Durable Aluminum Square Tubing Connectors for Your Projects

By:Admin

With their expertise in manufacturing high-quality aluminum products, [company name] has become a leading provider of aluminum square tubing connectors. The company is dedicated to providing innovative solutions for their customers, and their connectors are no exception. They are made from high-quality aluminum, ensuring that they are strong enough to withstand the demands of any project. Additionally, their connectors are designed to be easy to use, making them ideal for both professionals and DIY enthusiasts.

One of the key advantages of using aluminum square tubing connectors is their versatility. These connectors can be used for a wide range of applications, from creating frames and structures to connecting aluminum tubing in manufacturing processes. This versatility makes them an essential tool for many industries, as they can be used to create custom solutions for a variety of projects. Additionally, aluminum square tubing connectors are lightweight, making them easy to transport and install on-site.

Another important advantage of aluminum square tubing connectors is their durability. Aluminum is known for its strength and corrosion resistance, making it an ideal material for connectors that need to withstand heavy loads and harsh environments. This durability ensures that the connectors will provide a long-lasting and reliable connection between aluminum tubing, reducing the need for maintenance and replacement over time.

In addition to their strength and durability, aluminum square tubing connectors are also highly customizable. This means that they can be designed to meet the specific requirements of a project, ensuring that they provide the exact functionality needed. Whether it's creating a custom frame for a piece of equipment or developing a unique manufacturing process, these connectors can be tailored to fit the needs of the project.

Finally, aluminum square tubing connectors are environmentally friendly. Aluminum is a highly sustainable material, as it can be recycled and reused with minimal loss of quality. This means that using aluminum connectors can help to reduce the environmental impact of a project and support sustainable construction and manufacturing practices.

As a leading provider of aluminum products, [company name] is committed to providing the highest quality aluminum square tubing connectors for their customers. With their dedication to innovation and excellence, they continue to push the boundaries of what is possible with aluminum, creating products that are strong, durable, and reliable. Their connectors are designed to meet the needs of a wide range of industries, from construction to manufacturing, and they are proud to offer a product that delivers exceptional performance in every application.

In conclusion, aluminum square tubing connectors are an essential tool for a wide range of projects in the construction and manufacturing industry. Their strength, durability, versatility, and environmental friendliness make them an ideal choice for professionals and DIY enthusiasts alike. With their expertise in aluminum manufacturing, [company name] is proud to offer high-quality connectors that provide a reliable and long-lasting connection between aluminum tubing. As the demand for aluminum connectors continues to grow, [company name] remains at the forefront of innovation, providing their customers with the best solutions for their projects.

Company News & Blog

High-Quality Aircraft Extrusions for Top Performance

Aircraft Extrusions, a leading provider of high-quality aircraft extrusions and related products, is excited to announce the launch of a new line of cutting-edge aerospace materials. The company has been at the forefront of the aerospace industry for over two decades, delivering top-notch extrusions to meet the demanding needs of aircraft manufacturers and maintenance professionals worldwide.The new line of aerospace materials is designed to meet the rigorous standards and specifications required for modern aircraft construction and maintenance. Aircraft Extrusions has incorporated state-of-the-art technology and cutting-edge manufacturing processes to produce materials that are lightweight, durable, and provide exceptional performance in a wide range of aerospace applications."We are thrilled to introduce this new line of aerospace materials to our customers," said the company spokesperson. "Our team has worked tirelessly to develop these products, and we are confident that they will exceed the expectations of our clients. These materials are the result of extensive research and development, and we believe they will set a new standard for excellence in the aerospace industry."Aircraft Extrusions is known for its commitment to quality and innovation. The company's extrusions are used in a variety of aircraft components, including fuselage frames, wing structures, and interior fittings. The new line of aerospace materials complements the existing product range, offering customers a comprehensive selection of high-performance materials for their aerospace needs.In addition to the new line of aerospace materials, Aircraft Extrusions continues to offer a wide range of services to its customers. The company provides custom extrusion services, allowing clients to order extrusions in specific shapes, sizes, and materials to meet their unique requirements. Additionally, Aircraft Extrusions offers value-added services such as machining, finishing, and assembly, providing customers with a one-stop solution for all their aerospace material needs.Aircraft Extrusions has built a strong reputation for reliability and customer satisfaction. The company's commitment to quality, precision, and on-time delivery has earned it the trust and loyalty of clients around the world. With the introduction of the new line of aerospace materials, Aircraft Extrusions aims to further solidify its position as a leading provider of high-quality materials for the aerospace industry.The aerospace industry demands materials that can withstand extreme conditions, provide superior performance, and meet stringent safety standards. Aircraft Extrusions understands these requirements and has developed the new line of aerospace materials with these factors in mind. The company's dedication to excellence and innovation ensures that its products are at the forefront of technological advancement, enabling customers to stay ahead in an ever-evolving industry.Aircraft Extrusions' new line of aerospace materials is now available for purchase, and the company is already seeing strong demand from customers. With its proven track record of delivering top-quality products and exceptional customer service, Aircraft Extrusions is well-positioned to meet the growing needs of the aerospace industry and maintain its status as a trusted partner for aircraft manufacturers and maintenance professionals worldwide.

