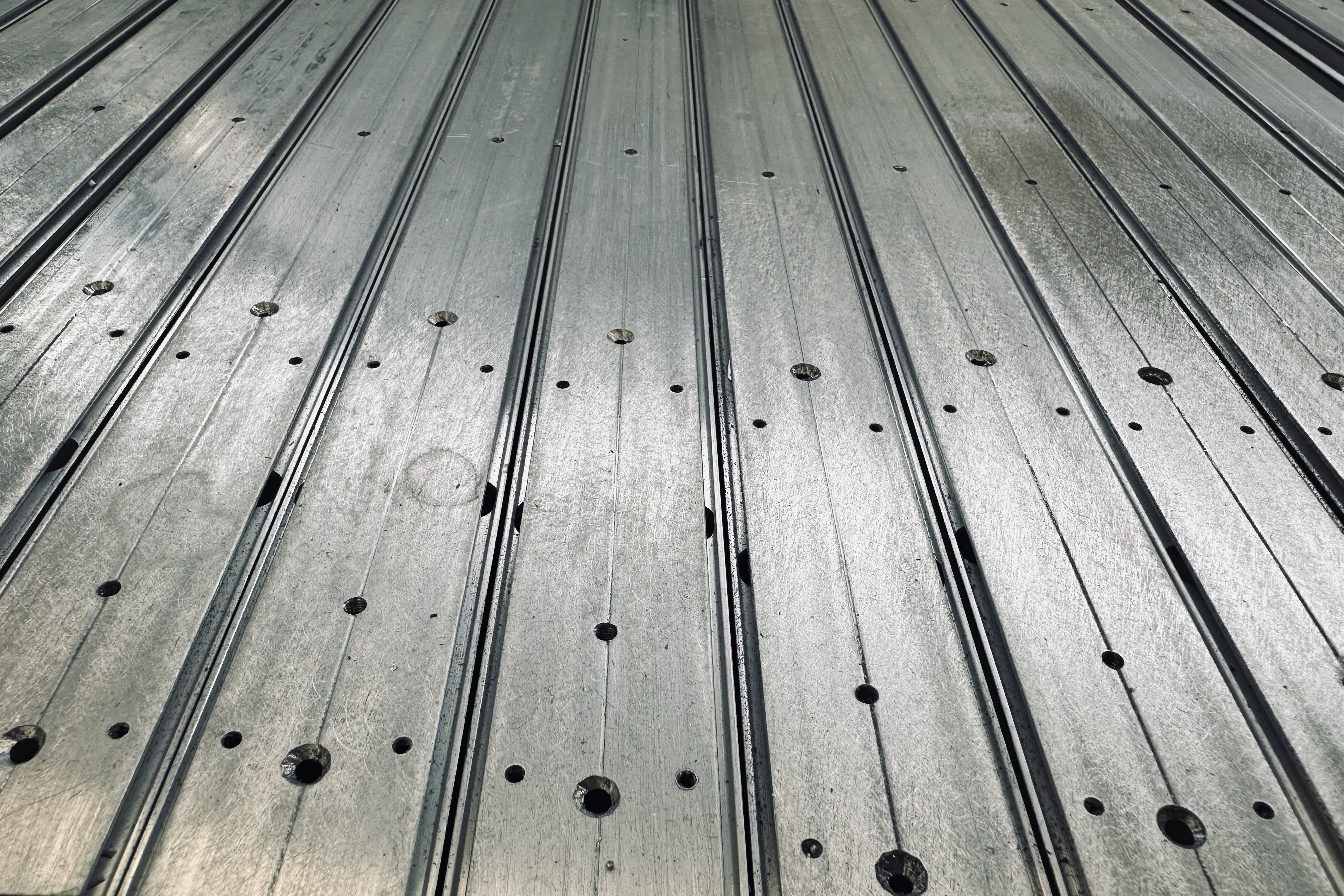

High-Quality Aluminum Profile Cutter for Precision Cutting

By:Admin

In today's fast-paced manufacturing industry, the use of innovative technologies and state-of-the-art machinery is crucial for staying ahead of the competition. One such revolutionary technology is the Aluminum Profile Cutter, a cutting-edge piece of equipment that has been making waves in the industry.

The Aluminum Profile Cutter, developed by a leading company in the field of manufacturing machinery, is designed to streamline the process of cutting aluminum profiles with precision and efficiency. The machine is equipped with advanced features such as high-speed cutting, automated operation, and a user-friendly interface, making it an indispensable tool for manufacturers across various industries.

The company behind the Aluminum Profile Cutter, {Company Name}, has been a driving force in the manufacturing industry for over two decades. With a focus on technological innovation and customer satisfaction, the company has established itself as a trusted provider of cutting-edge machinery and equipment.

