High-Quality Extruded Aluminum Material for Your Next Project

By:Admin

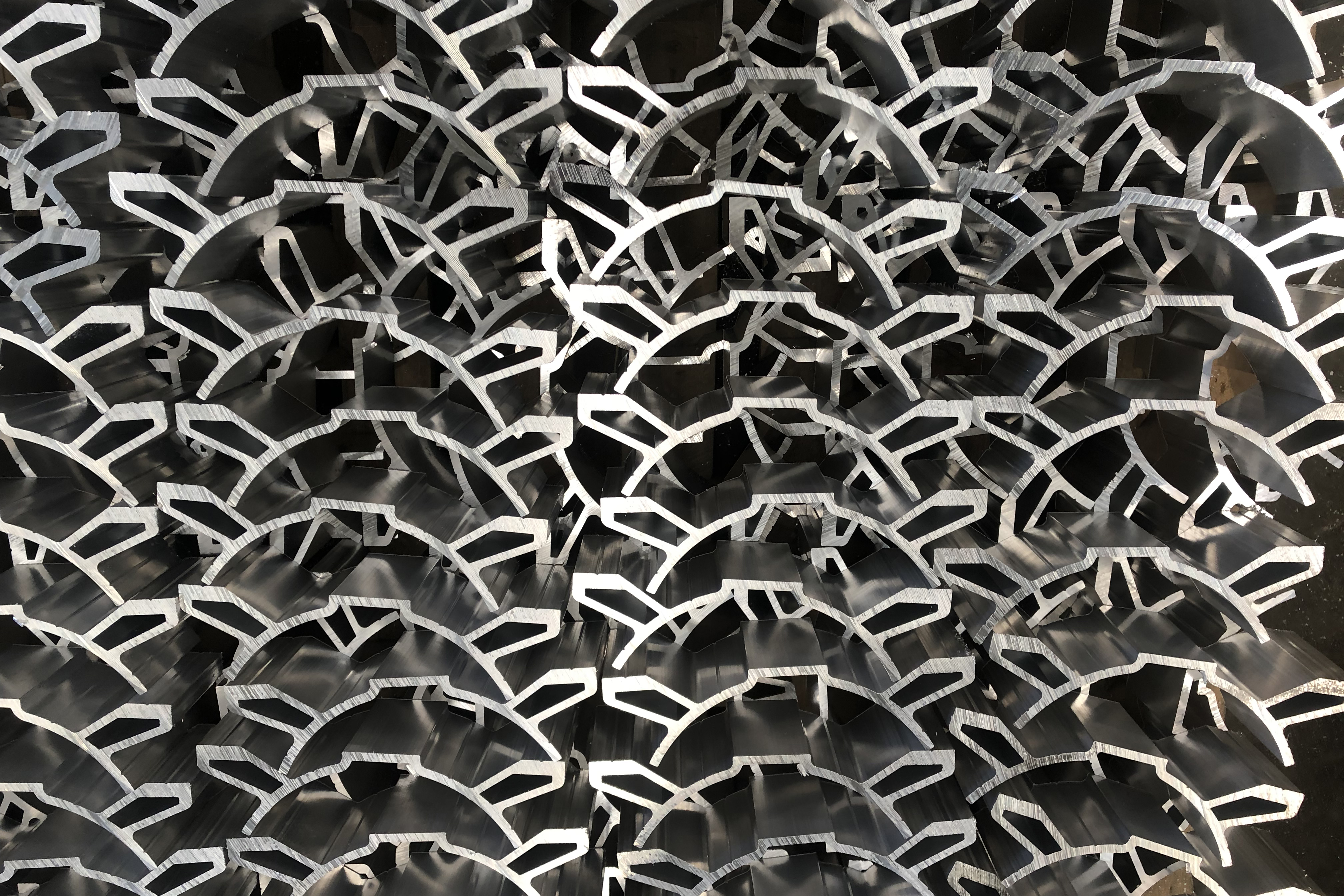

{City, Date} – The use of extruded aluminum material has become increasingly prevalent across various industries, and {Company} has emerged as a leading provider of innovative solutions that leverage the unique properties of this versatile material. With a commitment to quality, precision, and customer satisfaction, {Company} has established a strong presence in the market, offering a diverse range of products that are designed to meet the evolving needs of its clients.

Extruded aluminum material is a highly sought-after resource due to its lightweight nature, exceptional strength, and corrosion resistance. These properties make it an ideal choice for a wide array of applications, including construction, automotive, aerospace, electronics, and more. {Company} has recognized the immense potential of this material and has capitalized on its capabilities to develop cutting-edge solutions that set the company apart from its competitors.

