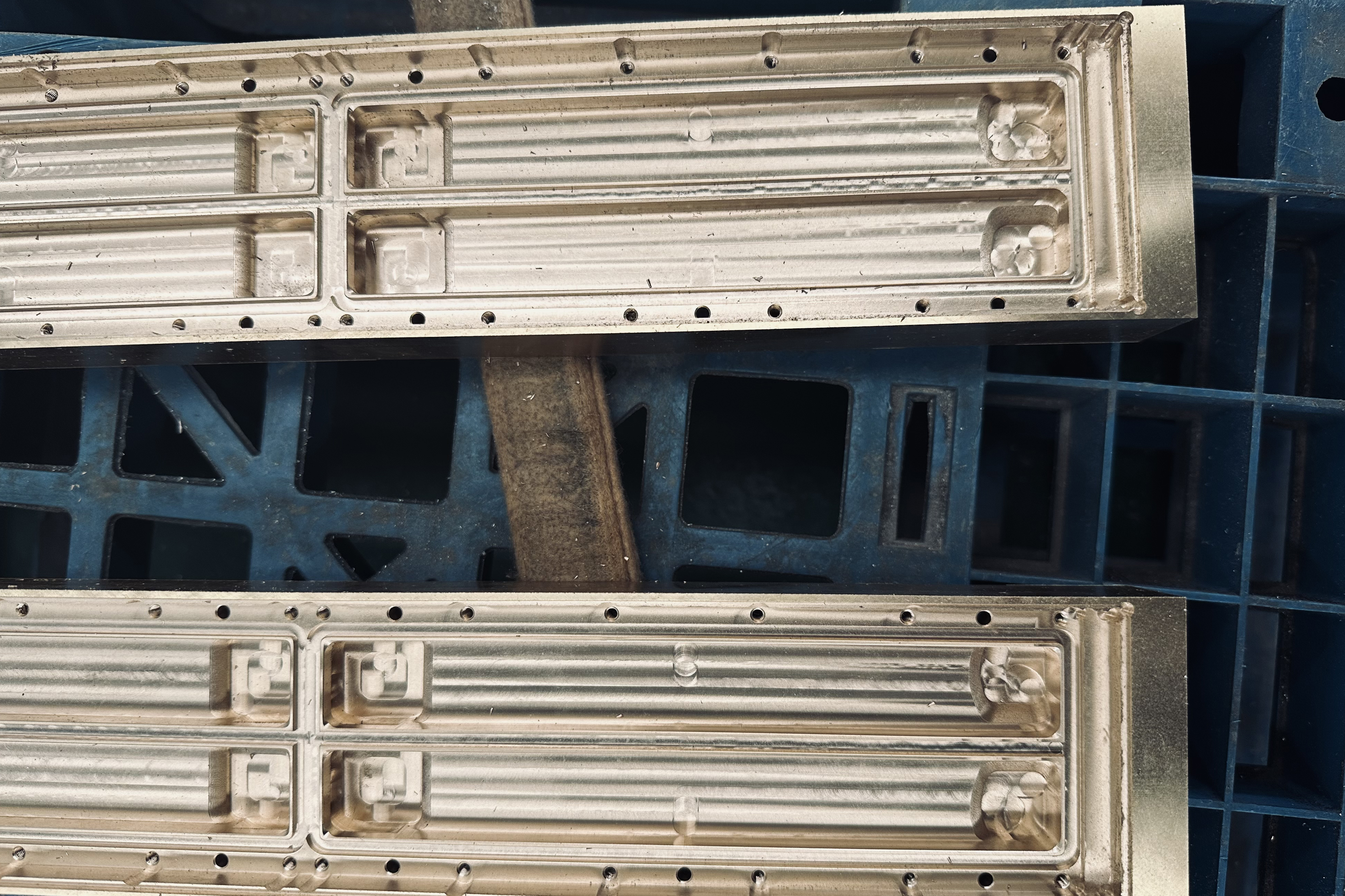

Aluminium Profile for CNC is an essential component in the manufacturing and production industry. This versatile material is widely used in the creation of various products through CNC machining processes. With its durable and lightweight properties, aluminium has become the go-to material for CNC applications across different industries.