{Company Name} takes pride in its commitment to research and development, continually striving to push the boundaries of what is possible in the manufacturing industry. The Aluminum Profile Cutter is a testament to this dedication, as it represents a significant leap forward in the field of aluminum profile cutting technology.

The Aluminum Profile Cutter has been met with resounding praise from manufacturers who have integrated it into their operations. One such manufacturer, {Client Company}, a leading producer of aluminum components, has reported a significant increase in efficiency and quality since implementing the Aluminum Profile Cutter into their production line.

"We were amazed by the precision and speed of the Aluminum Profile Cutter," said {Client Company's CEO}. "It has allowed us to meet our production targets more effectively and has improved the overall quality of our products. We are extremely satisfied with the performance of this cutting-edge machine."

In addition to its cutting-edge technology, the Aluminum Profile Cutter also boasts environmental benefits, with its efficient energy consumption and minimal waste production. This aligns with {Company Name}'s commitment to sustainability and eco-friendly manufacturing practices.

The success of the Aluminum Profile Cutter can be attributed to {Company Name}'s dedication to understanding the evolving needs of the manufacturing industry and developing solutions that address these needs. The company's team of engineers and technicians work tirelessly to ensure that their products are at the forefront of technological advancement, providing manufacturers with the tools they need to thrive in a competitive market.

Looking ahead, {Company Name} is poised to continue its upward trajectory, with plans to further expand its product line and enhance its technological capabilities. The Aluminum Profile Cutter is just the beginning of what promises to be a series of groundbreaking innovations from this pioneering company.

As the manufacturing industry continues to evolve, the Aluminum Profile Cutter remains a shining example of the power of innovation and technological advancement. With its unparalleled precision, efficiency, and environmental benefits, the Aluminum Profile Cutter has secured its place as a game-changer in the world of aluminum profile cutting. Thanks to the forward-thinking approach of {Company Name}, manufacturers now have access to a tool that is revolutionizing the way they produce aluminum components.

Company News & Blog

Top Quality Aluminum Extrusions for Various Applications

Aluminum Extrusions, a leading manufacturer of aluminum products, has recently made significant improvements to its production line. The company, which has been in operation for over 20 years, specializes in the production of high-quality aluminum extrusions for various industries, including construction, transportation, and consumer goods.With a state-of-the-art facility and a team of experienced engineers and technicians, Aluminum Extrusions has established a reputation for delivering precision-engineered aluminum products that meet the highest standards of quality and performance. The company's commitment to innovation and continuous improvement has enabled it to stay ahead of the competition and meet the evolving needs of its customers.One of the key improvements that Aluminum Extrusions has made to its production line is the addition of new extrusion equipment. This new equipment allows the company to produce aluminum extrusions with even greater precision and efficiency, resulting in products that are more consistent and have tighter tolerances. The new equipment also enables Aluminum Extrusions to offer a wider range of shapes and sizes, allowing customers to find the perfect solution for their specific needs.In addition to the new extrusion equipment, Aluminum Extrusions has also implemented advanced quality control measures to ensure that every product that leaves its facility meets the highest standards of excellence. The company has invested in cutting-edge technology to monitor and inspect its products throughout the production process, allowing for real-time adjustments and corrections to be made as needed. This commitment to quality has earned Aluminum Extrusions a reputation for reliability and consistency among its customers.Furthermore, Aluminum Extrusions has expanded its product offering to include a range of surface finishes for its aluminum extrusions. Customers can now choose from a variety of finishes, including anodized, powder-coated, and painted options, to achieve the desired aesthetic and functional properties for their applications. With this expanded offering, Aluminum Extrusions is able to provide a one-stop solution for all of its customers' aluminum extrusion needs.The company's dedication to customer satisfaction is also reflected in its commitment to providing exceptional customer service. Aluminum Extrusions works closely with its customers to understand their unique requirements and develop customized solutions that meet their specific needs. The company's team of experts is available to provide technical support, design assistance, and guidance throughout the entire process, ensuring that customers receive the best possible product and service experience.As a result of these improvements, Aluminum Extrusions has positioned itself as a trusted partner for companies looking for high-quality aluminum extrusions. The company's products are widely used in a variety of industries, including automotive, aerospace, marine, and architectural applications, where precision and performance are paramount. With its expanded capabilities and unwavering commitment to excellence, Aluminum Extrusions is poised to continue leading the way in the aluminum extrusion industry.In conclusion, Aluminum Extrusions has made significant improvements to its production line, including the addition of new extrusion equipment, advanced quality control measures, and an expanded product offering. With its dedication to customer satisfaction and a proven track record of delivering high-quality products, Aluminum Extrusions is well-positioned to meet the needs of its customers and maintain its leadership in the industry.