One of the key advantages of extruded aluminum material is its ability to be shaped into complex and intricate designs with high precision. This characteristic has enabled {Company} to create a diverse portfolio of products that cater to the specific requirements of its clientele. From custom extrusions for architectural projects to intricate components for the automotive industry, {Company} has demonstrated its expertise in harnessing the full potential of extruded aluminum material.

In addition to its exceptional physical properties, extruded aluminum material is also known for its sustainability and environmental benefits. As an infinitely recyclable material, aluminum plays a crucial role in {Company’s} commitment to reducing its environmental footprint and promoting eco-friendly practices. By incorporating extruded aluminum material into its products, {Company} is aligning itself with sustainable initiatives and contributing to the global effort to mitigate the impact of industrial processes on the environment.

{Company} takes great pride in its ability to deliver tailored solutions that meet the unique needs of its clients. The company’s team of experts works closely with customers to understand their requirements and develop customized products that integrate extruded aluminum material in innovative ways. This collaborative approach has positioned {Company} as a trusted partner for businesses seeking high-quality and specialized aluminum solutions.

As a testament to its dedication to excellence, {Company} has invested in state-of-the-art manufacturing facilities and cutting-edge technologies that enable the company to produce extruded aluminum products of the highest caliber. The company’s commitment to quality control and precision engineering ensures that every product that leaves its facilities meets the most stringent standards and exceeds the expectations of its customers.

Furthermore, {Company} places a strong emphasis on research and development, constantly exploring new possibilities and pushing the boundaries of what can be achieved with extruded aluminum material. The company’s forward-thinking approach and innovative spirit have led to the creation of groundbreaking products that have significantly impacted the industries it serves.

In conclusion, {Company} has established itself as a frontrunner in the utilization of extruded aluminum material for a wide range of applications. By leveraging the unique properties of this versatile material and combining it with advanced engineering and design expertise, {Company} has positioned itself as a leading provider of innovative aluminum solutions. With a steadfast commitment to quality, sustainability, and customer satisfaction, {Company} continues to set new benchmarks in the industry and remains a trusted partner for businesses seeking superior extruded aluminum products.

For more information about {Company} and its innovative product line, please visit {company website}.

Company News & Blog

Top-Quality CNC Aluminum Parts for Your Manufacturing Needs

Title: Leading Manufacturer Introduces State-of-the-Art CNC Aluminum PartsIntroduction:In an era of rapid technological advancements, precision engineering has become a vital aspect of various industries. One company that has continuously pushed the boundaries of precision manufacturing is internationally renowned (Company Name). With a reputation for excellence, (Company Name) has recently unveiled a revolutionary range of CNC Aluminum Parts. These cutting-edge components are set to transform various industries by providing unparalleled versatility, durability, and exceptional performance.I. Meeting Industry Demands:The introduction of the new CNC Aluminum Parts signifies (Company Name)'s commitment to meeting the ever-evolving demands of industries such as aerospace, automotive, electronics, and more. These industries require high-quality components that offer reliability, exceptional precision, and optimal strength-to-weight ratios. (Company Name)'s CNC Aluminum Parts prove to be the solution to these demands by combining state-of-the-art technology with an unmatched attention to detail.II. Groundbreaking Technology:(Credentials) have been at the forefront of precision manufacturing for over (number of years) and have implemented a myriad of cutting-edge technologies. Their CNC Aluminum Parts are no exception. Utilizing advanced computer numerical control (CNC) machines, the company is able to ensure accuracy within micrometers, resulting in components that exceed industry standards. This level of precision allows applications in critical fields where even the slightest variance can have significant consequences.III. Diverse Applications:The new range of CNC Aluminum Parts is designed to cater to various industries, offering unparalleled versatility and performance. For the aerospace industry, these components find applications in aircraft structural parts, landing gears, and engine components. In the automotive industry, they enable the production of lightweight yet rigid parts, enhancing fuel efficiency and overall performance. Electronics manufacturers benefit from the superior thermal conductivity and electromagnetic shielding capabilities of the CNC Aluminum Parts, making them ideal for circuit boards and housing components.IV. Unmatched Quality Assurance:(Credentials) understands the importance of quality assurance for critical applications. Their CNC Aluminum Parts undergo rigorous testing and inspection processes to ensure compliance with industry standards. Advanced x-ray inspection technology is deployed to detect internal flaws, while precise measurements are conducted using Coordinate Measuring Machines (CMM). By adhering to these stringent processes, (Company Name) guarantees the consistent delivery of top-tier quality components.V. Environmental Sustainability:Apart from meeting industry demands, (Company Name) is actively committed to promoting environmental sustainability. The CNC Aluminum Parts are manufactured using eco-friendly techniques that minimize waste and carbon emissions. The lightweight nature of aluminum also contributes to reduced fuel consumption in industries where weight reduction is crucial, such as automotive and aerospace applications. Moreover, (Company Name) actively explores recycling and reuse methods to minimize environmental impact throughout the manufacturing process.VI. Global Impact:With clients spanning across continents, (Company Name)'s revolutionary CNC Aluminum Parts are set to make a global impact. Their presence in the international market ensures that industries worldwide can benefit from the precision, durability, and versatility these components offer. By partnering with (Company Name), manufacturers worldwide gain access to cutting-edge technology and unparalleled support, enabling them to stay competitive in their respective markets.Conclusion:(Credentials) continue to drive innovation within the precision engineering industry with their latest introduction of CNC Aluminum Parts. Catering to diverse industries, these components not only meet industry demands but also set new standards for performance, durability, and environmental sustainability. As (Company Name) consistently demonstrates their commitment to excellence, it is clear that their revolutionary CNC Aluminum Parts will shape the future of precision manufacturing on a global scale.