{Company Name}, a leading manufacturer of aluminium profiles, has been at the forefront of providing high-quality aluminium products for CNC. Founded in {year}, the company has a strong reputation for its commitment to excellence and innovation in the manufacturing sector. With state-of-the-art facilities and a team of skilled professionals, {Company Name} has consistently demonstrated its ability to deliver top-notch aluminium profiles for CNC applications.

The aluminium profiles produced by {Company Name} are designed to meet the strict requirements of CNC machining. Their profiles are made from premium-grade aluminium, ensuring durability and precision in every CNC application. With a focus on quality and reliability, {Company Name} has established itself as a trusted supplier of aluminium profiles for CNC to industries such as automotive, aerospace, electronics, and construction.

In addition to its commitment to quality, {Company Name} also places a strong emphasis on innovation and customization. The company offers a wide range of aluminium profiles with different shapes, sizes, and finishes to cater to the diverse needs of CNC applications. Whether it's a specific design requirement or a unique application, {Company Name} has the capabilities to customize aluminium profiles to meet the exact specifications of its customers.

Furthermore, {Company Name} is dedicated to sustainability and environmental responsibility in its manufacturing processes. The company has implemented eco-friendly practices and technologies to minimize its carbon footprint and promote a greener manufacturing industry. With a focus on sustainable production, {Company Name} has positioned itself as a responsible and environmentally conscious supplier of aluminium profiles for CNC.

With its unwavering dedication to quality, innovation, and sustainability, {Company Name} has earned the trust and confidence of its customers in the manufacturing and production industry. The company's commitment to excellence has propelled it to the forefront of the aluminium profile market for CNC applications, making it a preferred choice for businesses looking for reliable and high-quality aluminium products.

As the demand for CNC machining continues to grow, {Company Name} remains at the forefront of delivering cutting-edge aluminium profiles that meet the evolving needs of the industry. With its focus on quality, customization, and sustainability, the company is well-positioned to continue its success in providing essential aluminium profiles for CNC applications.

In conclusion, aluminium profiles for CNC are an integral part of the manufacturing and production industry, and {Company Name} has established itself as a leading supplier of high-quality, customisable, and sustainable aluminium profiles for CNC applications. With its unwavering commitment to excellence and innovation, {Company Name} is poised to remain a top choice for businesses seeking reliable and top-notch aluminium products for their CNC machining needs.

Company News & Blog

Guide to Hollow Die Extrusion: Process and Applications

Hollow Die Extrusion, a leading company in the field of extrusion technology, is revolutionizing the industry with its innovative and state-of-the-art products. With a commitment to excellence and a focus on delivering superior solutions to its customers, Hollow Die Extrusion has cemented its position as a trusted and reliable partner in the global extrusion market.Established in {year}, Hollow Die Extrusion has rapidly grown to become a powerhouse in the industry. The company's success can be attributed to its relentless dedication to research and development, as well as its unwavering commitment to quality and customer satisfaction.One of the key differentiators for Hollow Die Extrusion is its cutting-edge technology. The company has invested heavily in research and development, continually pushing the boundaries of what is possible in extrusion technology. This has allowed them to develop a wide range of products that are at the forefront of the industry, setting new standards for performance, efficiency, and reliability.One of the flagship products of Hollow Die Extrusion is its {product name} series. This innovative line of extrusion dies is designed to deliver unmatched precision and consistency, allowing customers to achieve the highest levels of quality in their extruded products. Whether it's for {industry}, {industry}, or any other application, the {product name} series has set a new benchmark for excellence in extrusion technology.In addition to its exceptional products, Hollow Die Extrusion is also known for its outstanding customer service. The company takes great pride in its ability to understand and meet the unique needs of each customer, providing tailored solutions that deliver exceptional results. This customer-centric approach has earned Hollow Die Extrusion a reputation for reliability and trustworthiness, making them the go-to partner for companies around the world.With a strong presence in the global market, Hollow Die Extrusion has established itself as a leader in the industry. The company's products are used in a wide range of applications, from construction to automotive to packaging, and they continue to set new standards for performance and quality in each of these industries.Looking forward, Hollow Die Extrusion is poised for even greater success. The company is constantly innovating and evolving, pushing the boundaries of what is possible in extrusion technology. With a relentless focus on excellence and a deep commitment to its customers, Hollow Die Extrusion is well-positioned to continue leading the industry for years to come.In conclusion, Hollow Die Extrusion is a company that is redefining the possibilities in extrusion technology. With its innovative products, dedication to excellence, and unwavering commitment to customer satisfaction, Hollow Die Extrusion has set itself apart as a trusted leader in the global extrusion market. As the company continues to push the boundaries of what is possible, it is clear that Hollow Die Extrusion will remain at the forefront of the industry for many years to come.

