Discover the Ideal Thickness for Aluminium Profiles

By:Admin

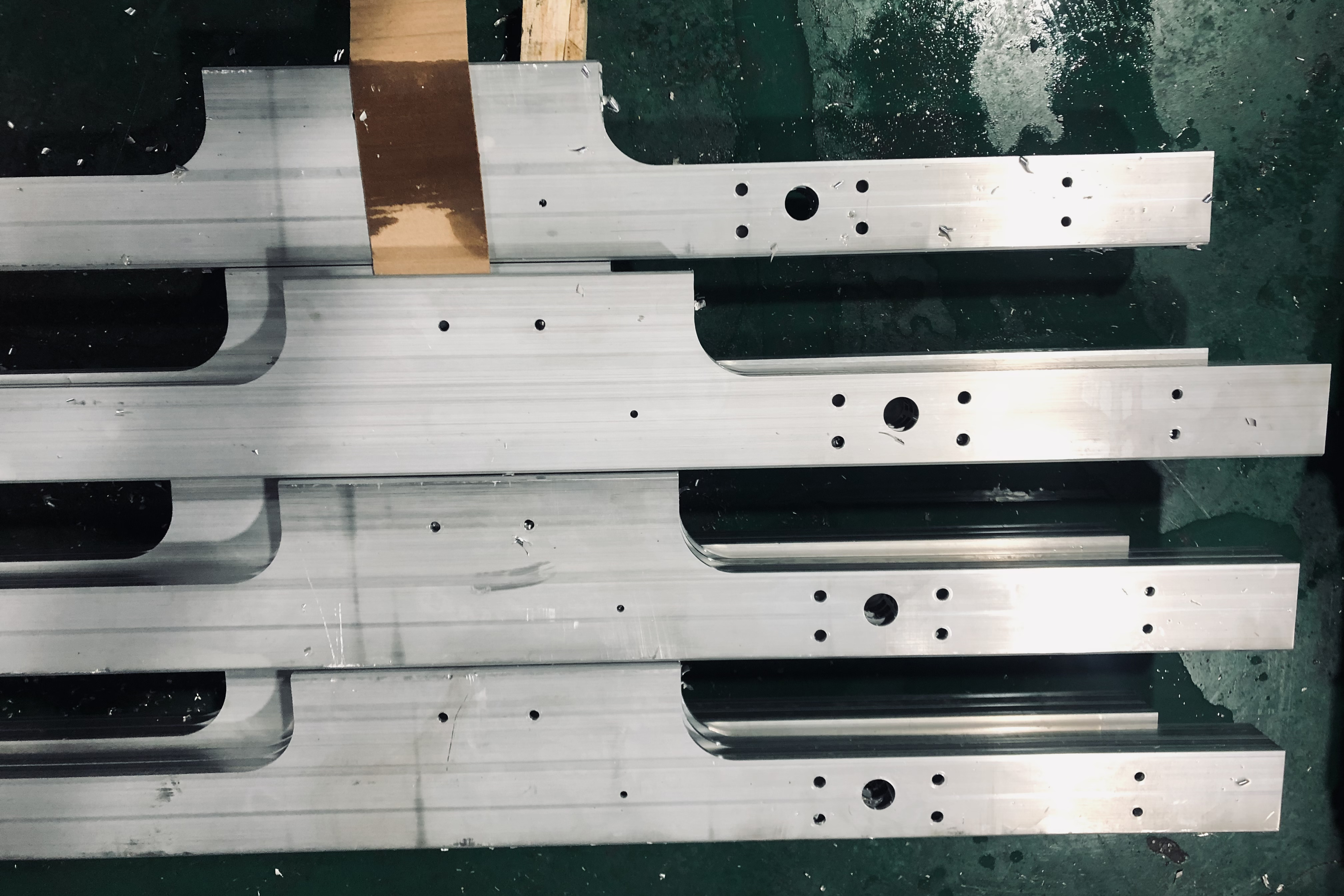

Aluminium profiles are widely used in various industries due to their durability and flexibility. The thickness of aluminium profiles plays a crucial role in the quality and strength of the final product. With the right thickness, aluminium profiles can be used in construction, automotive, aerospace, and other industries, providing a lightweight and durable solution for various applications.

One of the leading companies in the aluminium profile industry is (company name). With a history of excellence and innovation, they have been at the forefront of producing high-quality aluminium profiles with various thickness options to meet the diverse needs of their customers.

The thickness of aluminium profiles can range from 0.3mm to 6mm, depending on the specific requirements of the application. Thicker profiles are often used in heavy-duty applications where strength and durability are crucial, while thinner profiles are suitable for lightweight applications such as in the automotive and aerospace industries.

