How Aluminium is Impacting the Industry: Latest News and Updates

By:Admin

T Channel Aluminium has always been dedicated to providing top-notch aluminium products to their customers. Their extensive product range includes aluminium sheets, plates, bars, and various other extruded products that are widely used in the construction, transportation, and aerospace industries. The company's products are known for their durability, strength, and lightweight properties, making them the go-to choice for many construction projects.

In line with the global movement towards sustainability, T Channel Aluminium has taken a step further by developing a new line of eco-friendly aluminium materials. These materials are produced using advanced technology that reduces the carbon footprint and minimizes waste during the manufacturing process. The eco-friendly aluminium materials are also fully recyclable, making them a more sustainable option compared to traditional construction materials.

The new eco-friendly aluminium materials offered by T Channel Aluminium have been rigorously tested and proven to meet the highest industry standards for strength, durability, and performance. They are suitable for a wide range of construction applications, including roofing, cladding, windows, doors, and structural components. These materials are also designed to withstand harsh environmental conditions, making them ideal for both residential and commercial construction projects.

One of the key advantages of the new eco-friendly aluminium materials is their contribution to reducing the overall environmental impact of construction projects. The manufacturing process of these materials consumes less energy and resources, resulting in lower greenhouse gas emissions. Additionally, the recyclability of these materials promotes a circular economy, where products are reused and repurposed instead of being discarded after their initial use.

T Channel Aluminium's commitment to sustainability extends beyond their products. The company ensures that their manufacturing facilities adhere to strict environmental standards and continuously seeks ways to minimize their environmental footprint. By investing in sustainable practices, T Channel Aluminium aims to set an example for the industry and inspire other companies to prioritize sustainability in their operations.

The introduction of the new line of eco-friendly aluminium materials by T Channel Aluminium marks a significant milestone in the construction industry. As the demand for sustainable construction materials continues to rise, T Channel Aluminium is well-positioned to meet the needs of environmentally conscious builders and developers. The company's dedication to innovation and sustainability reaffirms their status as a leading provider of aluminium products in the market.

Alongside their existing product range, T Channel Aluminium's new eco-friendly aluminium materials are set to become a popular choice for construction projects seeking to reduce their environmental impact. With their proven track record of delivering high-quality products and their unwavering commitment to sustainability, T Channel Aluminium is poised to revolutionize the construction industry and pave the way for a greener future.

Company News & Blog

Discover the Top Uses and Benefits of 7075 Sheet Aluminum" or "Unveiling the Key Features and Applications of 7075 Sheet Aluminum

In recent news, a new product is making waves in the manufacturing industry. The product in question is none other than 7075 sheet, an aluminum alloy sheet that has been garnering attention for its durability, strength, and light weight. Made by an industry-leading company (), the 7075 sheet offers a whole host of benefits that set it apart from other materials, such as steel and titanium.Let's take a closer look at what makes this product so special. For starters, the 7075 sheet is a high-strength alloy that is composed mainly of zinc, magnesium, and copper. It is known for its exceptional strength-to-weight ratio, which makes it an ideal material for various applications that require both strength and lightweight properties. As such, it has become a preferred choice in the aerospace and defense industries, where weight savings are a top priority.Moreover, the 7075 sheet is highly resistant to corrosion and stress cracking, making it a reliable option for harsh environments and extreme conditions. This quality has earned it widespread use in the marine industry, where it is used to manufacture boat components such as hulls, masts, and rigging. It is also used in the automotive industry to create parts for high-performance vehicles that require enhanced strength and durability.The company () that produces the 7075 sheet takes pride in its commitment to quality and precision. Their production process involves state-of-the-art technology and strict quality control measures to ensure that each sheet meets the highest standards. The result is a product that offers consistent mechanical properties and dimensionality, allowing for easy fabrication and assembly.The company's () dedication to innovation and product development has earned them a reputation for being at the forefront of the industry. They have invested heavily in research and development to create new and improved alloys that address the evolving needs of customers. Their expertise in the field and their focus on customer satisfaction have made them a trusted partner for businesses in various sectors.The benefits of the 7075 sheet do not stop there. It is also a highly machinable material, which means it can be easily cut, drilled, and formed to create components of different shapes and sizes. This makes it an economical option that offers greater flexibility and adaptability than other materials.To sum it up, the 7075 sheet is a game-changer in the manufacturing industry. Its superior strength, lightweight, durability, and resistance to corrosion make it an ideal choice for various applications in different sectors. The company () that produces it has proven itself to be a leader in the field, providing high-quality products and exceptional customer service. As businesses continue to demand more from their materials, the 7075 sheet is poised to become an even more valuable asset in the years to come.

