- Home

- Blog

- New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

By:Admin

Revolutionizing the Aluminum Processing Industry

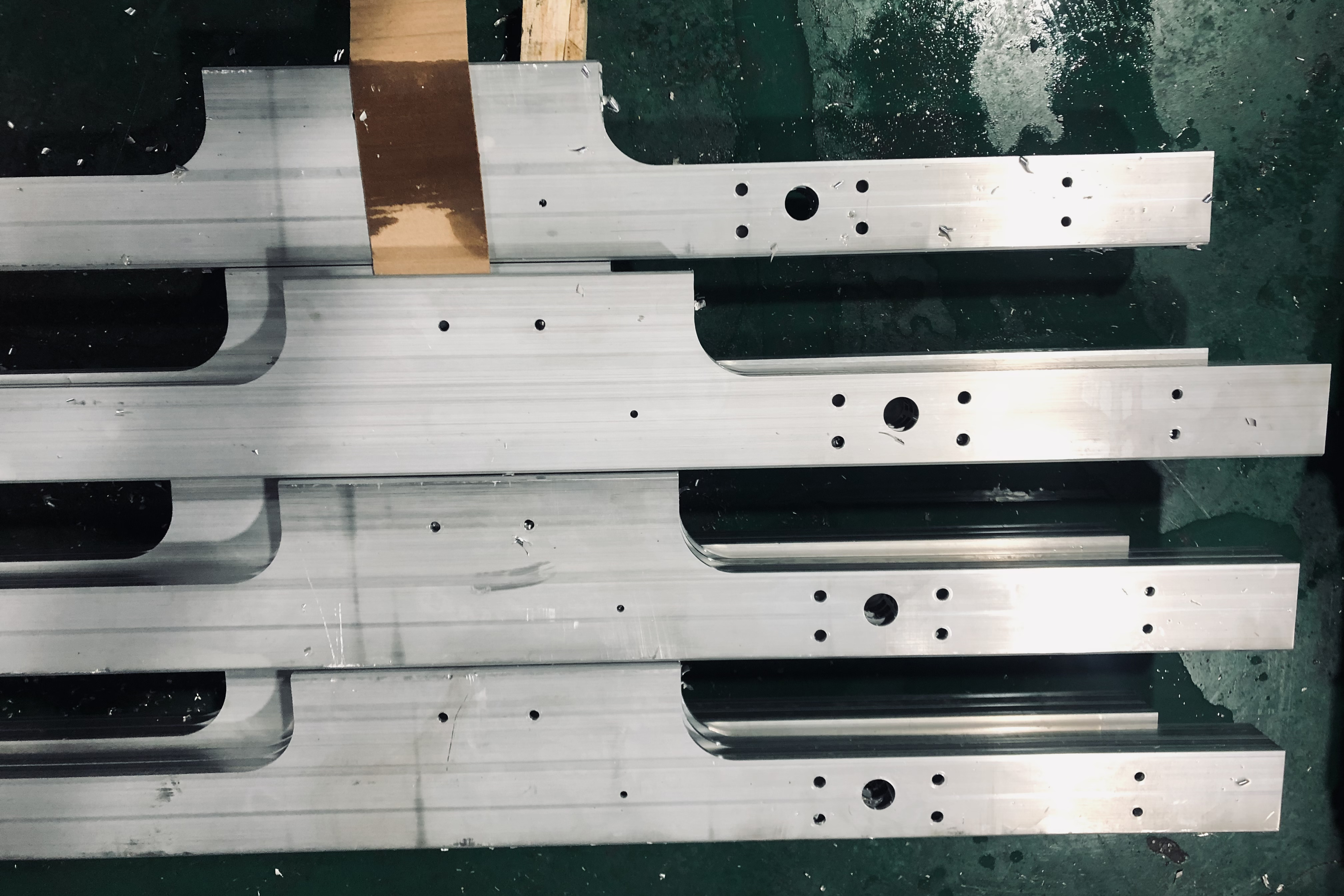

Aluminum extrusion has been a vital process in industries ranging from construction to automotive and aerospace. However, the process of cutting aluminum extrusions has often been problematic, with chipping and deformation being common issues. These problems are exacerbated when production demand is high, as is often the case in modern industrial enterprises. Thankfully, the Aluminum Extrusion Cutting Machine (need remove brand name) is poised to revolutionize this crucial process by providing a highly accurate, efficient, and reliable cutting solution.

The Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution designed specifically for aluminum extrusions. This machine overcomes many of the challenges that traditional cutting methods have faced, such as chipping or deformation, by implementing advanced technology and a number of innovative features. With this machine, the cutting process is made much smoother, allowing for a more efficient and streamlined production process.