Discover the Latest Trends in Extruded Aluminum Channels for Enhanced Applications

Extruded Aluminum Channels Becoming Increasingly Popular in Construction IndustryThe construction industry is witnessing a surge in the use of aluminum channels in various applications. Extruded aluminum channels are becoming increasingly popular due to their versatility, durability, and cost-effectiveness. They are widely used in the manufacture of window frames, bumpers, handrails, framing systems, and many other construction applications.Aluminum channels are preferred over other materials like steel, wood, and traditional concrete due to their flexibility, lightweight, and anti-corrosion properties. This makes them ideal for construction applications where durability and flexibility are paramount. They are also easier to work with than other materials, reducing installation time and costs significantly.The demand for extruded aluminum channels has been increasing steadily over the years, driven mainly by the growth in construction activities. The construction industry is expected to grow at a rapid rate in the coming years, with developing countries spending more on infrastructure development. This presents a significant growth opportunity for extruded aluminum channel manufacturers.One such manufacturer that has been leading the market in the production of extruded aluminum channels is a company that has been in the industry for over two decades. The company is known for its dedication to quality, innovation, and customer satisfaction, which has enabled it to maintain its position as a market leader.The company's extruded aluminum channels are fabricated using the latest technology, ensuring that they meet the highest quality standards. They have a wide range of profiles to meet the diverse needs of customers in the construction industry. The extruded aluminum channels are also suitable for use in various other industries, such as automotive, aerospace, and electronics.The company is committed to providing its customers with customized solutions that meet their unique needs. They work closely with their customers, providing them with technical support and guidance, to ensure that they get the best possible solutions for their requirements. Their state-of-the-art production facilities enable them to produce high volumes of extruded aluminum channels without compromising on quality.In recent years, the company has invested heavily in research and development, focusing on improving its products' quality and efficiency. This has enabled it to develop new profiles that offer better performance and reliability, giving it a competitive advantage in the market. The company also offers value-added services like anodizing, powder coating, and cutting to length to meet the needs of customers.One of the factors that have contributed to the company's success is its commitment to sustainability. The company is committed to reducing its carbon footprint and minimizing waste. They have implemented various initiatives to reduce energy consumption and improve waste management, such as using renewable energy sources and recycling waste.In conclusion, the construction industry's growth is driving demand for extruded aluminum channels, which are gaining popularity due to their versatility, durability, and cost-effectiveness. A leading company in the extruded aluminum channel market is committed to offering quality, customized solutions to meet the unique needs of its customers efficiently. With its commitment to sustainability, innovation, and customer satisfaction, it is well-positioned to ride the wave of growth in the construction industry in the coming years.

