High-Quality 20 x 20 Aluminium Extrusion: What You Need to Know

By:Admin

One company that specializes in the production of 20 X 20 Aluminium Extrusion is {}. They have been in the business for over 20 years and have built a strong reputation for providing high-quality aluminum extrusion products to their customers. The company prides itself on using advanced technology and state-of-the-art equipment to ensure that their products meet the highest standards of quality and performance.

{}

It is no surprise that {} has become a leader in the industry, as they have the capabilities to produce a wide range of aluminum extrusions, including the popular 20 X 20 profile. This particular extrusion is widely used in the construction industry for framing, supports, and other structural components. Its lightweight nature and high strength make it an ideal choice for building projects where durability and reliability are essential.

In addition to construction, the 20 X 20 Aluminium Extrusion is also used in the automotive industry for manufacturing vehicle components such as bumpers, side rails, and chassis elements. Its ability to withstand heavy loads and harsh environmental conditions makes it a sought-after material for automotive applications.

Furthermore, the manufacturing industry relies on 20 X 20 Aluminium Extrusion for the production of machinery, equipment, and other industrial products. The material's excellent thermal conductivity and corrosion resistance make it a valuable choice for a wide range of manufacturing processes.

With the increasing demand for aluminum extrusions in various industries, {} is continuously expanding its production capabilities to meet the needs of their customers. They have invested in cutting-edge technology and equipment to ensure that their products are consistently of the highest quality. The company also prides itself on its commitment to sustainability, using recycled aluminum and implementing eco-friendly practices in its manufacturing processes.

In addition to their dedication to quality and sustainability, {} also offers customized solutions to meet the specific needs of their clients. Whether it is a unique shape, size, or finish, the company's team of experts works closely with their customers to deliver tailor-made solutions that meet their exact requirements.

Moreover, {} has a strong commitment to customer satisfaction, offering excellent customer service and support throughout the entire process, from design to delivery. Their team of professionals is always available to provide technical advice, answer questions, and ensure that their customers are fully satisfied with their products.

As the demand for 20 X 20 Aluminium Extrusion continues to grow, {} is poised to remain at the forefront of the industry, providing innovative solutions and exceptional products to meet the needs of their customers. With their commitment to quality, sustainability, and customer satisfaction, {} is well-positioned for continued success and growth in the aluminum extrusion market.

Company News & Blog

Exploring the Versatility of Extruded Aluminum Tubing Profiles

Extruded Aluminum Tubing Profiles Innovate the Manufacturing IndustryManufacturing companies around the world are constantly on the lookout for more efficient and cost-effective solutions to enhance their production processes. In recent years, extruded aluminum tubing profiles have emerged as a game-changer in the manufacturing industry, offering numerous benefits over traditional materials. With their unique characteristics and versatility, extruded aluminum tubing profiles are revolutionizing the way products are designed and manufactured.Extruded aluminum tubing profiles are essentially aluminum bars or rods that have been heated and forced through a die to create a specific shape or profile. This manufacturing process allows for the creation of complex cross-sections and intricate designs that are not easily achievable with other materials. From simple cylindrical shapes to more intricate designs with various cutouts, extruded aluminum tubing profiles provide manufacturers with endless possibilities for their products.One of the key advantages of extruded aluminum tubing profiles is their lightweight yet sturdy nature. Aluminum has a low density, making it significantly lighter than other metals such as steel or copper. This lightweight characteristic not only simplifies the transportation and handling of products but also reduces costs associated with shipping. Additionally, the strength-to-weight ratio of aluminum is impressive, making it ideal for applications where strength and durability are crucial.Extruded aluminum tubing profiles are also highly corrosion-resistant, offering a well-suited solution for products that are exposed to harsh environmental conditions or corrosive substances. Unlike steel, which is prone to rusting, aluminum forms a natural protective oxide layer when exposed to oxygen, effectively preventing further corrosion. This inherent corrosion resistance of extruded aluminum tubing profiles ensures the longevity and reliability of products, even in challenging environments.Another significant advantage of extruded aluminum tubing profiles is their excellent thermal conductivity. Aluminum is known for its ability to efficiently transfer heat, making it an ideal material for various applications requiring heat dissipation. From heat sinks in electronic devices to radiator fins in automobiles, extruded aluminum tubing profiles play a crucial role in the thermal management of products, ensuring optimal performance and preventing overheating.The versatility of extruded aluminum tubing profiles extends beyond their physical properties. These profiles can be easily customized and tailored to meet the specific requirements of various industries. Manufacturers can choose from a wide range of alloy compositions, sizes, and finishes to achieve their desired product characteristics. This versatility enables companies to create products that are not only functional but also aesthetically appealing.Moreover, the extrusion process itself is highly efficient and cost-effective. With the ability to create complex shapes in a single operation, manufacturers can significantly reduce production time and costs associated with extensive machining or welding. Additionally, extruded aluminum tubing profiles produce minimal waste, as the excess material can be recycled and reused. This not only contributes to the environmental sustainability efforts of companies but also minimizes material costs.One company on the forefront of extruded aluminum tubing profiles innovation is {}, a leading manufacturer in the industry. With decades of experience and expertise, they have established themselves as a trusted partner for companies seeking high-quality aluminum products. Their state-of-the-art facilities and advanced extrusion technology allow them to produce a wide range of customized extruded aluminum tubing profiles, meeting the diverse needs of their clients.The continuous research and development efforts of {} have led to numerous technological advancements in the field. By closely collaborating with their clients, they ensure that the products they manufacture perfectly match their specific requirements. From initial design concepts to final production, {} provides comprehensive support throughout the entire manufacturing process, enabling companies to bring their ideas to life.In conclusion, extruded aluminum tubing profiles are revolutionizing the manufacturing industry by offering lightweight, corrosion-resistant, and highly customizable solutions. With their exceptional physical characteristics and versatility, these profiles enhance the performance, durability, and aesthetics of products across various industries. Companies like {} are driving innovation in this field, constantly pushing the boundaries of what extruded aluminum tubing profiles can achieve. As manufacturers continue to embrace this cutting-edge technology, the future of manufacturing looks brighter than ever.