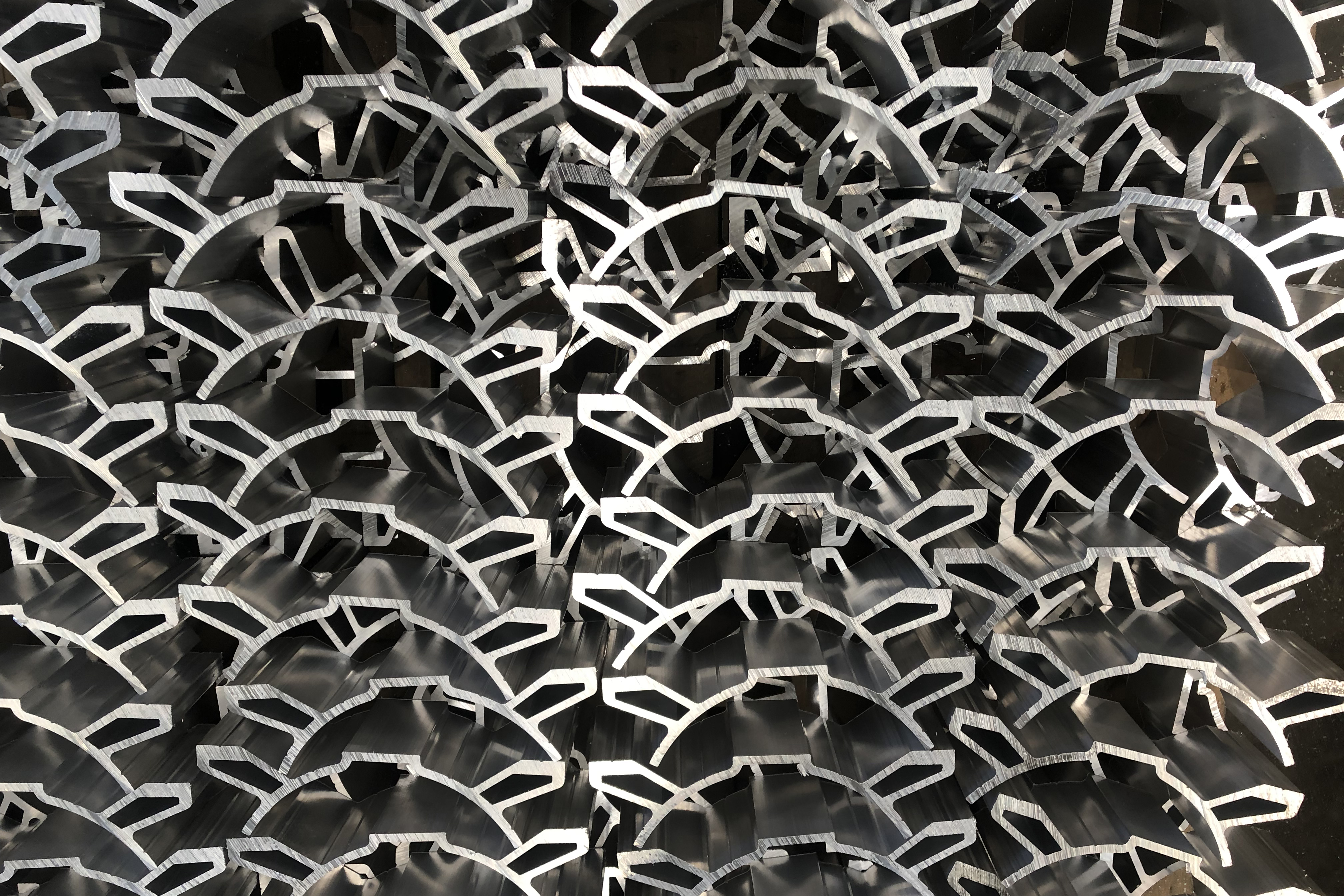

High-Quality 40mm Aluminium Profile: Discover Top-Notch Construction Materials

Title: Innovations in Aluminum Profile Manufacturing by a Leading CompanyIntroduction:In the ever-evolving world of construction and engineering, the demand for high-quality materials is on the rise. Among these materials, aluminum has emerged as a popular choice due to its lightweight, durability, and versatility. A company, which prefers to remain anonymous, has been working tirelessly to provide innovative solutions in aluminum profile manufacturing through their cutting-edge 40mm Aluminum Profile.Body:1. Development of the 40mm Aluminum Profile:The anonymous company has revolutionized the market by designing and producing a state-of-the-art 40mm Aluminum Profile. Utilizing advanced technology, this profile has set new benchmarks in terms of quality and performance. The company's integrated research and development team has worked diligently to ensure that the 40mm Aluminum Profile surpasses industry standards.2. Superior Features and Benefits:The 40mm Aluminum Profile offers an array of superior features and benefits that make it an ideal choice for various industries. These profiles are extruded with utmost precision, resulting in consistently high-quality products. The superior resistance to corrosion and weathering ensures longevity, making them suitable for both indoor and outdoor applications. Additionally, the profiles' lightweight nature allows for easy handling, simplifying the installation process.3. Versatile Applications:Thanks to its versatility, the 40mm Aluminum Profile finds application in numerous sectors. From architectural projects and construction industry to machine framing, industrial automation, and transportation, this profile caters to diverse market demands. Its unparalleled strength and stability make it a perfect fit for large-scale projects