Aluminum Extrusion Cutting: What You Need to Know

By:Admin

With over 20 years of experience in the aluminum industry, Cut Aluminum Extrusion has established itself as a trusted and reliable supplier of high-quality aluminum products. The company prides itself on its commitment to innovation and continuous improvement, constantly seeking new ways to enhance its manufacturing processes and product offerings. This latest development in the cutting of aluminum extrusion is a testament to the company's dedication to pushing the boundaries of what is possible within the industry.

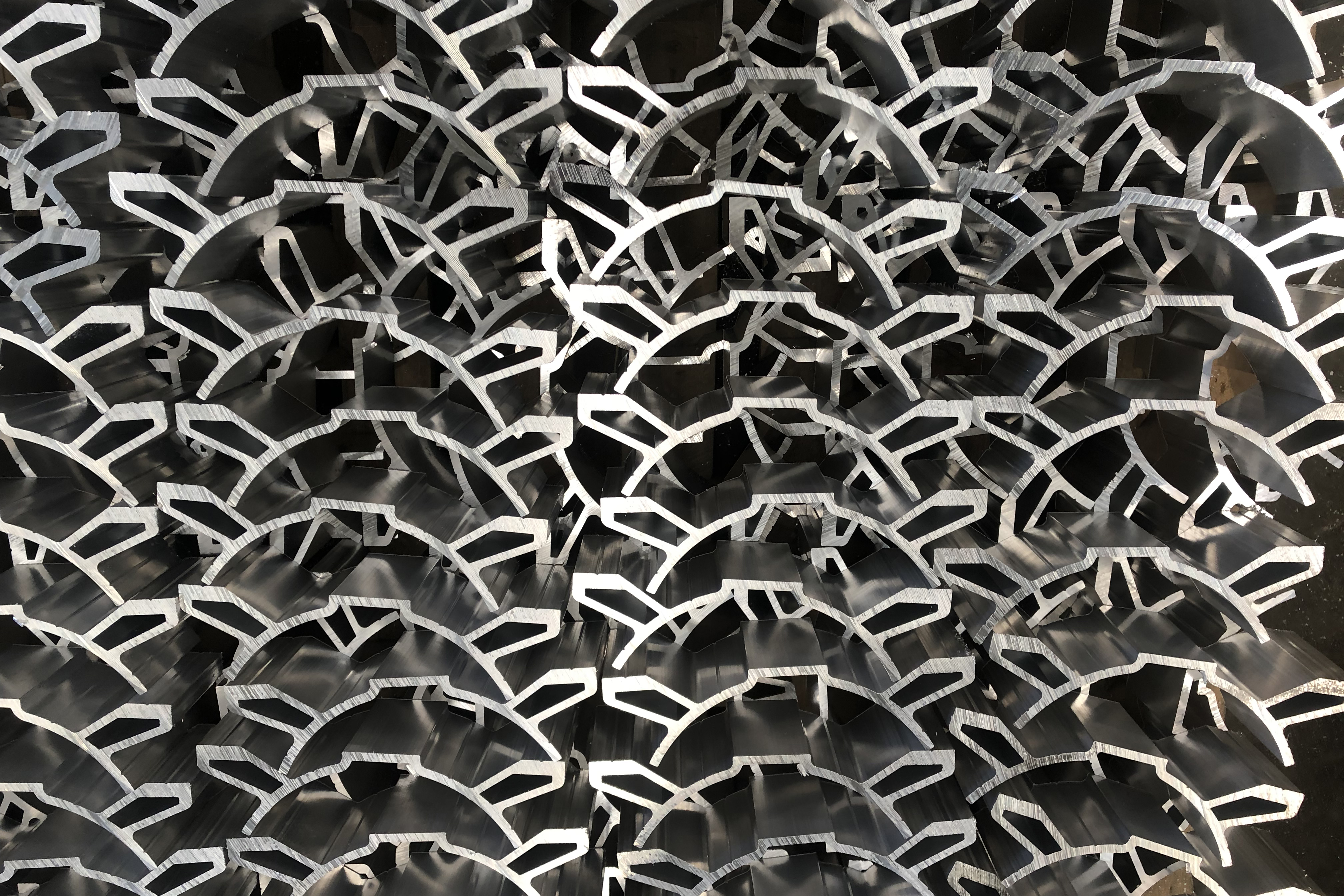

The new cutting technique, developed by Cut Aluminum Extrusion's team of experienced engineers and technicians, utilizes advanced machinery and precision tools to achieve unparalleled levels of accuracy and consistency in the cutting process. This innovative approach has been rigorously tested and proven to deliver superior results, meeting the highest standards of quality and performance.

