High-Quality 30mm Aluminum Square Tube for Sale: Durable and Versatile

By:Admin

The 30mm Aluminium Square Tube is designed to meet the growing demands of various industries, including construction, automotive, and aerospace. With its high strength-to-weight ratio, corrosion resistance, and excellent formability, this new product offers unparalleled performance and durability. The tube is meticulously crafted using state-of-the-art technology and premium-grade aluminum material, ensuring outstanding quality and precision.

One of the key features of the 30mm Aluminium Square Tube is its versatility. It can be used for a wide range of applications, such as framing, support structures, and architectural elements. The tube's sleek and modern design makes it an ideal choice for both indoor and outdoor projects. Additionally, it is available in various lengths and can be customized to meet specific requirements, making it a highly adaptable solution for different engineering needs.

"Our new 30mm Aluminium Square Tube is the result of extensive research, development, and testing to ensure that it meets the highest standards of performance and reliability," said [Company Name]'s spokesperson. "We are proud to offer this innovative product to our customers, empowering them with a premium aluminum solution that can enhance the efficiency and success of their projects."

As a leading manufacturer in the industry, [Company Name] is committed to providing top-notch aluminum products that exceed customer expectations. With a strong focus on innovation and quality, the company has a proven track record of delivering cutting-edge solutions to various market sectors globally. Its dedication to excellence and customer satisfaction has earned [Company Name] a solid reputation as a trusted and preferred aluminum supplier in the industry.

In addition to the 30mm Aluminium Square Tube, [Company Name] offers a comprehensive range of aluminum products, including sheets, plates, bars, and profiles, catering to diverse needs and specifications. The company's advanced manufacturing facilities and skilled workforce ensure that all products meet stringent quality standards and undergo rigorous inspection to guarantee consistency and reliability.

Furthermore, [Company Name] is known for its commitment to sustainability and environmental responsibility. The company adopts eco-friendly practices throughout its production processes and continuously seeks to minimize its environmental footprint. This means that customers can rely on [Company Name] not only for top-quality aluminum products but also for ethical and sustainable manufacturing practices.

With the launch of the 30mm Aluminium Square Tube, [Company Name] has once again demonstrated its dedication to driving innovation and meeting the evolving needs of the industry. As the company continues to expand its product portfolio and explore new opportunities, it remains steadfast in its mission to deliver excellence and value to its customers.

The 30mm Aluminium Square Tube is now available for purchase, and customers can expect the same level of exceptional service and support that [Company Name] is renowned for. With its unrivaled quality and performance, this innovative product is set to make a lasting impact in the aluminum market, solidifying [Company Name]'s position as a leader in the industry.

In conclusion, the launch of the 30mm Aluminium Square Tube underscores [Company Name]'s ongoing commitment to innovation, quality, and customer satisfaction. This new product stands as a testament to the company's relentless pursuit of excellence and its ability to deliver advanced solutions that meet the diverse needs of its customers. As [Company Name] continues to push the boundaries of aluminum technology, the 30mm Aluminium Square Tube is poised to set new industry standards and become a game-changer in the market.

Company News & Blog

Aluminum Components for Next-Generation Electric Vehicles

Aluminum For New Energy VehiclesThe automotive industry is undergoing a significant transformation, with a shift towards new energy vehicles (NEVs) becoming increasingly evident. As the demand for cleaner and more sustainable modes of transportation continues to rise, manufacturers are exploring innovative materials and technologies to drive the development of NEVs. One such material that is playing a crucial role in this evolution is aluminum.Aluminum is increasingly being integrated into the design and production of NEVs, thanks to its exceptional properties that make it an ideal choice for enhancing the performance and efficiency of these vehicles. Aluminum is lightweight, strong, and corrosion-resistant, making it a preferred material for reducing the overall weight of vehicles and improving their energy efficiency. Furthermore, aluminum is fully recyclable, aligning with the sustainability goals of the NEV industry.In this context, (remove brand name) is at the forefront of leveraging aluminum for the advancement of NEVs. As a leading manufacturer and supplier of aluminum products, (remove brand name) has been actively collaborating with NEV manufacturers to develop innovative solutions that meet the evolving needs of the industry.With a strong focus on research and development, (remove brand name) has introduced a range of aluminum products specifically tailored for NEVs. These products are designed to address the unique challenges and requirements of electric and hybrid vehicles, offering superior performance, durability, and sustainability.One such example is the use of high-strength aluminum alloys in the manufacturing of vehicle structures and components. By incorporating these alloys, NEV manufacturers can achieve significant weight savings without compromising on safety and structural integrity. This, in turn, contributes to extending the driving range and improving the overall efficiency of NEVs.Moreover, (remove brand name) has also developed aluminum solutions for the battery enclosures of NEVs. The use of aluminum in battery enclosures offers improved thermal management, enhanced safety, and better overall performance of the vehicle's power source. This contributes to the long-term reliability and durability of NEVs, while also supporting the efficient management of battery temperature and performance.In addition to its technical expertise, (remove brand name) has established a robust supply chain and manufacturing capabilities to meet the growing demand for aluminum in the NEV sector. With a commitment to quality and sustainability, (remove brand name) ensures that its aluminum products adhere to the highest industry standards, while also minimizing the environmental impact of their production and usage.As the NEV market continues to expand, the role of aluminum in driving innovation and progress in this industry is set to become even more significant. With its unparalleled advantages and versatility, aluminum is poised to play a pivotal role in shaping the future of transportation and advancing the development of sustainable mobility solutions.In conclusion, (remove brand name) is playing a crucial role in enabling the widespread adoption of aluminum in NEVs. Through its cutting-edge technology, manufacturing expertise, and focus on sustainability, (remove brand name) is well-positioned to support the evolving needs of the NEV industry and contribute to the realization of a cleaner and more sustainable transportation ecosystem. As the demand for NEVs continues to grow, the significance of aluminum in this sector is only expected to increase, further solidifying its position as a key enabler of the new era of mobility.