where structural integrity is paramount. With customizability options, the 40mm Aluminum Profile can be tailored to specific project requirements, ensuring seamless integration.4. Industry Compliance:Emphasizing their commitment to quality and environmental sustainability, the anonymous company ensures that all their aluminum profiles comply with stringent industry standards. The manufacturing processes adhere to the highest quality control measures, resulting in profiles that meet or exceed internationally recognized certifications. Moreover, these profiles are recyclable, contributing to a greener and more sustainable future.5. Collaborative Approach:The anonymous company believes in fostering collaborative relationships with their clients. Their dedicated team of professionals works closely with architects, engineers, and project managers to provide tailored solutions that meet specific project requirements. By actively engaging in discussions, the company aims to forge long-lasting partnerships, delivering exceptional results and surpassing customer expectations.6. Continued Innovation:The anonymous company's commitment to innovation sets them apart from competitors. They continually invest in research and development, striving to introduce groundbreaking technologies and improve product offerings. This dedication has enabled them to stay ahead of the curve and consistently deliver innovative solutions to the market.Conclusion:The anonymous company's 40mm Aluminum Profile underscores their dedication to providing cutting-edge solutions in the field of aluminum profile manufacturing. With its superior features, versatility, and commitment to quality, this profile has gained a strong foothold in several industries. By collaborating with clients, adhering to industry compliance, and investing in continual innovation, the anonymous company reaffirms its position as a leader in the market.