Some of the key features that set this machine apart from others include its robust frame and precision cutting mechanism. The machine is made from high-grade aluminum alloy, which ensures its durability and longevity. Moreover, its cutting mechanism has been designed to minimize deformation and produce smooth and clean cuts every time. This feature is particularly important because it effectively eliminates the need for additional finishing processes, which can add to the production time and costs.

The Aluminum Extrusion Cutting Machine (need remove brand name) also excels in terms of efficiency and precision. The machine is equipped with a highly accurate positioning system that ensures precise cuts each time. This system can be programmed to cut at specific lengths and angles, which enables manufacturers to produce custom parts quickly and with ease. Moreover, the machine's digital display makes it easy to adjust the cutting parameters as needed.

One of the most impressive aspects of this machine is its speed. The Aluminum Extrusion Cutting Machine (need remove brand name) possesses a spindle speed of up to 20,000 rpm, which is significantly faster than most other cutting machines. This high speed allows for a much faster production process, reducing lead times and enabling manufacturers to keep up with growing demand.

Of course, the true value of this machine is in its ability to deliver consistent results with every cut. The combination of precision, speed, and accuracy ensures that each cut is of the highest quality, allowing for seamless assembly and faster production times. This feature is particularly important in the manufacturing of complex applications, such as those found in the aerospace or automotive industries.

In addition to its impressive features, the Aluminum Extrusion Cutting Machine (need remove brand name) is also highly customizable. The machine can be configured to meet the specific needs of individual manufacturers, with options such as dust collection, lubrication systems, and more. This level of customization ensures that manufacturers can tailor the machine to their specific requirements, producing higher quality results in less time.

Finally, the machine's user-friendly design makes it easy to operate and maintain. The machine is equipped with a number of safety features, such as emergency stop buttons and an automatic lubrication system. The machine's digital control system makes it easy to adjust the cutting parameters, and its modular design allows for easy maintenance and repair.

In conclusion, the Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution that is poised to revolutionize the aluminum extrusion industry. With its high precision, speed, and accuracy, it is equipped to handle the demands of modern industrial enterprises, delivering consistent and high-quality results every time. Its innovative features, user-friendly design, and extensive customization options make it an ideal choice for manufacturers looking to streamline their production processes and stay ahead of the competition.

Company News & Blog

Discover the Benefits of Aluminium Frame Profiles: A Comprehensive Overview

Aluminium Frame Profile: The Preferred Choice for Durable and Strong StructuresIn today's fast-paced world, people's needs and preferences for construction material are constantly changing. From high-rise buildings to small domestic structures, the demand for technically advanced, high-performance materials that meet the needs of the modern world is increasing. Aluminium is a popular choice for such applications due to its durability, strength, and versatility.Aluminium Frame Profile, also known as aluminium extrusions, is the latest trend in construction material that is being used in a variety of applications such as commercial, residential, and industrial structures. They are a perfect replacement for traditional wooden and steel frames due to their unmatched strength, durability, and long-lasting finish. Aluminium frames can be custom-designed, cut, and shaped to meet the specific needs of any structure.The company, {}, has been a pioneer in manufacturing high-quality aluminium frame profile in a wide variety of designs and shapes. Their aluminium frame profiles are designed to meet the demands of modern construction, catering to the specific needs of the industry while providing customers with a reliable, long-lasting, and high-performance solution.One of the key benefits of aluminium frame profiles is their strength, as they are built to withstand harsh environmental conditions such as wind, rain, and extreme temperatures. Unlike other materials like wood and steel, aluminium does not rust or corrode, making it a preferred choice for outdoor applications. Additionally, the ease with which aluminium can be custom-cut and shaped makes it an ideal material for constructing unique designs.The company's aluminium frame profiles come in various designs such as T-slot, square, and rectangular profiles, allowing customers to choose the right fit for their construction needs. Additionally, the company's in-house fabrication capabilities enable them to offer a seamless, end-to-end service to customers, right from the design inception to the final installation.Another essential feature of the company's aluminium frame profiles is their versatility, which makes them ideal for use in a wide range of applications, including commercial storefronts, curtain walls, skylights, windows, doors, and balcony railings. Regardless of the application, the company's aluminium frame profiles provide a sleek and modern aesthetic, in line with contemporary architectural designs.Furthermore, aluminium frame profiles offer significant energy savings in a building due to their thermal conductivity properties. They are much less conductive than traditional steel frames and wood. As a result, they are an excellent solution for sustainable construction and energy-efficient buildings.To ensure product quality, the company adheres to strict manufacturing standards, using only high-grade aluminium material in their extrusion process. Their manufacturing process is automated, which ensures consistency in quality and accuracy in dimensional tolerances.In conclusion, Aluminium Frame Profile is an innovative solution for modern construction and building needs. Their versatility, strength, and durability make them an ideal material for use in a wide range of applications. With a commitment to quality, {} offers a wide range of high-performance aluminium frame profile products that cater to the diverse needs of customers, from commercial, residential, and industrial structures to energy-efficient buildings. If you are considering aluminium for your next construction project, do not hesitate to contact {} today.

