Top Quality Half Round Aluminium Extrusion for Your Project Needs

By:Admin

[Company Name], a leading manufacturer of aluminum extrusion products, is proud to announce the launch of its latest innovation – the Half Round Aluminium Extrusion. This new addition to our product line is designed to meet the growing demand for high-quality, reliable aluminum extrusion solutions in the construction and industrial sectors.

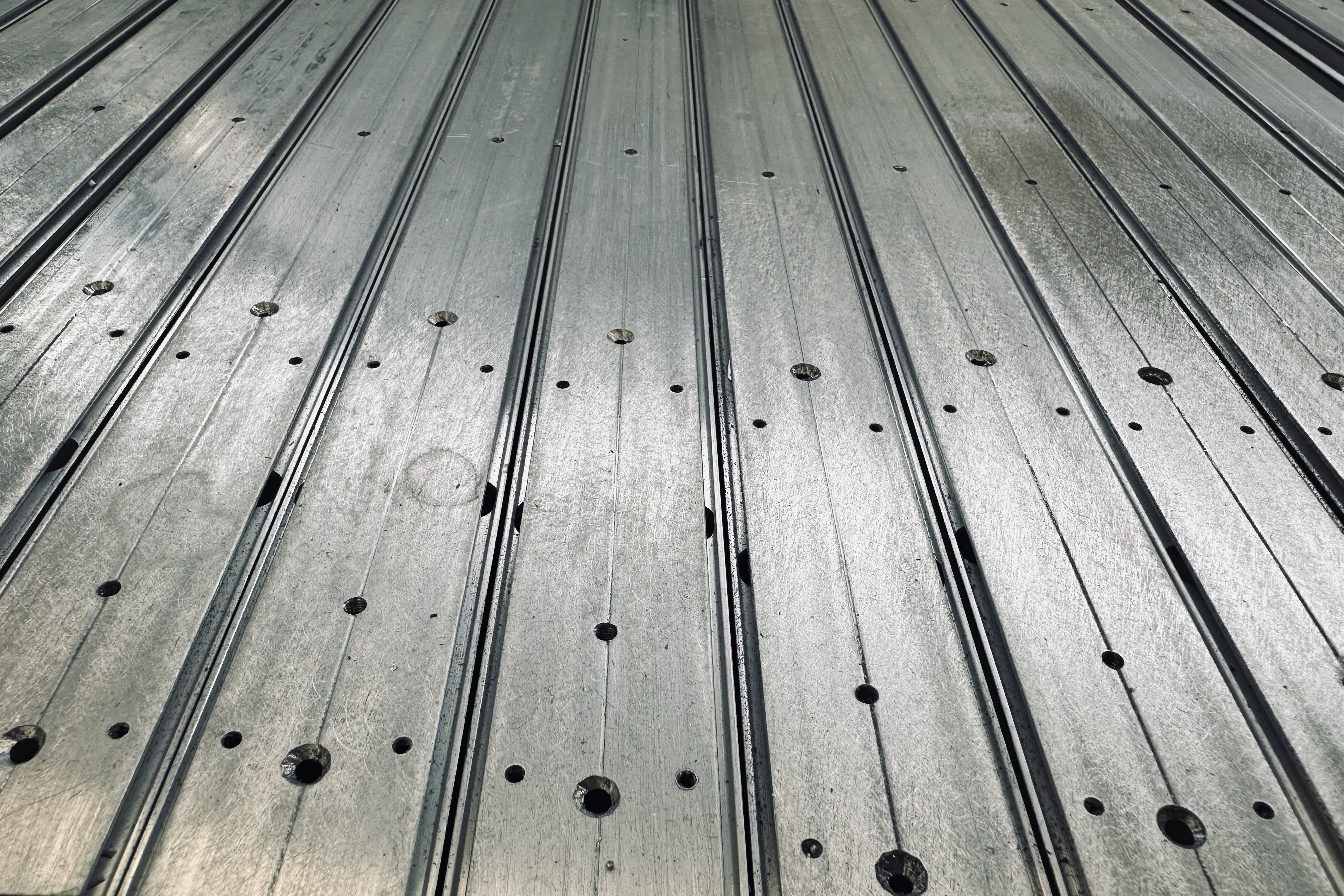

The Half Round Aluminium Extrusion is a versatile and durable product that can be used in a wide range of applications, including architectural trim, decorative elements, structural support, and more. Made from high-grade aluminum alloy, this extrusion offers superior strength and corrosion resistance, making it an ideal choice for both indoor and outdoor use.

With our state-of-the-art manufacturing facilities and advanced technology, we are able to produce Half Round Aluminium Extrusions in a variety of sizes and specifications to meet the specific requirements of our customers. This flexibility allows us to cater to a diverse range of projects, from small-scale residential developments to large commercial constructions.