Aluminum: An Essential Component for Hybrid Electric Vehicles (HEVs)

(title) Aluminum Innovations for Hybrid Electric Vehicles(Date)(News Organization)(Article)Hybrid Electric Vehicles (HEVs) have gained significant popularity over recent years as a more environmentally friendly alternative to traditional gasoline-powered vehicles. As the demand for HEVs continues to rise, automotive manufacturers are constantly seeking innovative solutions to enhance their performance, efficiency, and sustainability. One company that stands out in this endeavor is (remove brand name), a leading provider of cutting-edge aluminum technologies for the automotive industry.(Company Introduction)Founded in (year), (remove brand name) has established itself as a pioneer in the development and production of high-quality aluminum solutions for various industries. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible with aluminum, making it an ideal partner for automakers striving to optimize their HEV offerings.(Paragraph about the importance of lightweight materials in HEVs)In the context of HEVs, lightweight materials play a crucial role in improving overall vehicle efficiency and reducing emissions. Aluminum, being significantly lighter than traditional steel, offers substantial benefits to HEV manufacturers. By integrating lightweight aluminum components, automakers can achieve weight reduction without compromising the structural integrity and safety of the vehicles. Furthermore, the reduced weight allows for increased battery efficiency and improved overall performance.(Overview of aluminum innovations for HEVs)(remove brand name) has recently unveiled a range of innovative aluminum solutions specifically designed for HEVs. These advancements include but are not limited to:1. Aluminum Body-in-White (BIW) Structures: The company's advanced aluminum BIW structures provide a lightweight alternative to traditional steel frames without sacrificing safety. These structures offer exceptional strength, rigidity, and crashworthiness while significantly reducing the vehicle's overall weight.2. Aluminum Battery Enclosures: (remove brand name) has developed aluminum battery enclosures that effectively protect the HEV's battery pack and ensure its optimal performance. These enclosures offer excellent thermal management properties, preventing overheating and enhancing battery longevity.3. Aluminum Suspension Components: Incorporating aluminum suspension components allows for reduced unsprung weight, resulting in improved ride comfort and handling. Additionally, the lightweight nature of these components contributes to overall fuel efficiency and better energy recovery during regenerative braking.4. Aluminum Heat Exchangers: (remove brand name)'s aluminum heat exchangers provide efficient cooling solutions for HEVs. With their lightweight design and superior heat transfer capabilities, these exchangers ensure optimal thermal management while further reducing the vehicle's weight.(Another paragraph about the company's role in shaping the future of HEVs)By continuously investing in research and development, (remove brand name) is at the forefront of the aluminum revolution in the automotive industry. Their commitment to sustainability and innovation has positioned them as a key partner for automakers seeking to enhance the performance, efficiency, and overall appeal of HEVs. With their state-of-the-art aluminum solutions, (remove brand name) is contributing to the ongoing shift towards a greener and more sustainable transportation future.(Conclusion)As the global demand for HEVs continues to increase, companies like (remove brand name) play a vital role in shaping the future of automotive design. Through their groundbreaking aluminum innovations, they are enabling automakers to produce more energy-efficient and eco-friendly vehicles without compromising performance or safety. With the constant evolution of aluminum technologies, the possibilities for further advancements in HEVs are endless, and the future of sustainable transportation looks promising.

