Tips for Machining Aluminum Alloy 5083 Successfully

By:Admin

Introduction:

In today's rapidly evolving industrial landscape, machining plays a pivotal role in manufacturing processes. One renowned company stands at the forefront, constantly striving to push the boundaries of excellence and innovation. With their cutting-edge technology and extensive expertise, this industry leader has recently introduced remarkable advancements in machining 5083 aluminum. These techniques are set to revolutionize the precision and efficiency of aluminum machining, bringing in a new era of possibilities.

I. The Importance of Aluminum in Modern Manufacturing

Aluminum, known for its lightweight yet robust properties, has become an indispensable material in various industries. From aerospace and automotive to construction and electronics, the demand for aluminum products continues to soar. Machining 5083 aluminum, in particular, is highly sought after due to its exceptional corrosion resistance and excellent weldability. These properties make it ideal for marine applications, transportation infrastructure, and structural components in harsh environments.

II. The Need for Innovative Machining Techniques

As the demand for aluminum products rises, manufacturers face the challenge of meeting stringent quality requirements while ensuring cost-effectiveness. Traditional machining methods often struggle to handle the unique characteristics of 5083 aluminum, leading to issues such as tool wear, surface roughness, and dimensional inaccuracies. To address these challenges, our featured company has introduced groundbreaking machining techniques designed to unlock the full potential of 5083 aluminum.

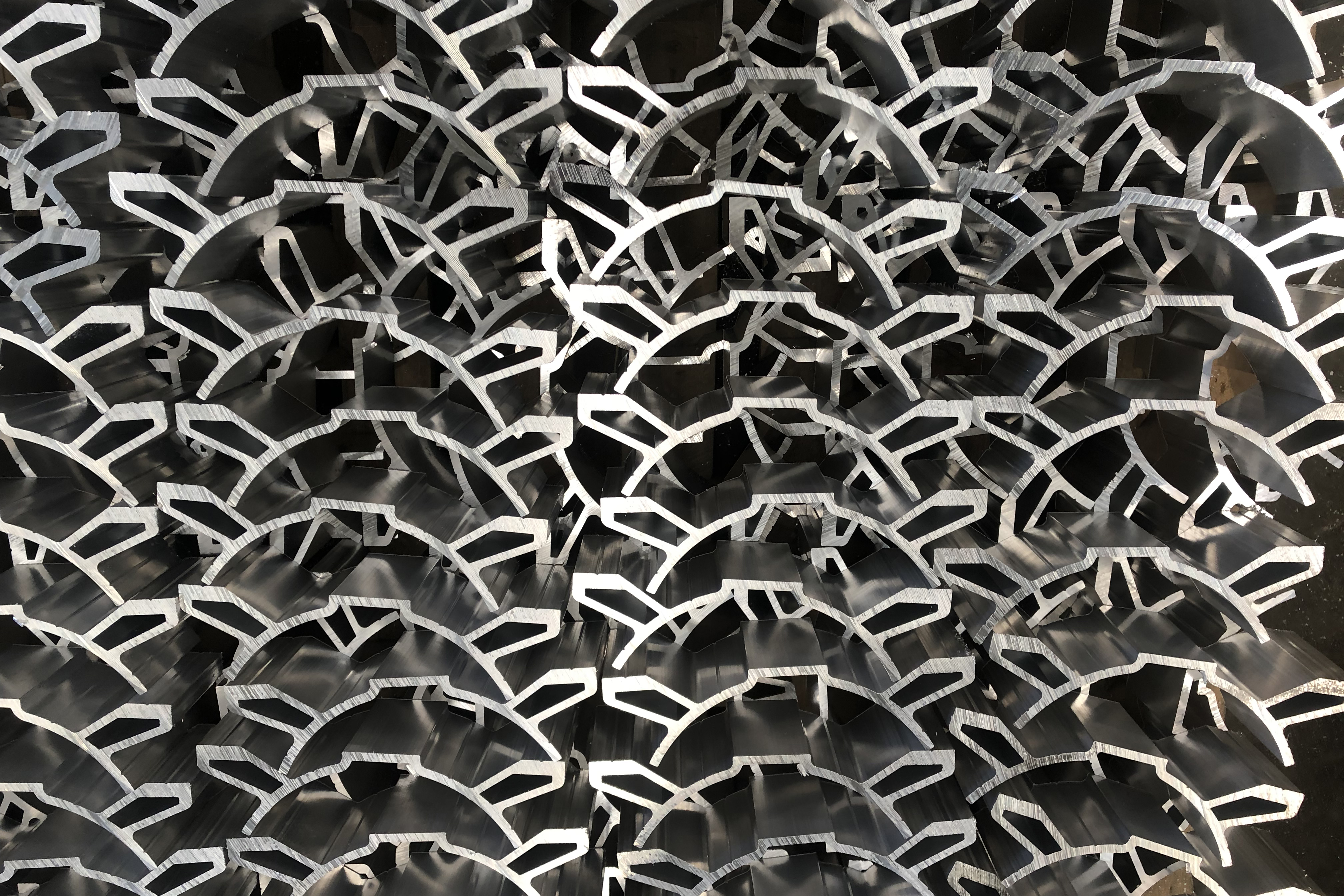

III. Advanced Tooling for Superior Machining Results

One of the key advancements by this forward-thinking company is the development of custom-designed precision tools specifically tailored for machining 5083 aluminum. Using state-of-the-art technologies, these tools offer improved tool life, reduced cutting forces, and enhanced chip evacuation. By optimizing tool geometry and employing innovative coatings, the company has succeeded in significantly improving the overall machining process, enhancing productivity, and minimizing downtime.