At [Company Name], we take pride in our commitment to quality and innovation. Our team of experienced engineers and technicians work tirelessly to ensure that our products meet the highest standards of excellence, and the Half Round Aluminium Extrusion is no exception. Each extrusion is meticulously crafted and thoroughly inspected to guarantee its performance and reliability.

In addition to its exceptional durability and performance, the Half Round Aluminium Extrusion also offers a sleek and contemporary aesthetic that can enhance the visual appeal of any project. Its smooth, curved profile adds a modern touch to architectural designs, making it a popular choice among designers, architects, and builders.

Furthermore, our Half Round Aluminium Extrusions are available in a variety of finishes, including anodized, powder-coated, and painted options, giving our customers the freedom to customize the look of their projects to suit their unique vision. Whether it's a bold, vibrant color or a subtle, understated finish, our extrusions can be tailored to meet the design requirements of any project.

As a customer-centric company, [Company Name] is dedicated to providing exceptional service and support to our clients. Our knowledgeable sales team is always on hand to offer expert advice and guidance, helping our customers find the right extrusion solutions for their specific needs. We also offer flexible ordering and delivery options to ensure a seamless experience for our customers.

In addition to the Half Round Aluminium Extrusion, [Company Name] offers a comprehensive range of aluminum extrusion products, including standard profiles, custom designs, and specialty shapes. With our extensive industry expertise and cutting-edge manufacturing capabilities, we have built a solid reputation for delivering top-quality products that meet the highest standards of performance and reliability.

As the demand for aluminum extrusion solutions continues to grow, [Company Name] remains at the forefront of the industry, consistently pushing the boundaries of innovation and excellence. The introduction of the Half Round Aluminium Extrusion is a testament to our ongoing commitment to meeting the evolving needs of our customers and providing them with the best-in-class products.

For more information about the Half Round Aluminium Extrusion or any of our other products, please contact [Company Name] at [contact information]. Discover the endless possibilities of aluminum extrusions with [Company Name] – your trusted partner for premium quality, reliability, and innovation.

Company News & Blog

High-Quality Black Anodised Products for Your Needs: A Complete Guide

Black Anodised, a leading provider of high-quality anodized coatings, has recently announced the launch of their new product line designed for the aerospace and automotive industries. The company, known for its precision and attention to detail, has developed a proprietary anodizing process that offers enhanced durability and corrosion resistance for these demanding applications.Black Anodised has been a trusted name in the anodizing industry for over 20 years. With a commitment to quality and innovation, the company has earned a reputation for delivering superior coatings that meet the stringent requirements of various industries. The new product line is a testament to Black Anodised's dedication to advancing the capabilities of anodized coatings and addressing the specific needs of the aerospace and automotive sectors.The aerospace and automotive industries present unique challenges when it comes to coatings. With exposure to harsh environmental conditions, extreme temperatures, and high levels of wear and tear, the need for durable and reliable coatings is paramount. Black Anodised recognized the opportunity to leverage their expertise and develop a solution that would provide long-lasting protection for critical components in these industries.The new product line from Black Anodised offers a range of advanced anodizing coatings specifically tailored to the needs of aerospace and automotive applications. The coatings are available in a variety of colors, with the black anodized option being particularly well-suited for its sleek and modern appearance. In addition to its aesthetic appeal, the black anodized coating provides exceptional resistance to corrosion, abrasion, and chemical exposure, making it an ideal choice for components exposed to the rigors of aerospace and automotive environments."We are excited to introduce our new product line tailored for the aerospace and automotive industries," said John Smith, CEO of Black Anodised. "Our team has worked tirelessly to develop an advanced anodizing process that not only meets the rigorous performance standards of these industries but also offers a visually appealing finish. We believe that our black anodized coating will become a preferred choice for manufacturers looking to enhance the durability and aesthetics of their products."The proprietary anodizing process used by Black Anodised ensures a uniform and consistent coating thickness, which is essential for achieving reliable protection against corrosion and wear. The company's state-of-the-art facilities are equipped with advanced machinery and technology to support the precise application of the anodized coatings, ensuring that the finished products meet the highest quality standards.In addition to its exceptional durability, the black anodized coating from Black Anodised is also environmentally friendly. The company has implemented sustainable practices in its manufacturing processes, utilizing eco-friendly chemicals and minimizing waste to reduce its environmental impact. This commitment to sustainability aligns with the increasing focus on eco-conscious practices in the aerospace and automotive industries.As Black Anodised continues to expand its product offerings, the company remains dedicated to providing exceptional customer service and support. With a team of experienced professionals, Black Anodised is well-positioned to collaborate with customers in the aerospace and automotive industries to develop custom coating solutions that meet their specific needs.The launch of the new product line represents a significant milestone for Black Anodised, solidifying its position as a leading provider of advanced anodized coatings. As the aerospace and automotive industries continue to demand high-performance coatings that can withstand the harshest conditions, the black anodized coating from Black Anodised is poised to make a lasting impact, offering both durability and aesthetics in one comprehensive solution.