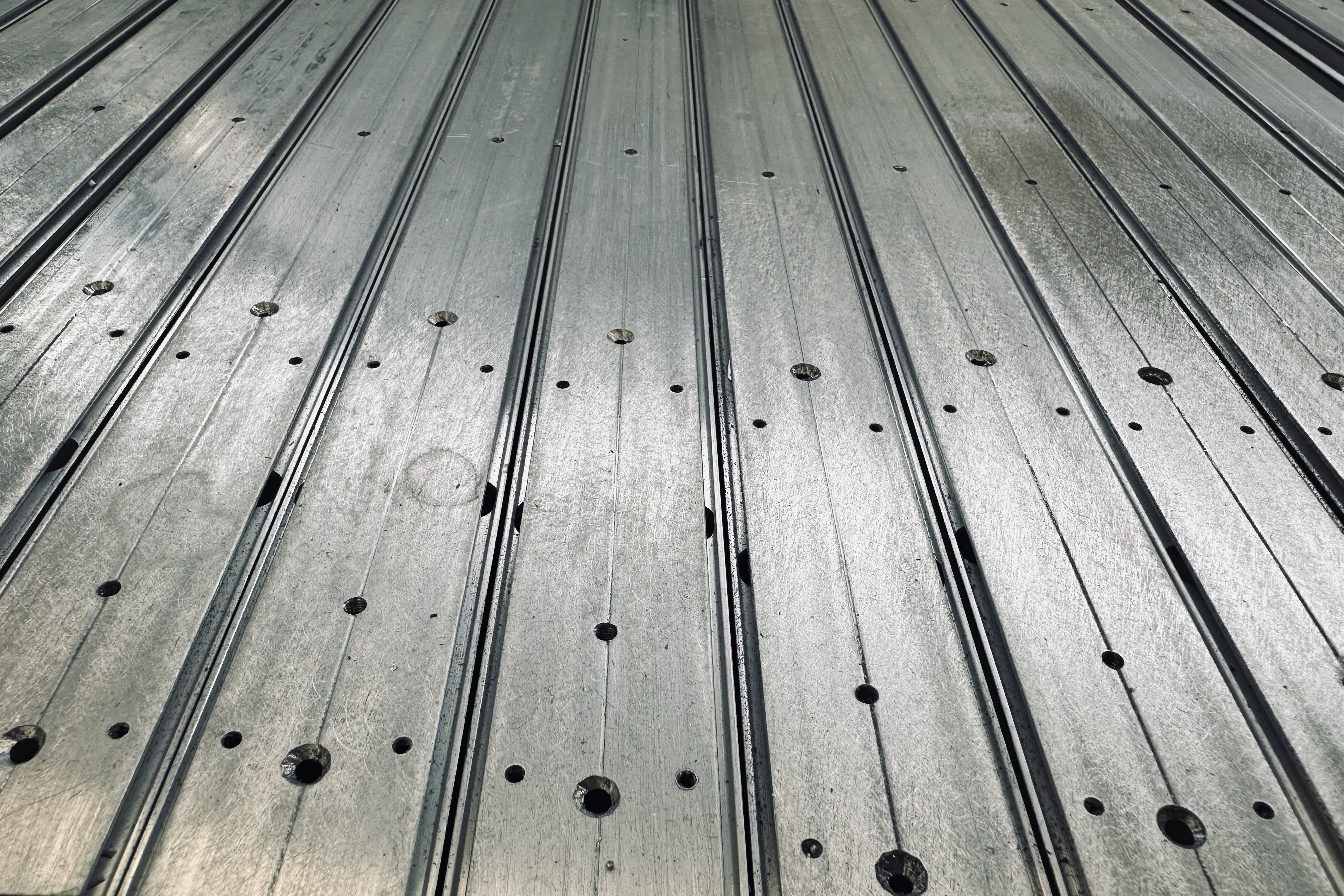

Aluminum CNC Cutting Services: A Detailed Guide

Laser cutting technology has revolutionized the manufacturing industry with its precision and efficiency. With the increasing demand for high-quality metal cutting services, {Company} has recently announced the addition of CNC cutting aluminum to its list of offerings. This new service will further expand the company's capabilities and enhance its position as a leading provider of metal fabrication solutions.CNC cutting, also known as computer numerical control cutting, utilizes a high-powered laser to cut through a variety of materials, including aluminum. The advanced technology allows for precise and intricate cuts, making it ideal for a wide range of applications in various industries.{Company} has been at the forefront of the metal fabrication industry for over a decade, providing reliable and cost-effective solutions to its clients. With a team of highly skilled engineers and technicians, the company has built a strong reputation for delivering exceptional results and exceeding customer expectations.The decision to incorporate CNC cutting aluminum into its services comes as a response to the growing demand for aluminum components in industries such as aerospace, automotive, and electronics. With its lightweight and durable properties, aluminum has become a popular choice for manufacturers seeking to improve the performance and efficiency of their products.By adding CNC cutting aluminum to its portfolio, {Company} aims to meet the needs of its clients who require precision-cut aluminum parts for their operations. Whether it's for prototyping, production runs, or custom fabrication projects, the company is well-equipped to handle a wide range of requirements with its state-of-the-art CNC cutting capabilities.The introduction of CNC cutting aluminum underscores {Company}'s commitment to staying ahead of industry trends and offering cutting-edge solutions to its clients. The company has continuously invested in the latest technologies and equipment to ensure that it remains at the forefront of the metal fabrication industry.In addition to CNC cutting aluminum, {Company} offers a comprehensive range of metal fabrication services, including laser cutting, welding, bending, and finishing. The company's modern facilities and skilled workforce enable it to handle projects of varying complexities and scales, delivering high-quality results within tight deadlines.{Company} takes pride in its ability to work closely with clients to understand their specific needs and deliver tailor-made solutions that meet and exceed their expectations. The addition of CNC cutting aluminum further demonstrates the company's dedication to providing comprehensive and versatile services to its clients.Furthermore, with a strong focus on quality, efficiency, and reliability, {Company} has established itself as a trusted partner for businesses in need of metal fabrication solutions. The company's commitment to excellence and customer satisfaction has earned it a loyal clientele and a reputation for delivering superior results.As the demand for aluminum components continues to grow across various industries, {Company} is well-positioned to fulfill the needs of its clients with its advanced CNC cutting capabilities. The company's investment in CNC cutting aluminum reaffirms its position as an industry leader and a go-to provider for all metal fabrication requirements.In conclusion, the addition of CNC cutting aluminum to {Company}'s list of offerings is a significant milestone that highlights the company's commitment to innovation and meeting the evolving needs of its clients. With its advanced technology, skilled workforce, and dedication to quality, {Company} is poised to deliver superior CNC cutting aluminum services to businesses seeking reliable and efficient metal fabrication solutions.