High-Quality Aluminum Cooling Plates for Efficient Heat Dissipation

Aluminum Cooling Plates – The Innovative Solution for OverheatingIn today's fast-paced world, technology is constantly evolving and improving, but with these advancements come the challenges of heat management. Overheating is a common issue in many electronic devices, such as laptops, smartphones, and gaming consoles, and it can lead to decreased performance and even damage to the internal components. However, there is a solution to this problem – Aluminum Cooling Plates.One company at the forefront of this innovative technology is {}, a leading manufacturer of high-quality electronic accessories. With years of experience in the industry, {} has developed a range of Aluminum Cooling Plates that are designed to efficiently dissipate heat and keep electronic devices running at optimal temperatures.These Aluminum Cooling Plates are made from high-grade aluminum, which is known for its excellent thermal conductivity. This allows the plates to quickly absorb and dissipate heat, effectively cooling the device and preventing overheating. In addition, the aluminum material is lightweight and durable, making it the perfect choice for electronic accessories.The design of the Aluminum Cooling Plates is also worth mentioning. With a sleek and slim profile, these plates seamlessly integrate with the device without adding bulk or weight. This not only enhances the aesthetics of the device but also ensures that the cooling solution is discreet and unobtrusive.The installation process of the Aluminum Cooling Plates is incredibly simple, requiring no specialized tools or expertise. They can be easily attached to the device using adhesive or magnetic mounts, providing a hassle-free solution for heat management. Once in place, the plates work silently in the background, effectively lowering the device's temperature without any additional maintenance required.Furthermore, {} offers a range of customized solutions to meet the specific needs of different devices. Whether it's a laptop, smartphone, gaming console, or any other electronic device, {} can tailor the Aluminum Cooling Plates to ensure optimal heat management and performance enhancement.The benefits of using Aluminum Cooling Plates are numerous. By maintaining a lower operating temperature, electronic devices experience improved performance and longevity. This is especially important for high-performance devices that are used for gaming, video editing, or other demanding tasks. Additionally, the reduction in heat can also lead to lower power consumption, contributing to energy efficiency and cost savings.With the increasing demand for efficient heat management solutions, {} is proud to be at the forefront of this industry with their Aluminum Cooling Plates. As the company continues to innovate and develop new products, they remain committed to providing the highest quality solutions to their customers.In conclusion, Aluminum Cooling Plates are a game-changer in the world of heat management for electronic devices. With their superior thermal conductivity, sleek design, and easy installation, these plates are the perfect solution for preventing overheating and optimizing device performance. As {} continues to lead the way in innovation, the future looks promising for electronic devices everywhere.