IV. Novel Cooling Systems for Efficiency and Sustainability

As efficient cooling is crucial for achieving precision and prolonging tool life, our featured company has also pioneered unique cooling systems for 5083 aluminum machining. Their innovative approach of combining advanced coolants and targeted cooling strategies ensures optimal heat dissipation, preventing thermal damage to both the tool and workpiece. Moreover, these cooling systems are designed with sustainability in mind, minimizing coolant consumption and reducing environmental impact.

V. Integrating Automation and Digital Solutions

To further enhance efficiency and productivity, the company has incorporated automation and digital solutions into its machining processes. By leveraging cutting-edge robotics and advanced software platforms, they have streamlined operations, reduced human error, and shortened lead times. Additionally, these digital advancements enable real-time monitoring, data analysis, and predictive maintenance, ensuring continuous improvement and maximizing manufacturing output.

VI. Collaborative Approach for Continuous Innovation

Our featured company believes that collaboration is key to driving innovation. With an open mindset, they actively engage with customers, industry partners, and academic institutions to exchange knowledge and explore novel ideas. By staying at the forefront of technological advancements and continually enhancing their machining capabilities, the company aims to deliver tailored solutions that exceed customer expectations and drive industry growth.

Conclusion:

With the introduction of groundbreaking machining techniques for 5083 aluminum, this renowned company has set a new benchmark for precision and efficiency in aluminum machining. Their advanced tooling, innovative cooling systems, and integration of automation and digital solutions highlight their commitment to continuous innovation. As a result, manufacturers can now strive for even higher quality standards with cost-effective and sustainable manufacturing processes. These advancements showcase the transformative power of collaboration and reinforce the company's position as an industry leader.

Company News & Blog

A Complete Catalog of Aircraft Aluminum Extrusion

Aircraft Aluminum Extrusion Catalog: Offering Top-notch Quality Extruded Aluminum ProductsAluminum extrusions play an essential role in the aviation industry as they serve as the backbone of various aircraft structures. They are used to create parts that are lightweight, durable, and have high stiffness and strength characteristics. That's why it's essential to choose a reliable supplier when it comes to aircraft aluminum extrusions solutions. And that is where the Aircraft Aluminum Extrusion Catalog comes in, providing high-quality extruded aluminum products to the aviation world.The Aircraft Aluminum Extrusion Catalog is a comprehensive guide to the vast range of extruded aluminum profiles, shapes, and sizes suitable for use in all aircraft models. The catalog provides a wide range of popular and reliable aluminum extrusion solutions to both new and existing aircraft OEMs, MROs, and aviation suppliers worldwide.The catalog, which has been a reliable source of information for aircraft engineers and designers for years, comes from a well-established manufacturer with decades of experience in the aviation industry. The company's expertise in providing high-quality aluminum aerospace solutions is unparalleled, guaranteeing its customers that all its provided products meet rigorous industry standards. Furthermore, the catalog has a well-designed layout, making it easy for customers to choose the appropriate aluminum extrusions solution to buy.The Aircraft Aluminum Extrusion Catalog contains a comprehensive list of extruded aluminum products, including standard, custom sections, and structural shapes. In the catalog, customers can find aluminum extruded profiles, bars, pipes, rods, channels, angles, and tubes, among other products. They can also get various custom-designed extrusions, including elliptical and rectangular profiles and unique forms.The extrusions catalog is regularly updated with new available aluminum extrusions designs developed for the aerospace industry. The company's dedicated team of engineers continually designs and manufactures products to meet customers' specific requirements. They are always working on innovative aluminum extrusion designs that focus on providing lightweight, durable, and efficient performances to meet any aviation requirements.The quality of the extruded aluminum products in the aircraft industry is vital. They must meet strict standards for use in critical applications such as airframes, landing gear, wing spars, engine support systems, and other critical parts. The extruded aluminum products in the Aircraft Aluminum Extrusion Catalog are tested to ensure they meet the industry requirements and are of top-notch quality.Another critical aspect of aviation aluminum extrusions is their finishing capabilities. The Aircraft Aluminum Extrusion Catalog provides a range of finishes, including anodizing, painting, and powder coating, among others. The finishes offer colors and aesthetics that match customers' specific requirements, including performance-enhancing options such as corrosion-resistant finishing. The aircraft extruded aluminum products provide solutions that maintain the highest level of aesthetics, performance, durability, and longevity.In conclusion, the Aircraft Aluminum Extrusion Catalog is an essential guide for any supplier looking for the best aluminum extruded solutions for their aviation customers. The variety of products, including custom-made solutions for specific customer requirements, ensures that the extruded aluminum profiles provided meet the exact needs of the aircraft industry.The Aerospace industry's requirements are continually evolving, and a reliable supplier must remain up-to-date and innovative to provide the best solution. With the Aircraft Aluminum Extrusion Catalog, customers can always have trust in the quality of the products provided and rely on the supplier's expertise in aviation aluminum extrusion solutions.