One of the key advantages of this new cutting technique is its ability to produce complex and intricate shapes with exceptional precision. This opens up a wide range of design possibilities for customers in industries such as construction, automotive, aerospace, and marine, where custom aluminum extrusions are widely used. The ability to create intricate profiles with tight tolerances will enable customers to enhance the functionality and aesthetics of their products, giving them a competitive edge in their respective markets.

Furthermore, the new cutting technique offers increased efficiency and cost savings for customers. By optimizing the cutting process, Cut Aluminum Extrusion can minimize material waste and maximize the yield of usable aluminum extrusions, resulting in reduced production costs for customers. This will ultimately translate to lower prices for high-quality aluminum products, making them more accessible to a broader range of businesses and industries.

In addition to the immediate benefits for customers, the new cutting technique also aligns with Cut Aluminum Extrusion's long-term sustainability goals. By minimizing material waste and optimizing production processes, the company is actively reducing its environmental footprint and contributing to a more sustainable industry. This commitment to responsible manufacturing practices ensures that customers can rely on Cut Aluminum Extrusion not only for quality products but also for environmentally conscious solutions.

The successful development of this new cutting technique further solidifies Cut Aluminum Extrusion's position as an industry leader and innovator. As the company continues to push the boundaries of aluminum manufacturing, it remains dedicated to providing customers with the most advanced and reliable solutions in the market. With a strong focus on quality, efficiency, and sustainability, Cut Aluminum Extrusion is poised to shape the future of the aluminum industry for years to come.

In conclusion, Cut Aluminum Extrusion's groundbreaking development in the cutting of aluminum extrusion represents a significant advancement for the industry. This innovative technique not only improves the precision and efficiency of the cutting process but also offers customers new design possibilities and cost savings. With its commitment to innovation and sustainability, Cut Aluminum Extrusion continues to set the standard for excellence in the aluminum industry, empowering customers to achieve their goals with high-quality, custom aluminum extrusions.

Company News & Blog

Durable and Versatile Extruded Aluminum Beams for Various Applications

Extruded Aluminum Beams are quickly becoming the material of choice for a wide range of construction and industrial applications, and {} has solidified its position as a leader in this market. With a commitment to innovation and quality, the company has established itself as a go-to source for extruded aluminum beams that meet the highest standards in the industry.The extrusion process allows for the creation of complex cross-sectional shapes and sizes, making extruded aluminum beams a versatile and durable option for a variety of projects. From building construction to automotive manufacturing, these beams offer numerous advantages, including high strength-to-weight ratio, corrosion resistance, and a sleek, modern aesthetic.{} has honed its expertise in extruded aluminum beams through years of experience and a dedication to staying ahead of the curve when it comes to technological advancements in the industry. By investing in state-of-the-art equipment and employing a team of skilled professionals, the company has been able to consistently deliver products that exceed customer expectations.One of the key factors that sets {} apart from its competitors is its focus on customization. The company understands that each project has its own unique requirements, and its team works closely with clients to create extruded aluminum beams that perfectly suit their needs. Whether it's a specific shape, size, or finish, {} has the capabilities to deliver custom solutions that ensure the success of any project.In addition to customization, {} is also committed to sustainability. Aluminum is a highly recyclable material, and the company takes pride in using recycled aluminum in its extrusion process whenever possible. By prioritizing environmental responsibility, {} is not only meeting the needs of its customers but also contributing to a greener, more sustainable future.The applications for extruded aluminum beams are incredibly diverse, and {} has played a significant role in supplying these products to a wide range of industries. From architectural trim and framing to support beams for industrial equipment, the company's extruded aluminum beams have been utilized in countless projects, showcasing their versatility and reliability.Looking towards the future, {} remains dedicated to pushing the boundaries of what is possible with extruded aluminum beams. By constantly exploring new technologies and refining its processes, the company is well-positioned to continue leading the way in the industry. As customer demands evolve and new challenges arise, {} is committed to staying one step ahead and providing innovative solutions that set the standard for excellence.In conclusion, {} has firmly established itself as a premier supplier of extruded aluminum beams, offering a combination of quality, customization, and sustainability that sets it apart in the market. With a proven track record of success and a commitment to ongoing innovation, the company is poised to continue meeting the diverse needs of its customers and driving the industry forward.