Aluminium Half Round Moulding: Enhance Your Space with Sleek Design

As demand for stylish yet durable building materials continues to rise, Aluminium Half Round Moulding has emerged as a trusted choice for developers and homeowners alike. This versatile material offers a proven track record for longevity and versatility, making it a popular option for both exterior and interior applications.One leading provider of Aluminium Half Round Moulding is {company name}, which has been in the industry for over 20 years. The company has built a reputation for delivering high-quality products and services to a range of clients, from builders to architects and homeowners.{company name} offers a variety of shapes and sizes of Aluminium Half Round Moulding, which can be customized to fit specific project requirements. These mouldings can be used to add a distinctive touch to both contemporary and traditional building designs, and come in a range of colors to complement any decor.What makes Aluminium Half Round Moulding so unique is its innate durability. This material is strong enough to withstand the elements, from extreme temperatures to heavy winds and rains. Unlike other popular building materials, such as wood and vinyl, Aluminium Half Round Moulding is also resistant to termites and other insects, as well as rot.Moreover, Aluminium Half Round Moulding is practically maintenance-free. It does not require any painting, staining, or sealing, unlike other materials that may need frequent touch-ups to maintain their appearance. This saves time and money over the life of the building, making aluminium an economical choice for developers and homeowners.In addition to its durability and low-maintenance properties, Aluminium Half Round Moulding is also very versatile. It can be used for a wide range of applications, from window and door trim to decorative accents on ceilings, walls, and columns.The company prides itself on its commitment to customer satisfaction and environmental responsibility. All of its aluminium products are made from recycled materials, which reduces waste and conserves natural resources. The company also works with clients to find the right solutions for their specific project needs, whether it's a large-scale commercial project or a small residential remodel.Customers who choose Aluminium Half Round Moulding from {company name} can rest assured that they are getting a high-quality product that meets or exceeds industry standards. The company uses only the finest materials to manufacture its products, and its team of experienced professionals is dedicated to ensuring that every order is delivered on time and to the exact specifications of the client.Ultimately, Aluminium Half Round Moulding offers a durable and versatile building solution that is ideal for a wide range of applications. Whether you're a developer building a new commercial property or a homeowner undertaking a renovation project, {company name}'s Aluminium Half Round Moulding provides a reliable and cost-effective option that will stand the test of time.

Revolutionary Aluminum Frame Design Aims to Disrupt the Industry" can be rewritten as "Innovative Aluminum Frame Design Set to Revolutionize the Industry".