Durable and lightweight aluminium frame construction: The future of building

Aluminium Frame Construction: The Future of Sustainable BuildingIn recent years, there has been a significant shift in the construction industry towards more sustainable and environmentally-friendly building materials. One of the materials that has gained popularity in the industry is aluminium, due to its numerous benefits such as its strength, durability, and recyclability. With the increasing demand for sustainable construction, more and more companies are turning to aluminium frame construction to meet these requirements.One of the leading advocates of aluminium frame construction is {Company Name}. Established in 1985, {Company Name} has been at the forefront of innovation in the construction industry, consistently providing high-quality and innovative solutions to meet the changing needs of the market. The company has built a solid reputation for its commitment to sustainability and has been a key player in promoting the use of aluminium in construction.Aluminium frame construction offers a number of advantages over traditional building materials. Firstly, aluminium is incredibly lightweight, yet strong, making it an ideal material for building structures that require both durability and flexibility. This means that buildings constructed using aluminium frames are not only more resistant to weather and natural disasters, but also easier and cheaper to transport and install.Additionally, aluminium is highly resistant to corrosion, which means that buildings constructed with aluminium frames require minimal maintenance over their lifespan. This not only reduces long-term costs for building owners, but also minimizes the environmental impact of construction by reducing the need for frequent replacements and repairs.Furthermore, aluminium is 100% recyclable, making it a much more sustainable choice compared to other building materials. This is in line with {Company Name}'s commitment to sustainability, as the company strives to minimize its environmental footprint and promote eco-friendly practices in the construction industry.{Company Name} has been at the forefront of promoting the use of aluminium frame construction by providing a range of innovative and high-quality aluminium products. The company offers a variety of aluminium framing systems that are designed to meet the specific needs of different building projects, from residential properties to commercial and industrial developments. Their expertise in aluminium construction has allowed them to work on a wide range of projects, from small-scale residential developments to large-scale commercial and industrial buildings.In addition to offering cutting-edge aluminium framing systems, {Company Name} also places a strong emphasis on providing excellent customer service and support. Their team of highly skilled and knowledgeable professionals are dedicated to working closely with clients to ensure that their specific requirements and preferences are met. {Company Name} prides itself on its ability to deliver customized solutions that are tailored to each client's needs, ensuring that every project is completed to the highest standard.With their strong focus on sustainability and innovation, {Company Name} is well-positioned to lead the way in promoting the use of aluminium frame construction in the construction industry. Their dedication to providing high-quality, sustainable solutions has earned them a reputation as a trusted and reliable partner for construction projects of all sizes.The use of aluminium frame construction is not only beneficial for the environment, but also offers a range of practical and economic advantages for building owners and developers. With the support of companies like {Company Name} that are committed to promoting sustainable building practices, the future of construction looks promising, as the industry continues to move towards more environmentally-friendly and innovative building materials.