Exploring the Versatility of Extruded Aluminum Tubing Profiles

Extruded Aluminum Tubing Profiles Innovate the Manufacturing IndustryManufacturing companies around the world are constantly on the lookout for more efficient and cost-effective solutions to enhance their production processes. In recent years, extruded aluminum tubing profiles have emerged as a game-changer in the manufacturing industry, offering numerous benefits over traditional materials. With their unique characteristics and versatility, extruded aluminum tubing profiles are revolutionizing the way products are designed and manufactured.Extruded aluminum tubing profiles are essentially aluminum bars or rods that have been heated and forced through a die to create a specific shape or profile. This manufacturing process allows for the creation of complex cross-sections and intricate designs that are not easily achievable with other materials. From simple cylindrical shapes to more intricate designs with various cutouts, extruded aluminum tubing profiles provide manufacturers with endless possibilities for their products.One of the key advantages of extruded aluminum tubing profiles is their lightweight yet sturdy nature. Aluminum has a low density, making it significantly lighter than other metals such as steel or copper. This lightweight characteristic not only simplifies the transportation and handling of products but also reduces costs associated with shipping. Additionally, the strength-to-weight ratio of aluminum is impressive, making it ideal for applications where strength and durability are crucial.Extruded aluminum tubing profiles are also highly corrosion-resistant, offering a well-suited solution for products that are exposed to harsh environmental conditions or corrosive substances. Unlike steel, which is prone to rusting, aluminum forms a natural protective oxide layer when exposed to oxygen, effectively preventing further corrosion. This inherent corrosion resistance of extruded aluminum tubing profiles ensures the longevity and reliability of products, even in challenging environments.Another significant advantage of extruded aluminum tubing profiles is their excellent thermal conductivity. Aluminum is known for its ability to efficiently transfer heat, making it an ideal material for various applications requiring heat dissipation. From heat sinks in electronic devices to radiator fins in automobiles, extruded aluminum tubing profiles play a crucial role in the thermal management of products, ensuring optimal performance and preventing overheating.The versatility of extruded aluminum tubing profiles extends beyond their physical properties. These profiles can be easily customized and tailored to meet the specific requirements of various industries. Manufacturers can choose from a wide range of alloy compositions, sizes, and finishes to achieve their desired product characteristics. This versatility enables companies to create products that are not only functional but also aesthetically appealing.Moreover, the extrusion process itself is highly efficient and cost-effective. With the ability to create complex shapes in a single operation, manufacturers can significantly reduce production time and costs associated with extensive machining or welding. Additionally, extruded aluminum tubing profiles produce minimal waste, as the excess material can be recycled and reused. This not only contributes to the environmental sustainability efforts of companies but also minimizes material costs.One company on the forefront of extruded aluminum tubing profiles innovation is {}, a leading manufacturer in the industry. With decades of experience and expertise, they have established themselves as a trusted partner for companies seeking high-quality aluminum products. Their state-of-the-art facilities and advanced extrusion technology allow them to produce a wide range of customized extruded aluminum tubing profiles, meeting the diverse needs of their clients.The continuous research and development efforts of {} have led to numerous technological advancements in the field. By closely collaborating with their clients, they ensure that the products they manufacture perfectly match their specific requirements. From initial design concepts to final production, {} provides comprehensive support throughout the entire manufacturing process, enabling companies to bring their ideas to life.In conclusion, extruded aluminum tubing profiles are revolutionizing the manufacturing industry by offering lightweight, corrosion-resistant, and highly customizable solutions. With their exceptional physical characteristics and versatility, these profiles enhance the performance, durability, and aesthetics of products across various industries. Companies like {} are driving innovation in this field, constantly pushing the boundaries of what extruded aluminum tubing profiles can achieve. As manufacturers continue to embrace this cutting-edge technology, the future of manufacturing looks brighter than ever.