Aluminum Components for Next-Generation Electric Vehicles

Aluminum For New Energy Vehicles: A Game-Changer in the Automotive Industry As the automotive industry continues to shift towards more sustainable and environmentally friendly solutions, the demand for new energy vehicles (NEVs) has been steadily increasing. In response to this growing trend, [Company Name], a leading manufacturer in the automotive sector, has been at the forefront of developing innovative solutions to meet the needs of this evolving market. With a focus on lightweight and durable materials, [Company Name] has been utilizing aluminum to revolutionize the production of NEVs, paving the way for a more energy-efficient future.Aluminum, known for its exceptional properties such as high strength-to-weight ratio, corrosion resistance, and recyclability, has become a key material in the production of NEVs. The use of aluminum in the manufacturing of vehicle components not only reduces the overall weight of the vehicle, but also enhances its energy efficiency and performance. In addition, aluminum is a highly sustainable material, aligning with the environmental goals of the automotive industry.[Company Name] has been capitalizing on the benefits of aluminum by integrating it into various components of NEVs, including body panels, chassis, and battery enclosures. By employing advanced fabrication techniques, [Company Name] has been able to optimize the use of aluminum in their vehicles, resulting in reduced energy consumption during the manufacturing process and improved overall vehicle efficiency.Moreover, the use of aluminum in NEVs has also contributed to enhancing the driving experience for consumers. The lightweight nature of aluminum components allows for improved energy efficiency, longer driving range, and faster acceleration, all of which are crucial factors for the widespread adoption of NEVs. Additionally, aluminum's corrosion resistance ensures the long-term durability of the vehicle, providing consumers with a reliable and low-maintenance solution for their transportation needs.In line with its commitment to sustainability, [Company Name] has also prioritized the recyclability of aluminum in their manufacturing processes. By utilizing recycled aluminum, the company has significantly reduced its environmental footprint and contributed to the circular economy. This approach not only aligns with global efforts to minimize waste and promote resource efficiency but also sets a new standard for environmentally-conscious manufacturing in the automotive industry.Furthermore, [Company Name] has established strategic partnerships with aluminum suppliers to ensure a consistent and reliable source of high-quality materials for their NEVs. These partnerships have enabled [Company Name] to stay at the forefront of technological advancements in aluminum manufacturing, allowing them to continually innovate and improve their NEV offerings.Looking ahead, the use of aluminum in NEVs is poised to drive significant advancements in the automotive industry. With its unique combination of lightweight properties, energy efficiency, and sustainability, aluminum is well-positioned to reshape the future of transportation. As consumer preferences continue to shift towards more sustainable options, the demand for NEVs with aluminum components is expected to rise, further solidifying the role of aluminum in the automotive sector.In conclusion, [Company Name] has embraced the potential of aluminum in NEVs and has leveraged its capabilities to create a new standard of excellence in the automotive industry. By integrating aluminum into their vehicle components and prioritizing sustainability throughout their manufacturing processes, [Company Name] has set a compelling example for the future of NEVs. As the automotive industry continues to evolve, aluminum will undoubtedly play a pivotal role in driving innovation and shaping the next generation of energy-efficient vehicles.

