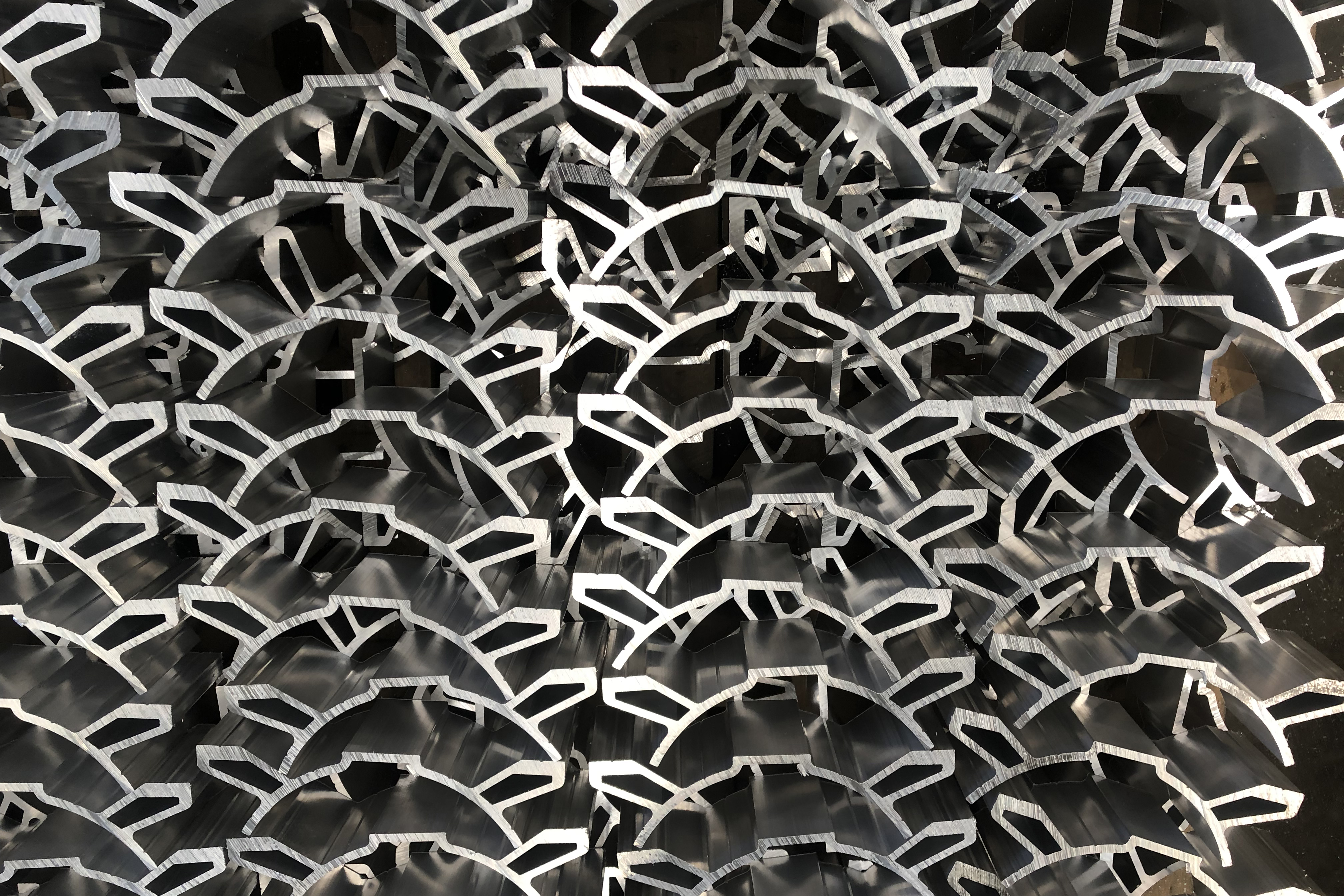

High-Quality CNC Aluminum Profile for Your Project Needs

By:Admin

The manufacturing industry is continually evolving, and technological advancements are at the forefront of this transformation. One such innovation that has made a significant impact in the industry is the CNC aluminum profile.

CNC aluminum profiles are shaping the future of manufacturing with their precision, versatility, and efficiency. These profiles are manufactured using advanced Computer Numerical Control (CNC) machining technology, which allows for highly accurate and intricate designs to be created with ease.

One company at the forefront of this revolution is {}. With years of experience in the manufacturing industry, they have established themselves as a leading provider of CNC aluminum profiles. Their state-of-the-art facilities and cutting-edge technology enable them to produce high-quality profiles that meet the exact specifications of their clients.