Military-Grade Aluminum Alloy 2024: Key Features and Applications Revealed

Military Aluminum Alloy 2024: The Next Gen Material for Aerospace IndustryAluminium is one of the essential materials that find significant usage in the modern aerospace industry. The aerospace sector's increasing demand for lightweight yet robust materials has led to the development of novel and advanced alloys that offer excellent mechanical and physical properties. Among these, Military Aluminum Alloy 2024 has emerged as one of the most promising candidates that provide an impressive combination of strength and toughness.Military Aluminum Alloy 2024 is a high-strength aluminum alloy that contains copper as its primary alloying element. This alloy is widely used in various applications that demand strength, fatigue resistance, and excellent machinability. Developed in the 1930s, Military Aluminum Alloy 2024 has been an essential material in the aerospace industry for decades. Its unique properties have made it a popular choice for structural components such as wing and fuselage structures, landing gear components, and rocket motor cases.Military Aluminum Alloy 2024 is known for its excellent strength-to-weight ratio, making it ideal for lightweight applications. This alloy has a tensile strength of 470 MPa, which is higher than most of the other aluminum alloys. Furthermore, it exhibits excellent fatigue resistance, corrosion resistance, and hardness, making it suitable for harsh environments. Military Aluminum Alloy 2024 is also easy to machine and weld, which simplifies the manufacturing process.One of the primary factors that make Military Aluminum Alloy 2024 an ideal material for aerospace applications is its ability to withstand high temperatures. This alloy can hold up in temperatures of up to 300°C, making it ideal for high-temperature applications like rocket motor cases. Additionally, it exhibits excellent thermal conductivity, which ensures efficient heat dissipation and prevents overheating.The aerospace industry has always been an innovation-driven industry, and companies constantly need to develop new material solutions to stay ahead in the competitive landscape. One such company that is at the forefront of material innovation is {Need to remove brand name}. They are a leading manufacturer and supplier of high-performance aluminum alloys, including Military Aluminum Alloy 2024.With over two decades of experience, {Need to remove brand name} has been developing advanced aluminum alloys that cater to the increasing demands of the aerospace industry. They offer a wide range of aluminum alloys that exhibit superior mechanical and physical properties, making them ideal for various applications.{Need to remove brand name} produces Military Aluminum Alloy 2024 that meets or exceeds all industry standards. Their 2024 alloy offers exceptional strength, toughness, and corrosion resistance, making it an ideal material for structural applications in the aerospace industry. It also has excellent machinability, which simplifies the manufacturing process and reduces production costs.{Need to remove brand name}'s military-grade aluminum alloy 2024 is widely used across the aerospace industry, including aircraft, helicopters, missiles, and spacecraft. Their 2024 alloy has been extensively tested and verified for its mechanical and physical properties, which ensures that it can withstand harsh conditions and deliver outstanding performance.In addition to military Aluminum Alloy 2024, {Need to remove brand name} also manufactures a range of other aluminum alloys that cater to different applications. Their aluminum alloys have been used in various industries, including defense, aerospace, automotive, marine, and industrial applications.{Need to remove brand name} has established itself as a reliable supplier of high-performance aluminum alloys, thanks to its state-of-the-art facilities and a team of experienced professionals. They offer customized solutions to their clients that meet their specific requirements and deliver their products on time and within budget.In conclusion, Military Aluminum Alloy 2024 offers an excellent combination of strength, toughness, and corrosion resistance, making it an ideal material for aerospace applications. {Need to remove brand name} is a leading manufacturer and supplier of military-grade aluminum alloy 2024 that meets all industry standards and provides exceptional performance. With their innovative solutions and outstanding customer support, {Need to remove brand name} is poised to drive the material innovation in the aerospace industry, ensuring a brighter and better future for all.