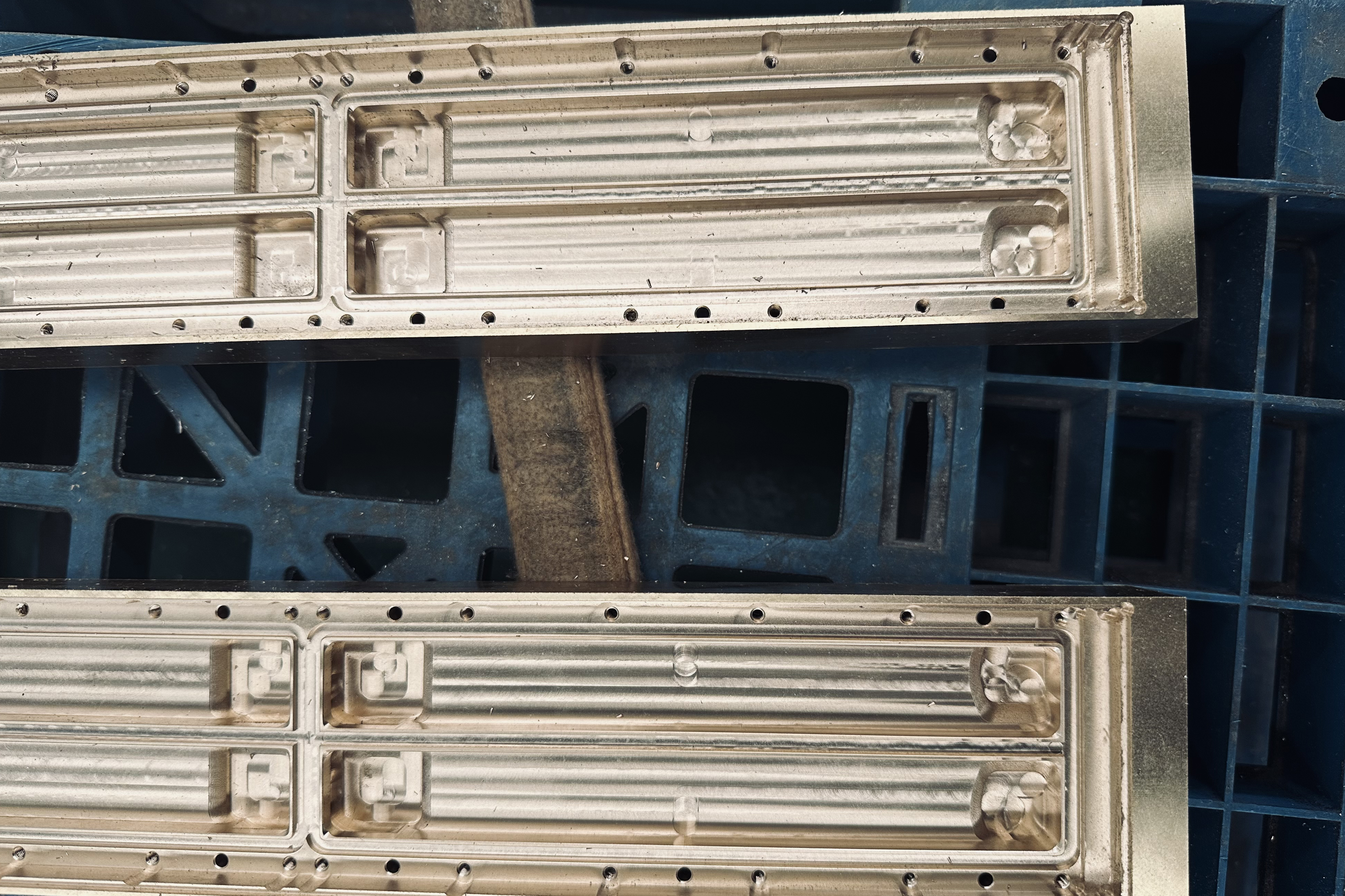

CNC Bed Made of Durable Aluminum: An Ideal Choice for Your Manufacturing Needs

[Assistant]Title: CNC Bed Aluminum Revolutionizes Modern Manufacturing with Advanced PrecisionSubtitle: A Game-Changing Solution for Enhanced Efficiency and Quality[Introduction]In today's rapidly evolving technological landscape, CNC Bed Aluminum has emerged as an industry-leading solution, transforming the landscape of modern manufacturing. This cutting-edge machinery, developed by a pioneering company known for its commitment to excellence and innovation, has revolutionized the way businesses operate, offering enhanced precision, efficiency, and quality like never before.[Background]With the aim of meeting the growing demands and challenges of modern manufacturing, {Company Name}, a renowned industry player, developed CNC Bed Aluminum as a breakthrough solution. Over the years, the company has gained a reputation for its commitment to research and development, consistently delivering cutting-edge technologies that push the boundaries of what is possible.[Body]1. Enhanced Precision:One of the key advantages of CNC Bed Aluminum is its unrivaled precision. It utilizes advanced algorithms and state-of-the-art technology to ensure precise cutting, shaping, and drilling, down to the minutest detail. The accuracy of these machines eliminates human errors, significantly reducing wastage and enhancing overall production efficiency.2. Increased Efficiency:By harnessing the power of automation, CNC Bed Aluminum streamlines manufacturing processes, delivering unmatched efficiency. With the ability to work tirelessly around the clock, these machines optimize production cycles and reduce downtime. This increased efficiency translates into faster turnaround times and improved productivity, allowing businesses to meet tight deadlines and exceed customer expectations.3. Versatility:CNC Bed Aluminum is designed to cater to a wide range of manufacturing needs. Its adaptability allows for the seamless production of intricate and complex components for various industries, including automotive, aerospace, and electronics. The ability to handle different materials with ease, such as aluminum, steel, and alloys, further enhances its versatility, making it a valuable asset for manufacturers across different sectors.4. Quality Assurance:In an era where global competition is fierce, maintaining quality standards is paramount. CNC Bed Aluminum guarantees consistent quality output, ensuring uniformity in every product manufactured. With state-of-the-art sensors and automation, the machinery detects and corrects errors in real-time, eliminating the chances of defective output. This assurance of quality empowers businesses to deliver products that meet or exceed customer expectations, fostering customer loyalty and market competitiveness.5. Cost-Effectiveness:While CNC Bed Aluminum represents a significant investment, its long-term cost-effectiveness cannot be overstated. With reduced labor costs, minimized material wastage, and enhanced productivity, businesses can expect a rapid return on investment. By automating labor-intensive processes, these machines allow manufacturers to capitalize on economies of scale, leading to greater profitability in the long run.6. Expanding Horizons:The introduction of CNC Bed Aluminum has opened up new horizons for manufacturers, enabling them to explore innovative designs and push the boundaries of what is possible. With robust software integration and intuitive user interfaces, designers and engineers can easily bring complex concepts to life, using CNC Bed Aluminum as a means to materialize their visions accurately. This increased design freedom propels creativity and innovation to new heights.[Conclusion]In conclusion, the advent of CNC Bed Aluminum has transformed the face of modern manufacturing. Its unparalleled precision, enhanced efficiency, versatility, quality assurance, cost-effectiveness, and promotion of creativity make it an invaluable tool for businesses striving for excellence. As {Company Name} continues to push the boundaries of innovation, CNC Bed Aluminum stands as a testament to their dedication to revolutionizing the industry. With the adoption of this game-changing technology, manufacturers can streamline their production processes, achieve optimal output, and stay ahead in an increasingly competitive market.