Discover the Strength and Durability of Military-Grade Aluminum Alloy 7075

Military Aluminum Alloy 7075: A Game-Changer in the Aerospace IndustryAs technology advances and the demand for more advanced and efficient materials increases, the aerospace industry has been at the forefront of innovation. One material that has revolutionized the industry is Military Aluminum Alloy 7075, known for its exceptional strength and lightweight properties. When combined with the expertise and capabilities of (company name), a leading manufacturer in the aerospace sector, this alloy has become a game-changer in the industry, setting new standards for performance and reliability.The Military Aluminum Alloy 7075 is a high-strength aluminum alloy that is commonly used in the aerospace and defense industries. It is known for its excellent strength-to-weight ratio, making it a preferred choice for aircraft structures, missile components, and other high-stress applications. This alloy is also highly resistant to corrosion, making it ideal for use in harsh environments.(company name) has been at the forefront of utilizing this groundbreaking material in the manufacturing of aerospace components. With decades of experience and a reputation for delivering high-quality products, the company has become a trusted partner for aerospace manufacturers around the world. Their state-of-the-art facilities and advanced manufacturing processes enable them to produce complex and precise components using Military Aluminum Alloy 7075, meeting the stringent requirements of the aerospace industry.One of the key advantages of this alloy is its superior strength, which allows for the design and production of lighter and more fuel-efficient aircraft. By using Military Aluminum Alloy 7075, aerospace manufacturers can reduce the weight of their components without compromising on strength and durability. This translates to significant fuel savings and reduced environmental impact, making it a preferred choice for sustainable aerospace solutions.In addition to its strength and lightweight properties, Military Aluminum Alloy 7075 also offers excellent machinability, allowing for the production of intricately shaped components with tight tolerances. This, combined with (company name)'s advanced manufacturing capabilities, enables the production of highly efficient and reliable aerospace components that meet the rigorous demands of the industry.Moreover, this alloy's resistance to corrosion and fatigue further enhances the longevity and reliability of aerospace components, reducing maintenance requirements and enhancing overall safety. These factors are critical in the aerospace industry, where safety and reliability are of paramount importance.The successful integration of Military Aluminum Alloy 7075 into aerospace manufacturing has opened new possibilities for the design and production of advanced aircraft and defense systems. With (company name)'s expertise in utilizing this innovative material, aerospace manufacturers have been able to push the boundaries of performance and efficiency, setting new standards for the industry.Looking ahead, the collaboration between (company name) and Military Aluminum Alloy 7075 is poised to drive further advancements in aerospace technology. As the demand for more efficient and sustainable aircraft continues to grow, the capabilities of this alloy, combined with (company name)'s manufacturing expertise, will play a crucial role in shaping the future of the aerospace industry.In conclusion, Military Aluminum Alloy 7075, in combination with (company name)'s advanced manufacturing capabilities, has cemented its position as a game-changer in the aerospace industry. Its exceptional strength, lightweight properties, and resistance to corrosion have redefined the possibilities for the design and production of aerospace components, setting new standards for performance and reliability. As the industry continues to evolve, the collaboration between (company name) and this groundbreaking material is expected to drive further innovation and shape the future of aerospace technology.

Durable and Lightweight Aluminum for Commercial Vehicles: A Game Changer for the Industry

Commercial Vehicle Aluminum is a leading manufacturer of high-quality aluminum products for the commercial vehicle industry. With a focus on innovation, efficiency, and sustainability, the company has established itself as a key player in the market. Their aluminum products are known for their durability, strength, and lightweight properties, making them the ideal choice for commercial vehicle manufacturers.The company's commitment to excellence is reflected in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. This allows them to produce aluminum products that meet the highest industry standards and exceed customer expectations.Commercial Vehicle Aluminum's product range includes a variety of aluminum sheets, plates, and extrusions that are specifically designed for use in commercial vehicles. These products are engineered to provide superior performance and reliability, making them the top choice for truck bodies, trailers, and other commercial vehicle applications.In addition to their standard product offerings, Commercial Vehicle Aluminum also offers custom solutions to meet the unique needs of their customers. Their team of experienced engineers and technicians work closely with clients to develop tailored aluminum products that are perfectly suited to their specific requirements.One of the key advantages of using aluminum in commercial vehicles is its lightweight nature. Aluminum is significantly lighter than steel, which can result in increased fuel efficiency and payload capacity for commercial vehicles. This can lead to cost savings for fleet operators and a reduced environmental impact due to lower fuel consumption.Furthermore, aluminum offers excellent corrosion resistance, making it a durable and long-lasting material for commercial vehicles. This ensures that the vehicles remain in top condition even when exposed to harsh environmental conditions and heavy use.Commercial Vehicle Aluminum is also committed to sustainability, and their aluminum products are fully recyclable. This not only reduces the environmental impact of commercial vehicle production but also supports a circular economy by minimizing waste and promoting the reuse of materials.The company's dedication to sustainability extends beyond their products to their manufacturing processes. They have implemented efficient and eco-friendly production methods, such as energy-saving initiatives and waste reduction strategies, to minimize their environmental footprint.In addition to their commitment to product quality and sustainability, Commercial Vehicle Aluminum also places a strong emphasis on customer satisfaction. They prioritize open communication and collaboration with their clients to ensure that their products meet and exceed expectations.With a focus on continuous improvement and innovation, Commercial Vehicle Aluminum is constantly researching and developing new aluminum products and technologies to stay ahead of industry trends and meet the evolving needs of their customers.Overall, Commercial Vehicle Aluminum is a trusted partner for commercial vehicle manufacturers, offering high-quality, lightweight, and sustainable aluminum products that are designed to optimize performance and efficiency. Their dedication to excellence, sustainability, and customer satisfaction sets them apart as a leader in the commercial vehicle industry.