[Innovation in Aluminum Frame Design: Revolutionizing the Industry]Aluminum Frame Design (AFD), an industry-leading innovator in the field of lightweight construction, continues to push the boundaries with its groundbreaking designs. With a relentless focus on sustainability, efficiency, and durability, AFD is revolutionizing various industries by delivering state-of-the-art solutions that are reshaping the future of manufacturing.AFD's commitment to excellence can be traced back to its humble beginnings. Founded in {year} by visionary engineers, {Company Name} started its journey with the aim of transforming traditional manufacturing processes. By harnessing the power of aluminum, a lightweight yet robust material, AFD has been able to bring groundbreaking ideas to life.The secret behind AFD's success lies in its innovative aluminum frame construction techniques. By capitalizing on the unique properties of aluminum, the company has developed cutting-edge solutions that are not only stronger but also lighter than traditional frames made from materials like steel. The use of aluminum frames has significantly reduced the weight of various products, from automobiles to consumer electronics, making them more fuel-efficient and environmentally friendly.One of AFD's noteworthy achievements is its collaboration with the automotive industry. Over the years, the company has worked closely with leading car manufacturers to optimize vehicle design and enhance overall performance. By replacing conventional steel frames with aluminum ones, AFD has reduced the weight of cars, leading to improved fuel efficiency and reduced emissions. Additionally, the aluminum frames offer superior collision protection due to their high strength-to-weight ratio, ensuring the safety of passengers in case of accidents.Another industry where AFD's aluminum frame technology is making waves is in the aerospace sector. By partnering with aerospace giants, AFD has revolutionized aircraft manufacturing. The implementation of lightweight aluminum frames has not only reduced aircraft weight but also increased fuel efficiency. This breakthrough has had a significant impact on the aviation industry, leading to lower operational costs and reduced environmental impact.The benefits of AFD's aluminum frames extend beyond the automotive and aerospace industries. The company's innovative designs have influenced various sectors, including consumer electronics, architecture, and renewable energy. In consumer electronics, AFD's lightweight yet durable aluminum frames have made devices more portable, while maintaining structural integrity. In architecture, the use of aluminum frames has allowed for sleek and modern designs, enabling architects to create visually stunning structures with enhanced energy efficiency. In the renewable energy sector, AFD's aluminum frames have contributed to the development of lightweight solar panels, making them easier to install and transport.With sustainability at the forefront of its mission, AFD is committed to reducing the environmental impact of its manufacturing processes. Aluminum, being a highly recyclable material, aligns perfectly with the company's sustainability goals. AFD ensures that its production facilities adhere to strict environmental regulations and focuses on minimizing waste throughout the manufacturing process. By utilizing recycled aluminum and optimizing material consumption, AFD further contributes to a greener future.Looking ahead, AFD shows no signs of slowing down. The company is continuously investing in research and development to further enhance its aluminum frame designs. Collaborations with academic institutions and other industry leaders allow AFD to stay at the forefront of innovation, driving progress in lightweight construction techniques.In conclusion, Aluminum Frame Design (AFD) has emerged as a pioneer in the world of lightweight construction. Through its innovative aluminum frame designs, AFD has revolutionized various industries, from automotive to aerospace, consumer electronics to architecture. By reducing weight, increasing efficiency, and promoting sustainability, AFD's groundbreaking solutions are reshaping the future of manufacturing and contributing to a greener world.

Revamp Your Home with Affordable Aluminum L-Shaped Shelves

Aluminum L Shape Taking the Industry by StormThe use of aluminum L shape is rapidly gaining popularity in the construction industry, thanks to its exceptional qualities. Among the reasons why it is quickly becoming the go-to option in construction are its strength, robustness, and aesthetic appeal.One of the major players in the design and supply of aluminum L shape is {Brand Name Removed}. The company has gained a reputation for its excellent service and innovative solutions. It employs state-of-the-art technology and only works with high-grade materials to produce premium quality products. From custom-made aluminum extrusions to standard profiles, {Brand Name Removed} offers a broad range of aluminum products to suit various construction projects.{Brand Name Removed} understands that the modern construction industry demands unique products that align with the latest trends and standards. This is why it has invested heavily in research and development to create innovative solutions for its clients. For instance, one of its products - the aluminum L shape - has been designed to meet the current demands of the market.Here's what makes the aluminum L shape an excellent choice for construction projects:Strength and DurabilityAluminum L shape is highly durable and resistant to corrosion, making it ideal for use in exterior and interior applications. Additionally, aluminum is structurally strong, providing excellent support for heavy loads.LightweightDespite its robust nature, aluminum L shape is lightweight, which makes it easy to handle and install.Aesthetic AppealAluminum L shape is highly versatile and available in various colors and finishes. This means it can be used to create any desired look, from a classic to a modern, sleek finish. Furthermore, {Brand Name Removed} offers custom solutions, allowing clients to have products that match their specific requirements.Environmentally FriendlyAluminum is 100% recyclable, making it an environmentally friendly option. This is particularly important in today's environmentally conscious society where people are keen on reducing their carbon footprint.ApplicationsAluminum L shape can be used in a broad range of applications, including facades, window frames, doors, furniture, and much more. It is also ideal for use in industrial and commercial applications where durability and strength are crucial.{Brand Name Removed} offers clients a complete range of services, from design to installation. Its team of experts works closely with clients to develop customized solutions that suit their unique needs. Moreover, the company has invested in modern technology to ensure that its clients receive high-quality products and services.One of the primary goals of {Brand Name Removed} is to provide clients with products that meet their budget without compromising on quality. The company has an efficient cost structure, which allows it to keep the prices of its products low without compromising on quality.In conclusion, the aluminum L shape is rapidly becoming a preferred choice in the construction industry. This is due to its exceptional qualities, including strength, durability, lightweight, aesthetic appeal, and environmentally friendly nature. {Brand Name Removed} is at the forefront of supplying high-quality aluminum L shape and other aluminum products to the industry. The company's innovative solutions, coupled with its dedication to excellent service, have earned it a reputation as a leading supplier in the industry.

