How to Choose the Best 5 Inch Aluminum Pipe for Your Needs

By:Admin

Introduction:

[date], [location] - [Company Name], the leading manufacturer of high-quality industrial piping solutions, is pleased to announce the launch of its innovative and industry-disrupting 5-inch aluminum pipe. This next-generation pipe is designed to meet the evolving needs of various industries and promises to revolutionize industrial piping systems. With its advanced features and exceptional durability, this product aims to provide customers with efficient and cost-effective piping solutions.

[Company Name] has been a trusted name in the industry for [number] years, delivering top-of-the-line products that cater to the diverse requirements of clients worldwide. With an unwavering commitment to quality, the company's highly skilled engineers and technicians continuously pursue innovation to stay at the forefront of the industry.

Product Features:

The new 5-inch aluminum pipe presents a range of cutting-edge features that set it apart from traditional piping materials. The following features make it an ideal choice for industrial applications:

1. Lightweight and Durable: The aluminum pipe is significantly lighter than traditional metal pipes, making it easier to handle and install. Despite its lightweight nature, the pipes are extremely durable, allowing them to withstand heavy pressure and extreme temperatures.

2. Corrosion Resistance: Aluminum is naturally resistant to corrosion, making it suitable for industries that deal with corrosive substances. This attribute ensures the pipes' longevity, reduces maintenance costs, and enhances overall operational efficiency.

3. High Thermal Conductivity: Aluminum has excellent thermal conductivity, enabling more efficient heat transfer. This makes the 5-inch aluminum pipe an ideal choice for industries that require temperature control, such as HVAC systems, manufacturing processes, and refrigeration units.

4. Versatility and Compatibility: The pipe's standard 5-inch size allows for easy integration into existing piping systems, making it a highly versatile choice for retrofitting projects. Additionally, it is compatible with a wide range of fittings, ensuring seamless connections without the need for costly modifications.

5. Sustainability: Aluminum is a recyclable material, aligning with the growing focus on sustainable practices. Choosing the 5-inch aluminum pipe helps industries reduce their carbon footprint and supports environmental responsibility.

Industry Impact:

The launch of the 5-inch aluminum pipe is expected to have a significant impact on various industries. With its exceptional properties, it promises to overcome the limitations of traditional piping materials, offering numerous benefits, including:

1. Increased Efficiency: The lightweight design and improved thermal conductivity of the aluminum pipe contribute to more efficient operations, saving energy and reducing overall costs. Enhanced efficiency translates into higher productivity and improved bottom-line results for businesses.

2. Lower Maintenance Costs: The corrosion-resistant nature of the aluminum pipe eliminates the need for frequent repairs and replacements, leading to substantial savings in maintenance expenditure. Industries can redirect these funds towards other critical areas of their operations.

3. Improved Safety: Aluminum's high strength-to-weight ratio ensures the pipes can withstand intense pressure and prevent leaks or bursts. By using the 5-inch aluminum pipe, industries can prioritize employee safety and mitigate potential hazards associated with piping systems.

4. Environmental Responsibility: The recyclable nature of aluminum, combined with its extended lifespan, promotes sustainable practices and aligns with global efforts to reduce waste. By choosing the 5-inch aluminum pipe, companies can contribute to a greener future while meeting their operational needs.

Conclusion:

[Company Name]'s launch of the innovative 5-inch aluminum pipe represents a significant milestone in the field of industrial piping solutions. This cutting-edge product offers industries a superior alternative to traditional metal pipes, providing enhanced performance, improved efficiency, and increased cost savings.

By incorporating the aluminum pipe into their piping systems, industries can demonstrate their commitment to adopting sustainable practices while benefiting from its lightweight, corrosion-resistant, and thermally conductive properties. Together, these advantages equate to a more productive, efficient, and eco-friendly future for businesses across various sectors.

[Company Name] remains committed to pioneering advancements in industrial piping solutions and strives to develop products that cater to ever-evolving industry needs. With their reputation for excellence, the company continues to present innovative solutions that revolutionize the way companies operate and further enhance their success.