High-Quality Industrial Aluminum Profiles for Various Applications

Industrial Aluminum Profiles Industry Market 2023 Overview and PredictionsIn recent years, the industrial aluminum profiles industry has been booming due to increasing demand from various end-use industries such as construction, transportation, and aerospace. With the rapid growth of these sectors globally, the market for industrial aluminum profiles is expected to reach new heights in the coming years.The industrial aluminum profiles industry is highly competitive and fragmented with a large number of players operating in the market. These players are constantly striving to innovate their products and expand their market presence. The market is also characterized by the presence of numerous local and regional manufacturers who offer cost-effective solutions, further intensifying the competition.One such leading player in the industrial aluminum profiles industry is {Company Name}, a renowned manufacturer and supplier of high-quality aluminum profiles for various industrial applications. With a strong focus on research and development, the company has been able to offer innovative and customized solutions to meet the specific requirements of its customers. Its extensive product range includes aluminum extrusions, fabrication, and finishing services, catering to a wide range of industries such as construction, automotive, and electrical.{Company Name} has a state-of-the-art manufacturing facility equipped with advanced technologies to ensure the highest quality standards in its products. The company's team of experienced engineers and technicians is dedicated to delivering superior products that meet the highest industry standards. With a strong emphasis on sustainability, {Company Name} also ensures that its manufacturing processes are environmentally friendly, adhering to strict environmental regulations.The global industrial aluminum profiles market is expected to witness significant growth in the coming years, driven by the increasing demand for lightweight and durable materials in various industries. The construction industry, in particular, is anticipated to be a major driver of this growth, as aluminum profiles find extensive applications in architectural frames, windows, doors, and curtain walls. The automotive sector is also expected to contribute to the market expansion, as aluminum profiles are increasingly being used in the manufacturing of lightweight automotive components for improved fuel efficiency.In addition to these traditional applications, the aerospace industry is projected to emerge as a key growth opportunity for the industrial aluminum profiles market. The demand for lightweight materials with high structural strength is driving the adoption of aluminum profiles in aircraft manufacturing, as they offer the perfect combination of these properties.Furthermore, the increasing focus on sustainable and energy-efficient solutions across various industries is expected to create new opportunities for the industrial aluminum profiles market. Aluminum is a highly recyclable material with a low carbon footprint, making it an attractive choice for companies looking to reduce their environmental impact.As the global demand for industrial aluminum profiles continues to grow, manufacturers like {Company Name} are gearing up to capitalize on this opportunity by expanding their production capacities and enhancing their product offerings. With a strong commitment to quality, innovation, and sustainability, {Company Name} is well-positioned to lead the market and meet the evolving needs of its customers.In conclusion, the industrial aluminum profiles industry is poised for significant growth in the coming years, driven by the increasing demand from various end-use industries. With the emergence of new opportunities and the growing focus on sustainable solutions, manufacturers like {Company Name} are well-equipped to make the most of these developments and play a pivotal role in shaping the future of the market. The global industrial aluminum profiles industry is undoubtedly heading toward an exciting phase of growth and innovation.