The process of determining the right thickness for aluminium profiles involves careful consideration of factors such as the intended use, load-bearing capacity, and environmental factors. Thicker profiles offer higher load-bearing capacity and resistance to bending, making them suitable for structural applications. Thinner profiles, on the other hand, are more flexible and lightweight, making them ideal for applications where weight is a critical factor.

In the construction industry, aluminium profiles with the right thickness are used in the fabrication of doors, windows, curtain walls, and structural components. The versatility of aluminium profiles allows architects and builders to create aesthetically pleasing designs while ensuring the structural integrity of the building.

In the automotive industry, aluminium profiles with specific thickness requirements are used for the fabrication of chassis components, body panels, and other structural parts. The lightweight nature of aluminium profiles contributes to improved fuel efficiency and overall performance of vehicles.

In the aerospace industry, the use of aluminium profiles with precise thickness specifications is essential for ensuring the structural integrity of aircraft components. The high strength-to-weight ratio of aluminium profiles makes them an ideal choice for use in critical applications such as aircraft wings, fuselage components, and landing gear.

The manufacturing process of aluminium profiles with custom thickness begins with the selection of high-quality aluminium alloys, followed by precision extrusion and heat treatment to achieve the desired mechanical properties. Advanced machining and finishing techniques ensure that the profiles meet the exacting specifications of the customers.

The expertise of (company name) in producing aluminium profiles with custom thickness options has earned them a reputation for delivering high-quality products that meet the stringent requirements of various industries. Their state-of-the-art manufacturing facilities and commitment to continuous improvement allow them to offer a wide range of aluminium profiles to cater to the diverse needs of their customers.

In conclusion, the thickness of aluminium profiles is a critical factor in determining their suitability for different applications. With the right thickness, aluminium profiles offer a combination of strength, durability, and lightweight properties that make them an ideal choice for a wide range of industries. The capabilities of (company name) in producing custom aluminium profiles with specific thickness options make them a trusted partner for businesses looking for high-quality aluminium solutions.

Company News & Blog

Durable and Versatile Extruded Aluminum Beams for Various Applications

Extruded Aluminum Beams are quickly becoming the material of choice for a wide range of construction and industrial applications, and {} has solidified its position as a leader in this market. With a commitment to innovation and quality, the company has established itself as a go-to source for extruded aluminum beams that meet the highest standards in the industry.The extrusion process allows for the creation of complex cross-sectional shapes and sizes, making extruded aluminum beams a versatile and durable option for a variety of projects. From building construction to automotive manufacturing, these beams offer numerous advantages, including high strength-to-weight ratio, corrosion resistance, and a sleek, modern aesthetic.{} has honed its expertise in extruded aluminum beams through years of experience and a dedication to staying ahead of the curve when it comes to technological advancements in the industry. By investing in state-of-the-art equipment and employing a team of skilled professionals, the company has been able to consistently deliver products that exceed customer expectations.One of the key factors that sets {} apart from its competitors is its focus on customization. The company understands that each project has its own unique requirements, and its team works closely with clients to create extruded aluminum beams that perfectly suit their needs. Whether it's a specific shape, size, or finish, {} has the capabilities to deliver custom solutions that ensure the success of any project.In addition to customization, {} is also committed to sustainability. Aluminum is a highly recyclable material, and the company takes pride in using recycled aluminum in its extrusion process whenever possible. By prioritizing environmental responsibility, {} is not only meeting the needs of its customers but also contributing to a greener, more sustainable future.The applications for extruded aluminum beams are incredibly diverse, and {} has played a significant role in supplying these products to a wide range of industries. From architectural trim and framing to support beams for industrial equipment, the company's extruded aluminum beams have been utilized in countless projects, showcasing their versatility and reliability.Looking towards the future, {} remains dedicated to pushing the boundaries of what is possible with extruded aluminum beams. By constantly exploring new technologies and refining its processes, the company is well-positioned to continue leading the way in the industry. As customer demands evolve and new challenges arise, {} is committed to staying one step ahead and providing innovative solutions that set the standard for excellence.In conclusion, {} has firmly established itself as a premier supplier of extruded aluminum beams, offering a combination of quality, customization, and sustainability that sets it apart in the market. With a proven track record of success and a commitment to ongoing innovation, the company is poised to continue meeting the diverse needs of its customers and driving the industry forward.