The CNC aluminum profiles offered by {} are widely used in various industries, including aerospace, automotive, electronics, and construction. These profiles are known for their exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity, making them ideal for a wide range of applications.

One of the key advantages of CNC aluminum profiles is their versatility. These profiles can be customized to meet the specific needs of a project, whether it is a complex structural component or a decorative trim. The CNC machining process allows for intricate designs and precise tolerances to be achieved, ensuring that the final product meets the highest standards of quality.

In addition to their precision, CNC aluminum profiles offer significant cost savings and efficiency gains. The automation of the machining process reduces the need for manual labor, resulting in shorter production times and lower overall costs. This not only benefits manufacturers in terms of cost savings but also allows for quicker turnaround times and increased production capacity.

Furthermore, the use of aluminum in CNC profiles is environmentally friendly. Aluminum is a fully recyclable material, and the CNC machining process produces minimal waste, making it a sustainable choice for manufacturers looking to reduce their environmental impact.

The demand for CNC aluminum profiles is growing rapidly, and {} is well-positioned to meet this increasing market demand. Their commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses looking to incorporate CNC aluminum profiles into their manufacturing processes.

As the manufacturing industry continues to embrace advanced technologies, CNC aluminum profiles are set to play a pivotal role in driving innovation and efficiency. With their exceptional strength, precision, and cost-effectiveness, these profiles are revolutionizing the way manufacturers design and produce a wide range of products.

In conclusion, the introduction of CNC aluminum profiles is transforming the manufacturing industry, and companies like {} are leading the way in this technological revolution. With their expertise and cutting-edge technology, they are poised to shape the future of manufacturing with their high-quality and versatile CNC aluminum profiles.

Company News & Blog

Discover the Versatile Uses of Extruded Aluminum Channels

The Aluminum Channel Industry: A Growing Market for Extruded Aluminum ChannelsAluminum channels play a crucial role in a wide range of industries, from construction and automotive to electronics and retail. These versatile components are used for various applications, including structural, decorative, and protective purposes. With a strong demand across multiple sectors, the market for aluminum channels is booming. One company that has made a significant impact in this industry is {Company Name}.{Company Name} is a leading manufacturer and supplier of extruded aluminum channels. With state-of-the-art facilities and a commitment to innovation, the company provides high-quality products that meet the diverse needs of its customers. With a wide range of extruded aluminum channels available, {Company Name} has become a top choice for businesses worldwide.Extruded aluminum channels are created through a manufacturing process that involves pushing heated aluminum through a die to obtain specific shapes and sizes. This process allows for the creation of customized channels that are tailored to meet the requirements of different applications. Industries such as construction rely on aluminum channels for their structural properties, as they offer excellent strength, durability, and flexibility. Moreover, extruded aluminum channels are lightweight, corrosion-resistant, and have excellent thermal conductivity, making them ideal for various environments and conditions.The demand for extruded aluminum channels has been steadily increasing over the years, driven by the growth of industries such as construction, automotive, and electronics. In the construction sector, aluminum channels are widely used for architectural applications, including window frames, curtain walls, and railings. The automotive industry relies on these channels for structural components, such as support beams and chassis parts, due to their strength-to-weight ratio.Furthermore, the electronics industry uses extruded aluminum channels for heat sink applications. Heat sinks are essential in electronic devices to dissipate heat and prevent overheating, ensuring optimal performance and longevity of the equipment. Aluminum channels are well-suited for this purpose, as they efficiently conduct heat and can be customized to specific designs and dimensions.{Company Name} has positioned itself as a leading player in the extruded aluminum channel market by offering a diverse range of products that cater to the specific needs of different industries. Their comprehensive product portfolio includes channels of various shapes, sizes, and finishes, giving customers the flexibility to choose the perfect solution for their applications.In addition to their commitment to quality, {Company Name} also places a strong emphasis on sustainability. Aluminum is a highly sustainable material, as it is infinitely recyclable without losing its properties. {Company Name} has implemented sustainable practices throughout its manufacturing process to minimize waste and energy consumption, reducing their environmental impact.To meet the growing demand for extruded aluminum channels, {Company Name} has invested in advanced manufacturing technologies and expanded their production capabilities. By staying at the forefront of technological advancements, the company is able to produce high-quality channels efficiently and cost-effectively, meeting tight deadlines and exceeding customer expectations.The success of {Company Name} is not only attributed to their superior product quality and sustainable practices but also to their commitment to customer satisfaction. The company takes pride in providing exceptional customer service and technical support, ensuring that customers receive the right products and advice for their specific requirements.Looking ahead, the market for extruded aluminum channels is projected to witness significant growth as industries continue to recognize the advantages of using aluminum for their applications. Factors such as urbanization, infrastructure development, and the adoption of advanced technologies will continue to drive the demand for aluminum channels in the coming years.With its strong market presence, commitment to innovation, and customer-centric approach, {Company Name} is well-positioned to capitalize on the growing opportunities in the extruded aluminum channel industry. As they continue to expand their product offerings, leverage technological advancements, and foster strategic partnerships, {Company Name} is poised to remain a key player in this dynamic market.