Explore the Latest Machinery and Equipment in the Aluminum Industry

Title: Machinery and Equipment Aluminum: A Game Changer in the Manufacturing IndustryIntroduction:In a constantly evolving manufacturing landscape, the role of machinery and equipment aluminum has become increasingly crucial. Its lightweight yet sturdy properties have revolutionized various sectors, from automotive to aerospace, promising efficiency and durability in the production process. Let us delve deeper into the world of machinery and equipment aluminum, exploring its diverse applications and the companies leading this transformative industry.I. The Rise of Machinery and Equipment Aluminum:Over the years, machinery and equipment aluminum has emerged as an essential material for manufacturers worldwide. Its remarkable strength-to-weight ratio and corrosion resistance make it an ideal choice for numerous applications, ranging from structural components to complex machinery parts.II. Versatile Applications:a) Automotive Sector: One of the primary beneficiaries of machinery and equipment aluminum is the automotive industry. With the pressing need for fuel efficiency, manufacturers have turned to this innovative material to reduce vehicle weight while maintaining structural integrity. By incorporating aluminum alloys into body frames, engine components, and transmission systems, automakers can enhance performance while reducing emissions.b) Aerospace Industry: In the aerospace sector, machinery and equipment aluminum has played an instrumental role in constructing lightweight but robust aircraft. The material's ability to withstand extreme temperatures and withstand high stress levels is crucial in ensuring safety and efficiency in aviation.c) Machinery Manufacturing: From heavy-duty machinery to delicate precision instruments, aluminum alloys have become indispensable in modern manufacturing equipment. The use of machinery and equipment aluminum has garnered attention for its contribution to reducing energy consumption, enhancing productivity, and improving product quality.III. Leading Companies in Machinery and Equipment Aluminum:a) Company A: With a rich history in the aluminum industry, Company A has positioned itself as a global leader in machinery and equipment aluminum manufacturing. Their state-of-the-art facilities and cutting-edge technology ensure the production of high-quality aluminum alloys, meeting the stringent demands of various industries.b) Company B: Known for its innovative approach, Company B excels in the research and development of machinery and equipment aluminum alloys. Their focus on continuous improvement and customization has allowed them to establish long-standing partnerships with manufacturers across different sectors.c) Company C: As pioneers in the machinery and equipment aluminum market, Company C boasts a wide range of advanced alloys that cater to diverse manufacturing needs. Their commitment to sustainability and environmentally friendly practices sets them apart, making them an industry benchmark for responsible production.IV. Emerging Trends and Future Prospects:The machinery and equipment aluminum industry shows no signs of slowing down, with several emerging trends on the horizon. These include:a) Advancements in Alloy Development: Ongoing research and development efforts aim to create aluminum alloys with enhanced mechanical properties, further expanding the possibilities for manufacturers.b) Greater Emphasis on Sustainability: With environmental concerns at the forefront, companies are actively seeking sustainable production methods and considering the recyclability of machinery and equipment aluminum.c) Increasing Automation: As automation gains traction across various industries, the demand for lightweight yet durable machinery and equipment aluminum will continue to rise, facilitating the development of more efficient and cost-effective manufacturing processes.Conclusion:As the manufacturing industry evolves to meet the challenges of efficiency and sustainability, machinery and equipment aluminum has emerged as a game-changer. Its versatility, strength, and lightness have revolutionized automotive, aerospace, and machinery manufacturing, reshaping the way products are made. With leading companies innovating in the field and exciting trends on the horizon, the future of machinery and equipment aluminum is promising.