Strong and Durable 1-Inch Aluminum Square Tubes for Various Applications

Title: Versatile 1 Inch Aluminium Square Tube: The Perfect Solution for Various Construction ProjectsIntroduction:With its exceptional strength, durability, and versatility, the 1 inch Aluminium Square Tube offers a wide range of applications in the construction industry. Manufactured with precision and advanced technology, this high-quality material is gaining significant popularity among architects, engineers, and DIY enthusiasts alike. Engineered to withstand heavy loads and adverse weather conditions, this tube is the perfect choice for structural framing, fencing, and various other construction projects.1. The Durability and Strength of Aluminium:The 1 inch Aluminium Square Tube, made from premium-grade aluminium, delivers unparalleled toughness. Aluminium's inherent strength allows it to withstand heavy loads and resist corrosion, making it ideal for both indoor and outdoor construction projects. Unlike other materials, aluminium does not rust, ensuring long-lasting performance and reduced maintenance costs.2. Versatile Applications:This aluminium tube's versatility ensures its suitability across a wide range of construction applications. Its strength-to-weight ratio makes it particularly advantageous for structural framing in buildings and infrastructure projects. From supporting beams and frames to staircases and handrails, the 1 inch Aluminium Square Tube provides the necessary structural integrity while maintaining a sleek and aesthetic appearance.Furthermore, these tubes are extensively used in the fencing industry. Their resistance to corrosion and ability to withstand harsh weather conditions make them perfect for both residential and commercial fencing applications. The lightweight nature of aluminium also makes it easier to transport and install, reducing labor costs and overall project expenses.3. Architectural Appeal and Customization:Architects and designers are increasingly turning to the 1 inch Aluminium Square Tube due to its aesthetic appeal. Its clean lines and sleek design complement modern architectural styles, adding a touch of elegance to any construction project. Additionally, this versatile material comes in various finishes, including polished, brushed, or powder-coated, enabling customization to suit individual architectural preferences.4. Environmental Considerations:In an era of rising environmental concerns, the 1 inch Aluminium Square Tube is an eco-friendly choice. Aluminium is highly recyclable, and its recycling process requires only a fraction of the energy needed for its initial production. By opting for aluminium, construction professionals actively contribute to reducing their carbon footprint and promoting sustainable construction practices.5. Quality Manufacturing Process:The manufacturing process of the 1 inch Aluminium Square Tube adheres to strict quality standards to ensure the highest levels of durability and performance. The manufacturer, (Company Name), follows advanced technological processes to guarantee precision and dimensional accuracy. A commitment to research and development further enhances the product's strength, making it the preferred choice for demanding construction projects.Conclusion:The 1 inch Aluminium Square Tube offers a transformative solution to construction needs. Its unmatched durability, versatility, and aesthetic appeal make it the go-to material for architects, engineers, and construction professionals. As the industry embraces sustainable practices, this aluminium tube stands out as an eco-friendly option. With its ability to withstand heavy loads and adverse weather conditions, it continues to prove itself as an ideal choice for structural framing, fencing, and various other construction projects. Invest in the 1 inch Aluminium Square Tube to ensure long-lasting, reliable, and visually appealing structures.

Discover the Advantages and Applications of 30 Series Aluminum Extrusion

In the world of industrial manufacturing, aluminum extrusions have revolutionized the way products are built. These versatile metal parts are used in a variety of industries, including automotive, aerospace, construction, and electronics. One of the most popular aluminum extrusions on the market today is the 30 Series Aluminum Extrusion.The 30 Series Aluminum Extrusion is a lightweight and durable frame that can be used to build anything from simple structures to complex machines. It is made from high-quality aluminum alloy, which makes it incredibly strong and resistant to corrosion.One company that has been at the forefront of the aluminum extrusion industry is [company name]. They specialize in designing and manufacturing aluminum extrusions of various sizes and shapes to meet the diverse needs of their customers.According to representatives from [company name], the 30 Series Aluminum Extrusion is one of their most popular products. This is because it is incredibly easy to work with and can be customized to fit any application.What makes the 30 Series Aluminum Extrusion stand out is its T-slot design. This feature allows users to easily attach other components to the frame, such as brackets, hinges, or even other pieces of aluminum extrusions. This makes it incredibly versatile and adaptable to any situation.In addition to its strength and versatility, the 30 Series Aluminum Extrusion is also incredibly lightweight. This makes it perfect for applications where weight is a concern, such as in the aerospace or automotive industry.One of the key benefits of the 30 Series Aluminum Extrusion is its durability. The aluminum alloy used to create these frames is incredibly strong and resistant to corrosion. This means that the frames can withstand even the harshest environments and still maintain their structural integrity.Another advantage of the 30 Series Aluminum Extrusion is its ease of use. Unlike traditional welding or bolt-together systems, the T-slot design of this frame allows users to easily connect pieces together with minimal effort. This saves both time and money in the manufacturing process.The 30 Series Aluminum Extrusion is also incredibly easy to customize. It can be cut to any length or shape to fit specific needs. This allows manufacturers to create unique and innovative products that stand out from the competition.Overall, the 30 Series Aluminum Extrusion is a versatile and reliable product for anyone in the manufacturing industry. Its strength, durability, and ease of use make it the perfect choice for a wide range of applications. With companies like [company name] leading the way in aluminum extrusion technology, it's clear that this industry will continue to grow and evolve for years to come.