Strong and Durable 1-Inch Aluminum Square Tubes for Various Applications

Title: Versatile 1 Inch Aluminium Square Tube: The Perfect Solution for Various Construction ProjectsIntroduction:With its exceptional strength, durability, and versatility, the 1 inch Aluminium Square Tube offers a wide range of applications in the construction industry. Manufactured with precision and advanced technology, this high-quality material is gaining significant popularity among architects, engineers, and DIY enthusiasts alike. Engineered to withstand heavy loads and adverse weather conditions, this tube is the perfect choice for structural framing, fencing, and various other construction projects.1. The Durability and Strength of Aluminium:The 1 inch Aluminium Square Tube, made from premium-grade aluminium, delivers unparalleled toughness. Aluminium's inherent strength allows it to withstand heavy loads and resist corrosion, making it ideal for both indoor and outdoor construction projects. Unlike other materials, aluminium does not rust, ensuring long-lasting performance and reduced maintenance costs.2. Versatile Applications:This aluminium tube's versatility ensures its suitability across a wide range of construction applications. Its strength-to-weight ratio makes it particularly advantageous for structural framing in buildings and infrastructure projects. From supporting beams and frames to staircases and handrails, the 1 inch Aluminium Square Tube provides the necessary structural integrity while maintaining a sleek and aesthetic appearance.Furthermore, these tubes are extensively used in the fencing industry. Their resistance to corrosion and ability to withstand harsh weather conditions make them perfect for both residential and commercial fencing applications. The lightweight nature of aluminium also makes it easier to transport and install, reducing labor costs and overall project expenses.3. Architectural Appeal and Customization:Architects and designers are increasingly turning to the 1 inch Aluminium Square Tube due to its aesthetic appeal. Its clean lines and sleek design complement modern architectural styles, adding a touch of elegance to any construction project. Additionally, this versatile material comes in various finishes, including polished, brushed, or powder-coated, enabling customization to suit individual architectural preferences.4. Environmental Considerations:In an era of rising environmental concerns, the 1 inch Aluminium Square Tube is an eco-friendly choice. Aluminium is highly recyclable, and its recycling process requires only a fraction of the energy needed for its initial production. By opting for aluminium, construction professionals actively contribute to reducing their carbon footprint and promoting sustainable construction practices.5. Quality Manufacturing Process:The manufacturing process of the 1 inch Aluminium Square Tube adheres to strict quality standards to ensure the highest levels of durability and performance. The manufacturer, (Company Name), follows advanced technological processes to guarantee precision and dimensional accuracy. A commitment to research and development further enhances the product's strength, making it the preferred choice for demanding construction projects.Conclusion:The 1 inch Aluminium Square Tube offers a transformative solution to construction needs. Its unmatched durability, versatility, and aesthetic appeal make it the go-to material for architects, engineers, and construction professionals. As the industry embraces sustainable practices, this aluminium tube stands out as an eco-friendly option. With its ability to withstand heavy loads and adverse weather conditions, it continues to prove itself as an ideal choice for structural framing, fencing, and various other construction projects. Invest in the 1 inch Aluminium Square Tube to ensure long-lasting, reliable, and visually appealing structures.