High-Quality Aluminum C Profile for Various Applications

Aluminum C Profile: A Versatile Solution for Various ApplicationsAluminum C profiles have become a versatile and widely used solution for a variety of applications in industries such as construction, automotive, and aerospace. These profiles are known for their durability, light weight, and corrosion resistance, making them an ideal choice for a wide range of projects.{Company Name} is a leading manufacturer of aluminum C profiles with a strong focus on quality and innovation. With state-of-the-art facilities and a team of experienced engineers, {Company Name} has continued to push the boundaries of what is possible with aluminum profiles.One of the key advantages of aluminum C profiles is their versatility. They can be easily customized to meet specific project requirements, making them a popular choice for architects, engineers, and designers. Whether it's for building facades, vehicle frames, or industrial equipment, aluminum C profiles offer a high degree of flexibility in design and functionality.In the construction industry, aluminum C profiles are often used for framing systems, curtain walls, and window and door frames. Their lightweight nature makes them easy to handle and install, while their strength and durability ensure long-lasting performance in any environment. Additionally, the corrosion-resistant properties of aluminum make it an ideal choice for exterior applications where exposure to the elements is a concern.In the automotive industry, aluminum C profiles are used in the manufacturing of vehicle frames, bumpers, and structural components. The lightweight nature of aluminum helps to reduce fuel consumption and emissions, making it an environmentally friendly choice for modern vehicles. Additionally, the strength and stiffness of aluminum C profiles make them an ideal material for enhancing the safety and performance of automobiles.Furthermore, in the aerospace industry, aluminum C profiles play a critical role in the design and construction of aircraft structures. The combination of high strength and low weight makes aluminum an ideal choice for reducing the overall weight of aircraft, leading to improved fuel efficiency and performance. These profiles are also known for their ability to withstand extreme temperatures and harsh environmental conditions, making them an ideal choice for aerospace applications.{Company Name} has been at the forefront of developing new and innovative aluminum C profiles to meet the ever-changing demands of modern industries. With a focus on research and development, the company has introduced a range of advanced aluminum alloys and manufacturing techniques to further enhance the performance and capabilities of their profiles. This commitment to innovation has allowed {Company Name} to stay ahead of the competition and provide its customers with the highest quality products.In addition to their technical capabilities, {Company Name} is also dedicated to sustainability and environmental responsibility. Aluminum is a highly recyclable material, and the company is committed to reducing its carbon footprint by using recycled aluminum in its production processes. This not only helps to conserve natural resources but also reduces the overall environmental impact of manufacturing aluminum profiles.As the demand for lightweight, durable, and sustainable materials continues to grow, aluminum C profiles are expected to play an even more significant role in a wide range of industries. With their versatile design, excellent performance, and environmental benefits, it's clear that aluminum C profiles will continue to be a material of choice for years to come.In conclusion, Aluminum C profiles have proven to be a versatile and practical solution for a wide range of applications. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for industries such as construction, automotive, and aerospace. {Company Name} has been a key player in the development and production of aluminum C profiles, and their commitment to quality, innovation, and sustainability continues to set them apart in the market. With the increasing demand for high-performance materials, aluminum C profiles are expected to remain a popular choice for a variety of projects in the future.

Durable and Versatile 1-Inch Square Aluminium Tube for Various Applications

With a growing demand for lightweight and durable materials in various industries, the use of aluminium square tubes has seen a significant rise. [Company Name] is one of the leading suppliers of high-quality aluminium square tubes, and their 1-inch square tube has gained popularity in the market for its exceptional strength and versatility.The 1-inch aluminium square tube offered by [Company Name] is constructed using premium quality aluminium, making it suitable for a wide range of applications. The lightweight nature of aluminium makes it an ideal choice for applications where weight reduction is crucial, such as in the aerospace and automotive industries. Additionally, the corrosion-resistant properties of aluminium make it a preferred material for outdoor and marine applications.One of the key advantages of the 1-inch aluminium square tube is its high strength-to-weight ratio. This makes it an excellent choice for structural applications where strength and durability are paramount. Whether it's for building frames, support structures, or furniture manufacturing, the aluminium square tube from [Company Name] offers the perfect combination of strength and lightness.In addition to its physical properties, the 1-inch aluminium square tube is also highly versatile in terms of fabrication and finishing. The inherent malleability of aluminium allows for easy shaping and forming, making it possible to create custom designs and profiles as per the specific requirements of the application. Furthermore, aluminium can be easily anodized or powder-coated to provide additional protection and enhance its aesthetic appeal.[Company Name] takes pride in its commitment to delivering top-quality products that meet the highest industry standards. Their 1-inch aluminium square tube is manufactured using advanced techniques and stringent quality control measures to ensure consistency and reliability. This attention to detail has earned [Company Name] a solid reputation for providing premium aluminium products that meet the diverse needs of their clients.With a customer-centric approach, [Company Name] offers a range of services to support their clients in their projects involving the 1-inch aluminium square tube. From expert technical guidance to efficient logistics and timely delivery, [Company Name] strives to provide a seamless experience for their customers. Their team of experienced professionals is dedicated to understanding the unique requirements of each client and offering tailored solutions to meet their specific needs.As a socially responsible company, [Company Name] is also committed to sustainable and eco-friendly practices in their operations. Aluminium is a highly recyclable material, and [Company Name] actively promotes the use of recycled aluminium in their products. This not only reduces the environmental impact but also contributes to a circular economy by minimizing waste and conserving natural resources.The 1-inch aluminium square tube from [Company Name] has gained popularity not only for its superior qualities but also for the comprehensive support and expertise that [Company Name] provides to its customers. Whether it's for industrial, commercial, or residential applications, the 1-inch aluminium square tube offers a reliable and cost-effective solution for a wide range of structural and decorative needs.In conclusion, the 1-inch aluminium square tube from [Company Name] stands out as a top choice for various applications due to its exceptional strength, lightness, versatility, and quality. With a focus on customer satisfaction and sustainability, [Company Name] continues to lead the industry in providing high-quality aluminium products that meet the evolving needs of their clients.