Revamp Your Home with Affordable Aluminum L-Shaped Shelves

Aluminum L Shape Taking the Industry by StormThe use of aluminum L shape is rapidly gaining popularity in the construction industry, thanks to its exceptional qualities. Among the reasons why it is quickly becoming the go-to option in construction are its strength, robustness, and aesthetic appeal.One of the major players in the design and supply of aluminum L shape is {Brand Name Removed}. The company has gained a reputation for its excellent service and innovative solutions. It employs state-of-the-art technology and only works with high-grade materials to produce premium quality products. From custom-made aluminum extrusions to standard profiles, {Brand Name Removed} offers a broad range of aluminum products to suit various construction projects.{Brand Name Removed} understands that the modern construction industry demands unique products that align with the latest trends and standards. This is why it has invested heavily in research and development to create innovative solutions for its clients. For instance, one of its products - the aluminum L shape - has been designed to meet the current demands of the market.Here's what makes the aluminum L shape an excellent choice for construction projects:Strength and DurabilityAluminum L shape is highly durable and resistant to corrosion, making it ideal for use in exterior and interior applications. Additionally, aluminum is structurally strong, providing excellent support for heavy loads.LightweightDespite its robust nature, aluminum L shape is lightweight, which makes it easy to handle and install.Aesthetic AppealAluminum L shape is highly versatile and available in various colors and finishes. This means it can be used to create any desired look, from a classic to a modern, sleek finish. Furthermore, {Brand Name Removed} offers custom solutions, allowing clients to have products that match their specific requirements.Environmentally FriendlyAluminum is 100% recyclable, making it an environmentally friendly option. This is particularly important in today's environmentally conscious society where people are keen on reducing their carbon footprint.ApplicationsAluminum L shape can be used in a broad range of applications, including facades, window frames, doors, furniture, and much more. It is also ideal for use in industrial and commercial applications where durability and strength are crucial.{Brand Name Removed} offers clients a complete range of services, from design to installation. Its team of experts works closely with clients to develop customized solutions that suit their unique needs. Moreover, the company has invested in modern technology to ensure that its clients receive high-quality products and services.One of the primary goals of {Brand Name Removed} is to provide clients with products that meet their budget without compromising on quality. The company has an efficient cost structure, which allows it to keep the prices of its products low without compromising on quality.In conclusion, the aluminum L shape is rapidly becoming a preferred choice in the construction industry. This is due to its exceptional qualities, including strength, durability, lightweight, aesthetic appeal, and environmentally friendly nature. {Brand Name Removed} is at the forefront of supplying high-quality aluminum L shape and other aluminum products to the industry. The company's innovative solutions, coupled with its dedication to excellent service, have earned it a reputation as a leading supplier in the industry.