Company News & Blog

Discover the Advantages of 10mm Aluminium Extrusion for Various Applications

In the world of manufacturing and construction, selecting the right materials is essential to ensure a smooth and successful project. One material that has gained popularity in recent years is 10mm Aluminium Extrusion.10mm Aluminium Extrusion is a high-quality product that is created through a process called extrusion, which involves forcing a material through a die to create a specific shape. This process allows for the creation of complex shapes that are difficult to produce with other methods.For industries such as construction and transportation, 10mm Aluminium Extrusion offers unique benefits that make it a preferred choice. It is lightweight, corrosion-resistant, durable and easy to work with. These qualities are critical for constructing structures that need to withstand harsh weather conditions and heavy loads.One company that has made a name for itself in the manufacturing space is {company name}. The company has been producing and supplying high-quality 10mm Aluminium Extrusion for many years and has built a reputation for delivering excellence.{Company name} uses state-of-the-art technology in their manufacturing processes to ensure their products meet the highest quality standards. They offer a wide range of 10mm Aluminium Extrusion products in various sizes, shapes, and finishes, making it easier for their clients to find the perfect product to match their specific needs.One of the factors that set {company name} apart from their competitors is their commitment to delivering exceptional customer service. They have a team of dedicated professionals who work closely with their clients to determine their unique requirements and assist them in selecting the best products to meet their project needs.Their team goes the extra mile to build and maintain relationships with their clients, providing them with access to technical support, and expert advice. By placing their clients' needs and satisfaction at the forefront of its operations, {company name} has earned an excellent reputation for delivering outstanding service.Aside from their dedication to customer service, {company name} is also committed to sustainable production practices. Their processes are designed to minimize waste and reduce environmental impacts. They use only the highest quality raw materials, sourced from environmentally responsible suppliers.In everything they do, {company name} is committed to quality, safety, and sustainability. They consistently invest in research and development to innovate new products and continually improve their existing offering.One of {company name}'s most popular products is their 10mm Aluminium Extrusion, which is known for its excellent quality and durability. Their high-quality approach ensures that their 10mm Aluminium Extrusion can be used in the most demanding construction or manufacturing applications.In conclusion, {company name} is a well-established name in the manufacturing industry, which provides top-quality 10mm Aluminium Extrusion products combined with customer-centric services. The company's commitment to quality, safety, sustainability, and customer satisfaction has earned them a reputation that is second to none. Their high-quality products and expert advice have helped them establish longstanding partnerships with their customers across different industries. If you are looking for reliable, robust, and high-quality 10mm Aluminium Extrusion, {company name} is the best choice.