Aluminum C Profile Surging in Popularity as a Versatile Construction Material

Aluminum C Profile: The Versatile Solution for Your Construction NeedsAluminum profiles have revolutionized the construction industry, providing an affordable and lightweight solution that is both durable and adaptable. One of the most popular profiles in use today is the aluminum C profile, which offers a range of benefits for construction projects of all types.What is an Aluminum C Profile?An aluminum C profile is a hollow, aluminum extrusion that has a distinctive C-shaped cross-section. The profile's shape allows it to be easily customized and adapted for a variety of construction applications.Benefits of Aluminum C Profiles1. Lightweight but StrongOne of the main advantages of aluminum C profiles is that they are lightweight yet strong. The hollow design of the profile reduces its weight, making it easier to handle on the job site. However, because of its design and the high-quality aluminum used in its construction, the C profile is still incredibly strong.2. VersatilityAluminum C profiles are highly versatile. They can be used in a variety of applications, from constructing simple frames for partitions to creating complex structures like bridges. The C profile's design allows it to be easily cut and customized, making it suitable for use in a wide range of construction projects.3. Weather ResistantAluminum C profiles are highly resistant to weather, making them ideal for use in outdoor construction projects. They do not rust or corrode, even in harsh weather conditions, making them a durable and long-lasting solution.4. Low MaintenanceAluminum C profiles require very little maintenance. Once installed, they do not need to be painted or recoated, and they are resistant to fading, chipping, or cracking due to exposure to the weather.5. Eco-FriendlyAluminum is a highly sustainable material as it can be easily recycled. Aluminum C profiles are made from high-quality, recycled materials, making them an eco-friendly option for construction projects.Company IntroductionAs a leading supplier of aluminum profiles, {the company’s name} is committed to providing high-quality, affordable aluminum profiles that meet the unique needs of our clients.Our aluminum C profiles are manufactured with the highest quality materials to ensure durability, strength, and performance. We offer a wide range of standard and custom C profile sizes, enabling clients to find the perfect solution for their construction needs.Our team of experts is dedicated to providing personalized support to all clients, from initial consultation to project completion. We work closely with our clients to ensure that they receive the best possible solution and support.We pride ourselves on the quality of our products, and we are committed to providing competitively priced aluminum profiles that are both efficient and environmentally sustainable.ConclusionAluminum C profiles offer a range of benefits that make them an excellent choice for construction projects. Companies seeking versatility, durability, and affordability can rely on {the company’s name} to provide the highest quality aluminum C profiles that meet their needs. With our experienced team and competitive pricing, we are the ideal choice for all your aluminum profile needs.

Custom Aluminum Extrusion: Benefits and Applications

Bespoke Aluminium Extrusion Announces Cutting-Edge Customization Services[Company Name], a global leader in advanced manufacturing and innovation, is proud to introduce its highly customizable aluminium extrusion solutions. With an unwavering commitment to quality and innovation, [Company Name] has emerged as a trusted partner for industries seeking tailored aluminium profiles.With the ever-increasing demand for uniqueness and precision in product design, [Company Name] recognizes the need for flexible and customizable manufacturing solutions. Traditional aluminium extrusion processes often fail to meet the diverse requirements of industries, limiting their design possibilities. In response, [Company Name] has developed cutting-edge technology and expertise to deliver bespoke aluminium extrusion services that cater to a wide range of applications.[Company Name]'s bespoke aluminium extrusion services are built on a foundation of years of expertise and consistent investment in research and development. The company boasts state-of-the-art facilities that incorporate the latest advancements in extrusion technology, enabling the production of complex cross-sectional shapes with exceptional dimensional control. From simplest profiles to intricate geometric configurations, [Company Name] has the capability to customize aluminium extrusions with utmost precision and accuracy.One of the key advantages of [Company Name]'s aluminium extrusion services is the ability to manufacture profiles with almost unlimited design possibilities. By leveraging advanced computer-aided design (CAD) software and simulation tools, the company can collaboratively work with clients to translate their unique vision into reality. This flexibility allows [Company Name] to cater to a wide range of industries such as automotive, aerospace, construction, electronics, and many more.[Company Name] further offers comprehensive in-house die design and manufacturing capabilities. This ensures that the entire extrusion process is tightly controlled, resulting in superior quality and consistency. The company's team of experienced engineers and technicians work in close collaboration with customers, providing valuable input throughout the design and manufacturing stages to optimize material usage, enhance performance, and reduce costs.Furthermore, [Company Name] places a strong emphasis on sustainability and environmental responsibility. The company adheres to rigorous environmental standards and implements eco-friendly practices throughout its manufacturing processes. Through efficient use of resources and recycling initiatives, [Company Name] strives to minimize its environmental impact while delivering exceptional products.In addition to bespoke aluminium extrusion services, [Company Name] also offers a range of value-added services to meet customers' specific needs. These services include precision cutting, CNC machining, surface finishing, and assembly, among others. By integrating these services into their manufacturing process, [Company Name] ensures that customers receive tailored solutions that are ready to be integrated into their final products.In conclusion, [Company Name] has positioned itself as a leading provider of bespoke aluminium extrusion services, setting new standards of customization and innovation in the industry. With its cutting-edge technology, extensive expertise, and commitment to customer satisfaction, [Company Name] is well-equipped to cater to the evolving demands of various industries and deliver unparalleled quality in aluminium extrusions.