Aluminum CNC Cutting Services: A Detailed Guide

Laser cutting technology has revolutionized the manufacturing industry with its precision and efficiency. With the increasing demand for high-quality metal cutting services, {Company} has recently announced the addition of CNC cutting aluminum to its list of offerings. This new service will further expand the company's capabilities and enhance its position as a leading provider of metal fabrication solutions.CNC cutting, also known as computer numerical control cutting, utilizes a high-powered laser to cut through a variety of materials, including aluminum. The advanced technology allows for precise and intricate cuts, making it ideal for a wide range of applications in various industries.{Company} has been at the forefront of the metal fabrication industry for over a decade, providing reliable and cost-effective solutions to its clients. With a team of highly skilled engineers and technicians, the company has built a strong reputation for delivering exceptional results and exceeding customer expectations.The decision to incorporate CNC cutting aluminum into its services comes as a response to the growing demand for aluminum components in industries such as aerospace, automotive, and electronics. With its lightweight and durable properties, aluminum has become a popular choice for manufacturers seeking to improve the performance and efficiency of their products.By adding CNC cutting aluminum to its portfolio, {Company} aims to meet the needs of its clients who require precision-cut aluminum parts for their operations. Whether it's for prototyping, production runs, or custom fabrication projects, the company is well-equipped to handle a wide range of requirements with its state-of-the-art CNC cutting capabilities.The introduction of CNC cutting aluminum underscores {Company}'s commitment to staying ahead of industry trends and offering cutting-edge solutions to its clients. The company has continuously invested in the latest technologies and equipment to ensure that it remains at the forefront of the metal fabrication industry.In addition to CNC cutting aluminum, {Company} offers a comprehensive range of metal fabrication services, including laser cutting, welding, bending, and finishing. The company's modern facilities and skilled workforce enable it to handle projects of varying complexities and scales, delivering high-quality results within tight deadlines.{Company} takes pride in its ability to work closely with clients to understand their specific needs and deliver tailor-made solutions that meet and exceed their expectations. The addition of CNC cutting aluminum further demonstrates the company's dedication to providing comprehensive and versatile services to its clients.Furthermore, with a strong focus on quality, efficiency, and reliability, {Company} has established itself as a trusted partner for businesses in need of metal fabrication solutions. The company's commitment to excellence and customer satisfaction has earned it a loyal clientele and a reputation for delivering superior results.As the demand for aluminum components continues to grow across various industries, {Company} is well-positioned to fulfill the needs of its clients with its advanced CNC cutting capabilities. The company's investment in CNC cutting aluminum reaffirms its position as an industry leader and a go-to provider for all metal fabrication requirements.In conclusion, the addition of CNC cutting aluminum to {Company}'s list of offerings is a significant milestone that highlights the company's commitment to innovation and meeting the evolving needs of its clients. With its advanced technology, skilled workforce, and dedication to quality, {Company} is poised to deliver superior CNC cutting aluminum services to businesses seeking reliable and efficient metal fabrication solutions.