Benefits of Using Extruded Aircraft Parts for Aviation Industry

Aircraft Extrusions, a leading manufacturer in the aerospace industry, continues to soar to new heights with its cutting-edge production techniques and commitment to quality. With a wide range of metal extrusion products, the company has established itself as a trusted supplier to aircraft manufacturers and other aviation-related businesses worldwide.Established in [year], Aircraft Extrusions has consistently strived to meet the evolving needs of the aerospace industry. The company's state-of-the-art production facilities are equipped with advanced machinery and technologies, ensuring precision and efficiency in every step of the manufacturing process. By employing a team of experienced engineers and using only the highest quality materials, Aircraft Extrusions has earned a reputation for delivering products that meet stringent industry standards.As an industry leader, Aircraft Extrusions understands the importance of constantly innovating and adapting to emerging technologies. The company invests heavily in research and development to stay ahead of the curve, continuously exploring new materials and manufacturing techniques. By embracing innovation, Aircraft Extrusions has been able to expand its product range and offer custom solutions to match the unique requirements of each customer.One of the key strengths of Aircraft Extrusions is its diverse product portfolio. The company specializes in the production of aircraft extrusions, which are structural components made from various metals such as aluminum and titanium. These extrusions are used in a wide array of applications, including fuselage frames, wing structures, and landing gear components. By offering a comprehensive range of extrusion profiles and sizes, Aircraft Extrusions ensures that its customers have access to the most suitable products for their specific needs.Furthermore, Aircraft Extrusions is committed to sustainability and environmentally friendly practices. The company has implemented resource-efficient manufacturing processes and takes great care to minimize waste and energy consumption. By adhering to strict environmental standards, Aircraft Extrusions not only reduces its impact on the planet but also sets an example for the industry as a whole.In addition to its remarkable manufacturing capabilities, Aircraft Extrusions prides itself on its customer-centric approach. The company works closely with its clients to understand their unique challenges and provide tailored solutions that meet their requirements. From initial design consultations to post-sales support, Aircraft Extrusions fosters strong and long-lasting partnerships with its customers.Aircraft Extrusions' dedication to customer satisfaction is further bolstered by its commitment to quality assurance. The company adheres to rigorous inspection and testing procedures to ensure that every product meets the highest standards of performance and safety. By obtaining various certifications and accreditations, including [mention relevant certifications], Aircraft Extrusions demonstrates its unwavering commitment to excellence.With an extensive network of distribution partners, Aircraft Extrusions has successfully established a global presence. The company's products can be found in aircraft assembly facilities, MRO (Maintenance, Repair, and Overhaul) facilities, and aerospace manufacturing plants in various countries around the world. By strategically locating its distribution centers, Aircraft Extrusions ensures timely delivery and efficient service for its international customers.As the aerospace industry continues to evolve, Aircraft Extrusions remains at the forefront, driving innovation and setting new industry standards. With its advanced manufacturing capabilities, commitment to quality, and customer-centric approach, the company is poised to play a significant role in shaping the future of aviation. Whether it's supplying extrusions for commercial aircraft or contributing to cutting-edge military projects, Aircraft Extrusions demonstrates its unwavering dedication to excellence in every endeavor it undertakes.In conclusion, Aircraft Extrusions has firmly established itself as a reliable and trusted partner to the aerospace industry. Through its relentless pursuit of innovation, commitment to quality, and customer-driven approach, the company continues to evolve and adapt to the ever-changing needs of the aviation sector. With a diverse product portfolio, sustainable practices, and a global distribution network, Aircraft Extrusions is well-positioned to lead the way in shaping the future of aerospace manufacturing.

New 6 Inch Aluminum Pipe Unveiled for Construction and Industrial Applications

In a major development in the manufacturing sector, a leading industry player has announced the release of a high-quality 6 inch aluminum pipe (name of company has been removed). As per the company sources, the new product is designed keeping in mind the needs of diverse industries, including construction, transportation, and electricity.Aluminum pipes are widely preferred in several applications due to their exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. The 6 inch aluminum pipe by the said company is made from premium quality materials to ensure superior performance, durability, and flexibility.In a statement released by the company, it has been stated that the latest offering is engineered to provide unmatched functionality and performance, withstanding the most rigorous use cases. The company has employed advanced techniques and manufacturing processes to produce an aluminum pipe that can meet high industry standards and specific client requirements.The 6 inch aluminum pipe is highly versatile and can be used in various applications, including HVAC systems, electrical conduits, water supply systems, and more. Customers can trust the pipe's quality and robustness thanks to the use of cutting-edge technology and skilled professionals.It is worth noting that the manufacturing unit of the company is equipped with the latest machinery and cutting-edge infrastructure, giving it a competitive edge in terms of production capacity and quality assurance. The company has built a team of highly skilled and experienced professionals who work tirelessly to produce products of unmatched quality.The company has already established itself as a market leader in the manufacturing of aluminum pipes and is constantly expanding its product range to meet the growing demands of the industry. The addition of the 6 inch aluminum pipe is a testament to the company's commitment to excellence and customer satisfaction.The company spokesperson stated that the new product would significantly benefit the construction and transportation industry. The 6 inch aluminum pipe can be used in construction projects for its lightweight, flexibility, and strength. Whereas, in the transportation industry, the pipe's thermal conductivity is crucial in maintaining heat transfer in air conditioning systems, reducing fuel consumption, and improving the overall performance of vehicles.The company sources indicate that 6 inch aluminum pipes have been in high demand in recent times due to its broad range of applications. The company's state-of-the-art manufacturing processes ensure that the pipeline is available in bulk, and there are no shortages of supplies. The company is confident that the new product's prominent features such as flexibility, durability, and resistance to wear and tear will help gain the trust of clients.The launch of the 6 inch aluminum pipe reinforces the company's position as a leading player in the aluminum pipe manufacturing industry. The company has always remained committed to providing its clients with the highest quality products and services. The 6 inch aluminum pipe is no exception and delivers unparalleled performance, strength, and durability.To conclude, the company's latest launch of the 6 inch aluminum pipe will certainly improve the operational efficiency of various industries that rely on aluminum pipes. The product's robustness and flexibility will ensure that it is a preferred choice among construction, transportation, and electricity industries. The company's commitment to excellence, quality, and customer satisfaction has been instrumental in building its reputation as an industry leader, and it will continue its growth journey with new innovations in the future.