Revamp Your Home with Affordable Aluminum L-Shaped Shelves

Aluminum L Shape Taking the Industry by StormThe use of aluminum L shape is rapidly gaining popularity in the construction industry, thanks to its exceptional qualities. Among the reasons why it is quickly becoming the go-to option in construction are its strength, robustness, and aesthetic appeal.One of the major players in the design and supply of aluminum L shape is {Brand Name Removed}. The company has gained a reputation for its excellent service and innovative solutions. It employs state-of-the-art technology and only works with high-grade materials to produce premium quality products. From custom-made aluminum extrusions to standard profiles, {Brand Name Removed} offers a broad range of aluminum products to suit various construction projects.{Brand Name Removed} understands that the modern construction industry demands unique products that align with the latest trends and standards. This is why it has invested heavily in research and development to create innovative solutions for its clients. For instance, one of its products - the aluminum L shape - has been designed to meet the current demands of the market.Here's what makes the aluminum L shape an excellent choice for construction projects:Strength and DurabilityAluminum L shape is highly durable and resistant to corrosion, making it ideal for use in exterior and interior applications. Additionally, aluminum is structurally strong, providing excellent support for heavy loads.LightweightDespite its robust nature, aluminum L shape is lightweight, which makes it easy to handle and install.Aesthetic AppealAluminum L shape is highly versatile and available in various colors and finishes. This means it can be used to create any desired look, from a classic to a modern, sleek finish. Furthermore, {Brand Name Removed} offers custom solutions, allowing clients to have products that match their specific requirements.Environmentally FriendlyAluminum is 100% recyclable, making it an environmentally friendly option. This is particularly important in today's environmentally conscious society where people are keen on reducing their carbon footprint.ApplicationsAluminum L shape can be used in a broad range of applications, including facades, window frames, doors, furniture, and much more. It is also ideal for use in industrial and commercial applications where durability and strength are crucial.{Brand Name Removed} offers clients a complete range of services, from design to installation. Its team of experts works closely with clients to develop customized solutions that suit their unique needs. Moreover, the company has invested in modern technology to ensure that its clients receive high-quality products and services.One of the primary goals of {Brand Name Removed} is to provide clients with products that meet their budget without compromising on quality. The company has an efficient cost structure, which allows it to keep the prices of its products low without compromising on quality.In conclusion, the aluminum L shape is rapidly becoming a preferred choice in the construction industry. This is due to its exceptional qualities, including strength, durability, lightweight, aesthetic appeal, and environmentally friendly nature. {Brand Name Removed} is at the forefront of supplying high-quality aluminum L shape and other aluminum products to the industry. The company's innovative solutions, coupled with its dedication to excellent service, have earned it a reputation as a leading supplier in the industry.

High-Quality Rolled Aluminum Plate and Sheet: The Latest Updates

[Title]: Global Aluminum Industry Sees Significant Growth with Rolled Aluminum Plate and Sheet[Subtitle]: Leading Aluminum Producer's Cutting-Edge Technology Revolutionizes Sheet Manufacturing[Date]: [Insert Date][City, Country]: [Insert City, Country][Company Name], the renowned aluminum producer, is revolutionizing the rolled aluminum plate and sheet manufacturing industry, witnessing significant growth and propelling the global aluminum industry forward. With its cutting-edge technology and expertise, [Company Name] is poised to cater to the increasing demand for aluminum products across various sectors.[Company Name], established in [insert year], has emerged as a key player in the global aluminum industry, manufacturing high-quality and sustainable aluminum products. Combining state-of-the-art technology, innovative processes, and stringent quality control measures, [Company Name] has consistently delivered superior performance and customer satisfaction.Rolled aluminum plate and sheet are integral components in numerous industries such as automotive, aerospace, building and construction, packaging, and electrical. These sectors rely heavily on aluminum due to its lightweight, durability, thermal conductivity, and corrosion resistance properties. To meet the soaring demand for aluminum products, [Company Name] has continually invested in research and development, constantly adapting its manufacturing processes to produce superior quality rolled aluminum plate and sheet. The company focuses on sustainability, employing advanced recycling techniques to minimize environmental impact.[Company Name]'s rolled aluminum plate and sheet manufacturing process involves several steps. Initially, high-quality aluminum ingots are melted at precise temperatures to ensure optimal metallurgical properties. The molten aluminum is then cast into slabs, which are sent through a sequence of rolling mills. The rolling mills progressively reduce the thickness of the slabs, resulting in high-quality aluminum sheets or plates of desired thickness.The cutting-edge technology employed by [Company Name] guarantees the highest level of precision, ensuring that the finished aluminum sheets and plates meet the most stringent industry standards. Each sheet is thoroughly inspected for surface defects, thickness variations, and mechanical properties to guarantee excellent performance.Notably, [Company Name] is well-known for its dedication to customer satisfaction. The company collaborates closely with its clients to understand their specific needs and preferences, offering customized solutions that cater to unique requirements. By maintaining strong relationships with its clientele, [Company Name] has built a reputation for delivering products with exceptional quality and timely deliveries.The lightweight and durability of aluminum make it an ideal material for the automotive industry. Aluminum sheets and plates find extensive applications in the manufacturing of automobile bodies, chassis, and various structural components. [Company Name]'s rolled aluminum plate and sheet, with their exceptional tensile strength, impact resistance, and attractive surface finish, are highly sought after by major automotive manufacturers.Additionally, the aerospace sector greatly benefits from [Company Name]'s rolled aluminum plate and sheet. Aluminum's excellent strength-to-weight ratio, resistance to corrosion, and thermal conductivity make it indispensable in aircraft manufacturing. Various aircraft components, including wings, fuselages, and structural assemblies, rely on high-quality rolled aluminum plate and sheet for reliable performance and safety.Furthermore, the construction industry capitalizes on the versatile applications of aluminum. Rolled aluminum plate and sheet are extensively used in building facades, roofing, curtain walls, and window frames. With their exceptional formability, durability, and corrosion resistance, [Company Name]'s aluminum products contribute to the aesthetics, durability, and energy efficiency of modern buildings.The packaging industry benefits from [Company Name]'s rolled aluminum plate and sheet as well, particularly in the production of cans and containers. Aluminum's lightness and excellent barrier properties preserve the quality and freshness of food and beverage products. [Company Name]'s aluminum sheets and plates are precisely engineered to meet the specific requirements of the packaging industry, ensuring efficient and sustainable packaging solutions.With its commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the rolled aluminum plate and sheet manufacturing industry. As the demand for aluminum products continues to grow across diverse sectors, [Company Name]'s cutting-edge technology and high-quality aluminum products position the company for further expansion and global recognition.