Durable High Strength Aluminum: A Game Changer in Manufacturing Industry

High Strength Aluminium: The Future of Lightweight and Durable Construction MaterialsIn recent years, the construction industry has seen a growing demand for materials that are not only lightweight but also offer high strength and durability. This need has led to the development of innovative solutions, one of which is high strength aluminium. This material has rapidly gained popularity due to its ability to meet the rigorous requirements of modern construction projects. One company at the forefront of this technological advancement is {company name}, a leading manufacturer of high strength aluminium products.{Company name} has been a pioneer in the development and production of high strength aluminium for various applications, including aerospace, automotive, and construction. By leveraging cutting-edge technology and state-of-the-art manufacturing processes, the company has been able to offer a wide range of high strength aluminium products that meet the stringent demands of its customers.The success of high strength aluminium lies in its unique properties, which make it an ideal material for construction purposes. Firstly, it is significantly lighter than traditional construction materials such as steel, making it easier to handle and transport. Despite its lightweight nature, high strength aluminium boasts impressive strength and durability, making it suitable for a wide range of structural applications, including beams, columns, and facades.One of the key advantages of using high strength aluminium in construction is its exceptional corrosion resistance. This important attribute ensures that structures built with high strength aluminium can withstand harsh environmental conditions, including exposure to moisture, chemicals, and pollutants. As a result, buildings and infrastructure made from high strength aluminium are able to maintain their structural integrity and aesthetic appeal for extended periods, thereby reducing maintenance and replacement costs.Furthermore, high strength aluminium is highly versatile, allowing for a wide range of design possibilities. Its malleability and formability enable architects and engineers to create innovative and unique structures that are not possible with traditional construction materials. This versatility has contributed to the widespread adoption of high strength aluminium in iconic architectural landmarks and modern urban developments around the world.{Company name} has been at the forefront of promoting the use of high strength aluminium in construction, offering a comprehensive range of products that cater to the diverse needs of the industry. The company's commitment to innovation and quality has earned it a reputation as a trusted partner for construction professionals seeking reliable and high-performance materials.One of the company's flagship products is {high strength aluminium product}, which has been specifically engineered to meet the stringent requirements of modern construction projects. This product has been extensively tested and certified to ensure compliance with international standards, providing customers with the confidence that they are using a material of the highest quality and performance.In addition to its high strength aluminium products, {company name} also offers a range of support services to assist customers in the design, fabrication, and installation of their construction projects. The company's team of experts is dedicated to providing technical expertise and guidance to ensure that customers are able to fully leverage the benefits of high strength aluminium in their construction projects.As the construction industry continues to evolve, the demand for lightweight, high strength, and durable materials is expected to grow exponentially. High strength aluminium, with its exceptional properties and versatility, is well-positioned to meet this demand and play a pivotal role in shaping the future of construction.{Company name}'s unwavering commitment to innovation and excellence places it in a prime position to lead the advancement of high strength aluminium in construction. With a strong track record of delivering high-quality products and exceptional customer support, {company name} is poised to be a driving force in the widespread adoption of high strength aluminium as the material of choice for modern construction projects.

Aluminum T-Slot Dimensions: A Complete Guide

T Slot Aluminum Dimensions is a leading provider of high-quality aluminum extrusion profiles for a wide range of applications. Their products are known for their precise dimensions, durability, and versatility, making them an ideal choice for various industries, including manufacturing, construction, and automotive. With a commitment to delivering top-notch products and excellent customer service, T Slot Aluminum Dimensions has established a strong reputation in the market.The company specializes in manufacturing T-slot aluminum extrusions, which are known for their unique T-shaped slots that allow for easy assembly and reconfiguration. These profiles are commonly used to build frames, workstations, shelving, enclosures, and other structures that require strong and lightweight components. T Slot Aluminum Dimensions offers a wide range of T-slot profiles in different sizes, shapes, and configurations to meet the diverse needs of their customers.One of the key advantages of T Slot Aluminum Dimensions' products is their precise dimensions. The company utilizes advanced manufacturing techniques and quality control measures to ensure that their aluminum extrusions meet the highest standards of accuracy and consistency. This precision is crucial for ensuring the seamless assembly and integration of T-slot profiles into various applications, allowing for efficient and reliable performance.Furthermore, T Slot Aluminum Dimensions' products are designed to be highly durable and long-lasting. The company uses high-quality materials and processes to ensure that their aluminum extrusions can withstand the rigors of demanding environments and applications. Whether it's heavy-duty industrial machinery or intricate architectural designs, T Slot Aluminum Dimensions' profiles are built to deliver exceptional strength and reliability.In addition to their dimensional accuracy and durability, T Slot Aluminum Dimensions' products are also highly versatile. The T-slot design allows for easy and flexible assembly, disassembly, and reconfiguration, making it easy to modify and adapt structures as needed. This versatility makes T Slot Aluminum Dimensions' profiles suitable for a wide range of applications, from modular assembly lines to custom-designed fixtures and displays.As a customer-focused company, T Slot Aluminum Dimensions is committed to providing exceptional service and support to their clients. Their team of experts is dedicated to helping customers find the right solutions for their specific needs and requirements. Whether it's selecting the appropriate T-slot profiles or providing technical assistance for assembly, T Slot Aluminum Dimensions is there to ensure a smooth and successful experience for their customers.Furthermore, T Slot Aluminum Dimensions offers customization services to meet unique specifications and designs. Their in-house engineering and manufacturing capabilities allow them to work closely with customers to develop custom T-slot profiles tailored to their exact requirements. This flexibility makes T Slot Aluminum Dimensions a preferred partner for companies looking for specialized aluminum extrusions for their projects.In conclusion, T Slot Aluminum Dimensions is a trusted provider of high-quality T-slot aluminum extrusions, known for their precise dimensions, durability, and versatility. With a strong focus on customer satisfaction and exceptional service, the company continues to be a leading choice for various industries seeking reliable aluminum extrusion solutions. Whether it's standard profiles or custom designs, T Slot Aluminum Dimensions is dedicated to delivering top-notch products and support for their valued customers.