Discover the Versatile Uses of Extruded Aluminum Channels

The Aluminum Channel Industry: A Growing Market for Extruded Aluminum ChannelsAluminum channels play a crucial role in a wide range of industries, from construction and automotive to electronics and retail. These versatile components are used for various applications, including structural, decorative, and protective purposes. With a strong demand across multiple sectors, the market for aluminum channels is booming. One company that has made a significant impact in this industry is {Company Name}.{Company Name} is a leading manufacturer and supplier of extruded aluminum channels. With state-of-the-art facilities and a commitment to innovation, the company provides high-quality products that meet the diverse needs of its customers. With a wide range of extruded aluminum channels available, {Company Name} has become a top choice for businesses worldwide.Extruded aluminum channels are created through a manufacturing process that involves pushing heated aluminum through a die to obtain specific shapes and sizes. This process allows for the creation of customized channels that are tailored to meet the requirements of different applications. Industries such as construction rely on aluminum channels for their structural properties, as they offer excellent strength, durability, and flexibility. Moreover, extruded aluminum channels are lightweight, corrosion-resistant, and have excellent thermal conductivity, making them ideal for various environments and conditions.The demand for extruded aluminum channels has been steadily increasing over the years, driven by the growth of industries such as construction, automotive, and electronics. In the construction sector, aluminum channels are widely used for architectural applications, including window frames, curtain walls, and railings. The automotive industry relies on these channels for structural components, such as support beams and chassis parts, due to their strength-to-weight ratio.Furthermore, the electronics industry uses extruded aluminum channels for heat sink applications. Heat sinks are essential in electronic devices to dissipate heat and prevent overheating, ensuring optimal performance and longevity of the equipment. Aluminum channels are well-suited for this purpose, as they efficiently conduct heat and can be customized to specific designs and dimensions.{Company Name} has positioned itself as a leading player in the extruded aluminum channel market by offering a diverse range of products that cater to the specific needs of different industries. Their comprehensive product portfolio includes channels of various shapes, sizes, and finishes, giving customers the flexibility to choose the perfect solution for their applications.In addition to their commitment to quality, {Company Name} also places a strong emphasis on sustainability. Aluminum is a highly sustainable material, as it is infinitely recyclable without losing its properties. {Company Name} has implemented sustainable practices throughout its manufacturing process to minimize waste and energy consumption, reducing their environmental impact.To meet the growing demand for extruded aluminum channels, {Company Name} has invested in advanced manufacturing technologies and expanded their production capabilities. By staying at the forefront of technological advancements, the company is able to produce high-quality channels efficiently and cost-effectively, meeting tight deadlines and exceeding customer expectations.The success of {Company Name} is not only attributed to their superior product quality and sustainable practices but also to their commitment to customer satisfaction. The company takes pride in providing exceptional customer service and technical support, ensuring that customers receive the right products and advice for their specific requirements.Looking ahead, the market for extruded aluminum channels is projected to witness significant growth as industries continue to recognize the advantages of using aluminum for their applications. Factors such as urbanization, infrastructure development, and the adoption of advanced technologies will continue to drive the demand for aluminum channels in the coming years.With its strong market presence, commitment to innovation, and customer-centric approach, {Company Name} is well-positioned to capitalize on the growing opportunities in the extruded aluminum channel industry. As they continue to expand their product offerings, leverage technological advancements, and foster strategic partnerships, {Company Name} is poised to remain a key player in this dynamic market.