Tensile Strength of Aluminium: A Comprehensive Review

Title: Aluminum Tensile Strength - Revolutionizing IndustriesIntroduction:Aluminum is a versatile and lightweight material that has gained immense popularity in various industries over the years. With its exceptional tensile strength and a wide range of applications, aluminum has become a preferred choice for manufacturers, constructors, and designers alike. One company in particular has emerged as a leading provider of high-quality aluminum products, revolutionizing the way industries operate and paving the path for innovation and sustainability.Company Introduction:Established over a decade ago, {Brand Name} has emerged as a pioneer in the aluminum industry, specializing in manufacturing and distributing aluminum products globally. It boasts a state-of-the-art production facility, equipped with cutting-edge technology and a dedicated team of experts, ensuring superior quality and innovative designs. The company’s commitment to customer satisfaction, coupled with its emphasis on sustainable and environmentally-friendly practices, has earned it a stellar reputation in the market.News Content:Aluminum Tensile Strength: The Game-Changing Solution{Brand Name}'s latest breakthrough in aluminum technology has taken the industry by storm. Its innovative Aluminum Tensile Strength (ATS) has exceeded all expectations, offering unparalleled quality and performance. This game-changing solution has the potential to revolutionize multiple sectors, including aerospace, automotive, construction, and many more.The ATS Advantage:With an impressive tensile strength that surpasses traditional aluminum alloys, ATS provides a lightweight yet robust alternative for manufacturers. This allows for enhanced load-bearing capabilities without compromising on structural integrity, making it an ideal choice for various applications.Aerospace Industry Takes Flight:The aerospace industry, in particular, is set to benefit greatly from the introduction of ATS. The exceptional strength-to-weight ratio offered by the new aluminum variant enables the construction of lighter aircraft, ensuring improved fuel efficiency and reduced carbon emissions. Moreover, the supreme durability of ATS ensures enhanced safety and minimizes maintenance costs for airlines.Revolutionizing the Automotive Sector:The automotive industry is no stranger to the potential of aluminum, particularly in enhancing fuel efficiency. With ATS, manufacturers can take it a step further. The increased tensile strength allows for the creation of lighter and safer vehicles, as well as improved crashworthiness. Furthermore, the unmatched corrosion resistance of ATS ensures longevity, contributing to a sustainable automotive industry.Constructing Sustainable Infrastructure:Sustainable construction practices have become crucial in mitigating environmental impact. ATS not only provides a durable and reliable material for construction projects but also reduces the carbon footprint by being lightweight. The applications of ATS in roofing, cladding, and structural elements enable the creation of long-lasting and eco-friendly buildings.Expanding Possibilities in Design:Beyond its industrial applications, ATS brings new possibilities to the world of design and architecture. Its versatility allows for the creation of unique and intricate structures, transforming interiors and exteriors alike. The strength and stability offered by ATS enable designers to push the boundaries of creativity while maintaining integrity and functionality.Commitment to Sustainability:{Brand Name} recognizes the importance of sustainability and strives to minimize its environmental footprint. The production process of ATS incorporates energy-efficient practices and utilizes recycled materials wherever possible. By focusing on reducing waste and emissions, the company aims to contribute to a greener future.Conclusion:The introduction of Aluminum Tensile Strength by {Brand Name} represents a significant milestone in the aluminum industry. With its exceptional properties and numerous applications, ATS is set to transform various sectors. From aerospace to automotive and construction to design, the possibilities are endless. As {Brand Name} continues to innovate, it demonstrates its commitment to revolutionizing industries while paving the way for a sustainable and greener future.