High-Quality Aluminum Cooling Plates for Effective Thermal Management

Aluminum Cooling Plates: Revolutionizing Thermal ManagementIn today's fast-paced world, electronic devices are becoming increasingly powerful and compact, resulting in higher heat loads. As a result, thermal management has become a critical concern for manufacturers and designers of electronic devices. This is where Aluminum Cooling Plates come in – offering a reliable and efficient solution for dissipating heat and maintaining optimal operating temperatures.A leading player in the industry, [Company Name] is at the forefront of developing and manufacturing advanced Aluminum Cooling Plates. These cooling plates are designed to meet the demanding thermal management needs of a wide range of electronic applications, including power electronics, LED lighting, automotive, medical devices, and telecommunications equipment.With a commitment to innovation and quality, [Company Name] has established itself as a trusted partner for companies seeking cutting-edge thermal management solutions. The company's Aluminum Cooling Plates are engineered to deliver superior thermal performance, durability, and reliability, making them an ideal choice for demanding applications.One of the key advantages of Aluminum Cooling Plates is their excellent thermal conductivity. Aluminum is known for its high thermal conductivity, which allows for efficient heat transfer from the electronic components to the cooling plate, thereby effectively dissipating heat. This helps in preventing overheating and ensures the reliable operation of electronic devices, even under high thermal loads.Furthermore, [Company Name]'s Aluminum Cooling Plates are lightweight and have a low density, making them easy to handle and integrate into various electronic devices. This not only contributes to the overall weight reduction of the devices but also allows for more compact and space-efficient designs, addressing the industry's ongoing trend towards miniaturization.In addition to their thermal performance and lightweight properties, [Company Name]'s Aluminum Cooling Plates are highly customizable, offering flexibility in terms of shape, size, and surface finish. This enables the company to work closely with customers to develop tailored solutions that meet their specific thermal management requirements, ultimately contributing to improved device performance and longevity.Moreover, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. The Aluminum Cooling Plates are manufactured using environmentally friendly processes and materials, reflecting the company's dedication to reducing its carbon footprint and contributing to a greener future.As electronic devices continue to evolve and become more complex, the demand for effective thermal management solutions will only continue to grow. [Company Name]'s Aluminum Cooling Plates are well-positioned to address this growing demand, offering a reliable and efficient means of managing heat in electronic devices across various industries.In conclusion, Aluminum Cooling Plates have become an indispensable component in the design and manufacture of electronic devices, offering a reliable and efficient solution for thermal management. With [Company Name] leading the way in the development and production of these advanced cooling plates, the industry can look forward to continued innovation and evolution in the field of thermal management. As the demand for high-performing, compact, and reliable electronic devices continues to rise, Aluminum Cooling Plates will undoubtedly play a crucial role in meeting these evolving needs.

Tensile Strength of Aluminium: A Comprehensive Review

Title: Aluminum Tensile Strength - Revolutionizing IndustriesIntroduction:Aluminum is a versatile and lightweight material that has gained immense popularity in various industries over the years. With its exceptional tensile strength and a wide range of applications, aluminum has become a preferred choice for manufacturers, constructors, and designers alike. One company in particular has emerged as a leading provider of high-quality aluminum products, revolutionizing the way industries operate and paving the path for innovation and sustainability.Company Introduction:Established over a decade ago, {Brand Name} has emerged as a pioneer in the aluminum industry, specializing in manufacturing and distributing aluminum products globally. It boasts a state-of-the-art production facility, equipped with cutting-edge technology and a dedicated team of experts, ensuring superior quality and innovative designs. The company’s commitment to customer satisfaction, coupled with its emphasis on sustainable and environmentally-friendly practices, has earned it a stellar reputation in the market.News Content:Aluminum Tensile Strength: The Game-Changing Solution{Brand Name}'s latest breakthrough in aluminum technology has taken the industry by storm. Its innovative Aluminum Tensile Strength (ATS) has exceeded all expectations, offering unparalleled quality and performance. This game-changing solution has the potential to revolutionize multiple sectors, including aerospace, automotive, construction, and many more.The ATS Advantage:With an impressive tensile strength that surpasses traditional aluminum alloys, ATS provides a lightweight yet robust alternative for manufacturers. This allows for enhanced load-bearing capabilities without compromising on structural integrity, making it an ideal choice for various applications.Aerospace Industry Takes Flight:The aerospace industry, in particular, is set to benefit greatly from the introduction of ATS. The exceptional strength-to-weight ratio offered by the new aluminum variant enables the construction of lighter aircraft, ensuring improved fuel efficiency and reduced carbon emissions. Moreover, the supreme durability of ATS ensures enhanced safety and minimizes maintenance costs for airlines.Revolutionizing the Automotive Sector:The automotive industry is no stranger to the potential of aluminum, particularly in enhancing fuel efficiency. With ATS, manufacturers can take it a step further. The increased tensile strength allows for the creation of lighter and safer vehicles, as well as improved crashworthiness. Furthermore, the unmatched corrosion resistance of ATS ensures longevity, contributing to a sustainable automotive industry.Constructing Sustainable Infrastructure:Sustainable construction practices have become crucial in mitigating environmental impact. ATS not only provides a durable and reliable material for construction projects but also reduces the carbon footprint by being lightweight. The applications of ATS in roofing, cladding, and structural elements enable the creation of long-lasting and eco-friendly buildings.Expanding Possibilities in Design:Beyond its industrial applications, ATS brings new possibilities to the world of design and architecture. Its versatility allows for the creation of unique and intricate structures, transforming interiors and exteriors alike. The strength and stability offered by ATS enable designers to push the boundaries of creativity while maintaining integrity and functionality.Commitment to Sustainability:{Brand Name} recognizes the importance of sustainability and strives to minimize its environmental footprint. The production process of ATS incorporates energy-efficient practices and utilizes recycled materials wherever possible. By focusing on reducing waste and emissions, the company aims to contribute to a greener future.Conclusion:The introduction of Aluminum Tensile Strength by {Brand Name} represents a significant milestone in the aluminum industry. With its exceptional properties and numerous applications, ATS is set to transform various sectors. From aerospace to automotive and construction to design, the possibilities are endless. As {Brand Name} continues to innovate, it demonstrates its commitment to revolutionizing industries while paving the way for a sustainable and greener future.