Durable and Lightweight Aluminum for Commercial Vehicles: A Game Changer for the Industry

Commercial Vehicle Aluminum is a leading manufacturer of high-quality aluminum products for the commercial vehicle industry. With a focus on innovation, efficiency, and sustainability, the company has established itself as a key player in the market. Their aluminum products are known for their durability, strength, and lightweight properties, making them the ideal choice for commercial vehicle manufacturers.The company's commitment to excellence is reflected in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. This allows them to produce aluminum products that meet the highest industry standards and exceed customer expectations.Commercial Vehicle Aluminum's product range includes a variety of aluminum sheets, plates, and extrusions that are specifically designed for use in commercial vehicles. These products are engineered to provide superior performance and reliability, making them the top choice for truck bodies, trailers, and other commercial vehicle applications.In addition to their standard product offerings, Commercial Vehicle Aluminum also offers custom solutions to meet the unique needs of their customers. Their team of experienced engineers and technicians work closely with clients to develop tailored aluminum products that are perfectly suited to their specific requirements.One of the key advantages of using aluminum in commercial vehicles is its lightweight nature. Aluminum is significantly lighter than steel, which can result in increased fuel efficiency and payload capacity for commercial vehicles. This can lead to cost savings for fleet operators and a reduced environmental impact due to lower fuel consumption.Furthermore, aluminum offers excellent corrosion resistance, making it a durable and long-lasting material for commercial vehicles. This ensures that the vehicles remain in top condition even when exposed to harsh environmental conditions and heavy use.Commercial Vehicle Aluminum is also committed to sustainability, and their aluminum products are fully recyclable. This not only reduces the environmental impact of commercial vehicle production but also supports a circular economy by minimizing waste and promoting the reuse of materials.The company's dedication to sustainability extends beyond their products to their manufacturing processes. They have implemented efficient and eco-friendly production methods, such as energy-saving initiatives and waste reduction strategies, to minimize their environmental footprint.In addition to their commitment to product quality and sustainability, Commercial Vehicle Aluminum also places a strong emphasis on customer satisfaction. They prioritize open communication and collaboration with their clients to ensure that their products meet and exceed expectations.With a focus on continuous improvement and innovation, Commercial Vehicle Aluminum is constantly researching and developing new aluminum products and technologies to stay ahead of industry trends and meet the evolving needs of their customers.Overall, Commercial Vehicle Aluminum is a trusted partner for commercial vehicle manufacturers, offering high-quality, lightweight, and sustainable aluminum products that are designed to optimize performance and efficiency. Their dedication to excellence, sustainability, and customer satisfaction sets them apart as a leader in the commercial vehicle industry.

New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

Aluminum Extrusion Cutting Machine (need remove brand name) Revolutionizing the Aluminum Processing IndustryAluminum extrusion has been a vital process in industries ranging from construction to automotive and aerospace. However, the process of cutting aluminum extrusions has often been problematic, with chipping and deformation being common issues. These problems are exacerbated when production demand is high, as is often the case in modern industrial enterprises. Thankfully, the Aluminum Extrusion Cutting Machine (need remove brand name) is poised to revolutionize this crucial process by providing a highly accurate, efficient, and reliable cutting solution.The Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution designed specifically for aluminum extrusions. This machine overcomes many of the challenges that traditional cutting methods have faced, such as chipping or deformation, by implementing advanced technology and a number of innovative features. With this machine, the cutting process is made much smoother, allowing for a more efficient and streamlined production process.Some of the key features that set this machine apart from others include its robust frame and precision cutting mechanism. The machine is made from high-grade aluminum alloy, which ensures its durability and longevity. Moreover, its cutting mechanism has been designed to minimize deformation and produce smooth and clean cuts every time. This feature is particularly important because it effectively eliminates the need for additional finishing processes, which can add to the production time and costs.The Aluminum Extrusion Cutting Machine (need remove brand name) also excels in terms of efficiency and precision. The machine is equipped with a highly accurate positioning system that ensures precise cuts each time. This system can be programmed to cut at specific lengths and angles, which enables manufacturers to produce custom parts quickly and with ease. Moreover, the machine's digital display makes it easy to adjust the cutting parameters as needed.One of the most impressive aspects of this machine is its speed. The Aluminum Extrusion Cutting Machine (need remove brand name) possesses a spindle speed of up to 20,000 rpm, which is significantly faster than most other cutting machines. This high speed allows for a much faster production process, reducing lead times and enabling manufacturers to keep up with growing demand.Of course, the true value of this machine is in its ability to deliver consistent results with every cut. The combination of precision, speed, and accuracy ensures that each cut is of the highest quality, allowing for seamless assembly and faster production times. This feature is particularly important in the manufacturing of complex applications, such as those found in the aerospace or automotive industries.In addition to its impressive features, the Aluminum Extrusion Cutting Machine (need remove brand name) is also highly customizable. The machine can be configured to meet the specific needs of individual manufacturers, with options such as dust collection, lubrication systems, and more. This level of customization ensures that manufacturers can tailor the machine to their specific requirements, producing higher quality results in less time.Finally, the machine's user-friendly design makes it easy to operate and maintain. The machine is equipped with a number of safety features, such as emergency stop buttons and an automatic lubrication system. The machine's digital control system makes it easy to adjust the cutting parameters, and its modular design allows for easy maintenance and repair.In conclusion, the Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution that is poised to revolutionize the aluminum extrusion industry. With its high precision, speed, and accuracy, it is equipped to handle the demands of modern industrial enterprises, delivering consistent and high-quality results every time. Its innovative features, user-friendly design, and extensive customization options make it an ideal choice for manufacturers looking to streamline their production processes and stay ahead of the competition.