Discover the Latest Advancements in Extruded Aluminium Sheet Technology

Extruded Aluminium Sheet: The Perfect Solution for Modern Construction NeedsExtruded aluminium sheet is one of the most versatile and widely used materials for various construction needs. It's popular among construction industry professionals due to its exceptional durability, rigidity and the ability to withstand harsh weather conditions.There is no doubt that extruded aluminium sheet has become a go-to solution for various construction projects. Its application in the commercial and residential sectors has seen a significant increase in demand as compared to other building materials. Companies such as XXX (need to remove brand name) have been at the forefront of this product's production and supply for over several years now.One reason behind its huge success is its manufacturing process. Extruded aluminium sheet is produced by the extrusion process, which involves pushing aluminium billets through a die to create the desired shape. This process allows for a high degree of flexibility in terms of design, giving architects and builders more options for their projects. It also ensures that the final product has better resistance to corrosion and wear and tear than other materials like wood or plastics.At XXX (need to remove brand name), the production of extruded aluminium sheet has been optimized over time through years of research and development. This attention to detail has allowed them to produce high-quality products that meet the specific requirements of their customers.Apart from its superior resistance to wear and tear, extruded aluminium sheet also has a low thermal conductivity, which makes it an ideal material for insulation. The material also has a high strength-to-weight ratio, making it lighter in weight and easier to handle.In construction, extruded aluminium sheet is used in various applications across different sectors. It's used for roofing, cladding walls, and even for creating exterior trims. Many architects and builders also prefer extruded aluminium sheet as a material for window frames, door frames, and curtain walls. This is because it can be configured into a variety of shapes and sizes, giving designers the flexibility to create customized solutions.Another significant benefit of extruded aluminium sheet is its sustainability. The material is entirely recyclable, making it an excellent choice for environmentally conscious builders. It reduces the carbon footprint of their projects by minimizing waste and reducing the need for raw materials.At XXX (need to remove brand name), sustainability has always been an important aspect of their business model. The company actively promotes the use of extruded aluminium sheet as a sustainable solution for building projects. They also ensure that all their products meet the highest environmental standards and certifications.In conclusion, extruded aluminium sheet is a versatile, durable, and sustainable material that has become increasingly popular in the construction industry. Its superior properties make it ideal for an array of applications across various sectors. Companies like XXX (need to remove brand name) have ensured that its production is optimized and of high quality. More importantly, the product manufactured by such companies is environmentally friendly, making it a perfect solution for modern construction needs.

Durable and Versatile Extruded Aluminum Beams for Various Applications

Extruded Aluminum Beams are quickly becoming the material of choice for a wide range of construction and industrial applications, and {} has solidified its position as a leader in this market. With a commitment to innovation and quality, the company has established itself as a go-to source for extruded aluminum beams that meet the highest standards in the industry.The extrusion process allows for the creation of complex cross-sectional shapes and sizes, making extruded aluminum beams a versatile and durable option for a variety of projects. From building construction to automotive manufacturing, these beams offer numerous advantages, including high strength-to-weight ratio, corrosion resistance, and a sleek, modern aesthetic.{} has honed its expertise in extruded aluminum beams through years of experience and a dedication to staying ahead of the curve when it comes to technological advancements in the industry. By investing in state-of-the-art equipment and employing a team of skilled professionals, the company has been able to consistently deliver products that exceed customer expectations.One of the key factors that sets {} apart from its competitors is its focus on customization. The company understands that each project has its own unique requirements, and its team works closely with clients to create extruded aluminum beams that perfectly suit their needs. Whether it's a specific shape, size, or finish, {} has the capabilities to deliver custom solutions that ensure the success of any project.In addition to customization, {} is also committed to sustainability. Aluminum is a highly recyclable material, and the company takes pride in using recycled aluminum in its extrusion process whenever possible. By prioritizing environmental responsibility, {} is not only meeting the needs of its customers but also contributing to a greener, more sustainable future.The applications for extruded aluminum beams are incredibly diverse, and {} has played a significant role in supplying these products to a wide range of industries. From architectural trim and framing to support beams for industrial equipment, the company's extruded aluminum beams have been utilized in countless projects, showcasing their versatility and reliability.Looking towards the future, {} remains dedicated to pushing the boundaries of what is possible with extruded aluminum beams. By constantly exploring new technologies and refining its processes, the company is well-positioned to continue leading the way in the industry. As customer demands evolve and new challenges arise, {} is committed to staying one step ahead and providing innovative solutions that set the standard for excellence.In conclusion, {} has firmly established itself as a premier supplier of extruded aluminum beams, offering a combination of quality, customization, and sustainability that sets it apart in the market. With a proven track record of success and a commitment to ongoing innovation, the company is poised to continue meeting the diverse needs of its customers and driving the industry forward.