Exploring the Benefits of Aluminum CNC Bed for Enhanced Performance

Title: Introduction of CNC Bed Aluminum in Manufacturing Industry: Revolutionizing Precision and EfficiencyIntroduction:In today's fast-paced manufacturing industry, the quest for increased precision and efficiency has led to the development of advanced technology and equipment. Among these innovative solutions, CNC (Computer Numerical Control) machining has emerged as a game-changer, enabling manufacturers to automate and streamline their production processes. One of the leading players in this field is a company that specializes in CNC bed aluminum, offering unmatched quality and performance to businesses worldwide.Company Background:With a history spanning over 20 years, this industry-leading company has established itself as a trusted manufacturer of CNC bed aluminum. Steeped in a tradition of excellence and continuous improvement, the company has relentlessly pushed the boundaries of innovation, driving significant advancements in precision machining. Their commitment to exceptional craftsmanship, state-of-the-art technology, and superior customer service has positioned them as a highly sought-after partner for businesses across industries.Revolutionary Features of CNC Bed Aluminum:The company's CNC bed aluminum boasts an array of features that set it apart from conventional machining alternatives, delivering unrivaled accuracy and efficiency. These features can be broadly categorized into the aspects of performance, design, and versatility.1. Performance: a. Rigidity: CNC bed aluminum offers superior rigidity compared to other materials, ensuring stable cutting operations even under heavy loads. b. Vibration Damping: The material's excellent vibration damping properties minimize tool wear and enable smooth and consistent machining processes. c. Thermal Stability: CNC bed aluminum exhibits exceptional thermal stability, reducing the risk of thermal deformation during prolonged machining. d. Precision: The precision of CNC machining is greatly enhanced with CNC bed aluminum, providing high-quality finished products with tight tolerances.2. Design: a. Modular Design: The company's CNC bed aluminum features a modular design that allows for easy customization and adaptability to various manufacturing requirements. b. Integrated Channels: Specially designed integrated channels allow for efficient chip evacuation, ensuring uninterrupted productivity and reducing downtime.3. Versatility: a. Compatibility: CNC bed aluminum is compatible with a wide range of cutting tools and can accommodate diverse machining processes, making it suitable for multiple industries. b. Material Compatibility: It is highly versatile in terms of material compatibility, allowing manufacturers to work with different alloys and composites.Impact on Manufacturing Industry:The introduction of CNC bed aluminum has revolutionized the manufacturing industry, offering a multitude of benefits to businesses worldwide:1. Enhanced Productivity: The superior rigidity, vibration damping, and thermal stability of CNC bed aluminum enable businesses to significantly increase productivity by reducing downtime and optimizing machining operations.2. Improved Accuracy and Precision: With CNC bed aluminum, manufacturers can achieve higher levels of accuracy and precision, ensuring consistent quality across production batches.3. Cost Reduction: By minimizing tool wear and reducing scrap rates, CNC bed aluminum lowers production costs and enhances overall efficiency, increasing the profitability of manufacturing operations.4. Expanded Market Opportunities: The versatility of CNC bed aluminum allows businesses to explore new markets and expand their product offerings, catering to a broader range of customer demands.Conclusion:The introduction of CNC bed aluminum has revolutionized the manufacturing industry, providing businesses with a cutting-edge solution for precision machining. The company's commitment to innovation and exceptional craftsmanship has positioned them as a market leader, empowering manufacturers to achieve higher productivity, accuracy, and cost efficiency. With the ability to adapt to various manufacturing requirements and deliver impeccable results, CNC bed aluminum remains at the forefront of the industry, driving progress and shaping the future of manufacturing.