Ultimate Guide to Using V Slot Extrusion in Your DIY Projects

article:V Slot Extrusion: The Perfect Solution for Your Structural NeedsStructural framing is an essential aspect of various industries. Whether for building construction, manufacturing plants, or automotives, sturdy structural framing is necessary. Mechanisms that support and withstand loads drive these industries. With a focus on mechanical design, particular attention to the strength of members must be at the forefront of any project. Proper structural support ensures better quality and performance of any machine or building. One structural framing system that stands out is V Slot Extrusion. 4040 V Slot Extrusion (link to non-brand website) is a robust structural framing material system that incorporates a unique v-shaped slot feature. Thanks to its v-shaped slot, V Slot Extrusion allows for easy slide-in installation of T-slot nuts. It has pre-installed mounting shelves that make it easy to position different types of components, from door frames to work tables. V Slot Extrusion is made of aluminum, making it light and strong at the same time.V Slot Extrusion has a wide range of applications. It is perfect for designing structural frameworks, including machines, industrial work benches, camera sliders, 3D printers, and many more. Its flexibility makes it fit for numerous uses.Various companies have embraced V Slot Extrusion for its versatility. In one instance, a construction company used V Slot Extrusion to refurbish a hotel bar counter. They installed a customized bar that had a unique lighting and sound system, as well as several other hidden features. The construction company stated that V Slot Extrusion made it easier to install the various components into the bar counter easily. The finished job looked stunning, modern, and well structured, not to mention that it was sturdy enough to support the weight of the components.Another company that benefited from using V Slot Extrusion is a manufacturing plant that manufactures automobile parts. Their work table was made using V Slot Extrusion. The table had a unique design with extrusions as legs and beams supporting the work surface. The plant’s engineers stated that V Slot Extrusion provided additional mobility and streamline design, ensuring the table could support heavy equipment.The automotive industry is known for its complexity of machinery and the need to create efficient solutions that handle the pressure of daily operations. V Slot Extrusion has been the foundation of the manufacturing plant's automated process since 2017. The material is trustworthy and suits their needs perfectly. The V-slot configuration used for their work table offers the best ratio of weight to strength. As the table is moved around the plant, it can carry dense, heavy equipment, without any signs of wear or tear.V Slot Extrusion is also trending in the home DIY arena. Many homeowners are now discovering how V Slot Extrusion can create multi-purpose structures such as wardrobes, standing desks, or even home bar counters. The extrusions provide a sleek and finished look that is perfect for modern interior designs.Installing V Slot Extrusion is an easy process. It is available in different sizes and lengths, making it versatile to use. It has a pre-cut design that makes it convenient to work with. Moreover, attaching screws and nuts to V Slot Extrusion is a breeze, meaning it helps to save time while improving the efficiency of the project. A company spokesperson stated that V Slot Extrusion simplified their project design process, from the component selection phase to installation. As a result, it has reduced their construction time for their structural framework to only a quarter of what it used to be.In conclusion, V Slot Extrusion is the go-to solution for different structural framing needs. From industrial buildings to modern home DIY projects, V Slot Extrusion provides robust, flexible, and streamlined solutions that make any project stand out. Its versatility, lightweight, and strength are further evidence that it is the perfect solution for structural needs.

How to Choose the Best 5 Inch Aluminum Pipe for Your Needs

Title: New 5 Inch Aluminum Pipe Revolutionizes Industrial Piping SolutionsIntroduction: [date], [location] - [Company Name], the leading manufacturer of high-quality industrial piping solutions, is pleased to announce the launch of its innovative and industry-disrupting 5-inch aluminum pipe. This next-generation pipe is designed to meet the evolving needs of various industries and promises to revolutionize industrial piping systems. With its advanced features and exceptional durability, this product aims to provide customers with efficient and cost-effective piping solutions.[Company Name] has been a trusted name in the industry for [number] years, delivering top-of-the-line products that cater to the diverse requirements of clients worldwide. With an unwavering commitment to quality, the company's highly skilled engineers and technicians continuously pursue innovation to stay at the forefront of the industry.Product Features:The new 5-inch aluminum pipe presents a range of cutting-edge features that set it apart from traditional piping materials. The following features make it an ideal choice for industrial applications:1. Lightweight and Durable: The aluminum pipe is significantly lighter than traditional metal pipes, making it easier to handle and install. Despite its lightweight nature, the pipes are extremely durable, allowing them to withstand heavy pressure and extreme temperatures.2. Corrosion Resistance: Aluminum is naturally resistant to corrosion, making it suitable for industries that deal with corrosive substances. This attribute ensures the pipes' longevity, reduces maintenance costs, and enhances overall operational efficiency.3. High Thermal Conductivity: Aluminum has excellent thermal conductivity, enabling more efficient heat transfer. This makes the 5-inch aluminum pipe an ideal choice for industries that require temperature control, such as HVAC systems, manufacturing processes, and refrigeration units.4. Versatility and Compatibility: The pipe's standard 5-inch size allows for easy integration into existing piping systems, making it a highly versatile choice for retrofitting projects. Additionally, it is compatible with a wide range of fittings, ensuring seamless connections without the need for costly modifications.5. Sustainability: Aluminum is a recyclable material, aligning with the growing focus on sustainable practices. Choosing the 5-inch aluminum pipe helps industries reduce their carbon footprint and supports environmental responsibility.Industry Impact:The launch of the 5-inch aluminum pipe is expected to have a significant impact on various industries. With its exceptional properties, it promises to overcome the limitations of traditional piping materials, offering numerous benefits, including:1. Increased Efficiency: The lightweight design and improved thermal conductivity of the aluminum pipe contribute to more efficient operations, saving energy and reducing overall costs. Enhanced efficiency translates into higher productivity and improved bottom-line results for businesses.2. Lower Maintenance Costs: The corrosion-resistant nature of the aluminum pipe eliminates the need for frequent repairs and replacements, leading to substantial savings in maintenance expenditure. Industries can redirect these funds towards other critical areas of their operations.3. Improved Safety: Aluminum's high strength-to-weight ratio ensures the pipes can withstand intense pressure and prevent leaks or bursts. By using the 5-inch aluminum pipe, industries can prioritize employee safety and mitigate potential hazards associated with piping systems.4. Environmental Responsibility: The recyclable nature of aluminum, combined with its extended lifespan, promotes sustainable practices and aligns with global efforts to reduce waste. By choosing the 5-inch aluminum pipe, companies can contribute to a greener future while meeting their operational needs.Conclusion:[Company Name]'s launch of the innovative 5-inch aluminum pipe represents a significant milestone in the field of industrial piping solutions. This cutting-edge product offers industries a superior alternative to traditional metal pipes, providing enhanced performance, improved efficiency, and increased cost savings.By incorporating the aluminum pipe into their piping systems, industries can demonstrate their commitment to adopting sustainable practices while benefiting from its lightweight, corrosion-resistant, and thermally conductive properties. Together, these advantages equate to a more productive, efficient, and eco-friendly future for businesses across various sectors.[Company Name] remains committed to pioneering advancements in industrial piping solutions and strives to develop products that cater to ever-evolving industry needs. With their reputation for excellence, the company continues to present innovative solutions that revolutionize the way companies operate and further enhance their success.