New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

Aluminum Extrusion Cutting Machine (need remove brand name) Revolutionizing the Aluminum Processing IndustryAluminum extrusion has been a vital process in industries ranging from construction to automotive and aerospace. However, the process of cutting aluminum extrusions has often been problematic, with chipping and deformation being common issues. These problems are exacerbated when production demand is high, as is often the case in modern industrial enterprises. Thankfully, the Aluminum Extrusion Cutting Machine (need remove brand name) is poised to revolutionize this crucial process by providing a highly accurate, efficient, and reliable cutting solution.The Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution designed specifically for aluminum extrusions. This machine overcomes many of the challenges that traditional cutting methods have faced, such as chipping or deformation, by implementing advanced technology and a number of innovative features. With this machine, the cutting process is made much smoother, allowing for a more efficient and streamlined production process.Some of the key features that set this machine apart from others include its robust frame and precision cutting mechanism. The machine is made from high-grade aluminum alloy, which ensures its durability and longevity. Moreover, its cutting mechanism has been designed to minimize deformation and produce smooth and clean cuts every time. This feature is particularly important because it effectively eliminates the need for additional finishing processes, which can add to the production time and costs.The Aluminum Extrusion Cutting Machine (need remove brand name) also excels in terms of efficiency and precision. The machine is equipped with a highly accurate positioning system that ensures precise cuts each time. This system can be programmed to cut at specific lengths and angles, which enables manufacturers to produce custom parts quickly and with ease. Moreover, the machine's digital display makes it easy to adjust the cutting parameters as needed.One of the most impressive aspects of this machine is its speed. The Aluminum Extrusion Cutting Machine (need remove brand name) possesses a spindle speed of up to 20,000 rpm, which is significantly faster than most other cutting machines. This high speed allows for a much faster production process, reducing lead times and enabling manufacturers to keep up with growing demand.Of course, the true value of this machine is in its ability to deliver consistent results with every cut. The combination of precision, speed, and accuracy ensures that each cut is of the highest quality, allowing for seamless assembly and faster production times. This feature is particularly important in the manufacturing of complex applications, such as those found in the aerospace or automotive industries.In addition to its impressive features, the Aluminum Extrusion Cutting Machine (need remove brand name) is also highly customizable. The machine can be configured to meet the specific needs of individual manufacturers, with options such as dust collection, lubrication systems, and more. This level of customization ensures that manufacturers can tailor the machine to their specific requirements, producing higher quality results in less time.Finally, the machine's user-friendly design makes it easy to operate and maintain. The machine is equipped with a number of safety features, such as emergency stop buttons and an automatic lubrication system. The machine's digital control system makes it easy to adjust the cutting parameters, and its modular design allows for easy maintenance and repair.In conclusion, the Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution that is poised to revolutionize the aluminum extrusion industry. With its high precision, speed, and accuracy, it is equipped to handle the demands of modern industrial enterprises, delivering consistent and high-quality results every time. Its innovative features, user-friendly design, and extensive customization options make it an ideal choice for manufacturers looking to streamline their production processes and stay ahead of the competition.

Aluminum: An Essential Component for Hybrid Electric Vehicles (HEVs)