Discover the Top Uses and Benefits of 7075 Sheet Aluminum" or "Unveiling the Key Features and Applications of 7075 Sheet Aluminum

In recent news, a new product is making waves in the manufacturing industry. The product in question is none other than 7075 sheet, an aluminum alloy sheet that has been garnering attention for its durability, strength, and light weight. Made by an industry-leading company (), the 7075 sheet offers a whole host of benefits that set it apart from other materials, such as steel and titanium.Let's take a closer look at what makes this product so special. For starters, the 7075 sheet is a high-strength alloy that is composed mainly of zinc, magnesium, and copper. It is known for its exceptional strength-to-weight ratio, which makes it an ideal material for various applications that require both strength and lightweight properties. As such, it has become a preferred choice in the aerospace and defense industries, where weight savings are a top priority.Moreover, the 7075 sheet is highly resistant to corrosion and stress cracking, making it a reliable option for harsh environments and extreme conditions. This quality has earned it widespread use in the marine industry, where it is used to manufacture boat components such as hulls, masts, and rigging. It is also used in the automotive industry to create parts for high-performance vehicles that require enhanced strength and durability.The company () that produces the 7075 sheet takes pride in its commitment to quality and precision. Their production process involves state-of-the-art technology and strict quality control measures to ensure that each sheet meets the highest standards. The result is a product that offers consistent mechanical properties and dimensionality, allowing for easy fabrication and assembly.The company's () dedication to innovation and product development has earned them a reputation for being at the forefront of the industry. They have invested heavily in research and development to create new and improved alloys that address the evolving needs of customers. Their expertise in the field and their focus on customer satisfaction have made them a trusted partner for businesses in various sectors.The benefits of the 7075 sheet do not stop there. It is also a highly machinable material, which means it can be easily cut, drilled, and formed to create components of different shapes and sizes. This makes it an economical option that offers greater flexibility and adaptability than other materials.To sum it up, the 7075 sheet is a game-changer in the manufacturing industry. Its superior strength, lightweight, durability, and resistance to corrosion make it an ideal choice for various applications in different sectors. The company () that produces it has proven itself to be a leader in the field, providing high-quality products and exceptional customer service. As businesses continue to demand more from their materials, the 7075 sheet is poised to become an even more valuable asset in the years to come.