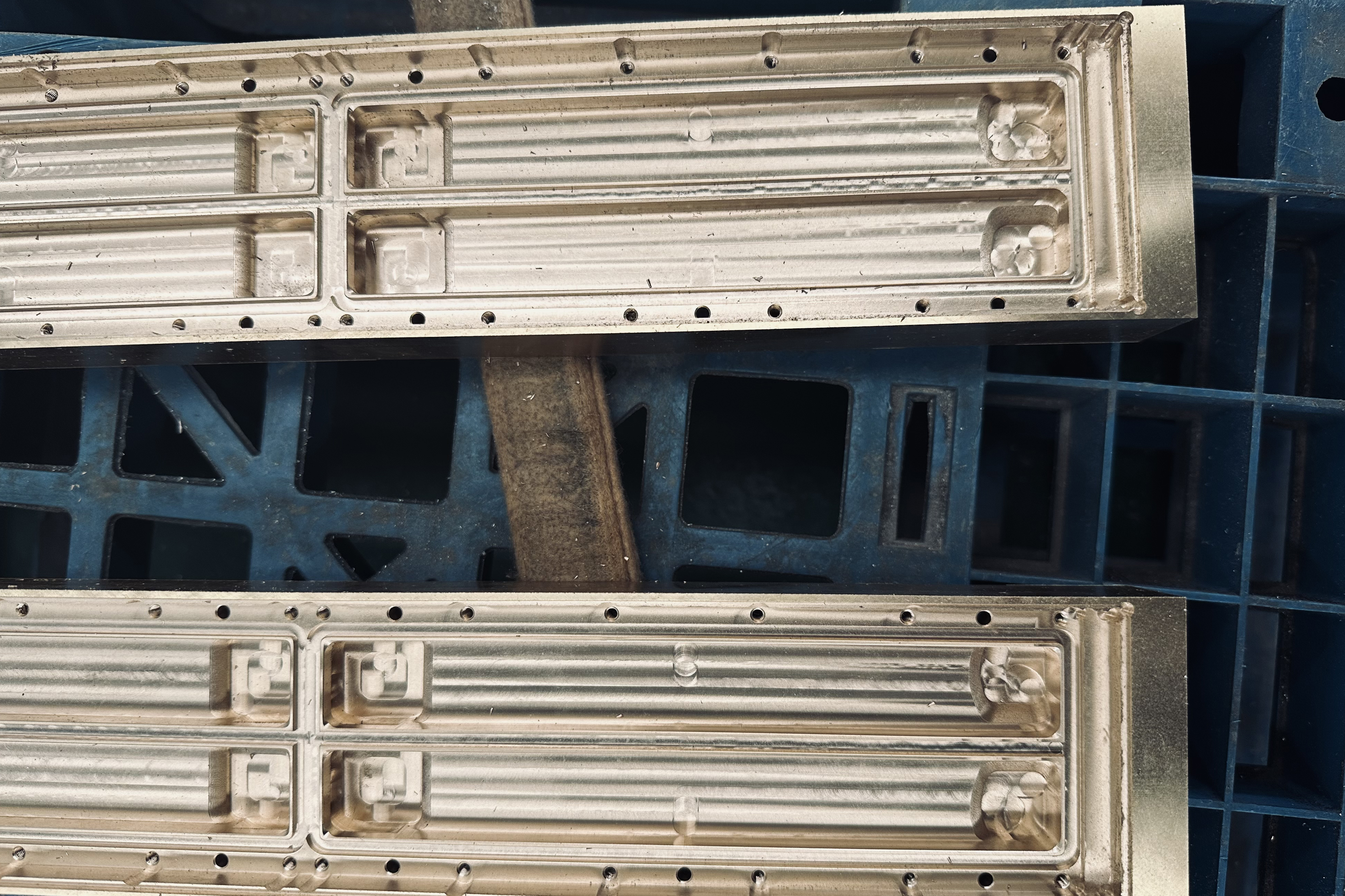

Aluminum Milling Services for Precision Metal Parts

In the world of manufacturing and engineering, precision is key. From aerospace components to automotive parts, the demand for precision machining and milling services is always on the rise. One company that has established itself as a leader in this field is Precision Aluminum Milling.Precision Aluminum Milling, based in [location], has been providing high-quality precision machining and milling services for over a decade. Specializing in aluminum fabrication, they cater to a wide range of industries, including aerospace, automotive, marine, and defense.The company prides itself on its state-of-the-art facilities and cutting-edge technologies, which allow them to deliver precision components with tight tolerances and complex geometries. With a focus on continuous improvement and investment in the latest machining equipment, Precision Aluminum Milling has positioned itself as a go-to solution for companies looking for reliable and high-quality aluminum machining services.One of the key aspects that sets Precision Aluminum Milling apart from its competitors is its team of highly skilled and experienced engineers and machinists. These professionals have a deep understanding of aluminum and its unique properties, allowing them to optimize the machining process for maximum precision and efficiency. They work closely with clients to understand their specific requirements and ensure that the final product meets their exact specifications.In addition to its machining capabilities, Precision Aluminum Milling also offers a range of value-added services, including assembly, finishing, and quality inspection. This comprehensive approach allows them to provide a complete solution to their customers, from initial design to final product delivery.Furthermore, the company is committed to maintaining the highest standards of quality and compliance. It is ISO 9001 certified, demonstrating its dedication to delivering products and services that meet international quality management standards. This commitment to quality has earned Precision Aluminum Milling a reputation for reliability and consistency in the industry.In recent years, Precision Aluminum Milling has also made significant investments in sustainability and environmental responsibility. The company has implemented various initiatives to reduce its environmental footprint, such as waste recycling and energy-efficient practices. By prioritizing sustainability, the company is not only contributing to a cleaner environment but also establishing itself as a socially responsible partner for its clients.Looking towards the future, Precision Aluminum Milling continues to expand its capabilities and explore new opportunities in the aluminum machining industry. With a focus on innovation and continuous improvement, the company is well-positioned to meet the evolving needs of its customers and stay ahead of the competition.With its commitment to precision, quality, and sustainability, Precision Aluminum Milling has earned its reputation as a trusted partner for precision aluminum machining services. As the demand for high-quality aluminum components continues to grow, the company is poised to play a key role in shaping the future of the manufacturing and engineering industries.

Exploring the Versatility of Extruded Aluminum Tubing Profiles

Extruded Aluminum Tubing Profiles Innovate the Manufacturing IndustryManufacturing companies around the world are constantly on the lookout for more efficient and cost-effective solutions to enhance their production processes. In recent years, extruded aluminum tubing profiles have emerged as a game-changer in the manufacturing industry, offering numerous benefits over traditional materials. With their unique characteristics and versatility, extruded aluminum tubing profiles are revolutionizing the way products are designed and manufactured.Extruded aluminum tubing profiles are essentially aluminum bars or rods that have been heated and forced through a die to create a specific shape or profile. This manufacturing process allows for the creation of complex