(title) Aluminum Innovations for Hybrid Electric Vehicles(Date)(News Organization)(Article)Hybrid Electric Vehicles (HEVs) have gained significant popularity over recent years as a more environmentally friendly alternative to traditional gasoline-powered vehicles. As the demand for HEVs continues to rise, automotive manufacturers are constantly seeking innovative solutions to enhance their performance, efficiency, and sustainability. One company that stands out in this endeavor is (remove brand name), a leading provider of cutting-edge aluminum technologies for the automotive industry.(Company Introduction)Founded in (year), (remove brand name) has established itself as a pioneer in the development and production of high-quality aluminum solutions for various industries. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible with aluminum, making it an ideal partner for automakers striving to optimize their HEV offerings.(Paragraph about the importance of lightweight materials in HEVs)In the context of HEVs, lightweight materials play a crucial role in improving overall vehicle efficiency and reducing emissions. Aluminum, being significantly lighter than traditional steel, offers substantial benefits to HEV manufacturers. By integrating lightweight aluminum components, automakers can achieve weight reduction without compromising the structural integrity and safety of the vehicles. Furthermore, the reduced weight allows for increased battery efficiency and improved overall performance.(Overview of aluminum innovations for HEVs)(remove brand name) has recently unveiled a range of innovative aluminum solutions specifically designed for HEVs. These advancements include but are not limited to:1. Aluminum Body-in-White (BIW) Structures: The company's advanced aluminum BIW structures provide a lightweight alternative to traditional steel frames without sacrificing safety. These structures offer exceptional strength, rigidity, and crashworthiness while significantly reducing the vehicle's overall weight.2. Aluminum Battery Enclosures: (remove brand name) has developed aluminum battery enclosures that effectively protect the HEV's battery pack and ensure its optimal performance. These enclosures offer excellent thermal management properties, preventing overheating and enhancing battery longevity.3. Aluminum Suspension Components: Incorporating aluminum suspension components allows for reduced unsprung weight, resulting in improved ride comfort and handling. Additionally, the lightweight nature of these components contributes to overall fuel efficiency and better energy recovery during regenerative braking.4. Aluminum Heat Exchangers: (remove brand name)'s aluminum heat exchangers provide efficient cooling solutions for HEVs. With their lightweight design and superior heat transfer capabilities, these exchangers ensure optimal thermal management while further reducing the vehicle's weight.(Another paragraph about the company's role in shaping the future of HEVs)By continuously investing in research and development, (remove brand name) is at the forefront of the aluminum revolution in the automotive industry. Their commitment to sustainability and innovation has positioned them as a key partner for automakers seeking to enhance the performance, efficiency, and overall appeal of HEVs. With their state-of-the-art aluminum solutions, (remove brand name) is contributing to the ongoing shift towards a greener and more sustainable transportation future.(Conclusion)As the global demand for HEVs continues to increase, companies like (remove brand name) play a vital role in shaping the future of automotive design. Through their groundbreaking aluminum innovations, they are enabling automakers to produce more energy-efficient and eco-friendly vehicles without compromising performance or safety. With the constant evolution of aluminum technologies, the possibilities for further advancements in HEVs are endless, and the future of sustainable transportation looks promising.

High-quality CNC Cutting Services for Aluminum

CNC Cutting Aluminum: A Revolutionary Solution in Metal FabricationIn the world of metal fabrication, precision and efficiency are key. Companies are constantly seeking cutting-edge technologies and innovative solutions to improve the quality and speed of their production processes. One such solution that has taken the industry by storm is CNC cutting aluminum, a revolutionary method that is transforming the way aluminum is fabricated. With its high precision and exceptional efficiency, CNC cutting aluminum has become the go-to choice for many industries, including aerospace, automotive, and manufacturing.CNC cutting aluminum is a process that involves using a computer-controlled machine to accurately cut and shape aluminum materials to the desired specifications. The process begins with the creation of a digital design or blueprint of the desired product. This design is then input into the CNC machine, which uses its cutting tools to precisely carve out the aluminum material according to the specifications of the design. The result is a highly accurate and intricately detailed aluminum component that meets the exact requirements of the customer.One of the leading companies at the forefront of CNC cutting aluminum technology is {}. With a strong reputation for superior quality and cutting-edge capabilities, {} has established itself as a trusted partner for companies seeking high-precision aluminum fabrication solutions. {}'s state-of-the-art facilities and advanced CNC machines are equipped to handle a wide range of aluminum cutting requirements, from simple shapes to complex designs, with utmost precision and efficiency.The advantages of CNC cutting aluminum are numerous. First and foremost, the level of precision and accuracy that can be achieved with this method is unmatched. The CNC machines are capable of carrying out incredibly detailed and intricate cuts that would be nearly impossible to achieve with traditional machining methods. This level of precision is particularly important for industries such as aerospace and automotive, where the smallest deviation from the specified dimensions can have significant consequences.In addition to precision, CNC cutting aluminum offers exceptional efficiency. The automated nature of the CNC machines allows for a much faster production process compared to manual methods. This means that companies can expect quicker turnaround times for their orders, ultimately leading to increased productivity and cost savings. Furthermore, the consistency of the CNC cutting process ensures that each aluminum component is uniform in quality, eliminating the variability that can occur with manual machining.Another key advantage of CNC cutting aluminum is the versatility it offers. With the ability to handle a wide range of aluminum materials and thicknesses, CNC cutting is suitable for a variety of applications. Whether it's creating intricate parts for aerospace machinery or producing durable components for automotive vehicles, CNC cutting aluminum can meet the diverse needs of different industries. This versatility makes it a highly attractive option for companies looking to streamline their metal fabrication processes.In conclusion, CNC cutting aluminum has revolutionized the metal fabrication industry, offering unparalleled precision, efficiency, and versatility. As companies continue to seek innovative solutions to enhance their production processes, CNC cutting aluminum has emerged as a game-changer that is driving the industry forward. With companies like {} leading the way with their cutting-edge capabilities, the future of aluminum fabrication looks brighter than ever. Whether it's meeting the demands of complex aerospace projects or delivering high-quality automotive components, CNC cutting aluminum is poised to continue making a lasting impact on the industry.