Aluminum Extrusion Case: A High-Quality Solution for Your Needs

Aluminum Extrusion Case Revolutionizing the Industrial SectorIn the fast-paced and competitive world of industrial manufacturing, innovation and efficiency are key to success. With this in mind, [Company Name] has introduced a groundbreaking Aluminum Extrusion Case that is set to revolutionize the industry.Aluminum extrusion is a process used to create complex and intricate shapes by forcing aluminum alloy through a die. This process allows for the creation of lightweight yet sturdy components that are vital in a wide range of industrial applications.[Company Name] is a leading supplier of aluminum extrusion products, and their new Aluminum Extrusion Case is a testament to their commitment to innovation and cutting-edge technology. This new product is designed to meet the demands of modern industrial applications, offering a lightweight and durable solution for the transportation and protection of valuable equipment and components.The Aluminum Extrusion Case from [Company Name] is manufactured using high-quality aluminum alloy, ensuring that it is lightweight and easy to handle while maintaining a high level of strength and durability. The extrusion process allows for the creation of custom shapes and dimensions, making the case versatile and adaptable to the specific needs of each customer.With a strong focus on design and engineering, [Company Name] has ensured that the Aluminum Extrusion Case offers a range of features to enhance its practicality and usability. These include customizable foam inserts to securely hold and protect valuable equipment, as well as a variety of latching and locking mechanisms to ensure the safety and security of the case's contents.The introduction of the Aluminum Extrusion Case from [Company Name] is set to have a significant impact on the industrial sector. Its lightweight and durable construction makes it an ideal solution for the transportation and protection of a wide range of equipment, from delicate electronic components to heavy-duty machinery.Furthermore, the ability to customize the shape and dimensions of the case makes it a versatile option for a variety of applications, from aerospace and automotive to medical and defense industries. This level of customization allows customers to tailor the case to their specific needs, ensuring the utmost protection for their valuable equipment.In addition to its practical features, the Aluminum Extrusion Case from [Company Name] is also environmentally friendly. Aluminum is fully recyclable, making it a sustainable and eco-friendly material choice for industrial applications. Furthermore, the lightweight nature of the case reduces fuel consumption during transportation, contributing to a greener and more sustainable industrial sector."We are thrilled to introduce our new Aluminum Extrusion Case to the market," said [Company Name] CEO. "This product represents the culmination of our commitment to innovation and excellence in the industrial sector. We believe that the Aluminum Extrusion Case will set new standards for transportation and protection of valuable equipment, and we are excited to see the positive impact it will have on our customers' operations."The launch of the Aluminum Extrusion Case from [Company Name] comes at a time when the industrial sector is becoming increasingly reliant on lightweight yet durable solutions for transportation and protection of equipment. With its innovative design, customizable features, and sustainability, this new product is set to meet and exceed the demands of modern industrial applications, solidifying [Company Name]'s position as a leader in the industry.As the industrial sector continues to evolve and adapt to new challenges, the introduction of the Aluminum Extrusion Case signifies a significant milestone in the pursuit of innovation and efficiency. With its advanced features and practical benefits, this new product is set to play a pivotal role in shaping the future of industrial transportation and equipment protection.

Aluminum Punching: The Latest in Precision Technology

Precision Aluminum Punching, a leading provider of aluminum punching services, has announced the expansion of its production capabilities to meet the growing demand for high-quality aluminum components in various industries.The company, known for its expertise in precision machining and fabrication, has invested in state-of-the-art equipment and technology to enhance its punching capabilities. This expansion is part of the company's commitment to maintaining its position as a top supplier of aluminum components for a wide range of applications, including automotive, aerospace, electronics, and construction.Precision Aluminum Punching specializes in the manufacturing of custom aluminum parts, utilizing advanced punching techniques to create precise and intricate designs. With the latest advancements in punching technology, the company is able to offer its customers a wider range of options for their aluminum component needs, including increased precision, tighter tolerances, and faster production times."Our investment in expanding our aluminum punching capabilities reflects our dedication to providing our customers with the highest quality products and services," said the spokesperson for Precision Aluminum Punching. "We understand the increasing demand for aluminum components in various industries, and we are committed to meeting and exceeding our customers' expectations."The company's expanded punching capabilities allow for the production of complex aluminum parts with enhanced precision and efficiency. This will enable Precision Aluminum Punching to cater to the evolving needs of its customers, offering customized solutions for their specific applications.In addition to its advanced punching capabilities, Precision Aluminum Punching also offers a range of secondary operations, including deburring, drilling, tapping, and assembly. This comprehensive approach allows the company to provide its customers with a complete solution for their aluminum component needs, from initial design and prototyping to full-scale production.The company's dedication to quality and precision is further demonstrated through its commitment to compliance with industry standards and regulations. Precision Aluminum Punching adheres to strict quality control measures throughout the manufacturing process, ensuring that all parts meet the highest standards of accuracy and performance.With its expanded punching capabilities, Precision Aluminum Punching is well-positioned to serve a diverse range of industries that rely on aluminum components for their products and systems. Whether it's for lightweight automotive parts, durable aerospace components, or critical electronic enclosures, the company is equipped to deliver precision-machined aluminum parts that meet the most demanding specifications.As the demand for aluminum components continues to grow across various industries, Precision Aluminum Punching is poised to be a trusted partner for companies seeking reliable and high-quality manufacturing solutions. The company's investment in advanced punching technology underscores its commitment to innovation and excellence, solidifying its position as a premier provider of precision-machined aluminum parts.The expansion of its punching capabilities is just one example of Precision Aluminum Punching's ongoing commitment to meeting the evolving needs of its customers and the industries it serves. With its dedication to quality, precision, and customer satisfaction, the company is well-prepared to continue its leadership in the manufacturing of custom aluminum components for years to come.