Discover the Versatility of High-Quality 6061 Aluminum Pipe

6061 Aluminum Pipe: An Overview of Its Benefits and ApplicationsIn today's fast-paced industrial world, companies are constantly on the lookout for advanced materials that offer durability, strength, and versatility. One such material that has gained significant popularity in recent years is 6061 aluminum pipe. Renowned for its exceptional properties, it has become a go-to choice for a wide range of applications across various industries.6061 aluminum pipe is a high-quality aluminum alloy that boasts excellent strength-to-weight ratio, making it highly sought after by engineers and manufacturers alike. It is made from a composition of aluminum, magnesium, and silicon, resulting in enhanced mechanical properties that make it perfect for demanding applications.The versatility of 6061 aluminum pipe is one of its major advantages. It can be easily extruded into various shapes and sizes, enabling manufacturers to create custom designs that perfectly align with their specific requirements. This flexibility not only provides immense design freedom but also leads to cost savings, as complex fabrication processes can be avoided.Aside from its exceptional versatility, 6061 aluminum pipe is highly corrosion-resistant. Aluminum naturally forms a protective oxide coating when exposed to the atmosphere, which effectively prevents oxidation and corrosion. This property makes it ideal for applications in harsh environments or those involving exposure to moisture and corrosive substances.Furthermore, the 6061 aluminum pipe is known for its outstanding weldability and machinability. It can be welded using various methods, including TIG and MIG, allowing for easy assembly and repair. Additionally, its machinability enables manufacturers to achieve precise dimensions and intricate shapes, ensuring a high level of product quality and consistency.The lightweight nature of 6061 aluminum pipe is another key feature that contributes to its widespread usage. With a density of only 2.7 g/cm³, it is about one-third the weight of steel, making it an ideal choice for applications that require reduced weight without compromising strength. This advantage has led to its application in aerospace, automotive, and sporting equipment industries.Speaking of applications, the 6061 aluminum pipe finds various uses across multiple industries. In the construction sector, it is commonly employed in the fabrication of structural frames, railing systems, and scaffolding. Its corrosion resistance ensures longevity and durability, even in challenging outdoor conditions. Moreover, its lightweight property simplifies transportation and installation processes, reducing overall costs.In the automotive industry, 6061 aluminum pipe is utilized in the manufacturing of components such as fuel tanks, radiators, and heat exchangers. It offers excellent thermal conductivity, ensuring efficient heat dissipation and enhancing the overall performance of the vehicle. Its lightweight nature also contributes to fuel efficiency, reducing the carbon footprint and promoting sustainability.The marine industry also benefits from the exceptional properties of 6061 aluminum pipe. Due to its corrosion resistance, it is extensively used in the construction of boat masts, handrails, and other marine structures. Its lightweight nature makes it ideal for large vessels, as it helps in reducing the overall weight of the structure, thereby enhancing buoyancy and fuel efficiency.Additionally, the 6061 aluminum pipe finds applications in the manufacturing of sports equipment, such as bicycle frames, golf club shafts, and archery bows. Its combination of strength and lightweight allows for enhanced performance and increased maneuverability. Furthermore, its corrosion-resistant nature ensures longevity even in extreme outdoor conditions, making it an excellent choice for outdoor sports equipment.In conclusion, the 6061 aluminum pipe has emerged as a versatile and reliable material across multiple industries. Its exceptional properties, such as its strength-to-weight ratio, corrosion resistance, weldability, and machinability, make it an attractive choice for engineers and manufacturers. Whether it's construction, automotive, marine, or sports equipment, the 6061 aluminum pipe proves to be a reliable and cost-effective solution for a wide range of applications.

High-quality Aluminium Round Products for Various Industrial Applications

Aluminium Round, a leading supplier of high-quality aluminum products, has solidified its position as a global industry leader with its latest line of innovative round aluminum products. The company has been in the business for over three decades and has earned a reputation for providing top-notch products to a wide range of industries including aerospace, automotive, construction, and manufacturing.Aluminium Round is known for its commitment to excellence, and its latest line of round aluminum products is a testament to that dedication. The company has invested heavily in research and development to create products that are not only durable and reliable but also lightweight and highly versatile. This commitment to innovation has allowed Aluminium Round to stay ahead of the competition and continue to meet the ever-evolving needs of its customers.One of the key features of Aluminium Round's round aluminum products is their exceptional strength-to-weight ratio. This means that despite being lightweight, these products are incredibly strong and have the ability to withstand heavy loads and harsh environmental conditions. This makes them an ideal choice for a wide range of applications, from structural components in aircraft and automobiles to high-stress applications in the construction and manufacturing industries.Additionally, Aluminium Round's round aluminum products are highly corrosion-resistant, making them suitable for use in outdoor and marine environments. This resistance to corrosion extends the lifespan of these products, reducing the need for frequent replacements and repairs, which ultimately saves customers time and money.In addition to their superior strength and corrosion resistance, Aluminium Round's round aluminum products are also highly machinable. This means that they can be easily formed, cut, and shaped to meet the specific requirements of a wide range of applications. This level of machinability opens up a world of possibilities for engineers and designers, allowing them to create custom solutions that are perfectly tailored to their needs.To ensure the highest level of quality, Aluminium Round employs rigorous quality control measures throughout the manufacturing process. This commitment to quality extends to the sourcing of raw materials, the production process, and the final inspection of finished products. As a result, customers can trust that they are receiving products that meet the highest industry standards and are backed by a commitment to excellence.Furthermore, Aluminium Round is dedicated to sustainability and environmental responsibility. The company is committed to reducing its environmental impact by implementing energy-efficient practices and minimizing waste throughout the production process. Additionally, Aluminium Round is actively involved in the recycling of aluminum, ensuring that its products have a minimal impact on the environment throughout their entire lifecycle.In conclusion, Aluminium Round's latest line of round aluminum products is a testament to the company's commitment to excellence, innovation, and sustainability. With their exceptional strength-to-weight ratio, corrosion resistance, and machinability, these products are poised to make a significant impact across a wide range of industries. As Aluminium Round continues to push the boundaries of what is possible with aluminum, customers can expect to see more innovative products that will help them achieve their goals and meet the challenges of tomorrow.