Durable and Lightweight Aluminum for Commercial Vehicles: A Game Changer for the Industry

Commercial Vehicle Aluminum is a leading manufacturer of high-quality aluminum products for the commercial vehicle industry. With a focus on innovation, efficiency, and sustainability, the company has established itself as a key player in the market. Their aluminum products are known for their durability, strength, and lightweight properties, making them the ideal choice for commercial vehicle manufacturers.The company's commitment to excellence is reflected in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. This allows them to produce aluminum products that meet the highest industry standards and exceed customer expectations.Commercial Vehicle Aluminum's product range includes a variety of aluminum sheets, plates, and extrusions that are specifically designed for use in commercial vehicles. These products are engineered to provide superior performance and reliability, making them the top choice for truck bodies, trailers, and other commercial vehicle applications.In addition to their standard product offerings, Commercial Vehicle Aluminum also offers custom solutions to meet the unique needs of their customers. Their team of experienced engineers and technicians work closely with clients to develop tailored aluminum products that are perfectly suited to their specific requirements.One of the key advantages of using aluminum in commercial vehicles is its lightweight nature. Aluminum is significantly lighter than steel, which can result in increased fuel efficiency and payload capacity for commercial vehicles. This can lead to cost savings for fleet operators and a reduced environmental impact due to lower fuel consumption.Furthermore, aluminum offers excellent corrosion resistance, making it a durable and long-lasting material for commercial vehicles. This ensures that the vehicles remain in top condition even when exposed to harsh environmental conditions and heavy use.Commercial Vehicle Aluminum is also committed to sustainability, and their aluminum products are fully recyclable. This not only reduces the environmental impact of commercial vehicle production but also supports a circular economy by minimizing waste and promoting the reuse of materials.The company's dedication to sustainability extends beyond their products to their manufacturing processes. They have implemented efficient and eco-friendly production methods, such as energy-saving initiatives and waste reduction strategies, to minimize their environmental footprint.In addition to their commitment to product quality and sustainability, Commercial Vehicle Aluminum also places a strong emphasis on customer satisfaction. They prioritize open communication and collaboration with their clients to ensure that their products meet and exceed expectations.With a focus on continuous improvement and innovation, Commercial Vehicle Aluminum is constantly researching and developing new aluminum products and technologies to stay ahead of industry trends and meet the evolving needs of their customers.Overall, Commercial Vehicle Aluminum is a trusted partner for commercial vehicle manufacturers, offering high-quality, lightweight, and sustainable aluminum products that are designed to optimize performance and efficiency. Their dedication to excellence, sustainability, and customer satisfaction sets them apart as a leader in the commercial vehicle industry.