High-Quality Aluminum Extrusion Cutting Machine for Precision Cuts

Aluminum Extrusion Cutting Machine revolutionizes the manufacturing industryIn the ever-evolving manufacturing industry, the demand for efficient and precise machinery is constantly on the rise. With the introduction of the Aluminum Extrusion Cutting Machine by [Company Name], this demand is being met with unparalleled quality and innovation. This cutting-edge machine has set a new standard for aluminum extrusion cutting, providing manufacturers with an efficient and cost-effective solution for their cutting needs.[Company Name] is a leading manufacturer of industrial machinery and equipment, specializing in the development and production of cutting-edge solutions for the manufacturing industry. With a strong focus on innovation and customer satisfaction, the company has established a reputation for delivering high-quality products that meet the diverse needs of their clients.The Aluminum Extrusion Cutting Machine is the latest addition to [Company Name]'s impressive portfolio of machinery. It has been designed to provide manufacturers with a versatile and efficient solution for cutting aluminum extrusions. With its advanced technology and precision engineering, this machine is capable of handling a wide range of cutting tasks, from simple straight cuts to complex angles and shapes.One of the key features of the Aluminum Extrusion Cutting Machine is its high-speed cutting capabilities. Equipped with state-of-the-art cutting tools and a powerful motor, the machine can achieve fast and accurate cuts, increasing productivity and reducing production time. This is particularly beneficial for manufacturers with high-volume production requirements, as it allows them to meet their production targets with ease.In addition to its speed, the machine also offers exceptional precision and accuracy. Its advanced cutting mechanisms and computerized controls ensure that each cut is executed with the utmost precision, resulting in clean and seamless edges. This level of precision is essential for manufacturers who require high-quality finishes for their products, as it helps to enhance the overall aesthetic and functionality of the aluminum extrusions.Furthermore, the Aluminum Extrusion Cutting Machine has been designed with user-friendliness in mind. Its intuitive interface and user-friendly controls make it easy to operate, even for operators with limited experience. This not only reduces the need for extensive training but also minimizes the risk of human error, ensuring consistent and reliable cutting results.Additionally, the machine has been built to withstand the rigors of industrial use, with a durable construction and robust components that can handle the demands of a busy manufacturing environment. This ensures longevity and reliability, providing manufacturers with a long-term cutting solution that can withstand the test of time.The introduction of the Aluminum Extrusion Cutting Machine by [Company Name] has already made a significant impact on the manufacturing industry. Manufacturers around the world are embracing this cutting-edge technology as a solution to their aluminum extrusion cutting needs, and the machine has received rave reviews for its performance and efficiency.In conclusion, the Aluminum Extrusion Cutting Machine by [Company Name] is shaping the future of aluminum extrusion cutting. With its cutting-edge technology, precision engineering, and user-friendly design, it offers manufacturers a versatile, efficient, and cost-effective solution for their cutting needs. As the manufacturing industry continues to evolve, [Company Name] remains at the forefront, delivering innovative solutions that set new standards for quality and performance.