Discover the Versatility of High-Quality 6061 Aluminum Pipe

6061 Aluminum Pipe: An Overview of Its Benefits and ApplicationsIn today's fast-paced industrial world, companies are constantly on the lookout for advanced materials that offer durability, strength, and versatility. One such material that has gained significant popularity in recent years is 6061 aluminum pipe. Renowned for its exceptional properties, it has become a go-to choice for a wide range of applications across various industries.6061 aluminum pipe is a high-quality aluminum alloy that boasts excellent strength-to-weight ratio, making it highly sought after by engineers and manufacturers alike. It is made from a composition of aluminum, magnesium, and silicon, resulting in enhanced mechanical properties that make it perfect for demanding applications.The versatility of 6061 aluminum pipe is one of its major advantages. It can be easily extruded into various shapes and sizes, enabling manufacturers to create custom designs that perfectly align with their specific requirements. This flexibility not only provides immense design freedom but also leads to cost savings, as complex fabrication processes can be avoided.Aside from its exceptional versatility, 6061 aluminum pipe is highly corrosion-resistant. Aluminum naturally forms a protective oxide coating when exposed to the atmosphere, which effectively prevents oxidation and corrosion. This property makes it ideal for applications in harsh environments or those involving exposure to moisture and corrosive substances.Furthermore, the 6061 aluminum pipe is known for its outstanding weldability and machinability. It can be welded using various methods, including TIG and MIG, allowing for easy assembly and repair. Additionally, its machinability enables manufacturers to achieve precise dimensions and intricate shapes, ensuring a high level of product quality and consistency.The lightweight nature of 6061 aluminum pipe is another key feature that contributes to its widespread usage. With a density of only 2.7 g/cm³, it is about one-third the weight of steel, making it an ideal choice for applications that require reduced weight without compromising strength. This advantage has led to its application in aerospace, automotive, and sporting equipment industries.Speaking of applications, the 6061 aluminum pipe finds various uses across multiple industries. In the construction sector, it is commonly employed in the fabrication of structural frames, railing systems, and scaffolding. Its corrosion resistance ensures longevity and durability, even in challenging outdoor conditions. Moreover, its lightweight property simplifies transportation and installation processes, reducing overall costs.In the automotive industry, 6061 aluminum pipe is utilized in the manufacturing of components such as fuel tanks, radiators, and heat exchangers. It offers excellent thermal conductivity, ensuring efficient heat dissipation and enhancing the overall performance of the vehicle. Its lightweight nature also contributes to fuel efficiency, reducing the carbon footprint and promoting sustainability.The marine industry also benefits from the exceptional properties of 6061 aluminum pipe. Due to its corrosion resistance, it is extensively used in the construction of boat masts, handrails, and other marine structures. Its lightweight nature makes it ideal for large vessels, as it helps in reducing the overall weight of the structure, thereby enhancing buoyancy and fuel efficiency.Additionally, the 6061 aluminum pipe finds applications in the manufacturing of sports equipment, such as bicycle frames, golf club shafts, and archery bows. Its combination of strength and lightweight allows for enhanced performance and increased maneuverability. Furthermore, its corrosion-resistant nature ensures longevity even in extreme outdoor conditions, making it an excellent choice for outdoor sports equipment.In conclusion, the 6061 aluminum pipe has emerged as a versatile and reliable material across multiple industries. Its exceptional properties, such as its strength-to-weight ratio, corrosion resistance, weldability, and machinability, make it an attractive choice for engineers and manufacturers. Whether it's construction, automotive, marine, or sports equipment, the 6061 aluminum pipe proves to be a reliable and cost-effective solution for a wide range of applications.