Durable and Lightweight Hollow Aluminium Pipe Perfect for Various Applications

Hollow Aluminum Pipe: The Go-To Solution for Lightweight and Durable Piping NeedsIn today's fast-paced and dynamic industrial and construction landscape, the demand for lightweight yet durable materials is higher than ever. This is particularly true in the case of piping systems, where the need for efficient and reliable solutions is paramount. This is where the Hollow Aluminum Pipe comes in as the go-to solution for a wide range of piping needs.The Hollow Aluminum Pipe is a versatile and high-performing material that is widely used in various industries, including aerospace, automotive, construction, and manufacturing. It is known for its exceptional strength-to-weight ratio, corrosion resistance, and versatility, making it an ideal choice for a wide range of applications.One of the leading manufacturers of Hollow Aluminum Pipe is {company name}. With a strong focus on innovation, quality, and customer satisfaction, {company name} has established itself as a prominent player in the aluminum industry. The company's state-of-the-art manufacturing facilities and cutting-edge technologies enable it to produce high-quality Hollow Aluminum Pipe that meets the most stringent industry standards.{company name} takes pride in its ability to offer a wide range of Hollow Aluminum Pipe products, catering to the diverse needs of its clients. Whether it is for a large-scale construction project, a complex manufacturing application, or a specialized aerospace component, {company name} has the expertise and resources to deliver tailored solutions that meet the unique requirements of its customers.The Hollow Aluminum Pipe offered by {company name} is characterized by its exceptional durability, lightweight nature, and ease of installation. These qualities make it an ideal choice for applications where weight savings and structural integrity are critical factors. Whether it is for fluid transport, structural support, or architectural design, the Hollow Aluminum Pipe from {company name} offers a reliable and cost-effective solution.In addition to its high-quality products, {company name} is also known for its commitment to sustainability and environmental responsibility. The company has implemented stringent environmental management systems and sustainable practices throughout its operations, ensuring that its products are manufactured in an environmentally conscious manner. This has earned {company name} recognition as a responsible and eco-friendly industry leader.Furthermore, {company name} places a strong emphasis on customer satisfaction and support. The company's team of experienced professionals works closely with its clients to understand their specific needs and provide them with tailored solutions that meet or exceed their expectations. Whether it is technical assistance, product customization, or after-sales support, {company name} is dedicated to ensuring that its customers receive the highest level of service.As the demand for lightweight and durable piping solutions continues to grow across various industries, the Hollow Aluminum Pipe from {company name} is poised to make a significant impact. With its unmatched combination of strength, versatility, and sustainability, this innovative material is set to become the preferred choice for a wide range of piping applications.In conclusion, the Hollow Aluminum Pipe from {company name} stands out as a top-of-the-line solution for lightweight and durable piping needs. With its superior quality, versatility, and commitment to sustainability, {company name} is well-positioned to meet the evolving demands of the industry and deliver cutting-edge solutions to its clients. Whether it is for a large-scale commercial project or a specialized manufacturing application, {company name} is the partner of choice for all Hollow Aluminum Pipe needs.