Aluminum Pipe Roundup: 7 Inch Pipe Surges in Popularity

Title: Company XYZ Introduces Innovative 7-Inch Aluminum Pipe, Revolutionizing the IndustryIntroduction:Company XYZ, a leading manufacturer in the metal materials industry, has recently unveiled their latest product, an exceptional 7-inch aluminum pipe. Built with cutting-edge technology and superior craftsmanship, this innovative addition to their product line offers unparalleled performance and durability. With its revolutionary design, the company aims to raise the standards of the industry and cater to a wide array of applications. This article will delve into the key features of the 7-inch aluminum pipe and explore the impact it is expected to have on various sectors.Superior Strength and Versatility:The 7-inch aluminum pipe manufactured by Company XYZ is engineered to be incredibly robust, ensuring maximum strength and durability for various industrial applications. Crafted from premium quality aluminum alloy, this pipe can withstand extreme pressure, temperature fluctuations, and corrosive environments without compromising its structural integrity.Additionally, the pipe's versatility allows it to be used across multiple industries, including construction, aerospace, automotive, and marine sectors. It can be employed for applications such as HVAC systems, fluid transmission, structural support, and more. The adaptability of the 7-inch aluminum pipe makes it a valuable asset for a wide range of projects, providing a cost-effective solution for many different requirements.Innovative Design and Precision Engineering:Company XYZ has implemented advanced manufacturing processes and precision engineering techniques to create the 7-inch aluminum pipe. The seamless construction ensures uniformity throughout the entire length of the pipe, eliminating weak points and enhancing overall performance.Furthermore, the incorporation of an innovative internal ribbing system enhances the pipe's structural integrity, effectively reducing any potential risks associated with external loading or stress. This design feature not only strengthens the pipe but also enables it to withstand higher pressure fluids, making it suitable for applications requiring optimal performance.Environmental Sustainability:Company XYZ acknowledges the critical importance of environmental sustainability in today's world. As a result, their 7-inch aluminum pipe is manufactured using recycled aluminum, minimizing the demand for raw materials and reducing the carbon footprint. This commitment to eco-friendly practices showcases the company's dedication to building a greener future while still delivering excellent products.Quality Assurance and Compliance:To ensure the utmost quality, Company XYZ rigorously tests the 7-inch aluminum pipe at every stage of its production cycle. Strict quality control measures are implemented to adhere to national and international standards, ensuring that each pipe meets industry regulations and specifications. This dedication to quality assurance guarantees the reliability and safety of the product, providing customers with peace of mind.Industry Implications:The introduction of the 7-inch aluminum pipe by Company XYZ is anticipated to bring significant changes to multiple industries:1. Construction Industry: The exceptional strength and durability of the pipe make it a perfect fit for structural applications, such as framework and support systems, where reliability is crucial.2. Aerospace Industry: The lightweight nature and high corrosion resistance of the aluminum pipe make it an ideal component for aircraft manufacturing, improving fuel efficiency, and reducing maintenance costs.3. Automotive Industry: The ability to withstand extreme temperatures and corrosive environments makes the 7-inch aluminum pipe suitable for exhaust systems and fluid transmission, enhancing the overall performance and longevity of vehicles.4. Marine Industry: With its superior resistance to saltwater corrosion, the aluminum pipe becomes an excellent choice for various marine applications, including shipbuilding, offshore structures, and desalination plants.In conclusion, Company XYZ's launch of the groundbreaking 7-inch aluminum pipe is set to revolutionize the industry, offering unparalleled strength, versatility, and environmental sustainability. The company's commitment to delivering high-quality products through innovation and precision engineering has positioned them at the forefront of the market. As various industries embrace this game-changing product, its positive impact is expected to resonate across numerous sectors, redefining standards and driving further advancements in the use of aluminum pipes.