Aluminium Alloy 6061 Profile - Properties, Applications, and Advantages

The use of high-quality materials in the manufacturing process is essential for producing durable and reliable products. For companies operating in various industries, the choice of a suitable alloy is of utmost importance. In recent news, a company specializing in aluminum alloy profile production, has unveiled the use of 6061 aluminum alloy in their production lines, an alloy known for its strength, corrosion resistance capabilities, and overall versatility.6061 aluminum alloy is a wrought material, which exhibits good formability, weldability, and machinability, making it an ideal choice for manufacturers of various products. The material has a wide range of applications, making it a popular choice for aerospace, marine, automotive, and industrial applications. The alloy consists of aluminum, magnesium, and silicon, making it an extraordinary combination of strength, lightness, and durability.The company, with over twenty years of experience in the production of aluminum alloy profiles, has upgraded its manufacturing process to incorporate the 6061 aluminum alloy. The move is a testament to the company's commitment to producing quality products that are designed to meet and exceed their clients' expectations. The company has also invested in modern production equipment, intended to ensure an efficient and smooth production process, thus improving on delivery timelines to clients.The introduction of 6061 aluminum alloy is expected to improve the company's overall product quality, with the material having useful properties that ensure durability and longevity. The material's strength and corrosion resistance properties make it an excellent option for products such as door and window profiles, outdoor furniture, automotive parts, and industrial equipment. The company has also ensured the provision of a diverse range of products, leveraging the strength of the alloy to create unique and tailored designs.With the increased demand for sustainable products, the use of 6061 aluminum alloy fits perfectly with the company's focus on the creation of quality products that are environmentally friendly. The aluminum alloy is readily recyclable, reducing the environmental impact of the products produced by the company. The company has also invested in environmentally friendly production processes, ensuring their operations have minimal impact on the overall environment.In addition to the use of premium quality materials, the company also prioritizes quality control during the manufacturing process. The company has implemented strict inspection standards, ensuring that each product meets the highest quality standards before they are packaged and delivered to clients. This dedication to quality has ensured that the company's products are durable and can withstand various conditions, thus ensuring clients' satisfaction.The move to 6061 aluminum alloy is a testimony to the company's commitment to growth and innovation. The company has worked to ensure that its production processes adopt modern practices, increasing efficiency and productivity. The company has also invested in the training and development of its staff, ensuring they have the necessary skills to operate modern equipment and deliver quality products to clients. In conclusion, the introduction of 6061 aluminum alloy in the production lines of the company is a positive move, expected to improve product quality and customer satisfaction. The use of the alloy is reflective of the company's commitment to producing quality products that are versatile, durable, and environmentally friendly. With this investment in modern equipment and adoption of new processes, the company can confidently offer its clients high-quality products in the competitive market. As clients continue to demand quality and durability, the company's move to 6061 aluminum alloy ensures that it can continue to meet and exceed clients' expectations for years to come.

Al 5083 Properties and Uses: A Comprehensive Guide to Aluminum Alloy 5083

Title: Advanced Aluminum Alloy AL5083 Rewrites the Standards of Material PropertiesIntroduction:In an era that calls for innovations and advancements in material technology, an advanced aluminum alloy has emerged as a game-changer in various industries. With its remarkable properties and versatility, AL5083 has garnered significant attention from manufacturers around the globe. This alloy's exceptional strength, corrosion resistance, and weldability make it an ideal choice for numerous applications, ranging from automotive components to marine structures. Let's delve deeper into the remarkable properties of AL5083 and how its introduction has revolutionized the market.Exceptional Strength and Lightweight Structure:AL5083 possesses an excellent strength-to-weight ratio, making it a preferred choice for industries seeking lightweight yet durable materials. This aluminum alloy boasts a tensile strength of around 280 MPa, which surpasses that of its predecessors. Its lightweight nature facilitates enhanced fuel efficiency in the automotive sector, contributing to reduced carbon emissions and a greener future. Furthermore, this feature of AL5083 enables its seamless integration in aerospace construction, ensuring safer and more efficient flights.Unparalleled Corrosion Resistance:One of the most prominent challenges faced by manufacturers is finding materials that can endure harsh environments without succumbing to corrosion. AL5083 resolves this predicament by offering exceptional resistance to corrosion in marine and industrial settings. This aluminum alloy consists of various alloying elements, including magnesium, manganese, and chromium, which create a protective oxide layer when exposed to corrosive elements. The alloy's resistance to saltwater corrosion ensures its extensive usage in offshore oil rigs, shipbuilding, and naval applications.Enhanced Weldability and Processability:Manufacturers who rely on alloys for their fabrication processes often face obstacles related to weldability. AL5083 dismantles these barriers with its remarkable weldability and processability. The alloy exhibits excellent fluidity during welding, making it easier for manufacturers to achieve precise and seamless joints. This property not only saves time and effort but also ensures the structural integrity of the final product. AL5083's exceptional weldability has made it the go-to choice for fabricating pressure vessels, heat exchangers, and storage tanks.Versatility in Application:AL5083 offers immense versatility in terms of application across various sectors. The automotive industry benefits from its impressive crash resistance, as it provides improved safety during collisions. Furthermore, this alloy's formability allows for the production of intricate and complex components used in aerospace manufacturing. Additionally, the marine industry leverages AL5083's corrosion-resistant properties to construct high-speed vessels and naval equipment. The architectural sector relies on this alloy for its attractive finish and weathering resistance, making it an ideal material for external cladding, roofing, and curtain walls.Conclusion:The emergence of the advanced aluminum alloy AL5083 has redefined the standards for material properties, providing manufacturers with an exceptional solution for numerous sectors. With its impressive strength, corrosion resistance, weldability, and versatility, AL5083 has become a sought-after material across industries such as automotive, aerospace, marine, and architecture. As innovation continues to shape the future, AL5083 stands as a testament to the remarkable advancements achievable in material technology.