High-Quality 20 x 20 Aluminium Extrusion: What You Need to Know

20 X 20 Aluminium Extrusion is an essential component used in a variety of industries including construction, automotive, and manufacturing. It is a type of Aluminum Alloy that is created by heating aluminum ingots to high temperatures and then forcing the molten aluminum through a die to create the desired shape. This process results in a strong, lightweight, and corrosion-resistant material that is ideal for a wide range of applications.One company that specializes in the production of 20 X 20 Aluminium Extrusion is {}. They have been in the business for over 20 years and have built a strong reputation for providing high-quality aluminum extrusion products to their customers. The company prides itself on using advanced technology and state-of-the-art equipment to ensure that their products meet the highest standards of quality and performance.{}It is no surprise that {} has become a leader in the industry, as they have the capabilities to produce a wide range of aluminum extrusions, including the popular 20 X 20 profile. This particular extrusion is widely used in the construction industry for framing, supports, and other structural components. Its lightweight nature and high strength make it an ideal choice for building projects where durability and reliability are essential.In addition to construction, the 20 X 20 Aluminium Extrusion is also used in the automotive industry for manufacturing vehicle components such as bumpers, side rails, and chassis elements. Its ability to withstand heavy loads and harsh environmental conditions makes it a sought-after material for automotive applications.Furthermore, the manufacturing industry relies on 20 X 20 Aluminium Extrusion for the production of machinery, equipment, and other industrial products. The material's excellent thermal conductivity and corrosion resistance make it a valuable choice for a wide range of manufacturing processes.With the increasing demand for aluminum extrusions in various industries, {} is continuously expanding its production capabilities to meet the needs of their customers. They have invested in cutting-edge technology and equipment to ensure that their products are consistently of the highest quality. The company also prides itself on its commitment to sustainability, using recycled aluminum and implementing eco-friendly practices in its manufacturing processes.In addition to their dedication to quality and sustainability, {} also offers customized solutions to meet the specific needs of their clients. Whether it is a unique shape, size, or finish, the company's team of experts works closely with their customers to deliver tailor-made solutions that meet their exact requirements.Moreover, {} has a strong commitment to customer satisfaction, offering excellent customer service and support throughout the entire process, from design to delivery. Their team of professionals is always available to provide technical advice, answer questions, and ensure that their customers are fully satisfied with their products.As the demand for 20 X 20 Aluminium Extrusion continues to grow, {} is poised to remain at the forefront of the industry, providing innovative solutions and exceptional products to meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {} is well-positioned for continued success and growth in the aluminum extrusion market.