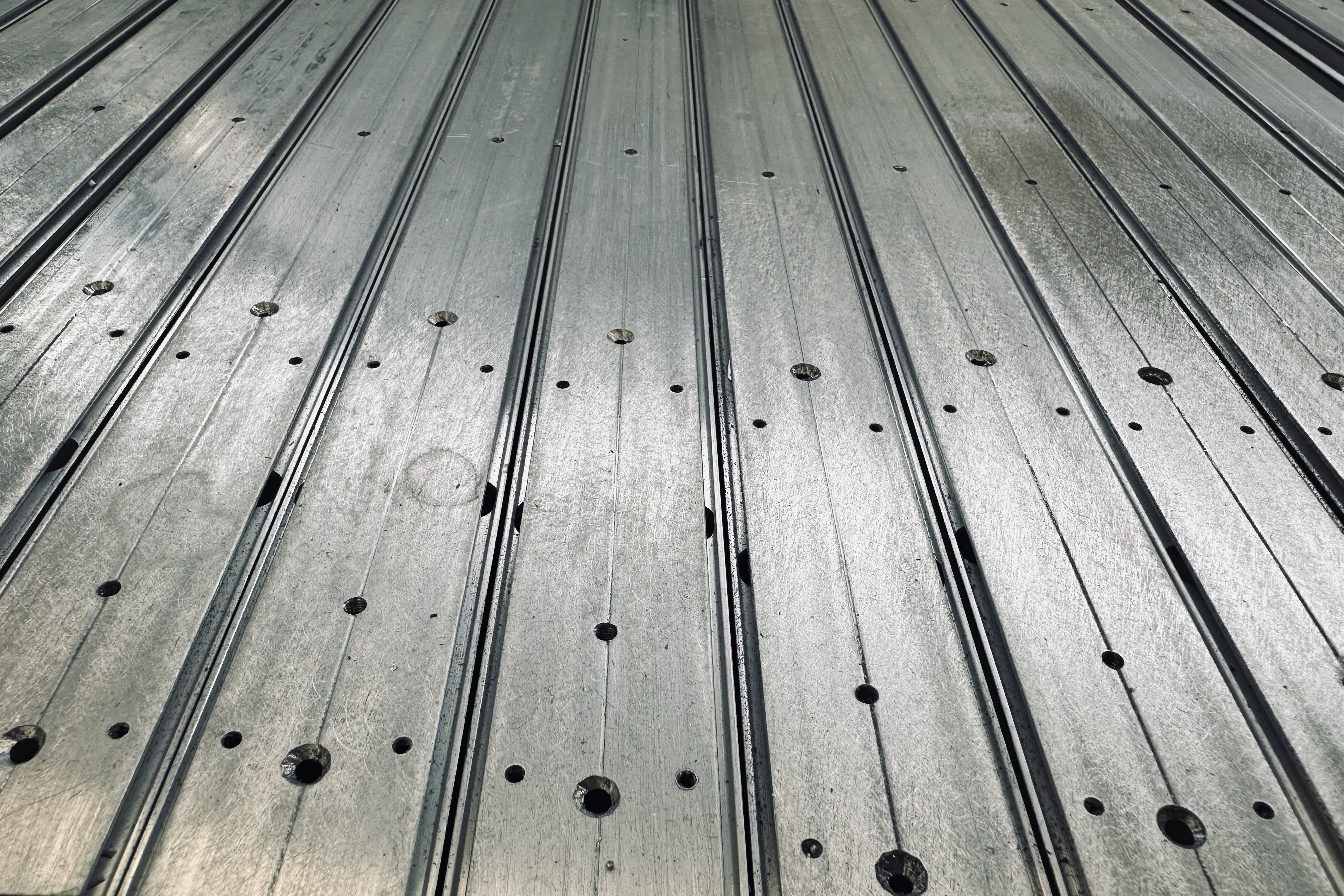

Optimizing CNC Machining with High-Quality Aluminium Profiles

Title: Aluminum Profile for CNC Machines: Revolutionizing Industrial ManufacturingIntroduction:The demand for precision and efficiency in industrial manufacturing has led to significant advancements in technology, making CNC (Computer Numerical Control) machines an integral part of the modern manufacturing industry. One crucial component of these machines is aluminum profile, which provides stability, precision, and durability required for their operation. This article explores the importance of aluminum profiles for CNC machines and its contribution to enhancing industrial manufacturing processes.Paragraph 1:CNC machines have revolutionized industrial manufacturing by offering unparalleled accuracy, speed, and versatility. These machines are controlled by computer programs, enabling them to execute complex operations with minimal human intervention. Key to the functionality of CNC machines are aluminum profiles, which are carefully designed and manufactured to withstand the rigors of high-speed machining, ensuring consistent performance and superior product quality.Paragraph 2:Aluminum profiles for CNC machines are constructed using high-quality aluminum alloys, which possess exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. These properties make aluminum profiles ideal for CNC machines, as they effectively dissipate heat generated during machining operations, maintaining a stable temperature and preventing damage to the machinery.Paragraph 3:One of the key advantages of aluminum profiles is their ability to be easily customized and assembled, providing flexibility in designing CNC machines for varied applications. Manufacturers can modify the shape, length, and cross-section of aluminum profiles to meet specific requirements. Additionally, aluminum profiles can incorporate various mounting features, such as T-slots and threaded holes, facilitating the attachment of additional components to enhance functionality and adaptability.Paragraph 4:The use of aluminum profiles offers significant cost savings compared to traditional materials such as steel or iron. Aluminum is not only