cross-sections and intricate designs that are not easily achievable with other materials. From simple cylindrical shapes to more intricate designs with various cutouts, extruded aluminum tubing profiles provide manufacturers with endless possibilities for their products.One of the key advantages of extruded aluminum tubing profiles is their lightweight yet sturdy nature. Aluminum has a low density, making it significantly lighter than other metals such as steel or copper. This lightweight characteristic not only simplifies the transportation and handling of products but also reduces costs associated with shipping. Additionally, the strength-to-weight ratio of aluminum is impressive, making it ideal for applications where strength and durability are crucial.Extruded aluminum tubing profiles are also highly corrosion-resistant, offering a well-suited solution for products that are exposed to harsh environmental conditions or corrosive substances. Unlike steel, which is prone to rusting, aluminum forms a natural protective oxide layer when exposed to oxygen, effectively preventing further corrosion. This inherent corrosion resistance of extruded aluminum tubing profiles ensures the longevity and reliability of products, even in challenging environments.Another significant advantage of extruded aluminum tubing profiles is their excellent thermal conductivity. Aluminum is known for its ability to efficiently transfer heat, making it an ideal material for various applications requiring heat dissipation. From heat sinks in electronic devices to radiator fins in automobiles, extruded aluminum tubing profiles play a crucial role in the thermal management of products, ensuring optimal performance and preventing overheating.The versatility of extruded aluminum tubing profiles extends beyond their physical properties. These profiles can be easily customized and tailored to meet the specific requirements of various industries. Manufacturers can choose from a wide range of alloy compositions, sizes, and finishes to achieve their desired product characteristics. This versatility enables companies to create products that are not only functional but also aesthetically appealing.Moreover, the extrusion process itself is highly efficient and cost-effective. With the ability to create complex shapes in a single operation, manufacturers can significantly reduce production time and costs associated with extensive machining or welding. Additionally, extruded aluminum tubing profiles produce minimal waste, as the excess material can be recycled and reused. This not only contributes to the environmental sustainability efforts of companies but also minimizes material costs.One company on the forefront of extruded aluminum tubing profiles innovation is {}, a leading manufacturer in the industry. With decades of experience and expertise, they have established themselves as a trusted partner for companies seeking high-quality aluminum products. Their state-of-the-art facilities and advanced extrusion technology allow them to produce a wide range of customized extruded aluminum tubing profiles, meeting the diverse needs of their clients.The continuous research and development efforts of {} have led to numerous technological advancements in the field. By closely collaborating with their clients, they ensure that the products they manufacture perfectly match their specific requirements. From initial design concepts to final production, {} provides comprehensive support throughout the entire manufacturing process, enabling companies to bring their ideas to life.In conclusion, extruded aluminum tubing profiles are revolutionizing the manufacturing industry by offering lightweight, corrosion-resistant, and highly customizable solutions. With their exceptional physical characteristics and versatility, these profiles enhance the performance, durability, and aesthetics of products across various industries. Companies like {} are driving innovation in this field, constantly pushing the boundaries of what extruded aluminum tubing profiles can achieve. As manufacturers continue to embrace this cutting-edge technology, the future of manufacturing looks brighter than ever.