The Latest Updates on Aluminum Profile Manufacturing in the CNC Industry

Title: Advancements in CNC Aluminum Profile Manufacturing: Shaping the Future of Industrial SolutionsIntroduction:In the realm of modern manufacturing, precision and efficiency are paramount. To meet these demands, companies are continually striving to improve their machining processes. One groundbreaking solution that has revolutionized the industry is the CNC (Computer Numerical Control) aluminum profile. In this article, we will delve deeper into the benefits and applications of CNC aluminum profiles, highlighting their crucial role in reshaping the future of industrial solutions.Body:1. Understanding CNC Aluminum Profile:CNC aluminum profiles are specialized extrusions that go through a meticulous machining process, wherein computers control the manufacturing equipment. This advanced technology enables manufacturers to consistently produce highly precise and customized aluminum profiles, resulting in improved functionality and performance.2. Unmatched Precision and Quality:The utilization of CNC technology ensures superior precision and quality in every aluminum profile produced. CNC machining allows for intricate shapes, tight tolerances, and complex designs, surpassing what traditional manufacturing techniques can achieve. As a result, industries such as aerospace, automotive, and construction are benefitting from the high-performance capabilities of CNC aluminum profiles.3. Enhanced Durability and Lightweight Design:Aluminum, known for its exceptional strength-to-weight ratio, is an ideal material for various applications. CNC aluminum profiles offer enhanced durability and structural stability while remaining lightweight. This combination of strength and reduced weight makes CNC aluminum profiles desirable in industries where both performance and weight restrictions pose significant challenges.4. Versatile Applications:The versatility of CNC aluminum profiles makes them suitable for a wide range of applications. From architectural frameworks to conveyor systems, CNC aluminum profiles find application in construction, industrial machinery, transportation vehicles, and more. Their inherent corrosion resistance and compatibility with other materials make them indispensable in creating robust solutions for demanding environments.5. Streamlined Automation and Efficiency:The automated nature of CNC aluminum profile manufacturing eliminates the need for manual intervention and reduces the margin of error. Manufacturers can program CNC machines to repetitively produce precise profiles, resulting in increased productivity and efficiency. This streamlined automation is a game-changer for industries seeking to optimize their manufacturing processes and meet market demands.6. Sustainable and Environmentally-Friendly:Aluminum is fully recyclable, and the CNC aluminum profile manufacturing process creates minimal waste. The ability to recycle and reuse aluminum profiles makes them an environmentally-friendly choice while also reducing material costs. As sustainability continues to gain importance across industries, CNC aluminum profiles offer an eco-friendly solution without compromising on performance or quality.7. Rising Demand and Future Prospects:With constant advancements in CNC technology, the demand for CNC aluminum profiles is projected to surge. Acclaimed for their versatility, precision, and efficiency, CNC aluminum profiles are poised to dominate various sectors. Furthermore, the integration of artificial intelligence and machine learning with CNC technology opens up endless possibilities for innovation, propelling the industrial solutions of tomorrow.Conclusion:Innovations in CNC aluminum profile manufacturing are transforming the way industries approach their manufacturing needs. With unmatched precision, enhanced durability, and lightweight design, CNC aluminum profiles are redefining the boundaries of what is possible. As companies continue to leverage their capabilities, CNC aluminum profiles are carving their place in the future of industrial solutions, ensuring increased productivity, reduced costs, and efficiency across numerous sectors.