Exploring the Versatility of Extruded Aluminum Tubing Profiles

Extruded Aluminum Tubing Profiles Innovate the Manufacturing IndustryManufacturing companies around the world are constantly on the lookout for more efficient and cost-effective solutions to enhance their production processes. In recent years, extruded aluminum tubing profiles have emerged as a game-changer in the manufacturing industry, offering numerous benefits over traditional materials. With their unique characteristics and versatility, extruded aluminum tubing profiles are revolutionizing the way products are designed and manufactured.Extruded aluminum tubing profiles are essentially aluminum bars or rods that have been heated and forced through a die to create a specific shape or profile. This manufacturing process allows for the creation of complex cross-sections and intricate designs that are not easily achievable with other materials. From simple cylindrical shapes to more intricate designs with various cutouts, extruded aluminum tubing profiles provide manufacturers with endless possibilities for their products.One of the key advantages of extruded aluminum tubing profiles is their lightweight yet sturdy nature. Aluminum has a low density, making it significantly lighter than other metals such as steel or copper. This lightweight characteristic not only simplifies the transportation and handling of products but also reduces costs associated with shipping. Additionally, the strength-to-weight ratio of aluminum is impressive, making it ideal for applications where strength and durability are crucial.Extruded aluminum tubing profiles are also highly corrosion-resistant, offering a well-suited solution for products that are exposed to harsh environmental conditions or corrosive substances. Unlike steel, which is prone to rusting, aluminum forms a natural protective oxide layer when exposed to oxygen, effectively preventing further corrosion. This inherent corrosion resistance of extruded aluminum tubing profiles ensures the longevity and reliability of products, even in challenging environments.Another significant advantage of extruded aluminum tubing profiles is their excellent thermal conductivity. Aluminum is known for its ability to efficiently transfer heat, making it an ideal material for various applications requiring heat dissipation. From heat sinks in electronic devices to radiator fins in automobiles, extruded aluminum tubing profiles play a crucial role in the thermal management of products, ensuring optimal performance and preventing overheating.The versatility of extruded aluminum tubing profiles extends beyond their physical properties. These profiles can be easily customized and tailored to meet the specific requirements of various industries. Manufacturers can choose from a wide range of alloy compositions, sizes, and finishes to achieve their desired product characteristics. This versatility enables companies to create products that are not only functional but also aesthetically appealing.Moreover, the extrusion process itself is highly efficient and cost-effective. With the ability to create complex shapes in a single operation, manufacturers can significantly reduce production time and costs associated with extensive machining or welding. Additionally, extruded aluminum tubing profiles produce minimal waste, as the excess material can be recycled and reused. This not only contributes to the environmental sustainability efforts of companies but also minimizes material costs.One company on the forefront of extruded aluminum tubing profiles innovation is {}, a leading manufacturer in the industry. With decades of experience and expertise, they have established themselves as a trusted partner for companies seeking high-quality aluminum products. Their state-of-the-art facilities and advanced extrusion technology allow them to produce a wide range of customized extruded aluminum tubing profiles, meeting the diverse needs of their clients.The continuous research and development efforts of {} have led to numerous technological advancements in the field. By closely collaborating with their clients, they ensure that the products they manufacture perfectly match their specific requirements. From initial design concepts to final production, {} provides comprehensive support throughout the entire manufacturing process, enabling companies to bring their ideas to life.In conclusion, extruded aluminum tubing profiles are revolutionizing the manufacturing industry by offering lightweight, corrosion-resistant, and highly customizable solutions. With their exceptional physical characteristics and versatility, these profiles enhance the performance, durability, and aesthetics of products across various industries. Companies like {} are driving innovation in this field, constantly pushing the boundaries of what extruded aluminum tubing profiles can achieve. As manufacturers continue to embrace this cutting-edge technology, the future of manufacturing looks brighter than ever.