High-Quality 20x20 Aluminum Profile: Durable and Versatile for All Your Needs

Title: A New Breakthrough in the Aluminium Industry Unveiled by {Company name}Introduction:{Company name}, a leading innovator in the aluminium industry, has recently introduced its latest product, the 20 X 20 Aluminium Profile. This groundbreaking innovation is set to revolutionize various sectors, ranging from construction and engineering to interior design and automotive manufacturing. By combining exceptional durability, versatility, and impeccable craftsmanship, {Company name} has once again reaffirmed its position as a trailblazer in the aluminium market.Body:1. Unmatched Durability and Strength:The 20 X 20 Aluminium Profile by {Company name} boasts exceptional durability and strength, surpassing traditional steel profiles. The high-grade aluminium alloy used in its construction enhances the product's resistance to corrosion and makes it suitable for use in diverse environments, including extreme weather conditions. Industries such as construction and engineering that rely on reliable and long-lasting materials will find this new profile highly advantageous.2. Versatility and Customization:The 20 X 20 Aluminium Profile offers unparalleled versatility, making it suitable for a wide range of applications. Its modular design allows for easy assembly and disassembly, making it ideal for temporary structures, exhibition booths, and industrial shelving systems. Moreover, its compatibility with various accessories and fittings enables users to customize their projects according to their specific requirements. From frame structures and machine guards to conveyors and workstations, this profile caters to a broad spectrum of applications.3. Innovative Design and Technology:{Company name}'s 20 X 20 Aluminium Profile incorporates cutting-edge design and manufacturing techniques, ensuring precision and consistency. The extrusion process guarantees the homogeneity of the sections, eliminating any minute variations and ensuring high-quality profiles. The precise dimensions, smooth finishes, and strict quality control measures employed by {Company name} result in profiles that seamlessly integrate into any project, providing a professional and refined look.4. Sustainability and Environmental Benefits:As sustainability becomes an increasingly significant concern, the 20 X 20 Aluminium Profile stands out as an eco-friendly alternative to other construction materials. Aluminium is inherently recyclable, meaning that the profile can be recycled indefinitely without compromising its quality and performance. Moreover, the lightweight nature of aluminium reduces transportation costs and carbon emissions. With this new profile, {Company name} reaffirms its commitment to providing environmentally responsible solutions without compromising durability and strength.5. Commitment to Customer Satisfaction and Support:{Company name} has always prioritized customer satisfaction, and the introduction of the 20 X 20 Aluminium Profile is no exception. By providing extensive technical support, product training, and prompt customer service, the company ensures that clients can maximize the benefits of this innovative product. Additionally, {Company name} offers tailored solutions to meet specific project requirements, ensuring that customers receive personalized assistance every step of the way.Conclusion:The launch of the 20 X 20 Aluminium Profile by {Company name} marks a significant milestone in the aluminium industry. With its unmatched durability, versatility, and sustainable characteristics, this innovative profile is set to transform the way various sectors approach construction projects, industrial designs, and beyond. By continuously pushing the boundaries of aluminium technology, {Company name} demonstrates its commitment to delivering high-performance solutions that meet both present and future demands.

High-Quality Precision Turning Services for Aluminum Components

Precision Aluminum Turning, a leading provider of high-quality aluminum precision machining solutions, has announced the expansion of its services in response to the growing demand for aluminum components in various industries.The company, which specializes in CNC machining of aluminum parts and components, has seen a steady increase in demand for its services due to the rise in the use of aluminum in automotive, aerospace, and electronics industries. With a commitment to providing precision machined parts with the highest level of quality and reliability, Precision Aluminum Turning has continuously invested in state-of-the-art equipment and technology to meet the evolving needs of its customers."Our goal at Precision Aluminum Turning is to provide unmatched precision machining solutions for our customers," said the company's CEO. "With the increasing demand for aluminum components, we have expanded our capabilities to ensure that we can meet the growing needs of our customers with superior precision and efficiency."The company's dedication to excellence in aluminum machining is evident in its investment in advanced CNC machining technology. With a team of highly skilled and experienced machinists, Precision Aluminum Turning is equipped to handle complex aluminum machining projects with the utmost precision and accuracy. The company's commitment to quality and precision has earned it a reputation as a trusted partner for a wide range of industries, including automotive, aerospace, and electronics.In addition to its precision machining capabilities, Precision Aluminum Turning offers a comprehensive range of aluminum finishing services to provide customers with a one-stop solution for their aluminum component needs. From anodizing and powder coating to laser marking and assembly, the company's complete suite of finishing services ensures that customers receive fully finished aluminum parts that meet their exact specifications and requirements.With its expanded service offerings, Precision Aluminum Turning is poised to continue its growth and to meet the increasing demand for high-quality aluminum components in the global market. The company's focus on precision, reliability, and customer satisfaction has made it a preferred partner for leading companies across various industries.Precision Aluminum Turning's dedication to excellence extends beyond its manufacturing capabilities. The company is committed to upholding the highest standards of quality and reliability in all aspects of its operations. From customer service to on-time delivery, Precision Aluminum Turning strives to exceed customer expectations at every stage of the manufacturing process.As the demand for aluminum components continues to rise, Precision Aluminum Turning is well-positioned to meet the needs of its customers with its expanded services and unwavering commitment to precision machining excellence. With a focus on quality, reliability, and customer satisfaction, the company is poised to remain a leader in the precision aluminum machining industry for years to come.