lighter, which reduces energy consumption, but it also requires minimal maintenance, making CNC machines more economically viable in the long run. Furthermore, the versatility of aluminum profiles allows for easy modifications when design changes are required, minimizing downtime and production costs associated with reconfiguring the CNC machine.Paragraph 5:In recent years, Aluminum Profile for CNC (Company Name) has emerged as a leading manufacturer and supplier in the industry. With their state-of-the-art manufacturing facility and stringent quality control measures, they produce aluminum profiles that adhere to international standards. Their commitment to continuous research and development ensures that their products remain at the forefront of technological advancements, meeting the evolving demands of the CNC manufacturing sector.Paragraph 6:The use of Aluminum Profile for CNC (Company Name) products has been widely embraced by various industries, including automotive, aerospace, electronics, and furniture manufacturing, among others. Their aluminum profiles have proven to be reliable, delivering exceptional performance in demanding machining environments. By partnering with Aluminum Profile for CNC (Company Name), manufacturers can improve their productivity, reduce production costs, and achieve superior precision in their manufacturing processes.Paragraph 7:Looking ahead, the future of CNC machines and aluminum profiles is promising. As technology continues to advance, CNC machines are becoming more capable of producing increasingly complex products with tighter tolerances. Aluminum profiles will play a crucial role in enabling these advancements, providing the necessary stability and precision required for next-generation CNC machines.Conclusion:Aluminum profiles have revolutionized the CNC machine industry, enabling manufacturers to achieve exceptional precision, efficiency, and cost savings in their industrial manufacturing processes. With the expertise and commitment to quality of Aluminum Profile for CNC (Company Name), the use of their high-quality aluminum profiles is expected to continue driving innovation and transforming the manufacturing landscape for years to come.