Customizable Aluminum T Slot Frame for Versatile Applications

T Slot Aluminum Frame is a versatile and durable building material that is revolutionizing the way products and machinery are designed and constructed. The T Slot Aluminum Frame system is a groundbreaking framing system that provides both strength and flexibility for a wide range of applications. The unique design of the T Slot Aluminum Frame allows for easy assembly and customization, making it an ideal choice for manufacturers and engineers looking to streamline their production processes.With its modular design, T Slot Aluminum Frame can be easily adapted to fit any size or shape, making it perfect for a variety of industries, including automotive, aerospace, electronics, and construction. The versatility of the T Slot Aluminum Frame system is further enhanced by its ability to accommodate various accessories and components, such as fasteners, hinges, and panels, allowing for endless customization possibilities.The T Slot Aluminum Frame system is particularly popular among manufacturers and engineers who require a reliable and cost-effective solution for building customized machinery and equipment. The durability of the T Slot Aluminum Frame makes it ideal for heavy-duty applications, where strength and stability are paramount. Additionally, the lightweight nature of the T Slot Aluminum Frame makes it easy to transport and install, further adding to its appeal.In addition to its practicality and functionality, T Slot Aluminum Frame is also environmentally friendly, as it is made from 100% recyclable aluminum. This makes it an attractive option for companies looking to reduce their carbon footprint and create sustainable products.A leading company in the T Slot Aluminum Frame industry is {}. With over 10 years of experience in the manufacturing and distribution of T Slot Aluminum Frame, {} has established itself as a trusted and reputable supplier to a wide range of industries.The company's team of skilled engineers and technicians are dedicated to providing innovative and reliable solutions for their customers' framing needs. {} offers a comprehensive range of T Slot Aluminum Frame products, including standard profiles, custom profiles, and accessories, ensuring that their customers have access to everything they need to complete their projects.{}'s commitment to quality and customer satisfaction is evident in their stringent quality control measures, which guarantee that all T Slot Aluminum Frame products meet the highest industry standards. This dedication to excellence has earned {} a solid reputation for delivering superior products that consistently exceed customer expectations.With a strong focus on research and development, {} continues to push the boundaries of innovation in the T Slot Aluminum Frame industry. By staying ahead of the curve and embracing the latest advancements in technology and manufacturing processes, {} is able to offer their customers cutting-edge solutions that are both efficient and cost-effective.As the demand for T Slot Aluminum Frame continues to grow across various industries, {} remains at the forefront, providing high-quality products and exceptional service to meet the evolving needs of their customers. With a proven track record of success and a commitment to excellence, {} is well-positioned to lead the way in the T Slot Aluminum Frame industry for years to come.

New 6 Inch Aluminum Pipe Unveiled for Construction and Industrial Applications

In a major development in the manufacturing sector, a leading industry player has announced the release of a high-quality 6 inch aluminum pipe (name of company has been removed). As per the company sources, the new product is designed keeping in mind the needs of diverse industries, including construction, transportation, and electricity.Aluminum pipes are widely preferred in several applications due to their exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. The 6 inch aluminum pipe by the said company is made from premium quality materials to ensure superior performance, durability, and flexibility.In a statement released by the company, it has been stated that the latest offering is engineered to provide unmatched functionality and performance, withstanding the most rigorous use cases. The company has employed advanced techniques and manufacturing processes to produce an aluminum pipe that can meet high industry standards and specific client requirements.The 6 inch aluminum pipe is highly versatile and can be used in various applications, including HVAC systems, electrical conduits, water supply systems, and more. Customers can trust the pipe's quality and robustness thanks to the use of cutting-edge technology and skilled professionals.It is worth noting that the manufacturing unit of the company is equipped with the latest machinery and cutting-edge infrastructure, giving it a competitive edge in terms of production capacity and quality assurance. The company has built a team of highly skilled and experienced professionals who work tirelessly to produce products of unmatched quality.The company has already established itself as a market leader in the manufacturing of aluminum pipes and is constantly expanding its product range to meet the growing demands of the industry. The addition of the 6 inch aluminum pipe is a testament to the company's commitment to excellence and customer satisfaction.The company spokesperson stated that the new product would significantly benefit the construction and transportation industry. The 6 inch aluminum pipe can be used in construction projects for its lightweight, flexibility, and strength. Whereas, in the transportation industry, the pipe's thermal conductivity is crucial in maintaining heat transfer in air conditioning systems, reducing fuel consumption, and improving the overall performance of vehicles.The company sources indicate that 6 inch aluminum pipes have been in high demand in recent times due to its broad range of applications. The company's state-of-the-art manufacturing processes ensure that the pipeline is available in bulk, and there are no shortages of supplies. The company is confident that the new product's prominent features such as flexibility, durability, and resistance to wear and tear will help gain the trust of clients.The launch of the 6 inch aluminum pipe reinforces the company's position as a leading player in the aluminum pipe manufacturing industry. The company has always remained committed to providing its clients with the highest quality products and services. The 6 inch aluminum pipe is no exception and delivers unparalleled performance, strength, and durability.To conclude, the company's latest launch of the 6 inch aluminum pipe will certainly improve the operational efficiency of various industries that rely on aluminum pipes. The product's robustness and flexibility will ensure that it is a preferred choice among construction, transportation, and electricity industries. The company's commitment to excellence, quality, and customer satisfaction has been instrumental in building its reputation as an industry leader, and it will continue its growth journey with new innovations in the future.