Discover the Benefits of Aluminum Z Bar Extrusions for Your Project

Aluminum Z Bar Extrusions: Revolutionizing Construction and Manufacturing IndustriesIn the ever-evolving construction and manufacturing sectors, advancements in materials and technology play a significant role in driving innovation and progress. One such development is the emergence of Aluminum Z Bar Extrusions, a versatile and durable material that has revolutionized various industries.Aluminum Z Bar Extrusions, as the name suggests, refer to aluminum profiles with a Z-shaped cross-section. These extrusions are created through a highly precise manufacturing process, where aluminum billets are heated and forced through a die to obtain the desired shape. The result is a lightweight yet robust structural component that offers numerous advantages over traditional materials.The key advantage of Aluminum Z Bar Extrusions lies in their exceptional strength-to-weight ratio. Aluminum is inherently light, making it an ideal choice for applications that require both strength and portability. The Z-shaped profile further enhances its structural integrity, allowing for greater load-bearing capacity while minimizing weight. This makes it an excellent choice for use in aerospace, automotive, marine, and architectural industries, where weight reduction without compromising strength is critical.Furthermore, Aluminum Z Bar Extrusions exhibit excellent corrosion resistance properties. Aluminum naturally forms a protective oxide layer when exposed to the atmosphere, which prevents rust and corrosion. This attribute makes it an attractive option for outdoor applications, as it can withstand harsh weather conditions, including high humidity and saltwater exposure. In addition, the extrusion process ensures that the material's surface is uniform and free from defects, further enhancing its durability and resistance to wear and tear.Another notable benefit of Aluminum Z Bar Extrusions is their flexibility in design. As a malleable material, aluminum can be easily fabricated and shaped into various forms, allowing for endless design possibilities. The Z-shaped profile provides added versatility, enabling precise and easy connections between structural components. This adaptability makes Aluminum Z Bar Extrusions highly sought-after in construction, where it is often used for framing, partitions, and accent features in modern architectural designs.The eco-conscious consumer and construction industries have also embraced Aluminum Z Bar Extrusions due to their recyclability. Aluminum is one of the few metals that can be recycled repeatedly without any loss of quality. This sustainability factor makes it a preferred choice for projects that aim to minimize environmental impact and carbon footprint.One company at the forefront of Aluminum Z Bar Extrusions innovation is {}. With years of experience in the aluminum extrusion industry, {} has established itself as a leader in providing high-quality and precision-engineered products. Their state-of-the-art manufacturing facilities and cutting-edge technologies enable them to offer custom solutions that meet the most demanding specifications.At {}, quality is paramount. The company employs stringent quality control measures throughout the production process to ensure that their Aluminum Z Bar Extrusions meet and exceed industry standards. This commitment to excellence has earned them a reputation for delivering superior products that meet the unique needs of their diverse clientele.As industries continue to evolve, the demand for lightweight, durable, and eco-friendly materials will only grow. Aluminum Z Bar Extrusions, with their exceptional properties and versatility, are poised to play a pivotal role in shaping the future of construction and manufacturing. With companies like {} driving innovation and setting new standards, the endless possibilities offered by Aluminum Z Bar Extrusions are limited only by our imagination.