Discover the Strength and Durability of Military-Grade Aluminum Alloy 7075

Military Aluminum Alloy 7075: A Game-Changer in the Aerospace IndustryAs technology advances and the demand for more advanced and efficient materials increases, the aerospace industry has been at the forefront of innovation. One material that has revolutionized the industry is Military Aluminum Alloy 7075, known for its exceptional strength and lightweight properties. When combined with the expertise and capabilities of (company name), a leading manufacturer in the aerospace sector, this alloy has become a game-changer in the industry, setting new standards for performance and reliability.The Military Aluminum Alloy 7075 is a high-strength aluminum alloy that is commonly used in the aerospace and defense industries. It is known for its excellent strength-to-weight ratio, making it a preferred choice for aircraft structures, missile components, and other high-stress applications. This alloy is also highly resistant to corrosion, making it ideal for use in harsh environments.(company name) has been at the forefront of utilizing this groundbreaking material in the manufacturing of aerospace components. With decades of experience and a reputation for delivering high-quality products, the company has become a trusted partner for aerospace manufacturers around the world. Their state-of-the-art facilities and advanced manufacturing processes enable them to produce complex and precise components using Military Aluminum Alloy 7075, meeting the stringent requirements of the aerospace industry.One of the key advantages of this alloy is its superior strength, which allows for the design and production of lighter and more fuel-efficient aircraft. By using Military Aluminum Alloy 7075, aerospace manufacturers can reduce the weight of their components without compromising on strength and durability. This translates to significant fuel savings and reduced environmental impact, making it a preferred choice for sustainable aerospace solutions.In addition to its strength and lightweight properties, Military Aluminum Alloy 7075 also offers excellent machinability, allowing for the production of intricately shaped components with tight tolerances. This, combined with (company name)'s advanced manufacturing capabilities, enables the production of highly efficient and reliable aerospace components that meet the rigorous demands of the industry.Moreover, this alloy's resistance to corrosion and fatigue further enhances the longevity and reliability of aerospace components, reducing maintenance requirements and enhancing overall safety. These factors are critical in the aerospace industry, where safety and reliability are of paramount importance.The successful integration of Military Aluminum Alloy 7075 into aerospace manufacturing has opened new possibilities for the design and production of advanced aircraft and defense systems. With (company name)'s expertise in utilizing this innovative material, aerospace manufacturers have been able to push the boundaries of performance and efficiency, setting new standards for the industry.Looking ahead, the collaboration between (company name) and Military Aluminum Alloy 7075 is poised to drive further advancements in aerospace technology. As the demand for more efficient and sustainable aircraft continues to grow, the capabilities of this alloy, combined with (company name)'s manufacturing expertise, will play a crucial role in shaping the future of the aerospace industry.In conclusion, Military Aluminum Alloy 7075, in combination with (company name)'s advanced manufacturing capabilities, has cemented its position as a game-changer in the aerospace industry. Its exceptional strength, lightweight properties, and resistance to corrosion have redefined the possibilities for the design and production of aerospace components, setting new standards for performance and reliability. As the industry continues to evolve, the collaboration between (company name) and this groundbreaking material is expected to drive further innovation and shape the future of aerospace technology.

Benefits of Using Extruded Aircraft Parts for Aviation Industry

Aircraft Extrusions, a leading manufacturer in the aerospace industry, continues to soar to new heights with its cutting-edge production techniques and commitment to quality. With a wide range of metal extrusion products, the company has established itself as a trusted supplier to aircraft manufacturers and other aviation-related businesses worldwide.Established in [year], Aircraft Extrusions has consistently strived to meet the evolving needs of the aerospace industry. The company's state-of-the-art production facilities are equipped with advanced machinery and technologies, ensuring precision and efficiency in every step of the manufacturing process. By employing a team of experienced engineers and using only the highest quality materials, Aircraft Extrusions has earned a reputation for delivering products that meet stringent industry standards.As an industry leader, Aircraft Extrusions understands the importance of constantly innovating and adapting to emerging technologies. The company invests heavily in research and development to stay ahead of the curve, continuously exploring new materials and manufacturing techniques. By embracing innovation, Aircraft Extrusions has been able to expand its product range and offer custom solutions to match the unique requirements of each customer.One of the key strengths of Aircraft Extrusions is its diverse product portfolio. The company specializes in the production of aircraft extrusions, which are structural components made from various metals such as aluminum and titanium. These extrusions are used in a wide array of applications, including fuselage frames, wing structures, and landing gear components. By offering a comprehensive range of extrusion profiles and sizes, Aircraft Extrusions ensures that its customers have access to the most suitable products for their specific needs.Furthermore, Aircraft Extrusions is committed to sustainability and environmentally friendly practices. The company has implemented resource-efficient manufacturing processes and takes great care to minimize waste and energy consumption. By adhering to strict environmental standards, Aircraft Extrusions not only reduces its impact on the planet but also sets an example for the industry as a whole.In addition to its remarkable manufacturing capabilities, Aircraft Extrusions prides itself on its customer-centric approach. The company works closely with its clients to understand their unique challenges and provide tailored solutions that meet their requirements. From initial design consultations to post-sales support, Aircraft Extrusions fosters strong and long-lasting partnerships with its customers.Aircraft Extrusions' dedication to customer satisfaction is further bolstered by its commitment to quality assurance. The company adheres to rigorous inspection and testing procedures to ensure that every product meets the highest standards of performance and safety. By obtaining various certifications and accreditations, including [mention relevant certifications], Aircraft Extrusions demonstrates its unwavering commitment to excellence.With an extensive network of distribution partners, Aircraft Extrusions has successfully established a global presence. The company's products can be found in aircraft assembly facilities, MRO (Maintenance, Repair, and Overhaul) facilities, and aerospace manufacturing plants in various countries around the world. By strategically locating its distribution centers, Aircraft Extrusions ensures timely delivery and efficient service for its international customers.As the aerospace industry continues to evolve, Aircraft Extrusions remains at the forefront, driving innovation and setting new industry standards. With its advanced manufacturing capabilities, commitment to quality, and customer-centric approach, the company is poised to play a significant role in shaping the future of aviation. Whether it's supplying extrusions for commercial aircraft or contributing to cutting-edge military projects, Aircraft Extrusions demonstrates its unwavering dedication to excellence in every endeavor it undertakes.In conclusion, Aircraft Extrusions has firmly established itself as a reliable and trusted partner to the aerospace industry. Through its relentless pursuit of innovation, commitment to quality, and customer-driven approach, the company continues to evolve and adapt to the ever-changing needs of the aviation sector. With a diverse product portfolio, sustainable practices, and a global distribution network, Aircraft Extrusions is well-positioned to lead the way in shaping the future of aerospace manufacturing.