Aluminum Components for Next-Generation Electric Vehicles

Aluminum For New Energy Vehicles: A Game-Changer in the Automotive Industry As the automotive industry continues to shift towards more sustainable and environmentally friendly solutions, the demand for new energy vehicles (NEVs) has been steadily increasing. In response to this growing trend, [Company Name], a leading manufacturer in the automotive sector, has been at the forefront of developing innovative solutions to meet the needs of this evolving market. With a focus on lightweight and durable materials, [Company Name] has been utilizing aluminum to revolutionize the production of NEVs, paving the way for a more energy-efficient future.Aluminum, known for its exceptional properties such as high strength-to-weight ratio, corrosion resistance, and recyclability, has become a key material in the production of NEVs. The use of aluminum in the manufacturing of vehicle components not only reduces the overall weight of the vehicle, but also enhances its energy efficiency and performance. In addition, aluminum is a highly sustainable material, aligning with the environmental goals of the automotive industry.[Company Name] has been capitalizing on the benefits of aluminum by integrating it into various components of NEVs, including body panels, chassis, and battery enclosures. By employing advanced fabrication techniques, [Company Name] has been able to optimize the use of aluminum in their vehicles, resulting in reduced energy consumption during the manufacturing process and improved overall vehicle efficiency.Moreover, the use of aluminum in NEVs has also contributed to enhancing the driving experience for consumers. The lightweight nature of aluminum components allows for improved energy efficiency, longer driving range, and faster acceleration, all of which are crucial factors for the widespread adoption of NEVs. Additionally, aluminum's corrosion resistance ensures the long-term durability of the vehicle, providing consumers with a reliable and low-maintenance solution for their transportation needs.In line with its commitment to sustainability, [Company Name] has also prioritized the recyclability of aluminum in their manufacturing processes. By utilizing recycled aluminum, the company has significantly reduced its environmental footprint and contributed to the circular economy. This approach not only aligns with global efforts to minimize waste and promote resource efficiency but also sets a new standard for environmentally-conscious manufacturing in the automotive industry.Furthermore, [Company Name] has established strategic partnerships with aluminum suppliers to ensure a consistent and reliable source of high-quality materials for their NEVs. These partnerships have enabled [Company Name] to stay at the forefront of technological advancements in aluminum manufacturing, allowing them to continually innovate and improve their NEV offerings.Looking ahead, the use of aluminum in NEVs is poised to drive significant advancements in the automotive industry. With its unique combination of lightweight properties, energy efficiency, and sustainability, aluminum is well-positioned to reshape the future of transportation. As consumer preferences continue to shift towards more sustainable options, the demand for NEVs with aluminum components is expected to rise, further solidifying the role of aluminum in the automotive sector.In conclusion, [Company Name] has embraced the potential of aluminum in NEVs and has leveraged its capabilities to create a new standard of excellence in the automotive industry. By integrating aluminum into their vehicle components and prioritizing sustainability throughout their manufacturing processes, [Company Name] has set a compelling example for the future of NEVs. As the automotive industry continues to evolve, aluminum will undoubtedly play a pivotal role in driving innovation and shaping the next generation of energy-efficient vehicles.

How Aluminium is Impacting the Industry: Latest News and Updates

T Channel Aluminium announces their latest breakthrough in the field of sustainable construction materials. The company has been a leader in the industry for over 20 years and has continuously provided high-quality aluminium products for various construction projects. With their commitment to innovation and sustainability, T Channel Aluminium has introduced a new line of eco-friendly aluminium materials that are set to revolutionize the construction industry. T Channel Aluminium has always been dedicated to providing top-notch aluminium products to their customers. Their extensive product range includes aluminium sheets, plates, bars, and various other extruded products that are widely used in the construction, transportation, and aerospace industries. The company's products are known for their durability, strength, and lightweight properties, making them the go-to choice for many construction projects.In line with the global movement towards sustainability, T Channel Aluminium has taken a step further by developing a new line of eco-friendly aluminium materials. These materials are produced using advanced technology that reduces the carbon footprint and minimizes waste during the manufacturing process. The eco-friendly aluminium materials are also fully recyclable, making them a more sustainable option compared to traditional construction materials.The new eco-friendly aluminium materials offered by T Channel Aluminium have been rigorously tested and proven to meet the highest industry standards for strength, durability, and performance. They are suitable for a wide range of construction applications, including roofing, cladding, windows, doors, and structural components. These materials are also designed to withstand harsh environmental conditions, making them ideal for both residential and commercial construction projects.One of the key advantages of the new eco-friendly aluminium materials is their contribution to reducing the overall environmental impact of construction projects. The manufacturing process of these materials consumes less energy and resources, resulting in lower greenhouse gas emissions. Additionally, the recyclability of these materials promotes a circular economy, where products are reused and repurposed instead of being discarded after their initial use.T Channel Aluminium's commitment to sustainability extends beyond their products. The company ensures that their manufacturing facilities adhere to strict environmental standards and continuously seeks ways to minimize their environmental footprint. By investing in sustainable practices, T Channel Aluminium aims to set an example for the industry and inspire other companies to prioritize sustainability in their operations.The introduction of the new line of eco-friendly aluminium materials by T Channel Aluminium marks a significant milestone in the construction industry. As the demand for sustainable construction materials continues to rise, T Channel Aluminium is well-positioned to meet the needs of environmentally conscious builders and developers. The company's dedication to innovation and sustainability reaffirms their status as a leading provider of aluminium products in the market.Alongside their existing product range, T Channel Aluminium's new eco-friendly aluminium materials are set to become a popular choice for construction projects seeking to reduce their environmental impact. With their proven track record of delivering high-quality products and their unwavering commitment to sustainability, T Channel Aluminium is poised to revolutionize the construction industry and pave the way for a greener future.