Discover the Strength and Versatility of Aluminium Tensile

Aluminium Tensile, a global leader in innovative aluminum solutions, has recently made a significant impact in the industry with the introduction of their latest product line. This new line of aluminum products is set to revolutionize the way companies approach their manufacturing and construction projects, providing enhanced strength and durability for a wide range of applications.With a focus on sustainability and innovation, Aluminium Tensile has become a trusted partner for businesses looking to incorporate high-quality aluminum into their operations. The company's dedication to excellence and commitment to pushing the boundaries of what is possible in the industry has led to the development of this groundbreaking new product line.Aluminium Tensile offers a diverse range of aluminum products that are designed to meet the specific needs of their customers. From lightweight and versatile aluminum sheets to durable and corrosion-resistant aluminum bars, the company provides solutions for a wide range of industries, including aerospace, automotive, construction, and more. The introduction of their latest product line further demonstrates Aluminium Tensile's ability to deliver cutting-edge solutions that can make a real difference for their clients.One of the standout features of the new product line from Aluminium Tensile is its superior tensile strength. The company has leveraged advanced manufacturing techniques and state-of-the-art materials to create aluminum products that offer unparalleled strength and resilience. This makes them well-suited for use in demanding applications where durability and performance are paramount.In addition to their impressive tensile strength, the new product line from Aluminium Tensile also boasts exceptional corrosion resistance. This is a critical feature for many industries, particularly those operating in harsh or corrosive environments. The company's aluminum products are engineered to withstand the elements, ensuring longevity and reliability in even the most challenging conditions.Furthermore, Aluminium Tensile is committed to sustainability and environmental responsibility. The company's aluminum products are fully recyclable, making them an attractive option for businesses looking to minimize their environmental footprint. By choosing Aluminium Tensile's products, companies can not only benefit from the superior performance of aluminum but also contribute to a more sustainable future."We are thrilled to introduce our latest product line, which represents a significant leap forward for the industry," said a spokesperson for Aluminium Tensile. "The combination of exceptional tensile strength, corrosion resistance, and sustainability make our new aluminum products the ideal choice for a wide range of applications. We are excited to see the impact that these innovative solutions will have for our customers."As a global leader in the industry, Aluminium Tensile is known for its unwavering commitment to quality and customer satisfaction. The company's team of experts works closely with clients to understand their specific requirements and develop tailored solutions that meet their needs. With the introduction of their new product line, Aluminium Tensile is poised to further solidify its position as a preferred partner for businesses seeking high-performance aluminum solutions.In conclusion, Aluminium Tensile's latest product line represents a significant advancement in the industry, offering enhanced tensile strength, corrosion resistance, and sustainability. As a trusted partner for businesses around the world, the company continues to push the boundaries of what is possible with aluminum, delivering innovative solutions that make a real impact. With their latest offering, Aluminium Tensile is set to redefine the standards for aluminum performance and set a new benchmark for the industry.