Optimizing CNC Machining with High-Quality Aluminium Profiles

Title: Aluminum Profile for CNC Machines: Revolutionizing Industrial ManufacturingIntroduction:The demand for precision and efficiency in industrial manufacturing has led to significant advancements in technology, making CNC (Computer Numerical Control) machines an integral part of the modern manufacturing industry. One crucial component of these machines is aluminum profile, which provides stability, precision, and durability required for their operation. This article explores the importance of aluminum profiles for CNC machines and its contribution to enhancing industrial manufacturing processes.Paragraph 1:CNC machines have revolutionized industrial manufacturing by offering unparalleled accuracy, speed, and versatility. These machines are controlled by computer programs, enabling them to execute complex operations with minimal human intervention. Key to the functionality of CNC machines are aluminum profiles, which are carefully designed and manufactured to withstand the rigors of high-speed machining, ensuring consistent performance and superior product quality.Paragraph 2:Aluminum profiles for CNC machines are constructed using high-quality aluminum alloys, which possess exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. These properties make aluminum profiles ideal for CNC machines, as they effectively dissipate heat generated during machining operations, maintaining a stable temperature and preventing damage to the machinery.Paragraph 3:One of the key advantages of aluminum profiles is their ability to be easily customized and assembled, providing flexibility in designing CNC machines for varied applications. Manufacturers can modify the shape, length, and cross-section of aluminum profiles to meet specific requirements. Additionally, aluminum profiles can incorporate various mounting features, such as T-slots and threaded holes, facilitating the attachment of additional components to enhance functionality and adaptability.Paragraph 4:The use of aluminum profiles offers significant cost savings compared to traditional materials such as steel or iron. Aluminum is not only lighter, which reduces energy consumption, but it also requires minimal maintenance, making CNC machines more economically viable in the long run. Furthermore, the versatility of aluminum profiles allows for easy modifications when design changes are required, minimizing downtime and production costs associated with reconfiguring the CNC machine.Paragraph 5:In recent years, Aluminum Profile for CNC (Company Name) has emerged as a leading manufacturer and supplier in the industry. With their state-of-the-art manufacturing facility and stringent quality control measures, they produce aluminum profiles that adhere to international standards. Their commitment to continuous research and development ensures that their products remain at the forefront of technological advancements, meeting the evolving demands of the CNC manufacturing sector.Paragraph 6:The use of Aluminum Profile for CNC (Company Name) products has been widely embraced by various industries, including automotive, aerospace, electronics, and furniture manufacturing, among others. Their aluminum profiles have proven to be reliable, delivering exceptional performance in demanding machining environments. By partnering with Aluminum Profile for CNC (Company Name), manufacturers can improve their productivity, reduce production costs, and achieve superior precision in their manufacturing processes.Paragraph 7:Looking ahead, the future of CNC machines and aluminum profiles is promising. As technology continues to advance, CNC machines are becoming more capable of producing increasingly complex products with tighter tolerances. Aluminum profiles will play a crucial role in enabling these advancements, providing the necessary stability and precision required for next-generation CNC machines.Conclusion:Aluminum profiles have revolutionized the CNC machine industry, enabling manufacturers to achieve exceptional precision, efficiency, and cost savings in their industrial manufacturing processes. With the expertise and commitment to quality of Aluminum Profile for CNC (Company Name), the use of their high-quality aluminum profiles is expected to continue driving innovation and transforming the manufacturing landscape for years to come.