Durable and Stylish Aluminum Tile Trim for Your Home Renovation

Tile Trim Aluminum is a lightweight and durable option for edge protection and finishing for tiled surfaces. The company has been a leading manufacturer and supplier of construction products and solutions for over a decade, providing high-quality products to customers around the world.With a focus on innovation and quality, the company has become a trusted name in the construction industry. Their tile trim aluminum products are designed to provide a clean and professional finish to tiled edges, while also protecting them from damage and wear over time.One of the key advantages of tile trim aluminum is its lightweight and easy-to-install nature. This makes it a popular choice for both professional contractors and DIY enthusiasts. The company offers a wide range of profiles and finishes to suit different tile types and design preferences, ensuring that customers can find the perfect solution for their projects.In addition to its aesthetic appeal, tile trim aluminum also offers functional benefits. It helps to prevent tiles from chipping or cracking at the edges, providing added durability and longevity to tiled surfaces. This makes it an essential component for ensuring the overall quality and longevity of tiling projects.The company's commitment to quality is reflected in its manufacturing processes. Each tile trim aluminum product undergoes rigorous testing and quality control measures to ensure that it meets the highest standards. This dedication to excellence has earned the company a reputation for reliability and performance in the industry.Furthermore, the company's customer-focused approach sets it apart in the market. They offer comprehensive support to customers, from product selection to installation guidance, ensuring that they have all the information and assistance they need to complete their projects successfully. This level of service has helped to foster strong and lasting relationships with customers who trust the company for their construction needs.In addition to its tile trim aluminum products, the company also offers a wide range of other construction solutions, including tile adhesives, grouts, and waterproofing products. This comprehensive product offering allows customers to source all their construction needs from a single, reliable supplier, streamlining the procurement process and ensuring consistency in quality and performance across different products.Looking to the future, the company is committed to ongoing innovation and product development. They continue to invest in research and development to bring new and improved solutions to the market, staying ahead of industry trends and meeting the evolving needs of customers. This forward-thinking approach positions the company as a leader in the construction industry, capable of providing cutting-edge products and solutions to its customers.In conclusion, Tile Trim Aluminum is a versatile and high-performance solution for finishing and protecting tiled surfaces. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted provider of construction products and solutions. As it continues to grow and expand its product offering, customers can rely on the company to deliver the best-in-class solutions for their construction needs.

The Latest Updates on Aluminum Profile Manufacturing in the CNC Industry

Title: Advancements in CNC Aluminum Profile Manufacturing: Shaping the Future of Industrial SolutionsIntroduction:In the realm of modern manufacturing, precision and efficiency are paramount. To meet these demands, companies are continually striving to improve their machining processes. One groundbreaking solution that has revolutionized the industry is the CNC (Computer Numerical Control) aluminum profile. In this article, we will delve deeper into the benefits and applications of CNC aluminum profiles, highlighting their crucial role in reshaping the future of industrial solutions.Body:1. Understanding CNC Aluminum Profile:CNC aluminum profiles are specialized extrusions that go through a meticulous machining process, wherein computers control the manufacturing equipment. This advanced technology enables manufacturers to consistently produce highly precise and customized aluminum profiles, resulting in improved functionality and performance.2. Unmatched Precision and Quality:The utilization of CNC technology ensures superior precision and quality in every aluminum profile produced. CNC machining allows for intricate shapes, tight tolerances, and complex designs, surpassing what traditional manufacturing techniques can achieve. As a result, industries such as aerospace, automotive, and construction are benefitting from the high-performance capabilities of CNC aluminum profiles.3. Enhanced Durability and Lightweight Design:Aluminum, known for its exceptional strength-to-weight ratio, is an ideal material for various applications. CNC aluminum profiles offer enhanced durability and structural stability while remaining lightweight. This combination of strength and reduced weight makes CNC aluminum profiles desirable in industries where both performance and weight restrictions pose significant challenges.4. Versatile Applications:The versatility of CNC aluminum profiles makes them suitable for a wide range of applications. From architectural frameworks to conveyor systems, CNC aluminum profiles find application in construction, industrial machinery, transportation vehicles, and more. Their inherent corrosion resistance and compatibility with other materials make them indispensable in creating robust solutions for demanding environments.5. Streamlined Automation and Efficiency:The automated nature of CNC aluminum profile manufacturing eliminates the need for manual intervention and reduces the margin of error. Manufacturers can program CNC machines to repetitively produce precise profiles, resulting in increased productivity and efficiency. This streamlined automation is a game-changer for industries seeking to optimize their manufacturing processes and meet market demands.6. Sustainable and Environmentally-Friendly:Aluminum is fully recyclable, and the CNC aluminum profile manufacturing process creates minimal waste. The ability to recycle and reuse aluminum profiles makes them an environmentally-friendly choice while also reducing material costs. As sustainability continues to gain importance across industries, CNC aluminum profiles offer an eco-friendly solution without compromising on performance or quality.7. Rising Demand and Future Prospects:With constant advancements in CNC technology, the demand for CNC aluminum profiles is projected to surge. Acclaimed for their versatility, precision, and efficiency, CNC aluminum profiles are poised to dominate various sectors. Furthermore, the integration of artificial intelligence and machine learning with CNC technology opens up endless possibilities for innovation, propelling the industrial solutions of tomorrow.Conclusion:Innovations in CNC aluminum profile manufacturing are transforming the way industries approach their manufacturing needs. With unmatched precision, enhanced durability, and lightweight design, CNC aluminum profiles are redefining the boundaries of what is possible. As companies continue to leverage their capabilities, CNC aluminum profiles are carving their place in the future of industrial solutions, ensuring increased productivity, reduced costs, and efficiency across numerous sectors.