Discover the Advantages and Applications of 30 Series Aluminum Extrusion

In the world of industrial manufacturing, aluminum extrusions have revolutionized the way products are built. These versatile metal parts are used in a variety of industries, including automotive, aerospace, construction, and electronics. One of the most popular aluminum extrusions on the market today is the 30 Series Aluminum Extrusion.The 30 Series Aluminum Extrusion is a lightweight and durable frame that can be used to build anything from simple structures to complex machines. It is made from high-quality aluminum alloy, which makes it incredibly strong and resistant to corrosion.One company that has been at the forefront of the aluminum extrusion industry is [company name]. They specialize in designing and manufacturing aluminum extrusions of various sizes and shapes to meet the diverse needs of their customers.According to representatives from [company name], the 30 Series Aluminum Extrusion is one of their most popular products. This is because it is incredibly easy to work with and can be customized to fit any application.What makes the 30 Series Aluminum Extrusion stand out is its T-slot design. This feature allows users to easily attach other components to the frame, such as brackets, hinges, or even other pieces of aluminum extrusions. This makes it incredibly versatile and adaptable to any situation.In addition to its strength and versatility, the 30 Series Aluminum Extrusion is also incredibly lightweight. This makes it perfect for applications where weight is a concern, such as in the aerospace or automotive industry.One of the key benefits of the 30 Series Aluminum Extrusion is its durability. The aluminum alloy used to create these frames is incredibly strong and resistant to corrosion. This means that the frames can withstand even the harshest environments and still maintain their structural integrity.Another advantage of the 30 Series Aluminum Extrusion is its ease of use. Unlike traditional welding or bolt-together systems, the T-slot design of this frame allows users to easily connect pieces together with minimal effort. This saves both time and money in the manufacturing process.The 30 Series Aluminum Extrusion is also incredibly easy to customize. It can be cut to any length or shape to fit specific needs. This allows manufacturers to create unique and innovative products that stand out from the competition.Overall, the 30 Series Aluminum Extrusion is a versatile and reliable product for anyone in the manufacturing industry. Its strength, durability, and ease of use make it the perfect choice for a wide range of applications. With companies like [company name] leading the way in aluminum extrusion technology, it's clear that this industry will continue to grow and evolve for years to come.