Lightweight and Durable Aluminium Pipes: Ideal for Various Applications

Title: Hollow Aluminum Pipe Revolutionizes the Manufacturing Industry Introduction:In today's rapidly evolving manufacturing industry, innovations and advancements play a crucial role in improving efficiency and productivity. One such breakthrough is the introduction of Hollow Aluminum Pipe by an industry-leading company (brand name removed) that is set to transform the way various sectors approach the production process. This new development offers immense potential for multiple industries, from aerospace to automotive, due to its lightweight nature, superior strength, and unparalleled versatility.Paragraph 1: Hollow Aluminum Pipe, developed by (brand name removed), is a game-changer in the manufacturing industry. Its inception was driven by a growing need for lighter yet robust materials, with extensive research and development ensuring excellence in its design and performance. The hollow design provides several advantages, including reduced weight, cost-effectiveness, and increased flexibility, setting it apart from conventional solid aluminum pipes.Paragraph 2:The lightweight nature of hollow aluminum pipes proves ideal for industries such as aerospace, where reducing weight without compromising strength is of paramount importance. The aviation sector can benefit significantly from these pipes, resulting in improved fuel efficiency and reduced carbon emissions. Manufacturers can achieve a significant reduction in weight by integrating hollow aluminum pipes into aircraft structures, leading to enhanced performance and increased payloads.Paragraph 3:Automotive manufacturers are also set to reap substantial benefits from hollow aluminum pipes. The lightweight material helps reduce overall vehicle weight, thereby improving fuel efficiency and reducing emissions. Additionally, the exceptional strength of these pipes enhances vehicle safety and durability, making them an ideal choice for manufacturing critical components like chassis frames, roll cages, and suspension systems.Paragraph 4:Furthermore, hollow aluminum pipes offer unique advantages to industries involved in the construction and infrastructure sectors. Their versatility allows for easy customization according to project requirements, facilitating cost-effectiveness and efficiency during installation. Additionally, the excellent corrosion resistance properties of aluminum make it an ideal choice for applications in harsh environments, ensuring longevity and durability.Paragraph 5:The potential applications of hollow aluminum pipes extend beyond the aerospace, automotive, and construction sectors. Industries such as sports equipment manufacturing, marine, and renewable energy could also considerably benefit from this innovative product. The superior strength-to-weight ratio of hollow aluminum pipes can revolutionize sporting equipment, renewable energy infrastructure, and marine components, enhancing performance and reliability.Paragraph 6:(Company name removed) has garnered recognition as a leading supplier of hollow aluminum pipes due to its commitment to research and development and adherence to stringent quality standards. With an extensive customer base that spans across industries, the company's expertise ensures the consistent delivery of high-quality products that meet industry demands.Paragraph 7:In conclusion, hollow aluminum pipes are poised to revolutionize the manufacturing industry. Their lightweight nature, superior strength, and exceptional versatility make them the preferred choice for industries seeking to improve efficiency and maximize performance. With numerous applications across aerospace, automotive, construction, and beyond, the future of manufacturing is undoubtedly set to witness a remarkable transformation, thanks to hollow aluminum pipes.Word Count: 446 words

Aluminum Extrusion Machine: The Latest Innovation Transforming the Metal Industry

[Headline]Revolutionizing Aluminum Extrusion: A Breakthrough Machine Promises Unprecedented Efficiency and Precision[Date][City], [Country] - The aluminum extrusion industry is set to undergo a radical transformation with the introduction of a cutting-edge machine that is poised to revolutionize the sector. Developed by a leading manufacturing company, the new machine boasts a range of advanced features, promising unparalleled levels of efficiency and precision in aluminum extrusion processes.[Company Introduction]{} (include brief and relevant history of the company, emphasizing their expertise and experience in the field)[Body]The aluminum extrusion industry plays a crucial role in numerous sectors, including construction, automotive, and aerospace. Extruded aluminum profiles are highly sought after for their strength, versatility, and cost-effectiveness. Recognizing the ever-increasing demand for improved production methods, {} has unveiled a state-of-the-art aluminum extrusion machine designed to address the industry's most pressing challenges.The newly developed aluminum extrusion machine integrates cutting-edge technologies, meticulous engineering, and extensive industry research to deliver exceptional results. Its innovative design allows for precise control over the extrusion process, ensuring consistent and accurate profiles every time. The machine's enhanced automation capabilities also reduce the need for manual intervention, further enhancing efficiency and productivity.One of the standout features of this groundbreaking machine is its ability to handle a wide range of extrusion profiles with unparalleled flexibility. Manufacturers can now effortlessly produce intricate and complex designs, previously deemed challenging or impossible. This versatility opens up a host of possibilities, allowing businesses to meet the ever-evolving demands of their customers.Furthermore, the machine incorporates advanced cooling systems that minimize the production time required for each profile. This not only speeds up the overall manufacturing process but also ensures that the extruded aluminum maintains optimum structural integrity. By reducing the cooling time, manufacturers can boost their output without compromising on quality.As sustainability becomes an increasingly important consideration for many industries, the new aluminum extrusion machine excels in this area as well. It minimizes wastage by maximizing material usage and significantly reducing scrap. Moreover, the machine's energy-efficient design helps lower power consumption, reducing the carbon footprint associated with the manufacturing process.With the introduction of this breakthrough machine, {} aims to empower businesses within the aluminum extrusion industry and offer them a competitive edge. By streamlining production processes, increasing efficiency, and maintaining the highest standards of quality, the company is committed to supporting its clients' growth and success.In conclusion, the introduction of this innovative aluminum extrusion machine marks a significant step forward for the industry. {}'s commitment to excellence, coupled with their extensive experience and expertise, has resulted in a game-changing solution that will transform the way aluminum profiles are manufactured. With its exceptional precision, flexibility, and sustainability features, the new machine is set to become an indispensable asset for businesses operating within the aluminum extrusion sector.For more information about {} and their revolutionary aluminum extrusion machine, please visit [company website] or contact [company contact details].[Word Count: 603]