Discover the Best Bracket Options for Your Aluminium Profiles

Brackets for Aluminium Profile: An Innovative Solution for Your Construction NeedsAs construction and manufacturing industries continue to prosper, demands for more efficient and effective solutions are also on the rise. One of these solutions is the use of aluminium profiles, a material that has become increasingly popular in the industry due to its strength, durability and versatility.However, one of the challenges in using aluminium profiles is finding the right bracket to provide the needed support and stability. Fortunately, there is now a solution that has made construction work a lot simpler and more efficient- the versatile bracket for aluminium profile.The Bracket for Aluminium Profile is a new innovative product that has been designed to make metal fabrication and construction projects much easier and faster. This new hardware features a combination of features that would make fabrication much easier for builders and DIY enthusiasts alike. Typically, brackets are used to support something in place, whether it be a shelf, a structural beam or another object. The bracket for aluminium profile is no exception to this, but it comes with added versatility that can make your construction needs easier to meet.The brackets are perfect for joining together or connecting different pieces of aluminium profile, resulting in a more stable structure. The brackets also have the ability to securely fasten and anchor elements in place, providing a more stable and robust foundation. This feature makes it ideal for those who are looking for an effective solution for heavier loads.Another advantage of this innovative product is its ability to reduce fabrication time. With the bracket for aluminium profile, individual pieces can be joined together more quickly and easily, which can help cut back on assembly time. The brackets are designed for quick and simple installation, which means that even those without experience in metal fabrication can install it with ease. The brackets also eliminate the need for more traditional steel plates that can be awkward and cumbersome to install, further reducing time and costs for construction projects.Apart from its functionality, the bracket for aluminium profile also offers aesthetic advantages. It is designed to blend in seamlessly with the profile, giving it a sleek and modern look. The brackets can also be easily painted, ensuring that it matches the profile colour, making it a great option for those who want their construction and manufacturing projects to look finished and complete.One company that provides high-quality and reliable brackets for aluminium profiles is {the company's name which needs to be removed}. They are one of the leading manufacturers of brackets for aluminium profiles who have gained a reputation for their exceptional service and reliability for many years. They provide clients with an extensive range of high-quality brackets and fixing options for all aluminium profile applications. They offer everything from standard brackets to unique designs that cater to bespoke requirements. {The company's name which needs to be removed} is proud to offer their customers bespoke solutions tailored to meet their needs and expectations. They also provide technical support, installation, and test reports upon request. This dedication to a personalised service approach is what separates them from other manufacturers in the industry.Their products are made in their state-of-the-art facility using the highest quality materials and modern equipment. They maintain strict quality control measures to ensure the high quality and durability of their products.As the demand for aluminium profiles continues to grow, builders and industry experts alike are seeking innovative solutions to make fabrication and assembly easier. The bracket for aluminium profile is a small but important step in the right direction in meeting these needs. Manufacturers like {the company's name which needs to be removed} are at the forefront of producing high-quality and reliable brackets that cater to these needs. With their dedication to design, quality and support, they are an ideal choice for those who need quality brackets for their construction and manufacturing needs. In conclusion, the Bracket for Aluminium Profile is a great innovation that has made metal fabrication and construction projects simpler and faster. It offers numerous benefits that can make using aluminium profiles more efficient, effective and aesthetically pleasing. Companies such as {the company's name which needs to be removed} have provided a reliable and high-quality solution to the industry, making them an ideal supplier of aluminium profile brackets for builders and industry experts.