Discover the Versatile Uses of Extruded Aluminum Channels

The Aluminum Channel Industry: A Growing Market for Extruded Aluminum ChannelsAluminum channels play a crucial role in a wide range of industries, from construction and automotive to electronics and retail. These versatile components are used for various applications, including structural, decorative, and protective purposes. With a strong demand across multiple sectors, the market for aluminum channels is booming. One company that has made a significant impact in this industry is {Company Name}.{Company Name} is a leading manufacturer and supplier of extruded aluminum channels. With state-of-the-art facilities and a commitment to innovation, the company provides high-quality products that meet the diverse needs of its customers. With a wide range of extruded aluminum channels available, {Company Name} has become a top choice for businesses worldwide.Extruded aluminum channels are created through a manufacturing process that involves pushing heated aluminum through a die to obtain specific shapes and sizes. This process allows for the creation of customized channels that are tailored to meet the requirements of different applications. Industries such as construction rely on aluminum channels for their structural properties, as they offer excellent strength, durability, and flexibility. Moreover, extruded aluminum channels are lightweight, corrosion-resistant, and have excellent thermal conductivity, making them ideal for various environments and conditions.The demand for extruded aluminum channels has been steadily increasing over the years, driven by the growth of industries such as construction, automotive, and electronics. In the construction sector, aluminum channels are widely used for architectural applications, including window frames, curtain walls, and railings. The automotive industry relies on these channels for structural components, such as support beams and chassis parts, due to their strength-to-weight ratio.Furthermore, the electronics industry uses extruded aluminum channels for heat sink applications. Heat sinks are essential in electronic devices to dissipate heat and prevent overheating, ensuring optimal performance and longevity of the equipment. Aluminum channels are well-suited for this purpose, as they efficiently conduct heat and can be customized to specific designs and dimensions.{Company Name} has positioned itself as a leading player in the extruded aluminum channel market by offering a diverse range of products that cater to the specific needs of different industries. Their comprehensive product portfolio includes channels of various shapes, sizes, and finishes, giving customers the flexibility to choose the perfect solution for their applications.In addition to their commitment to quality, {Company Name} also places a strong emphasis on sustainability. Aluminum is a highly sustainable material, as it is infinitely recyclable without losing its properties. {Company Name} has implemented sustainable practices throughout its manufacturing process to minimize waste and energy consumption, reducing their environmental impact.To meet the growing demand for extruded aluminum channels, {Company Name} has invested in advanced manufacturing technologies and expanded their production capabilities. By staying at the forefront of technological advancements, the company is able to produce high-quality channels efficiently and cost-effectively, meeting tight deadlines and exceeding customer expectations.The success of {Company Name} is not only attributed to their superior product quality and sustainable practices but also to their commitment to customer satisfaction. The company takes pride in providing exceptional customer service and technical support, ensuring that customers receive the right products and advice for their specific requirements.Looking ahead, the market for extruded aluminum channels is projected to witness significant growth as industries continue to recognize the advantages of using aluminum for their applications. Factors such as urbanization, infrastructure development, and the adoption of advanced technologies will continue to drive the demand for aluminum channels in the coming years.With its strong market presence, commitment to innovation, and customer-centric approach, {Company Name} is well-positioned to capitalize on the growing opportunities in the extruded aluminum channel industry. As they continue to expand their product offerings, leverage technological advancements, and foster strategic partnerships, {Company Name} is poised to remain a key player in this dynamic market.

Industry group predicts growth in aluminum extrusions for 2021

Aluminum Extrusion Association Announces New Initiatives to Promote Sustainability and Innovation in the Industry[City], [Date] - The Aluminum Extrusion Association is proud to announce a series of new initiatives aimed at promoting sustainability and innovation in the aluminum extrusion industry. These initiatives will help to improve the environmental footprint of aluminum extrusion processes, while also fostering innovation and collaboration within the industry.As a leading trade association dedicated to advancing the extrusion industry, the Aluminum Extrusion Association is committed to driving positive change across all aspects of the industry. This includes environmental sustainability, product performance, and technological advancements.To support these objectives, the Aluminum Extrusion Association has developed a comprehensive sustainability program. This program aims to reduce the environmental impact of aluminum extrusion processes through measures such as energy conservation, waste reduction, and increased use of recycled materials.One key aspect of the sustainability program is the promotion of energy-efficient practices. Aluminum extrusion is an energy-intensive process, and as such, finding ways to minimize energy consumption is critical. To achieve this, the Aluminum Extrusion Association will provide resources and guidance to its members on implementing energy-saving technologies and best practices.Another area of focus for the sustainability program is waste reduction. Aluminum extrusion generates a significant amount of waste material, but this waste can often be recycled or repurposed. The Association will work closely with its members to develop strategies for waste reduction and recycling, helping to minimize the industry's environmental impact.In addition to its sustainability program, the Aluminum Extrusion Association is also placing a strong emphasis on innovation. The Association recognizes that innovation is key to driving growth and competitiveness in the industry, and as such, it is actively promoting collaboration and knowledge-sharing among its members.To facilitate innovation, the Aluminum Extrusion Association is establishing a dedicated research and development (R&D) fund. This fund will support research projects focused on advancing aluminum extrusion technologies, exploring new applications, and improving product performance. By investing in R&D, the Association aims to foster a culture of innovation and facilitate the development of new and improved products and processes.Furthermore, the Aluminum Extrusion Association will organize industry conferences, seminars, and workshops to encourage collaboration and knowledge exchange. These events will provide a platform for industry experts to discuss and share their experiences, fostering a culture of continuous learning and improvement within the industry.The Aluminum Extrusion Association understands the importance of collaboration with other organizations and stakeholders. As such, it will actively seek partnerships with government agencies, research institutions, and other relevant bodies to drive the sustainability and innovation agenda forward."We are excited to launch these new initiatives aimed at promoting sustainability and innovation within the aluminum extrusion industry," said [Spokesperson Name], [Title] of the Aluminum Extrusion Association. "By working together, we can drive positive change, reduce our environmental impact, and unlock new opportunities for growth and success."The Aluminum Extrusion Association's commitment to sustainability and innovation reflects the industry's increasing focus on environmental responsibility and competitiveness. By implementing these initiatives, the Association aims to position the aluminum extrusion industry as a leader in sustainable manufacturing practices, while also driving innovation and growth.About the Aluminum Extrusion Association:[Company name], a leading trade association, represents the aluminum extrusion industry in [Location]. With a membership spanning manufacturers, suppliers, and other industry stakeholders, the Association is dedicated to advancing the extrusion industry through advocacy, education, and collaborative initiatives. By promoting sustainability and innovation, the Aluminum Extrusion Association strives to drive positive change and position the industry for continued success.