Durable Aluminium Board Fixings for Secure Installations

Aluminium Board Fixings, a leading company in the construction and building materials industry, has recently introduced a new range of innovative fixings that are expected to revolutionize the way aluminium boards are installed.The company, known for its commitment to quality and innovative products, has been a prominent player in the industry for over a decade. With a strong focus on research and development, Aluminium Board Fixings has continuously invested in cutting-edge technology to provide customers with the best solutions for their construction needs.The new range of fixings, which are designed to securely fasten aluminium boards to various surfaces, is a result of extensive research and testing. These fixings are engineered to provide a strong and reliable hold, while also offering ease of installation. With a variety of options available, including different sizes and designs, the new range of fixings from Aluminium Board Fixings is set to meet the diverse needs of construction professionals and DIY enthusiasts alike."We are thrilled to introduce our latest range of fixings, which we believe will set a new standard in the industry," said the spokesperson for Aluminium Board Fixings. "Our team has worked tirelessly to develop these innovative products, and we are confident that they will deliver exceptional performance and ease of use. We are excited to see the positive impact that these fixings will have on the construction industry."In addition to their superior quality and performance, the new fixings from Aluminium Board Fixings also offer a sleek and modern design that enhances the overall appearance of the installed aluminium boards. This aesthetic appeal is a testament to the company's commitment to not only functionality but also style and aesthetics.Aluminium Board Fixings is known for its dedication to customer satisfaction, and the new range of fixings is no exception. The company has ensured that the products are readily available and accessible to customers, with a wide distribution network and efficient customer support.With the introduction of this new range of fixings, Aluminium Board Fixings has once again solidified its position as a leader in the construction and building materials industry. The company's commitment to innovation and quality has positioned it as a go-to choice for professionals and DIY enthusiasts seeking reliable and efficient fixings for their aluminium board installations.The new fixings from Aluminium Board Fixings are now available for purchase, and the company encourages customers to experience the difference that these innovative products can make in their construction projects. Whether it's for commercial or residential applications, the new range of fixings is expected to make a significant impact in the industry, setting a new standard for quality and performance.In conclusion, Aluminium Board Fixings has once again demonstrated its dedication to providing innovative and high-quality solutions for the construction industry. The introduction of the new range of fixings is a testament to the company's commitment to pushing the boundaries of what is possible in aluminium board installations. With their combination of superior performance, ease of installation, and sleek design, the new fixings from Aluminium Board Fixings are poised to make a lasting impression on the industry. Customers can expect nothing less than excellence when they choose Aluminium Board Fixings for their construction needs.