Durable and Stylish Aluminium Edge Profile for Various Applications

Aluminium Edge Profile has been revolutionizing the construction and manufacturing industries with its high-quality and innovative products. The company has been a leader in the aluminium extrusion industry for over 20 years, providing top-notch solutions for a wide range of applications. From architectural projects to industrial machinery, Aluminium Edge Profile has been trusted by customers around the world for its exceptional products and exceptional service.Aluminium Edge Profile's dedication to quality and innovation has made it a preferred choice for customers looking for custom aluminium extrusion solutions. The company's state-of-the-art manufacturing facilities and advanced equipment enable it to produce a wide range of aluminium profiles, including the highly coveted Aluminium Edge Profile. This unique profile is designed to provide a sleek and durable finish to edges, corners, and joints, making it an ideal choice for various architectural and industrial applications.One of the key features of Aluminium Edge Profile is its versatility. It can be customized to fit specific design requirements, allowing customers to achieve the exact look and functionality they desire. Whether it's for a modern architectural project or a complex industrial application, Aluminium Edge Profile offers the flexibility and performance needed to meet even the most demanding requirements.In addition to its exceptional product range, Aluminium Edge Profile is also known for its commitment to sustainability. The company uses environmentally friendly production processes and materials, ensuring that its products have minimal impact on the environment. This dedication to sustainability has earned Aluminium Edge Profile recognition and praise from customers and industry experts alike.Furthermore, Aluminium Edge Profile is dedicated to providing excellent customer service. The company's team of experts is always available to assist customers with their aluminium extrusion needs, offering valuable advice and support throughout the design and manufacturing process. This commitment to customer satisfaction has helped Aluminium Edge Profile build long-lasting relationships with clients and partners, further solidifying its reputation as a trusted industry leader.In recent news, Aluminium Edge Profile has announced the launch of its latest product line, which includes an expanded range of profiles designed to meet the evolving needs of the construction and manufacturing industries. This new line is set to offer even more options for customers looking for high-quality and reliable aluminium extrusion solutions. With its continued dedication to innovation and excellence, Aluminium Edge Profile is poised to remain at the forefront of the industry for years to come.The company's proven track record of delivering top-notch products and exceptional service has made it a preferred choice for customers around the world. Whether it's for a small-scale construction project or a large industrial application, Aluminium Edge Profile has the expertise and capabilities to provide the perfect aluminium extrusion solutions. With its commitment to quality, sustainability, and customer satisfaction, Aluminium Edge Profile is set to continue leading the way in the aluminium extrusion industry.