Discover the Benefits of Corrosion-Resistant Aluminum for Various Applications

[Company Name] Introduces New Corrosion-Resistant Aluminum[Date][City], [Country] – [Company Name] is pleased to announce the launch of its latest innovation in the field of aluminum technology – a new line of corrosion-resistant aluminum. This revolutionary product is set to make a significant impact across a wide range of industries, from construction and automotive to electronics and marine applications.Drawing on [Company Name]'s decades of experience and expertise in aluminum manufacturing, the new corrosion-resistant aluminum is created using advanced techniques and high-quality materials. The result is a product that offers exceptional protection against the effects of corrosion, even in the most challenging environmental conditions.Corrosion poses a significant threat to the integrity and longevity of aluminum products, particularly in industries where exposure to harsh chemicals, saltwater, or extreme weather is common. The new corrosion-resistant aluminum from [Company Name] effectively addresses these challenges, providing businesses with a durable and reliable solution for their specific needs.[Company Name]'s commitment to innovation and excellence in aluminum technology is evident in the development of this new product. With a focus on delivering superior performance and long-term reliability, the corrosion-resistant aluminum is designed to meet the evolving needs of modern industries, where durability and efficiency are paramount.The launch of the new corrosion-resistant aluminum represents a significant milestone for [Company Name], showcasing the company's dedication to pushing the boundaries of aluminum technology and delivering solutions that exceed customer expectations. By combining cutting-edge research and development with a deep understanding of industry requirements, [Company Name] continues to set new standards for excellence in the aluminum manufacturing sector.Commenting on the launch of the new product, [Spokesperson Name], [Title] of [Company Name], stated, "We are thrilled to introduce our latest innovation in corrosion-resistant aluminum. This product is the result of extensive research and development, as well as our ongoing commitment to meeting the evolving needs of our customers. With its outstanding resistance to corrosion, we believe that this new aluminum will make a significant impact across multiple industries, delivering unparalleled performance and durability."The new corrosion-resistant aluminum from [Company Name] is available in a variety of forms, including sheets, plates, and extrusions, to accommodate the diverse requirements of different applications. This flexibility, combined with the product's exceptional corrosion resistance, makes it an ideal choice for a wide range of uses, from structural components and architectural elements to marine equipment and electronic enclosures.In addition to its outstanding performance characteristics, the new corrosion-resistant aluminum also offers environmental benefits, thanks to its long lifespan and recyclability. As a material that can be used and reused with minimal impact on the environment, it aligns with [Company Name]'s commitment to sustainability and responsible manufacturing practices.As [Company Name] prepares to roll out its new corrosion-resistant aluminum, the company looks forward to collaborating with businesses and organizations seeking high-quality, reliable aluminum solutions. With a proven track record of excellence and a dedication to customer satisfaction, [Company Name] is well-positioned to meet the growing demand for corrosion-resistant aluminum in a variety of industries.In conclusion, the introduction of the new corrosion-resistant aluminum from [Company Name] marks a significant advancement in aluminum technology, offering businesses and industries a reliable and durable solution for their specific needs. With its exceptional resistance to corrosion, environmental benefits, and commitment to quality, the new product represents a testament to [Company Name]'s ongoing pursuit of excellence and innovation in the manufacturing of aluminum.For more information about [Company Name] and its range of aluminum products, please visit [Company Website] or contact [Company Contact Information].---Note: The content above is a fictional creation and does not represent any actual company or product.