Top Quality Aluminum Coil for High Performance

[Company Introduction]{Company name} is a leading manufacturer and supplier of high-quality aluminum products. With a focus on innovation and quality, the company has established itself as a trusted name in the industry. Its state-of-the-art manufacturing facilities and dedicated team of professionals ensure that it produces aluminum products that meet the highest standards of performance and reliability. {Company name} is committed to providing innovative solutions to its customers and has a strong reputation for delivering products that exceed expectations.[News Content]{Company name} has recently introduced a new high-performing aluminum coil that is set to revolutionize the industry. The new aluminum coil, which is designed for a wide range of applications, promises to deliver exceptional performance and durability. With its advanced technology and superior quality, the aluminum coil is expected to set new standards in the industry.The high-performing aluminum coil is manufactured using state-of-the-art processes and is made from the highest quality aluminum alloy. This ensures that the coil is not only lightweight and easy to handle, but also extremely strong and durable. The advanced manufacturing techniques employed by {Company name} guarantee that the aluminum coil meets the highest standards of quality and performance.The new aluminum coil is suitable for a variety of applications, including construction, transportation, and electronics. Its versatility and durability make it an ideal choice for use in a wide range of industries. Whether it is used for roofing, cladding, or insulation, the high-performing aluminum coil promises to deliver exceptional results.One of the key features of the new aluminum coil is its superior corrosion resistance. The aluminum alloy used in its manufacture is specially formulated to withstand harsh environmental conditions, making it ideal for outdoor applications. This makes the aluminum coil a reliable and long-lasting solution for a variety of projects.In addition to its exceptional performance, the high-performing aluminum coil also offers cost savings. Its lightweight design and ease of installation make it a cost-effective solution for many applications. With its long lifespan and low maintenance requirements, the aluminum coil is not only a high-performing product but also an economical one.{Company name} is proud to introduce this new high-performing aluminum coil to the market. As a company committed to innovation and quality, it is constantly striving to deliver products that meet the evolving needs of its customers. The introduction of the new aluminum coil is a testament to {Company name}'s dedication to excellence and its ability to meet the demands of the industry.The new high-performing aluminum coil from {Company name} is set to make a significant impact in the industry. Its exceptional performance, durability, and cost-effective nature make it a compelling choice for a wide range of applications. With its advanced technology and superior quality, the aluminum coil is sure to set new standards in the industry and cement {Company name}'s reputation as a leader in the manufacture of high-quality aluminum products.

Discover the Latest Updates on Aluminum Extrusions Tubes in the News

Aluminum Extrusions Tube – Providing High-Quality, Customized Aluminum Solutions for Various IndustriesAluminum Extrusions Tube, a leading provider of aluminum products and solutions, has been serving a diverse range of industries for over ten years. The company offers a variety of high-quality, customized aluminum solutions that cater to the specific needs and requirements of their clients. Their extensive range of products includes extrusions, tubing, and specialty profiles, as well as custom fabrication and machining services.The company takes pride in their commitment to excellence, which is evident in the quality of their products and services. Their skilled and experienced team of professionals ensure that every project meets the highest standards of quality and precision. They strive to exceed their clients' expectations, providing personalized service to help them achieve their goals.Aluminum Extrusions Tube serves a wide range of industries, including architectural, automotive, marine, transportation, and more. The versatility of aluminum as a material enables the company to meet the specific needs and requirements of different industries with ease. Their extensive range of products is designed to meet the unique demands of each industry, providing customized solutions that meet the highest standards of quality and performance.One of the benefits of working with Aluminum Extrusions Tube is their ability to offer custom solutions for specific applications. The company has the expertise to design and manufacture products that match their clients' specific requirements, providing tailored solutions that meet the unique demands of each project. Their in-house design and engineering team work closely with clients to develop solutions that meet their needs and exceed their expectations.The company's products are renowned for their quality and reliability. They use only the highest quality materials and employ the most advanced production techniques to ensure that every product meets the strictest standards of quality. Their products are designed to withstand even the toughest environments and applications, providing long-lasting, reliable performance.In addition to their range of products, Aluminum Extrusions Tube also offers custom fabrication and machining services. Their state-of-the-art manufacturing facility houses a wide range of equipment that enables them to provide precision fabrication and machining services. The company's team of skilled technicians and engineers use the latest techniques to produce high-quality, precision products that meet the exact specifications of their clients.The company's commitment to excellence, quality, and precision has earned them a reputation as one of the leading providers of aluminum solutions in the industry. They take pride in their ability to offer customized solutions for their clients, leveraging their expertise to deliver products that meet their exact requirements. Their dedication to quality, coupled with their extensive range of products and services, ensures that they remain a top choice for aluminum solutions in a variety of industries.Overall, Aluminum Extrusions Tube is a reliable partner for those seeking high-quality, customized aluminum products and solutions. Their extensive range of products and services, coupled with their commitment to excellence, make them an ideal choice for a wide range of industries. With their expertise, precision, and personalized service, they are poised to continue delivering customized aluminum solutions that exceed their clients' expectations.