Discover the Advantages of 7000 Series Alloy in Manufacturing

The 7000 Series Alloy has been making waves in the aerospace industry due to its superior strength and lightweight properties. This high-strength alloy has become a game-changer for aircraft manufacturing, offering a combination of strength and durability that is unmatched by other materials. With its exceptional performance and versatility, the 7000 Series Alloy has quickly become the go-to choice for aerospace engineers and designers looking to push the boundaries of innovation in aircraft construction.The 7000 Series Alloy is a family of high-strength aluminum alloys that are commonly used in aerospace applications. These alloys are known for their excellent strength-to-weight ratio, making them ideal for use in aircraft components that require high strength and low weight. This makes them particularly well-suited for aircraft structures such as wings, fuselages, and landing gear, where the need for strength and durability is paramount.One company at the forefront of utilizing the 7000 Series Alloy in its aircraft manufacturing is {}. With a strong focus on innovation and cutting-edge technology, {} has embraced the 7000 Series Alloy as a key material in its aircraft production. By incorporating this advanced alloy into its aircraft designs, {} has been able to create aircraft that are not only stronger and more durable, but also lighter and more fuel-efficient.{} has a long history of pushing the boundaries of aerospace technology, and the use of the 7000 Series Alloy is yet another example of the company's commitment to innovation. By integrating this advanced alloy into its aircraft, {} has been able to create aircraft that are capable of withstanding the rigors of flight while remaining lightweight and agile. This has not only improved the performance of {} aircraft, but has also set new standards for the entire aerospace industry.The use of the 7000 Series Alloy has had a significant impact on the aircraft manufacturing industry as a whole. {}'s adoption of this advanced material has spurred interest and investment in the development of new manufacturing processes and technologies, with the aim of further improving the performance and capabilities of the 7000 Series Alloy. As a result, the aerospace industry as a whole has seen a renewed focus on developing lighter, stronger, and more durable aircraft components, with the ultimate goal of creating aircraft that are safer, more efficient, and more cost-effective to operate.The exceptional properties of the 7000 Series Alloy have also led to increased collaboration and partnership between aerospace companies and material suppliers. With the demand for this advanced alloy constantly growing, material suppliers have been working closely with aerospace manufacturers to ensure a stable and reliable supply of the 7000 Series Alloy. This collaboration has not only helped to meet the growing demand for the alloy, but has also led to further advancements in its production and processing, ultimately benefiting the entire aerospace industry.In conclusion, the 7000 Series Alloy has proven to be a game-changer for the aerospace industry, with its exceptional strength, lightweight properties, and versatility. {}'s embrace of this advanced alloy has set new standards for aircraft manufacturing, pushing the boundaries of what is possible in terms of aircraft performance and capabilities. As the aerospace industry continues to evolve, the 7000 Series Alloy is sure to play a key role in shaping the future of aircraft manufacturing, offering new opportunities for innovation and advancement.

Revolutionary Aluminum Frame Design Aims to Disrupt the Industry" can be rewritten as "Innovative Aluminum Frame Design Set to Revolutionize the Industry".

[Innovation in Aluminum Frame Design: Revolutionizing the Industry]Aluminum Frame Design (AFD), an industry-leading innovator in the field of lightweight construction, continues to push the boundaries with its groundbreaking designs. With a relentless focus on sustainability, efficiency, and durability, AFD is revolutionizing various industries by delivering state-of-the-art solutions that are reshaping the future of manufacturing.AFD's commitment to excellence can be traced back to its humble beginnings. Founded in {year} by visionary engineers, {Company Name} started its journey with the aim of transforming traditional manufacturing processes. By harnessing the power of aluminum, a lightweight yet robust material, AFD has been able to bring groundbreaking ideas to life.The secret behind AFD's success lies in its innovative aluminum frame construction techniques. By capitalizing on the unique properties of aluminum, the company has developed cutting-edge solutions that are not only stronger but also lighter than traditional frames made from materials like steel. The use of aluminum frames has significantly reduced the weight of various products, from automobiles to consumer electronics, making them more fuel-efficient and environmentally friendly.One of AFD's noteworthy achievements is its collaboration with the automotive industry. Over the years, the company has worked closely with leading car manufacturers to optimize vehicle design and enhance overall performance. By replacing conventional steel frames with aluminum ones, AFD has reduced the weight of cars, leading to improved fuel efficiency and reduced emissions. Additionally, the aluminum frames offer superior collision protection due to their high strength-to-weight ratio, ensuring the safety of passengers in case of accidents.Another industry where AFD's aluminum frame technology is making waves is in the aerospace sector. By partnering with aerospace giants, AFD has revolutionized aircraft manufacturing. The implementation of lightweight aluminum frames has not only reduced aircraft weight but also increased fuel efficiency. This breakthrough has had a significant impact on the aviation industry, leading to lower operational costs and reduced environmental impact.The benefits of AFD's aluminum frames extend beyond the automotive and aerospace industries. The company's innovative designs have influenced various sectors, including consumer electronics, architecture, and renewable energy. In consumer electronics, AFD's lightweight yet durable aluminum frames have made devices more portable, while maintaining structural integrity. In architecture, the use of aluminum frames has allowed for sleek and modern designs, enabling architects to create visually stunning structures with enhanced energy efficiency. In the renewable energy sector, AFD's aluminum frames have contributed to the development of lightweight solar panels, making them easier to install and transport.With sustainability at the forefront of its mission, AFD is committed to reducing the environmental impact of its manufacturing processes. Aluminum, being a highly recyclable material, aligns perfectly with the company's sustainability goals. AFD ensures that its production facilities adhere to strict environmental regulations and focuses on minimizing waste throughout the manufacturing process. By utilizing recycled aluminum and optimizing material consumption, AFD further contributes to a greener future.Looking ahead, AFD shows no signs of slowing down. The company is continuously investing in research and development to further enhance its aluminum frame designs. Collaborations with academic institutions and other industry leaders allow AFD to stay at the forefront of innovation, driving progress in lightweight construction techniques.In conclusion, Aluminum Frame Design (AFD) has emerged as a pioneer in the world of lightweight construction. Through its innovative aluminum frame designs, AFD has revolutionized various industries, from automotive to aerospace, consumer electronics to architecture. By reducing weight, increasing efficiency, and promoting sustainability, AFD's groundbreaking solutions are reshaping the future of manufacturing and contributing to a greener world.