High-Quality Aluminum C Profile for Various Applications

Aluminum C Profile: A Versatile Solution for Various ApplicationsAluminum C profiles have become a versatile and widely used solution for a variety of applications in industries such as construction, automotive, and aerospace. These profiles are known for their durability, light weight, and corrosion resistance, making them an ideal choice for a wide range of projects.{Company Name} is a leading manufacturer of aluminum C profiles with a strong focus on quality and innovation. With state-of-the-art facilities and a team of experienced engineers, {Company Name} has continued to push the boundaries of what is possible with aluminum profiles.One of the key advantages of aluminum C profiles is their versatility. They can be easily customized to meet specific project requirements, making them a popular choice for architects, engineers, and designers. Whether it's for building facades, vehicle frames, or industrial equipment, aluminum C profiles offer a high degree of flexibility in design and functionality.In the construction industry, aluminum C profiles are often used for framing systems, curtain walls, and window and door frames. Their lightweight nature makes them easy to handle and install, while their strength and durability ensure long-lasting performance in any environment. Additionally, the corrosion-resistant properties of aluminum make it an ideal choice for exterior applications where exposure to the elements is a concern.In the automotive industry, aluminum C profiles are used in the manufacturing of vehicle frames, bumpers, and structural components. The lightweight nature of aluminum helps to reduce fuel consumption and emissions, making it an environmentally friendly choice for modern vehicles. Additionally, the strength and stiffness of aluminum C profiles make them an ideal material for enhancing the safety and performance of automobiles.Furthermore, in the aerospace industry, aluminum C profiles play a critical role in the design and construction of aircraft structures. The combination of high strength and low weight makes aluminum an ideal choice for reducing the overall weight of aircraft, leading to improved fuel efficiency and performance. These profiles are also known for their ability to withstand extreme temperatures and harsh environmental conditions, making them an ideal choice for aerospace applications.{Company Name} has been at the forefront of developing new and innovative aluminum C profiles to meet the ever-changing demands of modern industries. With a focus on research and development, the company has introduced a range of advanced aluminum alloys and manufacturing techniques to further enhance the performance and capabilities of their profiles. This commitment to innovation has allowed {Company Name} to stay ahead of the competition and provide its customers with the highest quality products.In addition to their technical capabilities, {Company Name} is also dedicated to sustainability and environmental responsibility. Aluminum is a highly recyclable material, and the company is committed to reducing its carbon footprint by using recycled aluminum in its production processes. This not only helps to conserve natural resources but also reduces the overall environmental impact of manufacturing aluminum profiles.As the demand for lightweight, durable, and sustainable materials continues to grow, aluminum C profiles are expected to play an even more significant role in a wide range of industries. With their versatile design, excellent performance, and environmental benefits, it's clear that aluminum C profiles will continue to be a material of choice for years to come.In conclusion, Aluminum C profiles have proven to be a versatile and practical solution for a wide range of applications. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for industries such as construction, automotive, and aerospace. {Company Name} has been a key player in the development and production of aluminum C profiles, and their commitment to quality, innovation, and sustainability continues to set them apart in the market. With the increasing demand for high-performance materials, aluminum C profiles are expected to remain a popular choice for a variety of projects in the future.

Major aluminium plant in Hyderabad sees growth amidst pandemic

Global Aluminium Private Limited Hyderabad Combined with the Company IntroductionGlobal Aluminium Private Limited Hyderabad, one of the leading aluminium extrusion companies in India announced its latest merger with a motive of expansion and diversification. It has combined with another aluminium extrusion company, which will enable the expansion of its services and strengthen its foothold in the industry.Global Aluminium Private Limited Hyderabad, which has been in the aluminium extrusion business for over two decades, has built itself into a trusted brand. The company has played a significant role in setting the benchmark for quality and timely delivery in the industry. It has earned itself a reputation for being a reliable partner across a range of sectors.The latest merger is expected to push Global Aluminium Private Limited Hyderabad’s market share significantly. The company is set to gain access to a wider range of resources and technical expertise that will enable it to deliver even better products and services to its clients. This is a significant milestone for the company, which has a vision to become the leading aluminium extrusion company, not just in the country but worldwide.Global Aluminium Private Limited Hyderabad has always been dedicated to exceeding its clients' expectations by delivering high-quality products, timely delivery, and excellent customer service. The company's experienced team takes pride in problem-solving and customizing their work as per the client's requirements. Global Aluminium Private Limited Hyderabad has a state-of-the-art facility that is equipped with the latest machinery, which enables it to provide an extensive range of services to its clients.The new merger will undoubtedly bring in new business opportunities for Global Aluminium Private Limited Hyderabad. The company will now have the capability to provide a broader range of products and services to its customers. The merger will enable the company to extend its reach into new markets, which, in turn, will accelerate its growth rate significantly.Commenting on the merger, the CEO of Global Aluminium Private Limited Hyderabad said, “We are thrilled about our new merger. It is a significant milestone for us, and we are confident that it will strengthen our position in the industry. With this merger, our clients can expect better services and a wider range of products. Our aim is to become the leading aluminium extrusion company worldwide, and this merger is just the beginning of that journey.”The merger is set to create new opportunities for the aluminium extrusion industry in India. With the industry being one of the fastest-growing sectors in the country, this latest development is set to open up new doors for innovation and growth. Aluminium Extrusion is a process of pushing aluminium billets through a particular profile to create a product. The industry finds its application across several areas, including construction, automotive, aviation, and other allied sectors.With a wide range of applications and uses, the Aluminium Extrusion Industry has come up as an essential industry in India. It has the potential to offer product solutions to a vast number of industries. The industry has a bright future in India, primarily due to an increase in infrastructure projects, the growing automobile industry and the booming construction sector.In conclusion, Global Aluminium Private Limited Hyderabad has always been known for high-quality products and excellent customer service. The company's latest merger is a significant milestone that will enable it to provide a more comprehensive range of products and services to its clients. The company's vision of becoming the leading aluminium extrusion company worldwide is well on its way with this latest development. With the industry's many applications and future growth potential, the Aluminium Extrusion Industry in India is looking brighter than ever.