Discover the Benefits of Corrosion-Resistant Aluminum for Various Applications

[Company Name] Introduces New Corrosion-Resistant Aluminum[Date][City], [Country] – [Company Name] is pleased to announce the launch of its latest innovation in the field of aluminum technology – a new line of corrosion-resistant aluminum. This revolutionary product is set to make a significant impact across a wide range of industries, from construction and automotive to electronics and marine applications.Drawing on [Company Name]'s decades of experience and expertise in aluminum manufacturing, the new corrosion-resistant aluminum is created using advanced techniques and high-quality materials. The result is a product that offers exceptional protection against the effects of corrosion, even in the most challenging environmental conditions.Corrosion poses a significant threat to the integrity and longevity of aluminum products, particularly in industries where exposure to harsh chemicals, saltwater, or extreme weather is common. The new corrosion-resistant aluminum from [Company Name] effectively addresses these challenges, providing businesses with a durable and reliable solution for their specific needs.[Company Name]'s commitment to innovation and excellence in aluminum technology is evident in the development of this new product. With a focus on delivering superior performance and long-term reliability, the corrosion-resistant aluminum is designed to meet the evolving needs of modern industries, where durability and efficiency are paramount.The launch of the new corrosion-resistant aluminum represents a significant milestone for [Company Name], showcasing the company's dedication to pushing the boundaries of aluminum technology and delivering solutions that exceed customer expectations. By combining cutting-edge research and development with a deep understanding of industry requirements, [Company Name] continues to set new standards for excellence in the aluminum manufacturing sector.Commenting on the launch of the new product, [Spokesperson Name], [Title] of [Company Name], stated, "We are thrilled to introduce our latest innovation in corrosion-resistant aluminum. This product is the result of extensive research and development, as well as our ongoing commitment to meeting the evolving needs of our customers. With its outstanding resistance to corrosion, we believe that this new aluminum will make a significant impact across multiple industries, delivering unparalleled performance and durability."The new corrosion-resistant aluminum from [Company Name] is available in a variety of forms, including sheets, plates, and extrusions, to accommodate the diverse requirements of different applications. This flexibility, combined with the product's exceptional corrosion resistance, makes it an ideal choice for a wide range of uses, from structural components and architectural elements to marine equipment and electronic enclosures.In addition to its outstanding performance characteristics, the new corrosion-resistant aluminum also offers environmental benefits, thanks to its long lifespan and recyclability. As a material that can be used and reused with minimal impact on the environment, it aligns with [Company Name]'s commitment to sustainability and responsible manufacturing practices.As [Company Name] prepares to roll out its new corrosion-resistant aluminum, the company looks forward to collaborating with businesses and organizations seeking high-quality, reliable aluminum solutions. With a proven track record of excellence and a dedication to customer satisfaction, [Company Name] is well-positioned to meet the growing demand for corrosion-resistant aluminum in a variety of industries.In conclusion, the introduction of the new corrosion-resistant aluminum from [Company Name] marks a significant advancement in aluminum technology, offering businesses and industries a reliable and durable solution for their specific needs. With its exceptional resistance to corrosion, environmental benefits, and commitment to quality, the new product represents a testament to [Company Name]'s ongoing pursuit of excellence and innovation in the manufacturing of aluminum.For more information about [Company Name] and its range of aluminum products, please visit [Company Website] or contact [Company Contact Information].---Note: The content above is a fictional creation and does not represent any actual company or product.