Discover the Ideal Thickness for Aluminium Profiles

Aluminium Profile ThicknessAluminium profiles are widely used in various industries due to their durability and flexibility. The thickness of aluminium profiles plays a crucial role in the quality and strength of the final product. With the right thickness, aluminium profiles can be used in construction, automotive, aerospace, and other industries, providing a lightweight and durable solution for various applications.One of the leading companies in the aluminium profile industry is (company name). With a history of excellence and innovation, they have been at the forefront of producing high-quality aluminium profiles with various thickness options to meet the diverse needs of their customers.The thickness of aluminium profiles can range from 0.3mm to 6mm, depending on the specific requirements of the application. Thicker profiles are often used in heavy-duty applications where strength and durability are crucial, while thinner profiles are suitable for lightweight applications such as in the automotive and aerospace industries.The process of determining the right thickness for aluminium profiles involves careful consideration of factors such as the intended use, load-bearing capacity, and environmental factors. Thicker profiles offer higher load-bearing capacity and resistance to bending, making them suitable for structural applications. Thinner profiles, on the other hand, are more flexible and lightweight, making them ideal for applications where weight is a critical factor.In the construction industry, aluminium profiles with the right thickness are used in the fabrication of doors, windows, curtain walls, and structural components. The versatility of aluminium profiles allows architects and builders to create aesthetically pleasing designs while ensuring the structural integrity of the building.In the automotive industry, aluminium profiles with specific thickness requirements are used for the fabrication of chassis components, body panels, and other structural parts. The lightweight nature of aluminium profiles contributes to improved fuel efficiency and overall performance of vehicles.In the aerospace industry, the use of aluminium profiles with precise thickness specifications is essential for ensuring the structural integrity of aircraft components. The high strength-to-weight ratio of aluminium profiles makes them an ideal choice for use in critical applications such as aircraft wings, fuselage components, and landing gear.The manufacturing process of aluminium profiles with custom thickness begins with the selection of high-quality aluminium alloys, followed by precision extrusion and heat treatment to achieve the desired mechanical properties. Advanced machining and finishing techniques ensure that the profiles meet the exacting specifications of the customers.The expertise of (company name) in producing aluminium profiles with custom thickness options has earned them a reputation for delivering high-quality products that meet the stringent requirements of various industries. Their state-of-the-art manufacturing facilities and commitment to continuous improvement allow them to offer a wide range of aluminium profiles to cater to the diverse needs of their customers.In conclusion, the thickness of aluminium profiles is a critical factor in determining their suitability for different applications. With the right thickness, aluminium profiles offer a combination of strength, durability, and lightweight properties that make them an ideal choice for a wide range of industries. The capabilities of (company name) in producing custom aluminium profiles with specific thickness options make them a trusted partner for businesses looking for high-quality aluminium solutions.