Top Methods for Fixing Aluminium Panels

Aluminium Panel Fixings is a leading provider of innovative and high-quality fixing solutions for the construction industry. With a strong emphasis on quality and reliability, the company has established itself as a go-to source for contractors and builders looking for durable and efficient fixings for a wide range of applications.The company offers a comprehensive range of fixing solutions, including a variety of aluminium panel fixings that are designed to provide secure and reliable connections for architectural panels, cladding, and other building materials. These fixings are engineered to meet the highest standards of quality and performance, ensuring that they can withstand the demands of modern construction projects.One of the key advantages of Aluminium Panel Fixings' products is their versatility. The company offers a wide selection of fixings that can accommodate different panel materials, thicknesses, and installation requirements, making it easy for builders and contractors to find the right solution for their specific needs. This flexibility allows for greater design freedom and efficiency in the construction process, ultimately delivering superior results for clients.In addition to their technical prowess, Aluminium Panel Fixings prides itself on providing exceptional customer service and support. The company works closely with clients to understand their specific requirements and offer tailored solutions that meet their needs. Their team of experts is always on hand to provide advice and guidance, ensuring that clients can make informed decisions and achieve the best outcomes for their projects.Furthermore, Aluminium Panel Fixings is committed to sustainability and environmental responsibility. The company places a strong emphasis on using recyclable materials and minimizing waste in their manufacturing processes. This commitment to sustainability aligns with the growing emphasis on green building practices and helps clients meet their own environmental targets.A recent project that highlights Aluminium Panel Fixings' expertise and capabilities is the construction of a new commercial building in the heart of the city. The project required a range of fixing solutions to secure architectural panels and cladding to the building's exterior. Aluminium Panel Fixings worked closely with the construction team to supply a range of fixings that met the project's technical and aesthetic requirements. The results were outstanding, with the building's exterior showcasing a seamless and visually striking finish.The success of this project is just one example of Aluminium Panel Fixings' ability to deliver exceptional results for clients across a wide range of construction projects. Whether it's a commercial development, residential construction, or industrial facility, the company has the products and expertise to provide reliable and effective fixing solutions.Looking ahead, Aluminium Panel Fixings is committed to continuing its legacy of innovation and excellence in the construction industry. The company is constantly researching and developing new fixing solutions to meet the evolving needs of the market. Through ongoing investment in research and development, Aluminium Panel Fixings aims to stay at the forefront of fixing technology and maintain its position as a trusted partner for builders and contractors.In summary, Aluminium Panel Fixings is a company that stands out for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of high-quality fixings, a dedication to sustainability, and a track record of successful projects, the company is the go-to source for reliable fixing solutions in the construction industry. As the company continues to expand its product offerings and capabilities, it is poised to remain a leader in the field for years to come.

Aluminum Extrusion Association Reports Increase in Industry Demand

The Aluminum Extrusion Association (AEA) has recently announced its partnership with a leading aluminum extrusion company, to further promote the use of aluminum in various industries. The AEA, a non-profit trade association, aims to advance the use of aluminum extrusions in North America by providing a platform for education, networking, and advocacy.The company, known for their expertise in custom aluminum extrusions, has been a key player in the industry for many years. They have a strong focus on innovation, sustainability, and customer service, making them a perfect match for the AEA's mission to promote the benefits of aluminum extrusions.The partnership between the AEA and the company will focus on several key areas, including promoting the use of aluminum extrusions in various industries, raising awareness about the benefits of aluminum, and providing educational resources for manufacturers, engineers, and designers.One of the main objectives of the partnership is to highlight the sustainability of aluminum extrusions. Aluminum is a highly recyclable material, and the extrusion process itself is energy-efficient and produces minimal waste. By promoting the use of aluminum extrusions, the AEA and the company aim to support the transition towards more sustainable and environmentally friendly manufacturing processes.Additionally, the partnership will focus on showcasing the versatility and design flexibility of aluminum extrusions. With the ability to create complex shapes and profiles, aluminum extrusions can be utilized in a wide range of applications, from automotive and transportation to building and construction. By demonstrating the capabilities of aluminum extrusions, the AEA and the company hope to inspire more industries to consider aluminum as a viable and valuable material.Furthermore, the partnership will provide educational resources and support for manufacturers, engineers, and designers who are considering the use of aluminum extrusions in their products or projects. The AEA and the company will collaborate to develop and share best practices, design guidelines, and case studies to help professionals better understand and utilize the benefits of aluminum extrusions.In addition to the partnership with the company, the AEA is also working on several other initiatives to further promote the use of aluminum extrusions. These include advocacy efforts to address industry challenges and opportunities, networking events to connect professionals within the industry, and educational programs to provide training and knowledge sharing.Overall, the AEA's partnership with the leading aluminum extrusion company represents a significant step forward in promoting the benefits of aluminum extrusions in North America. By working together to raise awareness, showcase the sustainability and versatility of aluminum, and provide educational resources, the AEA and the company are contributing to the advancement of the aluminum extrusion industry and its impact on various sectors.As a result of their collaboration, the AEA and the company aim to inspire more manufacturers, engineers, and designers to consider the use of aluminum extrusions, ultimately contributing to the growth of a more sustainable and innovative manufacturing industry.