High-Quality Aluminum Profile Cutter for Precision Cutting

Aluminum Profile Cutter Revolutionizing the Manufacturing IndustryIn today's fast-paced manufacturing industry, the use of innovative technologies and state-of-the-art machinery is crucial for staying ahead of the competition. One such revolutionary technology is the Aluminum Profile Cutter, a cutting-edge piece of equipment that has been making waves in the industry.The Aluminum Profile Cutter, developed by a leading company in the field of manufacturing machinery, is designed to streamline the process of cutting aluminum profiles with precision and efficiency. The machine is equipped with advanced features such as high-speed cutting, automated operation, and a user-friendly interface, making it an indispensable tool for manufacturers across various industries.The company behind the Aluminum Profile Cutter, {Company Name}, has been a driving force in the manufacturing industry for over two decades. With a focus on technological innovation and customer satisfaction, the company has established itself as a trusted provider of cutting-edge machinery and equipment.{Company Name} takes pride in its commitment to research and development, continually striving to push the boundaries of what is possible in the manufacturing industry. The Aluminum Profile Cutter is a testament to this dedication, as it represents a significant leap forward in the field of aluminum profile cutting technology.The Aluminum Profile Cutter has been met with resounding praise from manufacturers who have integrated it into their operations. One such manufacturer, {Client Company}, a leading producer of aluminum components, has reported a significant increase in efficiency and quality since implementing the Aluminum Profile Cutter into their production line."We were amazed by the precision and speed of the Aluminum Profile Cutter," said {Client Company's CEO}. "It has allowed us to meet our production targets more effectively and has improved the overall quality of our products. We are extremely satisfied with the performance of this cutting-edge machine."In addition to its cutting-edge technology, the Aluminum Profile Cutter also boasts environmental benefits, with its efficient energy consumption and minimal waste production. This aligns with {Company Name}'s commitment to sustainability and eco-friendly manufacturing practices.The success of the Aluminum Profile Cutter can be attributed to {Company Name}'s dedication to understanding the evolving needs of the manufacturing industry and developing solutions that address these needs. The company's team of engineers and technicians work tirelessly to ensure that their products are at the forefront of technological advancement, providing manufacturers with the tools they need to thrive in a competitive market.Looking ahead, {Company Name} is poised to continue its upward trajectory, with plans to further expand its product line and enhance its technological capabilities. The Aluminum Profile Cutter is just the beginning of what promises to be a series of groundbreaking innovations from this pioneering company.As the manufacturing industry continues to evolve, the Aluminum Profile Cutter remains a shining example of the power of innovation and technological advancement. With its unparalleled precision, efficiency, and environmental benefits, the Aluminum Profile Cutter has secured its place as a game-changer in the world of aluminum profile cutting. Thanks to the forward-thinking approach of {Company Name}, manufacturers now have access to a tool that is revolutionizing the way they produce aluminum components.

Durable Aluminum Alloy 7075: A Strong and Lightweight Material

Al Alloy 7075 has been hailed as one of the strongest and most reliable aluminum alloys on the market today. With its high strength-to-weight ratio and impressive resistance to stress and corrosion, this material has become a popular choice for a wide range of industrial applications. One company that has been at the forefront of using this innovative material is {Company}.{Company} is a leading manufacturer and supplier of high-quality aluminum products, including Al Alloy 7075. With a strong focus on innovation and quality, the company has been able to carve out a niche for itself in the highly competitive aluminum industry. Their commitment to providing superior products and excellent customer service has earned them a solid reputation among their clients and peers.Al Alloy 7075 is a high-strength aluminum alloy that is commonly used in aerospace, automotive, and structural applications. It is known for its excellent strength and toughness, making it an ideal material for components and parts that are subjected to high stress and heavy loads. The alloy also offers good machinability and resistance to corrosion, further adding to its appeal in various industries.{Company} has been able to leverage the unique properties of Al Alloy 7075 to develop a wide range of products that meet the stringent requirements of their diverse customer base. From structural components for the aerospace industry to precision parts for the automotive sector, the company's Al Alloy 7075 products have proven to be reliable and efficient in demanding applications.One of the key advantages of Al Alloy 7075 is its high strength-to-weight ratio, which allows for the production of lighter and more fuel-efficient components. This has made the alloy particularly attractive to the automotive industry, where reducing weight and improving efficiency are top priorities. {Company} has been able to capitalize on this trend by offering a range of Al Alloy 7075 products that help their automotive clients meet their performance and sustainability goals.In addition to its use in the automotive and aerospace industries, Al Alloy 7075 has also found applications in the manufacturing of structural components for buildings and bridges. Its high strength and resistance to corrosion make it an excellent choice for these critical infrastructure projects, where durability and reliability are paramount. {Company} has been able to supply Al Alloy 7075 products for such applications, contributing to the safety and integrity of important structures worldwide.Another area where Al Alloy 7075 has made significant inroads is the defense industry. The alloy's exceptional strength and toughness make it an ideal material for military vehicles, aircraft, and equipment. {Company} has been able to meet the stringent requirements of defense contractors by providing top-notch Al Alloy 7075 products that help ensure the safety and performance of critical defense applications.In conclusion, Al Alloy 7075 has established itself as a pivotal material in a wide range of industries, thanks to its impressive strength, durability, and versatility. {Company} has been at the forefront of harnessing the potential of this innovative alloy, offering a diverse range of high-quality products that cater to the unique needs of their clients. With their commitment to innovation and excellence, {Company} is well-positioned to continue leading the way in the use of Al Alloy 7075 for years to come.