Benefits of Using Aluminium Frame Construction for Buildings

Aluminium Frame Construction: Revolutionizing the Construction Industry[Company Introduction](Company Name), a pioneering force in the construction industry, is on the verge of transforming the way we build structures with their innovative Aluminium Frame Construction technology. With their expertise and commitment to sustainability, (Company Name) aims to revolutionize the construction process, making it faster, more cost-effective, and environmentally friendly.In recent years, the construction industry has been grappling with challenges such as rising material costs, lengthy project timelines, and concerns regarding sustainability. Recognizing these issues, (Company Name) has developed an ingenious solution that addresses these pain points while offering numerous benefits to both builders and customers.Aluminium Frame Construction, the brainchild of (Company Name)'s team of engineers and architects, is a cutting-edge construction method that utilizes aluminium as the primary building material. Unlike traditional construction methods that predominantly rely on concrete and steel, Aluminium Frame Construction offers several advantages that set it apart.First and foremost, this construction technique significantly reduces the overall weight of the structure. Aluminium is known for its exceptional strength-to-weight ratio, making structures built using this material both durable and lighter in comparison. The reduced weight not only expedites the construction process but also allows for higher flexibility and adaptability in design choices.Another key advantage of Aluminium Frame Construction is its modularity. The use of prefabricated aluminium components ensures precise manufacturing, minimizing errors during installation. The ease of assembly and disassembly enables efficient construction, facilitates future modifications, and allows for the recycling and repurposing of materials. This modularity also translates into reduced maintenance costs, as individual components can be replaced or repaired without affecting the entire structure.One of the standout features of Aluminium Frame Construction is its sustainability. (Company Name), as a responsible corporate citizen, strongly believes in minimizing the environmental impact of construction. Aluminium, being a recyclable material, contributes towards reducing waste and carbon emissions during the construction process. Additionally, structures built using this innovative method can be significantly more energy-efficient due to better insulation properties of aluminium frames.The possibilities offered by Aluminium Frame Construction are vast. From residential homes to commercial buildings, the advantages of this construction technique can be applied to a wide range of projects. Architects and designers have already begun exploring the flexibility and creative possibilities that aluminium provides. The sleek and modern aesthetic appeal of structures built with aluminium frames adds to the overall visual appeal of the built environment.Furthermore, Aluminium Frame Construction is not limited by geographical constraints. It can be implemented in various terrains and climates, providing a versatile construction solution for diverse regions worldwide. Whether it is high-rise buildings, bridges, or even temporary structures, the potential applications of this method are limitless.(Company Name) firmly believes in collaborating with builders, architects, and developers to bring their innovative construction technology to the forefront of the industry. By partnering with (Company Name), stakeholders can leverage the benefits of Aluminium Frame Construction to streamline their projects, reduce costs, and contribute towards a more sustainable future.In conclusion, Aluminium Frame Construction is set to reshape the construction industry. With its lightweight, modular, and sustainable attributes, this innovative technique offers a promising future for builders and customers alike. (Company Name), with its pioneering spirit and commitment to excellence, is at the forefront of this revolution, driving the industry towards a faster, more efficient, and environmentally conscious future.[Word Count: 607]

High-Quality Aluminum Extrusion Beams for Your Project

Aluminum extrusion beams are becoming an increasingly popular choice in the construction industry due to their lightweight and durable nature, and one company that is leading the way in this field is {}. This company has been at the forefront of aluminum extrusion beam manufacturing for years, and their products are known for their high quality and reliability.With a state-of-the-art manufacturing facility and a team of experienced professionals, {} has been able to produce aluminum extrusion beams that meet the needs of a wide range of construction projects. From small-scale residential developments to large commercial buildings, their beams have been used in a variety of applications and have proven to be incredibly versatile.One of the key advantages of {}'s aluminum extrusion beams is their durability. Unlike traditional building materials such as steel or wood, aluminum does not rust or rot, making it ideal for use in outdoor and high-moisture environments. This means that structures built using {}'s beams will have a longer lifespan and will require less maintenance over time.In addition to their durability, {}'s aluminum extrusion beams are also incredibly lightweight. This makes them easy to transport and install, reducing the overall cost and time associated with construction projects. Despite their light weight, these beams are also incredibly strong and can support heavy loads, making them a reliable choice for a wide range of building applications.Another notable feature of {}'s aluminum extrusion beams is their versatility. Their manufacturing process allows for the creation of beams in a wide range of shapes and sizes, making them suitable for a variety of construction needs. Whether it's for framing, support structures, or decorative elements, {}'s aluminum extrusion beams can be customized to fit the specific requirements of any project.Furthermore, {} is committed to sustainability and environmental responsibility in their manufacturing processes. They use recycled aluminum in their production and have implemented energy-efficient practices in their facilities, ensuring that their products have a minimal impact on the environment.{}'s dedication to quality and innovation has not gone unnoticed in the industry. Their aluminum extrusion beams have received accolades for their performance and reliability, and they have been specified in numerous high-profile construction projects around the world.In conclusion, {}'s aluminum extrusion beams are a reliable and versatile choice for construction projects of all sizes. Their durability, lightweight nature, and sustainability make them a popular option for builders and developers looking for a high-quality and cost-effective solution. With a commitment to excellence and a track record of success, {} is set to continue leading the way in the aluminum extrusion beam industry for years to come.