Aluminum Punching Services: High-Quality Precision Machining Techniques

Title: Revolutionizing the Aluminum Fabrication Industry: Innovations in Precision Aluminum PunchingIntroduction:In an ever-evolving industrial landscape, Precision Aluminum Punching has emerged as a leading force, transforming the aluminum fabrication sector. This innovative technology, offered by a pioneering company, promises unprecedented levels of precision and efficiency, revolutionizing the way aluminum components are manufactured. Embracing cutting-edge techniques, this breakthrough solution is poised to redefine the standards of the industry.Company Introduction:At the forefront of this groundbreaking technology is a company committed to driving excellence in aluminum fabrication. With years of expertise and an unwavering dedication to precision, this industry leader has successfully incorporated advanced machinery and automation into their production processes. Constantly pushing boundaries, they have earned an esteemed reputation for delivering top-quality aluminum components worldwide.Article:Revolutionizing Aluminum Fabrication: Precision Aluminum Punching Takes Center StageIn recent years, the aluminum fabrication industry has experienced significant advancements, setting new benchmarks in precision and productivity. Central to this transformation is the introduction of Precision Aluminum Punching, a revolutionary technology that combines the expertise of a prominent company with state-of-the-art machinery.Precision Aluminum Punching leverages advanced machinery, such as high-speed presses and computer-controlled systems, to create intricate patterns, designs, and precise holes in aluminum sheets and profiles. This precise punching process results in components with exceptional dimensional accuracy, enabling seamless integration into various industries like automotive, aerospace, construction, and electronics.This cutting-edge technology optimizes both time and cost efficiency, as it eliminates the need for post-processing operations, such as drilling, milling, or cutting. By reducing the number of production steps, Precision Aluminum Punching significantly streamlines manufacturing processes, leading to increased productivity and shorter lead times.Furthermore, this advanced technology also improves material utilization, minimizing waste and maximizing resource efficiency. With greater scrap utilization rates, manufacturers can enhance sustainability efforts while ensuring significant cost savings.The benefits of Precision Aluminum Punching go beyond its immediate impact on the manufacturing process. By enabling intricate designs and complex shapes, aluminum components produced through this technology exhibit superior aesthetics, providing added value and versatility to end products. This opens up new design possibilities, giving manufacturers a competitive edge in the market.The company at the forefront of this innovation boasts a highly skilled team of engineers and technicians who work seamlessly to develop customized solutions for diverse client requirements. By leveraging their expertise and integrating cutting-edge technology, they guarantee the highest levels of precision, quality, and customer satisfaction.When compared to traditional aluminum fabrication processes, Precision Aluminum Punching offers a range of advantages. By eliminating the need for multiple equipment setups and complex tooling, manufacturers can drastically reduce production costs and enhance overall efficiency. The precise punching capabilities also eliminate errors and inconsistencies associated with traditional methods, ensuring unparalleled accuracy throughout the manufacturing process.Moreover, the scalability of Precision Aluminum Punching enables manufacturers to easily adapt to evolving market demands. With the ability to produce complex components in large quantities, the technology offers flexibility and agility in meeting varied customer requirements within tight deadlines.As the aluminum fabrication industry continues to evolve, Precision Aluminum Punching emerges as a game-changer, setting new standards for excellence. Its ability to achieve exceptional precision, reduce costs, and enhance manufacturing efficiency positions it as the technology of the future. This innovative solution, combined with the expertise of the leading company, paves the way for a new era of aluminum component manufacturing.Conclusion:Precision Aluminum Punching revolutionizes the aluminum fabrication industry, offering unmatched precision, efficiency, and versatility. With an industry-leading company at its helm, this groundbreaking technology holds the potential to reinvent traditional manufacturing processes, empowering businesses to deliver top-quality components with exceptional accuracy and cost-effectiveness. As more manufacturers adopt this cutting-edge solution, the aluminum fabrication industry is poised for continued growth and innovation.