Aluminium CNC Machining: Benefits and Techniques

CNC Aluminium Machining: Revolutionizing the Manufacturing IndustryIn today's fast-paced and ever-evolving manufacturing industry, precision and efficiency are key factors that drive success. With the advent of advanced technology, CNC Aluminium Machining has emerged as a game-changing innovation that is transforming the way aluminium components are produced.CNC Aluminium Machining, also known as Computer Numerical Control machining, is a highly sophisticated and precise method of manufacturing aluminium parts and components. This cutting-edge technology allows for the creation of intricate and complex designs with remarkable accuracy and consistency. As a result, CNC Aluminium Machining has become an indispensable tool for industries such as automotive, aerospace, electronics, and many others.One company that has been at the forefront of CNC Aluminium Machining is {}. With years of experience and expertise in the field of precision engineering, {} has established itself as a leading provider of CNC machining services. The company boasts a state-of-the-art facility equipped with advanced CNC machines and a team of skilled engineers and technicians who are dedicated to delivering high-quality, bespoke solutions to their clients.The utilization of CNC Aluminium Machining has revolutionized the manufacturing processes at {}. By leveraging the power of computer-controlled precision, the company is able to produce aluminium components with unparalleled accuracy and efficiency. This has not only improved the overall quality of their products but has also significantly reduced lead times, resulting in a more streamlined and cost-effective production process.One of the key advantages of CNC Aluminium Machining is its ability to create complex shapes and designs that would be virtually impossible to achieve using traditional machining methods. This versatility has enabled {} to cater to a wide range of industries and provide tailor-made solutions to meet the unique requirements of their clients. Whether it's producing intricate components for the automotive industry or manufacturing precision parts for the aerospace sector, {} has consistently demonstrated their ability to deliver exceptional results.Moreover, CNC Aluminium Machining has also opened up new possibilities in terms of material optimization and waste reduction. By employing advanced cutting techniques and toolpath strategies, {} is able to maximize the utilization of aluminium, resulting in minimal material wastage and ultimately reducing costs. This eco-friendly approach has not only contributed to sustainable manufacturing practices but has also positioned {} as a responsible and forward-thinking industry leader.In addition to their technical expertise, {} prides itself on its commitment to customer satisfaction and continuous improvement. The company works closely with clients throughout the entire manufacturing process, from initial design concepts to the final product, ensuring that their exact specifications and requirements are met. This collaborative approach has earned {} a stellar reputation for reliability and excellence in the industry.As CNC Aluminium Machining continues to gain prominence in the manufacturing landscape, companies like {} are leading the way in driving innovation and setting new standards for precision engineering. With a strong track record of delivering exceptional results and a dedication to pushing the boundaries of what is possible, {} is well-positioned to thrive in an increasingly competitive market.In conclusion, CNC Aluminium Machining is undeniably a game-changer in the manufacturing industry, offering unparalleled precision, efficiency, and versatility. As a company that has fully embraced this cutting-edge technology, {} stands as a testament to the incredible potential of CNC Aluminium Machining, and its ability to shape the future of manufacturing. With a steadfast commitment to excellence and a relentless pursuit of innovation, {} is poised to continue making significant contributions to the industry for years to come.

Top 5 Aluminium Board Fixings for Your Next Project

Aluminium Board Fixings, are an essential component in the construction industry. These fixings are used to secure aluminium boards in place, providing a strong and reliable fixing solution for a variety of applications. These fixings are widely used in the construction of commercial buildings, residential homes, and other structures where aluminium boards are used as a cladding material.One company that specializes in the manufacturing of Aluminium Board Fixings is {}. With over 20 years of experience in the industry, {} has established itself as a leading supplier of high-quality fixings for aluminium boards. The company prides itself on its commitment to providing innovative and reliable fixing solutions for the construction industry, and its products are trusted by architects, contractors, and builders worldwide.{} offers a wide range of Aluminium Board Fixings, including self-drilling screws, rivets, and other fastening solutions. These fixings are designed to provide a secure and long-lasting attachment for aluminium boards, ensuring that they remain in place even in the harshest of weather conditions. The company's fixings are made from high-quality materials, and they are manufactured to the highest standards to ensure superior performance and durability.In addition to its range of Aluminium Board Fixings, {} also offers a variety of other construction and building products. This includes a comprehensive selection of cladding materials, insulation products, and accessories to meet the needs of its customers. With a focus on quality and innovation, {} is dedicated to providing solutions that are not only reliable but also environmentally friendly, helping to promote sustainable building practices.{}'s commitment to quality and excellence has earned them a solid reputation in the construction industry. The company is known for its exceptional customer service, and it works closely with its clients to understand their specific requirements and provide tailored solutions to meet their needs. Whether it's a large commercial project or a small residential build, {} has the expertise and products to deliver reliable and cost-effective fixing solutions.Furthermore, {} is dedicated to staying at the forefront of technological advancements in the construction industry. The company invests in research and development to continuously improve its products and processes, ensuring that it remains a leader in the market. By embracing new technologies and sustainable practices, {} is able to deliver products that are not only superior in quality but also environmentally friendly.In conclusion, Aluminium Board Fixings are an essential component in the construction industry, and {} is a trusted supplier of high-quality fixings for a wide range of applications. With a focus on innovation, quality, and customer satisfaction, {} has established itself as a leading provider of reliable fixing solutions for aluminium boards. Whether it's for a commercial project or a residential build, customers can trust {} to deliver the products and expertise needed to ensure a successful and durable construction.