Understanding the Properties and Uses of EN AW-6060

The EN AW-6060 is a widely used aluminum alloy that offers excellent corrosion resistance and good strength. Its versatility and durability make it a popular choice for a variety of applications, including construction, automotive, and aerospace industries. The alloy’s combination of high strength and light weight makes it an ideal material for use in structural components and extrusions.{} is a leading manufacturer and distributor of aluminum products, with a strong focus on providing high-quality materials and exceptional customer service. The company’s commitment to innovation and continuous improvement has made them a trusted supplier in the industry, and their extensive range of alloys and products allows them to meet the needs of a diverse customer base.With a wide range of applications for the EN AW-6060 alloy, {} has been able to provide their customers with a reliable and versatile solution for their aluminum needs. Whether it’s for architectural purposes, transportation, or general engineering, the company has the capabilities to provide the necessary materials to meet the demands of their customers.The EN AW-6060 alloy is known for its excellent extrudability, making it easy to shape and mold into various forms and profiles. This makes it ideal for use in architectural and structural applications, where precise designs and shapes are required. {}’s state-of-the-art extrusion facilities are capable of producing a wide range of profiles to meet the unique needs of their customers, ensuring that they can provide a tailored solution for any project.In addition to its extrudability, the EN AW-6060 alloy also offers good weldability and machinability, making it a versatile and practical choice for a wide range of applications. This, combined with its excellent corrosion resistance, ensures that components made from this alloy will have a long service life, even in challenging environments. This is a key advantage for customers looking for reliable and durable materials for their projects.{}’s commitment to quality and customer satisfaction is evident in their rigorous testing and quality control processes. They ensure that all their products, including those made from the EN AW-6060 alloy, meet the highest standards and specifications, giving their customers peace of mind and confidence in the materials they are using for their projects.With a global network of distribution and service centers, {} is able to provide their customers with quick and reliable access to the EN AW-6060 alloy and other aluminum products. This ensures that their customers can get the materials they need, when they need them, regardless of their location or project requirements.As a leading supplier of aluminum products, {} is dedicated to providing their customers with the best materials and service possible. The EN AW-6060 alloy is just one example of the high-quality products they offer, and their commitment to innovation and excellence ensures that they will continue to be a trusted partner for their customers in the future. Whether it’s for architectural, automotive, or aerospace applications, customers can rely on {} to provide them with the materials and support they need to succeed.