Ultimate Guide to Using V Slot Extrusion for Your DIY Projects

In today's competitive manufacturing industry, companies are always searching for the latest and greatest components to improve productivity and efficiency. One such component that has been making waves recently is the 4040 V Slot Extrusion (brand name removed).Several leading manufacturers including (company name) have integrated this component into their production lines to improve the process and output. The extrusion is a patented product that utilizes a unique design to provide superior strength and stability while remaining incredibly lightweight. This has made it a popular choice in numerous industries, particularly those that require precision machining.One major reason why the 4040 V Slot Extrusion is so highly sought after is due to its versatility. It is capable of being configured in a vast array of shapes and sizes, ensuring that it can be integrated into virtually any manufacturing process. This adaptability also means that the extrusion can be reconfigured quickly and easily, allowing companies to adjust their production lines on the fly to meet changing demand.Another significant benefit of the 4040 V Slot Extrusion is its high precision. During the manufacturing process, the extrusion undergoes strict quality control measures to ensure accuracy and consistency. This means that when integrated into a production line, it can help to improve the overall quality of the products being produced.One of the key factors that make the 4040 V Slot Extrusion stand out from other similar products on the market is its durability. The extrusion is built to last, thanks to the use of high-quality materials and advanced manufacturing techniques. It is therefore capable of withstanding significant amounts of stress and fatigue, making it an ideal component for heavy-duty production processes.The 4040 V Slot Extrusion also provides excellent scalability. As companies grow and expand their operations, they need components that can keep up with the increased demand. The extrusion's modular design means that it can be easily added to or removed from a production line as needed, allowing companies to scale up or down without incurring significant costs.At (company name), we have been offering the 4040 V Slot Extrusion to our clients for some time now, and the results have been impressive. Our clients have reported significant improvements in productivity, efficiency, and quality, making it a valuable addition to any manufacturing process. Furthermore, the extrusion's versatility and scalability mean that it can be used in a wide range of applications, making it an ideal choice for companies looking to improve their production processes.Overall, the 4040 V Slot Extrusion is an innovative and highly effective component that is playing an increasingly vital role in many manufacturing industries. Its strength, durability, and precision make it a reliable choice for companies looking to improve their production processes, while its versatility and scalability make it an adaptable component that can grow and change with the company. As the manufacturing industry continues to evolve, we believe that the 4040 V Slot Extrusion will remain a key player in driving innovation and productivity.

High-quality CNC Cutting Services for Aluminum

CNC Cutting Aluminum: A Revolutionary Solution in Metal FabricationIn the world of metal fabrication, precision and efficiency are key. Companies are constantly seeking cutting-edge technologies and innovative solutions to improve the quality and speed of their production processes. One such solution that has taken the industry by storm is CNC cutting aluminum, a revolutionary method that is transforming the way aluminum is fabricated. With its high precision and exceptional efficiency, CNC cutting aluminum has become the go-to choice for many industries, including aerospace, automotive, and manufacturing.CNC cutting aluminum is a process that involves using a computer-controlled machine to accurately cut and shape aluminum materials to the desired specifications. The process begins with the creation of a digital design or blueprint of the desired product. This design is then input into the CNC machine, which uses its cutting tools to precisely carve out the aluminum material according to the specifications of the design. The result is a highly accurate and intricately detailed aluminum component that meets the exact requirements of the customer.One of the leading companies at the forefront of CNC cutting aluminum technology is {}. With a strong reputation for superior quality and cutting-edge capabilities, {} has established itself as a trusted partner for companies seeking high-precision aluminum fabrication solutions. {}'s state-of-the-art facilities and advanced CNC machines are equipped to handle a wide range of aluminum cutting requirements, from simple shapes to complex designs, with utmost precision and efficiency.The advantages of CNC cutting aluminum are numerous. First and foremost, the level of precision and accuracy that can be achieved with this method is unmatched. The CNC machines are capable of carrying out incredibly detailed and intricate cuts that would be nearly impossible to achieve with traditional machining methods. This level of precision is particularly important for industries such as aerospace and automotive, where the smallest deviation from the specified dimensions can have significant consequences.In addition to precision, CNC cutting aluminum offers exceptional efficiency. The automated nature of the CNC machines allows for a much faster production process compared to manual methods. This means that companies can expect quicker turnaround times for their orders, ultimately leading to increased productivity and cost savings. Furthermore, the consistency of the CNC cutting process ensures that each aluminum component is uniform in quality, eliminating the variability that can occur with manual machining.Another key advantage of CNC cutting aluminum is the versatility it offers. With the ability to handle a wide range of aluminum materials and thicknesses, CNC cutting is suitable for a variety of applications. Whether it's creating intricate parts for aerospace machinery or producing durable components for automotive vehicles, CNC cutting aluminum can meet the diverse needs of different industries. This versatility makes it a highly attractive option for companies looking to streamline their metal fabrication processes.In conclusion, CNC cutting aluminum has revolutionized the metal fabrication industry, offering unparalleled precision, efficiency, and versatility. As companies continue to seek innovative solutions to enhance their production processes, CNC cutting aluminum has emerged as a game-changer that is driving the industry forward. With companies like {} leading the way with their cutting-edge capabilities, the future of aluminum fabrication looks brighter than ever. Whether it's meeting the demands of complex aerospace projects or delivering high-quality automotive components, CNC cutting aluminum is poised to continue making a lasting impact on the industry.