Durable and Versatile Extruded Aluminum Material for Various Applications

Extruded Aluminum Material is a leading supplier of high-quality aluminum products that are used in a wide range of industries including construction, automotive, and aerospace. The company specializes in the extrusion of aluminum to create custom shapes and profiles that meet the specific needs of their clients. With a focus on innovation and precision, Extruded Aluminum Material has established itself as a trusted partner for businesses seeking reliable and high-performance aluminum products.The company’s commitment to delivering top-notch products is evident in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and operated by a team of highly skilled professionals. This allows Extruded Aluminum Material to produce aluminum products that meet the highest standards of quality and performance. In addition, the company’s dedication to sustainability and environmental responsibility is reflected in their use of recycled aluminum in their manufacturing process, which helps to minimize their environmental impact and reduce their carbon footprint.Extruded Aluminum Material’s dedication to customer satisfaction is evident in their ability to provide custom solutions that meet the unique needs of their clients. By working closely with their customers, the company is able to develop innovative aluminum products that address specific challenges and deliver exceptional performance. Whether it’s creating custom extrusions for architectural applications or developing specialized aluminum components for the automotive industry, Extruded Aluminum Material has the expertise and resources to deliver superior solutions that exceed their clients’ expectations.In addition to their commitment to quality and innovation, Extruded Aluminum Material also places a strong emphasis on customer service. The company’s team of professionals is dedicated to providing exceptional support to their clients throughout the entire process, from initial consultation to product delivery. This level of personalized service sets Extruded Aluminum Material apart from other suppliers and has earned them a reputation for reliability and excellence in the industry.With a strong track record of delivering exceptional products and outstanding service, Extruded Aluminum Material has built a loyal and diverse customer base. From small businesses to large corporations, the company’s aluminum products are trusted by a wide range of clients who rely on them for their precision, performance, and durability. Whether it’s for architectural design, automotive manufacturing, or any other industry, Extruded Aluminum Material’s products have become essential components in a variety of applications.Looking ahead, Extruded Aluminum Material is poised to continue its success and remain at the forefront of the industry. The company’s ongoing commitment to innovation, quality, and customer service will ensure that they continue to meet the evolving needs of their clients and maintain their position as a leading supplier of aluminum products. With a focus on sustainability and a dedication to excellence, Extruded Aluminum Material is well-positioned to drive continued growth and success in the years to come.In conclusion, Extruded Aluminum Material is a trusted and reliable supplier of high-quality aluminum products, serving a diverse range of industries with precision, innovation, and superior customer service. With a dedication to excellence and a focus on sustainability, the company is well-positioned for continued success and growth in the future.