Discover the Advantages and Applications of 30 Series Aluminum Extrusion

In the world of industrial manufacturing, aluminum extrusions have revolutionized the way products are built. These versatile metal parts are used in a variety of industries, including automotive, aerospace, construction, and electronics. One of the most popular aluminum extrusions on the market today is the 30 Series Aluminum Extrusion.The 30 Series Aluminum Extrusion is a lightweight and durable frame that can be used to build anything from simple structures to complex machines. It is made from high-quality aluminum alloy, which makes it incredibly strong and resistant to corrosion.One company that has been at the forefront of the aluminum extrusion industry is [company name]. They specialize in designing and manufacturing aluminum extrusions of various sizes and shapes to meet the diverse needs of their customers.According to representatives from [company name], the 30 Series Aluminum Extrusion is one of their most popular products. This is because it is incredibly easy to work with and can be customized to fit any application.What makes the 30 Series Aluminum Extrusion stand out is its T-slot design. This feature allows users to easily attach other components to the frame, such as brackets, hinges, or even other pieces of aluminum extrusions. This makes it incredibly versatile and adaptable to any situation.In addition to its strength and versatility, the 30 Series Aluminum Extrusion is also incredibly lightweight. This makes it perfect for applications where weight is a concern, such as in the aerospace or automotive industry.One of the key benefits of the 30 Series Aluminum Extrusion is its durability. The aluminum alloy used to create these frames is incredibly strong and resistant to corrosion. This means that the frames can withstand even the harshest environments and still maintain their structural integrity.Another advantage of the 30 Series Aluminum Extrusion is its ease of use. Unlike traditional welding or bolt-together systems, the T-slot design of this frame allows users to easily connect pieces together with minimal effort. This saves both time and money in the manufacturing process.The 30 Series Aluminum Extrusion is also incredibly easy to customize. It can be cut to any length or shape to fit specific needs. This allows manufacturers to create unique and innovative products that stand out from the competition.Overall, the 30 Series Aluminum Extrusion is a versatile and reliable product for anyone in the manufacturing industry. Its strength, durability, and ease of use make it the perfect choice for a wide range of applications. With companies like [company name] leading the way in aluminum extrusion technology, it's clear that this industry will continue to grow and evolve for years to come.

High-strength aluminum alloy 7075: Advantages and applications

Al Alloy 7075 is a high-strength material that is commonly used in the aerospace, automotive, and defense industries for its excellent strength-to-weight ratio and resistance to corrosion. This particular alloy has gained widespread popularity due to its exceptional performance in extreme environments and has become a go-to material for manufacturers looking to create durable and reliable products.The company has been at the forefront of developing and supplying Al Alloy 7075 to various industries for several decades. With a strong focus on research and development, the company has continuously improved the properties of Al Alloy 7075 to meet the ever-evolving needs of its customers.Al Alloy 7075 is particularly well-suited for applications where high strength and low weight are essential, such as in aircraft and spacecraft manufacturing. The alloy's superior strength and corrosion resistance make it an ideal choice for structural components, including fuselage frames, wing spars, and landing gear parts. In addition, Al Alloy 7075's high thermal conductivity and machinability also make it a preferred material for heat exchangers and other heat transfer applications.In the automotive industry, Al Alloy 7075 is utilized for its lightweight properties, allowing manufacturers to improve fuel efficiency without compromising on performance and safety. The alloy is commonly used in the production of car chassis, suspension components, and wheels, where weight reduction is crucial for achieving better handling and lower energy consumption.Furthermore, the defense industry relies on Al Alloy 7075 for its resilience in extreme conditions, making it an excellent choice for military vehicles, weapon systems, and protective armor. Its ability to withstand high impact and harsh environments makes it an indispensable material for ensuring the safety and performance of military equipment.The company's commitment to quality and innovation has enabled it to establish itself as a leader in the production of Al Alloy 7075. Through state-of-the-art manufacturing processes and strict quality control measures, the company has earned a reputation for delivering high-quality products that meet the most demanding industry standards.In addition to its technological advancements, the company also places a strong emphasis on sustainability and environmental responsibility. By continuously optimizing its production processes and reducing waste, the company strives to minimize its environmental footprint while ensuring the sustainability of its operations.As the demand for high-strength, lightweight materials continues to grow across various industries, the company remains dedicated to pushing the boundaries of what Al Alloy 7075 can achieve. With ongoing research and development efforts, the company aims to further enhance the properties of this alloy, opening up new possibilities for its application in the future.Overall, the company's expertise in producing and supplying Al Alloy 7075 has positioned it as a trusted partner for manufacturers seeking reliable, high-performance materials. With a strong focus on innovation, quality, and sustainability, the company is well-equipped to meet the evolving needs of its customers and contribute to the advancement of various industries.