New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

Aluminum Extrusion Cutting Machine (need remove brand name) Revolutionizing the Aluminum Processing IndustryAluminum extrusion has been a vital process in industries ranging from construction to automotive and aerospace. However, the process of cutting aluminum extrusions has often been problematic, with chipping and deformation being common issues. These problems are exacerbated when production demand is high, as is often the case in modern industrial enterprises. Thankfully, the Aluminum Extrusion Cutting Machine (need remove brand name) is poised to revolutionize this crucial process by providing a highly accurate, efficient, and reliable cutting solution.The Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution designed specifically for aluminum extrusions. This machine overcomes many of the challenges that traditional cutting methods have faced, such as chipping or deformation, by implementing advanced technology and a number of innovative features. With this machine, the cutting process is made much smoother, allowing for a more efficient and streamlined production process.Some of the key features that set this machine apart from others include its robust frame and precision cutting mechanism. The machine is made from high-grade aluminum alloy, which ensures its durability and longevity. Moreover, its cutting mechanism has been designed to minimize deformation and produce smooth and clean cuts every time. This feature is particularly important because it effectively eliminates the need for additional finishing processes, which can add to the production time and costs.The Aluminum Extrusion Cutting Machine (need remove brand name) also excels in terms of efficiency and precision. The machine is equipped with a highly accurate positioning system that ensures precise cuts each time. This system can be programmed to cut at specific lengths and angles, which enables manufacturers to produce custom parts quickly and with ease. Moreover, the machine's digital display makes it easy to adjust the cutting parameters as needed.One of the most impressive aspects of this machine is its speed. The Aluminum Extrusion Cutting Machine (need remove brand name) possesses a spindle speed of up to 20,000 rpm, which is significantly faster than most other cutting machines. This high speed allows for a much faster production process, reducing lead times and enabling manufacturers to keep up with growing demand.Of course, the true value of this machine is in its ability to deliver consistent results with every cut. The combination of precision, speed, and accuracy ensures that each cut is of the highest quality, allowing for seamless assembly and faster production times. This feature is particularly important in the manufacturing of complex applications, such as those found in the aerospace or automotive industries.In addition to its impressive features, the Aluminum Extrusion Cutting Machine (need remove brand name) is also highly customizable. The machine can be configured to meet the specific needs of individual manufacturers, with options such as dust collection, lubrication systems, and more. This level of customization ensures that manufacturers can tailor the machine to their specific requirements, producing higher quality results in less time.Finally, the machine's user-friendly design makes it easy to operate and maintain. The machine is equipped with a number of safety features, such as emergency stop buttons and an automatic lubrication system. The machine's digital control system makes it easy to adjust the cutting parameters, and its modular design allows for easy maintenance and repair.In conclusion, the Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution that is poised to revolutionize the aluminum extrusion industry. With its high precision, speed, and accuracy, it is equipped to handle the demands of modern industrial enterprises, delivering consistent and high-quality results every time. Its innovative features, user-friendly design, and extensive customization options make it an ideal choice for manufacturers looking to streamline their production processes and stay ahead of the competition.

Aluminium CNC Profile: The Ultimate Guide to Precision Machining

Aluminium Profile for CNC: Innovation and Quality at Its BestAluminium profile for CNC machining is a popular innovation in the industrial sector that has continued to receive widespread recognition due to its versatility, durability, and affordability. This innovative technology was first introduced to the market by a leading industry player who has continued to set the pace in the production of top-quality aluminium profiles in China.The company is renowned for its commitment to quality and excellence, and this has been demonstrated through their investment in superior technologies and the implementation of strict quality control measures. They boast of a state-of-the-art production facility that is equipped with advanced CNC machines, which enables them to produce high-quality aluminium profiles that meet the unique needs of their clients.Their aluminium profile for CNC machining is designed with precision and accuracy, making it ideal for use in various industrial settings, including aerospace, architecture, automotive, electronics, and even medical devices. The profile boasts of superior strength, rigidity, and resistance to wear and tear, making it ideal for use in CNC machines that require high precision and speed.One of the significant advantages of this innovative technology is that it offers immense flexibility, allowing the design of various shapes and sizes to meet specific industrial requirements. The company has a skilled team of engineers and professionals who leverage their expertise and creativity to produce custom aluminum profiles that meet the specific demands of their clients.The company has also gained popularity for its keen attention to environmental sustainability and social corporate responsibility. It's committed to reducing its carbon footprint and implements eco-friendly practices in its production processes, which include the use of solar energy and the recycling of materials, among others.Additionally, they promote transparency and fairness in their operations by engaging in ethical business practices that abide by global industry standards, which has earned them numerous accolades and certifications. Some of the awards that they have received include ISO 9001:2015 Quality Management System certification and European Union CE certification.The aluminium profile for CNC machining produced by the company has continued to receive rave reviews from clients across the globe, with many praising its durability, flexibility, and affordability. Several clients have also commended the company's customer-centric approach, which involves the seamless integration of their clients' specific needs during the production process.In conclusion, the aluminium profile for CNC machining is a game-changer in the industrial sector due to its unmatched versatility, durability, and affordability. The company behind this innovative technology has demonstrated its commitment to quality and excellence, environmental sustainability, and social corporate responsibility, which has earned its global recognition. Therefore, for industries looking for top-quality aluminium profiles that guarantee reliability and precision, the aluminium profile for CNC machining from this leading industry player is undoubtedly the way to go.