Lightweight and Durable Aluminium Pipes: Ideal for Various Applications

Title: Hollow Aluminum Pipe Revolutionizes the Manufacturing Industry Introduction:In today's rapidly evolving manufacturing industry, innovations and advancements play a crucial role in improving efficiency and productivity. One such breakthrough is the introduction of Hollow Aluminum Pipe by an industry-leading company (brand name removed) that is set to transform the way various sectors approach the production process. This new development offers immense potential for multiple industries, from aerospace to automotive, due to its lightweight nature, superior strength, and unparalleled versatility.Paragraph 1: Hollow Aluminum Pipe, developed by (brand name removed), is a game-changer in the manufacturing industry. Its inception was driven by a growing need for lighter yet robust materials, with extensive research and development ensuring excellence in its design and performance. The hollow design provides several advantages, including reduced weight, cost-effectiveness, and increased flexibility, setting it apart from conventional solid aluminum pipes.Paragraph 2:The lightweight nature of hollow aluminum pipes proves ideal for industries such as aerospace, where reducing weight without compromising strength is of paramount importance. The aviation sector can benefit significantly from these pipes, resulting in improved fuel efficiency and reduced carbon emissions. Manufacturers can achieve a significant reduction in weight by integrating hollow aluminum pipes into aircraft structures, leading to enhanced performance and increased payloads.Paragraph 3:Automotive manufacturers are also set to reap substantial benefits from hollow aluminum pipes. The lightweight material helps reduce overall vehicle weight, thereby improving fuel efficiency and reducing emissions. Additionally, the exceptional strength of these pipes enhances vehicle safety and durability, making them an ideal choice for manufacturing critical components like chassis frames, roll cages, and suspension systems.Paragraph 4:Furthermore, hollow aluminum pipes offer unique advantages to industries involved in the construction and infrastructure sectors. Their versatility allows for easy customization according to project requirements, facilitating cost-effectiveness and efficiency during installation. Additionally, the excellent corrosion resistance properties of aluminum make it an ideal choice for applications in harsh environments, ensuring longevity and durability.Paragraph 5:The potential applications of hollow aluminum pipes extend beyond the aerospace, automotive, and construction sectors. Industries such as sports equipment manufacturing, marine, and renewable energy could also considerably benefit from this innovative product. The superior strength-to-weight ratio of hollow aluminum pipes can revolutionize sporting equipment, renewable energy infrastructure, and marine components, enhancing performance and reliability.Paragraph 6:(Company name removed) has garnered recognition as a leading supplier of hollow aluminum pipes due to its commitment to research and development and adherence to stringent quality standards. With an extensive customer base that spans across industries, the company's expertise ensures the consistent delivery of high-quality products that meet industry demands.Paragraph 7:In conclusion, hollow aluminum pipes are poised to revolutionize the manufacturing industry. Their lightweight nature, superior strength, and exceptional versatility make them the preferred choice for industries seeking to improve efficiency and maximize performance. With numerous applications across aerospace, automotive, construction, and beyond, the future of manufacturing is undoubtedly set to witness a remarkable transformation, thanks to hollow aluminum pipes.Word Count: 446 words

Improve Your Product Quality with Expert Extrusion Die Design

Extrusion Die Design: The Key to Efficient ManufacturingIn today's competitive manufacturing environment, companies are constantly striving for increased efficiency and productivity. One crucial factor in achieving these goals is the design of extrusion dies. These dies are used in the production of a wide range of products, from plastic pipes and tubing to metal profiles and rods. The design of these dies plays a critical role in the quality, consistency, and speed of the extrusion process.One company that has been at the forefront of extrusion die design is {}. With over 30 years of experience in the industry, {} has established itself as a leader in the design and manufacture of high-quality extrusion dies. The company's team of experienced engineers and designers work closely with customers to develop custom die designs that meet their specific requirements and production goals. By leveraging the latest technology and engineering practices, {} is able to deliver innovative die solutions that optimize the extrusion process and enhance overall manufacturing efficiency.The design of extrusion dies is a complex and intricate process that requires a deep understanding of material behavior, flow dynamics, and thermal management. {} excels in this area by utilizing advanced computer-aided design (CAD) software and simulation tools to model and analyze the extrusion process. This allows the company to fine-tune die designs and optimize critical parameters such as flow rates, temperature profiles, and material distribution. The result is a die design that maximizes material utilization, minimizes waste, and ensures consistent product quality.One of the key factors that sets {} apart in the industry is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay at the forefront of extrusion die technology. By staying abreast of the latest materials, processing techniques, and industry trends, {} is able to develop cutting-edge die designs that push the boundaries of what is possible in extrusion manufacturing. This commitment to innovation has earned {} a reputation as a trusted partner for companies looking to improve their extrusion processes and stay ahead of the competition.In addition to its technical expertise, {} also prides itself on its customer-centric approach to business. The company works closely with customers throughout the entire die design and manufacturing process, ensuring that their needs and expectations are met. From initial concept design to final production, {} collaborates with customers to deliver die solutions that are tailored to their unique requirements. This level of customer engagement and support sets {} apart as a true partner in helping companies achieve their manufacturing goals.As the manufacturing industry continues to evolve, the importance of extrusion die design will only grow. Companies that invest in high-quality, custom-designed die solutions stand to gain a significant competitive advantage. With its proven track record of innovation, technical expertise, and commitment to customer satisfaction, {} is well-positioned to continue leading the way in the field of extrusion die design.In conclusion, the design of extrusion dies is a critical factor in the success of modern manufacturing operations. With its wealth of experience, technical capabilities, and customer-focused approach, {} is a trusted partner for companies looking to optimize their extrusion processes. By leveraging cutting-edge design practices and a commitment to innovation, {} continues to set the standard for excellence in extrusion die design.