High-strength Aircraft Aluminum Alloy 7050: A Game-changer in Aerospace Manufacturing

Aircraft Aluminum Alloy 7050: The Perfect Combination of Strength and Innovation[Company Name], a leading provider of aerospace products and services, has recently made a significant breakthrough in the development of aircraft aluminum alloy 7050. This revolutionary material is set to redefine the standards of strength and durability in the aerospace industry, offering exceptional performance and reliability for a wide range of applications. With the introduction of this advanced alloy, [Company Name] continues to exemplify its commitment to technological innovation and excellence in the field of aerospace engineering.Aircraft aluminum alloy 7050 is a high-strength material that is ideally suited for use in aircraft structures, as well as in other demanding industrial and commercial applications. It is known for its outstanding combination of strength, toughness, and corrosion resistance, making it a top choice for critical components that require exceptional performance under challenging operating conditions. With a composition of aluminum, zinc, magnesium, and copper, this alloy offers a unique blend of properties that make it an optimal material for aerospace applications.The innovative process developed by [Company Name] for the production of aircraft aluminum alloy 7050 involves the use of state-of-the-art manufacturing techniques and precision engineering. Through meticulous research and development efforts, the company has successfully optimized the mechanical properties of the alloy, ensuring superior performance and reliability in demanding operational environments. The result is a material that surpasses traditional aluminum alloys in terms of strength and toughness, while also maintaining a favorable balance of weight and cost-effectiveness.In addition to its exceptional mechanical properties, aircraft aluminum alloy 7050 is also highly resistant to corrosion, ensuring long-term durability and reliability in harsh operating conditions. This makes it an ideal choice for aerospace applications, where components are subjected to extreme temperatures, pressure differentials, and environmental factors. The alloy's ability to withstand these challenges makes it a valuable asset for the development of next-generation aircraft and space exploration vehicles, as well as for the enhancement of existing aerospace platforms.Beyond its application in aerospace engineering, aircraft aluminum alloy 7050 holds promise for a wide range of industrial and commercial uses. Its exceptional combination of strength, durability, and corrosion resistance makes it a preferred material for critical components in automotive, marine, and structural engineering applications. With its superior mechanical properties and performance characteristics, this alloy is poised to make a significant impact across various industries, facilitating the development of innovative solutions and driving technological advancement.The introduction of aircraft aluminum alloy 7050 reinforces [Company Name]'s status as a leader in the aerospace industry, demonstrating its commitment to pushing the boundaries of material science and engineering. By harnessing the potential of this advanced alloy, the company is well-positioned to address the evolving needs of the aerospace market, while also providing solutions for diverse industrial and commercial applications. Through its dedication to innovation and excellence, [Company Name] is driving the development of cutting-edge materials and technologies that will shape the future of aerospace and beyond.In conclusion, the introduction of aircraft aluminum alloy 7050 represents a significant milestone in the advancement of materials engineering, offering unprecedented strength, durability, and reliability for aerospace and industrial applications. With its exceptional mechanical properties and corrosion resistance, this innovative alloy is set to redefine the standards of performance and innovation in the aerospace industry, as well as across various industrial and commercial sectors. As [Company Name] continues to lead the way in material science and aerospace engineering, the potential for aircraft aluminum alloy 7050 to catalyze technological advancement and drive progress is truly unparalleled.

High-Quality Extruded Aluminum Tubing Profiles for Various Applications

Extruded Aluminum Tubing Profiles: Why They’re the Future of ManufacturingThe manufacturing industry is constantly growing and pushing boundaries to meet increasing demands of the market. This has led to the development of new and innovative manufacturing techniques and materials to support this advancement. One such material that has become increasingly popular is the extruded aluminum tubing profiles. The innovation has revolutionized the manufacturing industry and is now the preferred choice for many industries.With the advent of this new technology, a company has taken charge of offering custom-made extruded aluminum tubing profiles to meet everyone's unique demand. With a mission of providing top-notch services while offering the best price ever, this company stands out and remains the trusted supplier in the industry. They have been producing extruded aluminum that is used to create complex shapes and designs, resulting in quality goods. They have been able to achieve this due to their use of advanced extruding technology and knowledge that has over time helped to refine their production processes and techniques. The application of extruded aluminum tubing profiles in manufacturing has brought about various benefits. Below are some of the advantages that make the material the future of manufacturing.Cost-effectiveExtruded aluminum tubing profiles have become the preferred option for many manufacturing industries because it is very cost-effective. Compared to other materials like steel or titanium, aluminum is cheaper and lighter but still retains the same strength and durability needed by most parts manufactured. This cost-effective material has ensured the manufacturing industry can produce high-end goods at a lower cost without sacrificing the product's quality.DurabilityAlthough aluminum is a light material, it is still structurally strong and durable. When extruded into tubing profiles, its strength and durability are increased and can withstand heavy loads. This means most products made from extruded aluminum tubing profiles are likely to last for long with frequent use and are less susceptible to damage compared to other materials.VersatilityExtruded aluminum tubing profiles have made possible the production of products that are versatile, compared to other materials. The profiles can be extruded into various shapes and sizes to achieve a manufacturer's exact requirement. Its flexibility allows for the production of unique shapes that will enhance the beauty of a product.Ease of fabricationAluminum extrusion is an efficient method of manufacturing because it is easy to fabricate the material into whatever shape or design desired. This makes it ideal for producing complex parts, and the process can be done quickly. Additionally, the process also requires minimal post-production machining, which can reduce product quality and production time.SustainabilityThe use of extruded aluminum tubing profiles in manufacturing is highly sustainable. Aluminum is a recyclable material, and recycling it uses 95% less energy compared to producing new aluminum. This reduces the environmental impact of manufacturing, making it more eco-friendly.ConclusionThe many benefits of extruded aluminum tubing profiles make it a significant breakthrough in the manufacturing industry. Its use has brought innovation and efficiency to the field, creating less environmental impact and reliability. With the increasing demand for high-quality goods at an affordable price, manufacturers need to consider extruded aluminum tubing profiles. By incorporating this material, they can remain competitive and meet the market demands while still offering high-end products. The reputable company that provides custom-made products continues to remain vital in the industry's development and growth while providing top-notch quality services.