Top Aircraft Aluminum Extrusion Options for Your Project Needs

Aircraft Aluminum Extrusion Catalog Now Available from Leading Manufacturer{Company Name}, a prominent leader in the manufacturing of high-quality aluminum extrusions, is proud to announce the release of their new Aircraft Aluminum Extrusion Catalog. This comprehensive catalog showcases the company's wide range of precision-engineered extruded products specifically designed for the aerospace industry.With over {number} years of experience in the field, {Company Name} has established itself as a trusted and reliable source for high-performance aluminum extrusions. Their products are known for their exceptional strength, durability, and precision, making them the preferred choice for aerospace manufacturers and suppliers.The newly released Aircraft Aluminum Extrusion Catalog features a diverse selection of extruded profiles, including angles, channels, tees, zees, and custom shapes. Each extrusion is meticulously manufactured to meet the strict industry standards set forth by aerospace regulatory bodies. {Company Name} utilizes advanced manufacturing techniques and state-of-the-art equipment to ensure the highest level of quality and consistency in every extruded product."We are thrilled to introduce our new Aircraft Aluminum Extrusion Catalog, which represents our ongoing commitment to delivering innovative solutions for the aerospace industry," said {Spokesperson Name}, the CEO of {Company Name}. "Our team of skilled engineers and technicians have worked diligently to develop a diverse range of extruded profiles that meet the exacting requirements of modern aircraft design and construction."In addition to standard extrusion profiles, {Company Name} also offers custom design and manufacturing services to accommodate the unique needs of their aerospace clients. Their in-house engineering team collaborates closely with customers to develop tailored extrusion solutions that optimize performance, weight savings, and cost efficiency for their specific aircraft applications.{Company Name} takes pride in its ISO 9001-certified manufacturing facilities, which are equipped with advanced capabilities for aluminum extrusion, precision machining, surface finishing, and inspection. Their commitment to quality control and process efficiency ensures that customers receive extruded products that consistently meet or exceed their expectations.The release of the Aircraft Aluminum Extrusion Catalog underscores {Company Name}'s position as a leading provider of aluminum extrusion solutions for the aerospace industry. Their dedication to technological innovation, engineering excellence, and customer satisfaction has earned them a sterling reputation among aerospace manufacturers and suppliers worldwide."We understand the critical role that aluminum extrusions play in the construction of modern aircraft, which is why we strive to offer the highest level of product performance, reliability, and consistency," added {Spokesperson Name}. "Our new catalog represents the culmination of extensive research, development, and collaboration with industry experts to bring forth a comprehensive selection of aluminum extrusions for aerospace applications."As the aerospace industry continues to evolve and demand for advanced aircraft technology grows, {Company Name} remains committed to driving innovation and excellence in aluminum extrusion manufacturing. Their new Aircraft Aluminum Extrusion Catalog is a testament to their dedication to meeting the evolving needs of the aerospace sector and providing cutting-edge solutions for aircraft design and production.

Durable and Versatile Anodized Aluminum: A Look at Its Many Applications

Anodized Aluminum is a versatile and durable material that has found its way into a wide range of industries due to its many benefits. It is used in everything from aerospace components to consumer electronics, thanks to its lightweight nature, corrosion resistance, and attractive finish. One company that has made a name for itself in the anodized aluminum industry is {}. With a strong focus on quality and innovation, {} has become a leader in the production of anodized aluminum products.Founded in 1985, {} has been at the forefront of anodized aluminum manufacturing for over three decades. The company's state-of-the-art facilities and cutting-edge technology allow it to produce high-quality anodized aluminum products that meet the needs of various industries. Whether it's architectural panels, automotive parts, or electronic enclosures, {} has the capability to deliver precision-engineered anodized aluminum components to its customers.One of the key advantages of {}'s anodized aluminum products is their exceptional durability. The anodization process creates a protective oxide layer on the surface of the aluminum, making it highly resistant to corrosion, wear, and scratches. This makes it an ideal material for applications where longevity and performance are crucial, such as in the aerospace and defense sectors.Furthermore, {} offers a wide range of color options for its anodized aluminum products, allowing customers to customize the appearance of their components to suit their specific requirements. This versatility makes {}'s anodized aluminum products well-suited for architectural and decorative applications, where aesthetics play a significant role.In addition to its commitment to quality and performance, {} places a strong emphasis on environmental sustainability in its manufacturing processes. The anodizing process used by the company is an environmentally friendly method of finishing aluminum, as it does not produce harmful by-products or waste. As a result, {}'s anodized aluminum products are not only durable and high-performing but also eco-friendly, making them a preferred choice for companies looking to reduce their environmental impact.With a focus on continuous improvement and innovation, {} remains at the forefront of the anodized aluminum industry. The company invests heavily in research and development to stay ahead of the curve in terms of technology and materials, ensuring that its products meet the evolving needs of its customers. This commitment to innovation has enabled {} to expand its product range and capabilities, allowing it to serve a broader market and maintain its position as a leading anodized aluminum manufacturer.Looking to the future, {} is committed to further advancing its anodized aluminum products, exploring new applications and markets, and continuing to set new standards for quality and performance in the industry. With a strong foundation built on decades of experience and a dedication to excellence, {} is poised to remain a key player in the anodized aluminum industry for years to come.In conclusion, Anodized Aluminum is a highly versatile and durable material that has become essential in a wide range of industries, and {} has established itself as a leader in the manufacturing of anodized aluminum products. With a focus on quality, innovation, and environmental sustainability, {} has earned a reputation for delivering high-performance anodized aluminum components that meet the diverse needs of its customers. As the company continues to invest in research and development and expand its capabilities, it is well-positioned to maintain its position as a top provider of anodized aluminum products in the years ahead.