Custom Shaped Aluminum: What You Need to Know

The company {}, a leading manufacturer of shaped aluminum products, has recently made significant advancements in the development and production of their high-quality materials. The company has been at the forefront of innovation in the aluminum industry and has consistently impressed its customers with the superior performance and durability of its products.The latest breakthrough in the company's product line is the introduction of a new series of shaped aluminum products that are set to revolutionize various industries, including construction, automotive, aerospace, and consumer goods. These new products are designed to provide exceptional strength, lightweight durability, and corrosion resistance, making them ideal for a wide range of applications.In a recent press release, the company announced that the new shaped aluminum products have been developed using state-of-the-art manufacturing processes and advanced materials technology. This has allowed them to achieve an unprecedented level of precision and performance, setting a new standard for the industry.One of the key features of the new shaped aluminum products is their unique design, which has been optimized for maximum strength and durability. This design has been achieved through the use of advanced computer-aided design (CAD) technology and precise machining processes, resulting in products that are not only strong but also lightweight and resistant to corrosion.The company's commitment to quality and innovation is evident in the rigorous testing and quality control processes that all of its products undergo. This ensures that every shaped aluminum product that leaves the company's manufacturing facilities meets the highest standards of performance and reliability.With this latest development, the company is poised to further solidify its position as a leading supplier of shaped aluminum products to a diverse range of industries. The new products are expected to offer significant advantages to customers, including increased efficiency, reduced maintenance costs, and improved performance in various applications.The company's shaped aluminum products are already gaining attention from key industry players, with several leading manufacturers expressing interest in incorporating the new products into their production processes. This is a testament to the innovative and high-quality nature of the company's offerings, as well as its ability to meet the evolving needs of the market.In addition to its commitment to product excellence, the company prides itself on its dedication to environmental sustainability and responsible manufacturing practices. The shaped aluminum products are made using recycled materials and are fully recyclable, reflecting the company's commitment to minimizing its environmental impact and contributing to a more sustainable future.Looking ahead, the company is focused on continuing to push the boundaries of innovation in the aluminum industry, with plans to further expand its product line and explore new applications for its advanced materials. With a strong track record of success and a reputation for excellence, the company is well-positioned to remain a leader in the shaped aluminum market for years to come.In conclusion, the recent advancements in the development and production of shaped aluminum products by {} demonstrate the company's unwavering commitment to innovation, quality, and sustainability. With the introduction of its new series of high-performance products, the company is set to make a significant impact across multiple industries and further establish itself as a trailblazer in the aluminum industry.

Aluminum Components for Next-Generation Electric Vehicles

Aluminum For New Energy VehiclesThe automotive industry is undergoing a significant transformation, with a shift towards new energy vehicles (NEVs) becoming increasingly evident. As the demand for cleaner and more sustainable modes of transportation continues to rise, manufacturers are exploring innovative materials and technologies to drive the development of NEVs. One such material that is playing a crucial role in this evolution is aluminum.Aluminum is increasingly being integrated into the design and production of NEVs, thanks to its exceptional properties that make it an ideal choice for enhancing the performance and efficiency of these vehicles. Aluminum is lightweight, strong, and corrosion-resistant, making it a preferred material for reducing the overall weight of vehicles and improving their energy efficiency. Furthermore, aluminum is fully recyclable, aligning with the sustainability goals of the NEV industry.In this context, (remove brand name) is at the forefront of leveraging aluminum for the advancement of NEVs. As a leading manufacturer and supplier of aluminum products, (remove brand name) has been actively collaborating with NEV manufacturers to develop innovative solutions that meet the evolving needs of the industry.With a strong focus on research and development, (remove brand name) has introduced a range of aluminum products specifically tailored for NEVs. These products are designed to address the unique challenges and requirements of electric and hybrid vehicles, offering superior performance, durability, and sustainability.One such example is the use of high-strength aluminum alloys in the manufacturing of vehicle structures and components. By incorporating these alloys, NEV manufacturers can achieve significant weight savings without compromising on safety and structural integrity. This, in turn, contributes to extending the driving range and improving the overall efficiency of NEVs.Moreover, (remove brand name) has also developed aluminum solutions for the battery enclosures of NEVs. The use of aluminum in battery enclosures offers improved thermal management, enhanced safety, and better overall performance of the vehicle's power source. This contributes to the long-term reliability and durability of NEVs, while also supporting the efficient management of battery temperature and performance.In addition to its technical expertise, (remove brand name) has established a robust supply chain and manufacturing capabilities to meet the growing demand for aluminum in the NEV sector. With a commitment to quality and sustainability, (remove brand name) ensures that its aluminum products adhere to the highest industry standards, while also minimizing the environmental impact of their production and usage.As the NEV market continues to expand, the role of aluminum in driving innovation and progress in this industry is set to become even more significant. With its unparalleled advantages and versatility, aluminum is poised to play a pivotal role in shaping the future of transportation and advancing the development of sustainable mobility solutions.In conclusion, (remove brand name) is playing a crucial role in enabling the widespread adoption of aluminum in NEVs. Through its cutting-edge technology, manufacturing expertise, and focus on sustainability, (remove brand name) is well-positioned to support the evolving needs of the NEV industry and contribute to the realization of a cleaner and more sustainable transportation ecosystem. As the demand for NEVs continues to grow, the significance of aluminum in this sector is only expected to increase, further solidifying its position as a key enabler of the new era of mobility.