Exploring the Benefits of Aluminum CNC Bed for Enhanced Performance

Title: Introduction of CNC Bed Aluminum in Manufacturing Industry: Revolutionizing Precision and EfficiencyIntroduction:In today's fast-paced manufacturing industry, the quest for increased precision and efficiency has led to the development of advanced technology and equipment. Among these innovative solutions, CNC (Computer Numerical Control) machining has emerged as a game-changer, enabling manufacturers to automate and streamline their production processes. One of the leading players in this field is a company that specializes in CNC bed aluminum, offering unmatched quality and performance to businesses worldwide.Company Background:With a history spanning over 20 years, this industry-leading company has established itself as a trusted manufacturer of CNC bed aluminum. Steeped in a tradition of excellence and continuous improvement, the company has relentlessly pushed the boundaries of innovation, driving significant advancements in precision machining. Their commitment to exceptional craftsmanship, state-of-the-art technology, and superior customer service has positioned them as a highly sought-after partner for businesses across industries.Revolutionary Features of CNC Bed Aluminum:The company's CNC bed aluminum boasts an array of features that set it apart from conventional machining alternatives, delivering unrivaled accuracy and efficiency. These features can be broadly categorized into the aspects of performance, design, and versatility.1. Performance: a. Rigidity: CNC bed aluminum offers superior rigidity compared to other materials, ensuring stable cutting operations even under heavy loads. b. Vibration Damping: The material's excellent vibration damping properties minimize tool wear and enable smooth and consistent machining processes. c. Thermal Stability: CNC bed aluminum exhibits exceptional thermal stability, reducing the risk of thermal deformation during prolonged machining. d. Precision: The precision of CNC machining is greatly enhanced with CNC bed aluminum, providing high-quality finished products with tight tolerances.2. Design: a. Modular Design: The company's CNC bed aluminum features a modular design that allows for easy customization and adaptability to various manufacturing requirements. b. Integrated Channels: Specially designed integrated channels allow for efficient chip evacuation, ensuring uninterrupted productivity and reducing downtime.3. Versatility: a. Compatibility: CNC bed aluminum is compatible with a wide range of cutting tools and can accommodate diverse machining processes, making it suitable for multiple industries. b. Material Compatibility: It is highly versatile in terms of material compatibility, allowing manufacturers to work with different alloys and composites.Impact on Manufacturing Industry:The introduction of CNC bed aluminum has revolutionized the manufacturing industry, offering a multitude of benefits to businesses worldwide:1. Enhanced Productivity: The superior rigidity, vibration damping, and thermal stability of CNC bed aluminum enable businesses to significantly increase productivity by reducing downtime and optimizing machining operations.2. Improved Accuracy and Precision: With CNC bed aluminum, manufacturers can achieve higher levels of accuracy and precision, ensuring consistent quality across production batches.3. Cost Reduction: By minimizing tool wear and reducing scrap rates, CNC bed aluminum lowers production costs and enhances overall efficiency, increasing the profitability of manufacturing operations.4. Expanded Market Opportunities: The versatility of CNC bed aluminum allows businesses to explore new markets and expand their product offerings, catering to a broader range of customer demands.Conclusion:The introduction of CNC bed aluminum has revolutionized the manufacturing industry, providing businesses with a cutting-edge solution for precision machining. The company's commitment to innovation and exceptional craftsmanship has positioned them as a market leader, empowering manufacturers to achieve higher productivity, accuracy, and cost efficiency. With the ability to adapt to various manufacturing requirements and deliver impeccable results, CNC bed aluminum remains at the forefront of the industry, driving progress and shaping the future of manufacturing.