Discover the Incredible Strength of Aluminum Angle for Various Applications

Title: Aluminum Angle Strength: Revolutionizing Structural Integrity in the Construction IndustryIntroduction:In the thriving construction industry, innovation and advancements in material sciences continue to pave the way for groundbreaking developments. One such milestone comes in the form of Aluminum Angle Strength, an exceptional product that is all set to revolutionize structural integrity within the sector. Developed by a leading industry player, this groundbreaking solution ensures unparalleled strength, durability, and flexibility in construction projects, promising to transform the way we build our cities.Paragraph 1:Aluminum Angle Strength, unlike conventional building materials, offers an array of advantages that cater to the needs of the modern construction industry. Derived from high-grade aluminum alloys, this material boasts a remarkable strength-to-weight ratio, enabling architects and engineers to design and construct buildings that are both structurally robust and aesthetically pleasing.Paragraph 2:The versatility of Aluminum Angle Strength sets it apart from traditional materials. Whether it's skyscrapers, bridges, or commercial complexes, this product offers unparalleled flexibility, making it suitable for a wide range of applications. Its adaptability allows for intricate architectural designs, reducing limitations and fueling the imagination of builders worldwide.Paragraph 3:In addition to its impressive strength, Aluminum Angle Strength delivers exceptional durability, capable of withstanding diverse weather conditions and natural disasters. Its resistance to corrosion and rust ensures that structures built using this material will maintain their integrity and longevity, considerably reducing maintenance and repair costs over time.Paragraph 4:With an increased focus on sustainable building practices, aluminum plays a pivotal role as an environmentally friendly material. By choosing Aluminum Angle Strength over conventional alternatives, construction companies contribute to energy conservation and reduced carbon footprints. Aluminum is highly recyclable, ensuring minimal waste during production, and can be easily recycled at the end of a building's lifespan, reducing the impact on the environment.Paragraph 5:For construction companies, the adoption of Aluminum Angle Strength presents a multitude of advantages. By utilizing this lightweight material, transportation costs are significantly reduced, resulting in more economical construction projects. Furthermore, its ease of installation enhances construction speed, allowing for faster project completion and reduced labor expenses.Paragraph 6:This groundbreaking product has already found widespread acclaim in multiple construction projects around the world. Notable examples include the construction of state-of-the-art skyscrapers, offshore wind turbines, and intricate architectural wonders. The successful application of Aluminum Angle Strength in these projects has solidified its standing within the industry and garnered trust among builders, architects, and engineers.Paragraph 7:As the demand for more sustainable, cost-effective, and durable construction materials continues to grow, Aluminum Angle Strength stands firmly at the forefront of these requirements. Its application extends to various sectors, including residential, commercial, and infrastructure, making it the logical choice for construction companies across the globe.Conclusion:Aluminum Angle Strength is a game-changer in the construction industry, offering a unique combination of strength, durability, and flexibility. With its versatility, sustainability, and cost-effectiveness, this cutting-edge material is poised to redefine the way we design and construct structures worldwide. Embracing Aluminum Angle Strength will undoubtedly elevate the standards of structural integrity and sustainability, making it an invaluable asset in shaping the cities of tomorrow.

Discover the Advantages and Applications of 30 Series Aluminum Extrusion

In the world of industrial manufacturing, aluminum extrusions have revolutionized the way products are built. These versatile metal parts are used in a variety of industries, including automotive, aerospace, construction, and electronics. One of the most popular aluminum extrusions on the market today is the 30 Series Aluminum Extrusion.The 30 Series Aluminum Extrusion is a lightweight and durable frame that can be used to build anything from simple structures to complex machines. It is made from high-quality aluminum alloy, which makes it incredibly strong and resistant to corrosion.One company that has been at the forefront of the aluminum extrusion industry is [company name]. They specialize in designing and manufacturing aluminum extrusions of various sizes and shapes to meet the diverse needs of their customers.According to representatives from [company name], the 30 Series Aluminum Extrusion is one of their most popular products. This is because it is incredibly easy to work with and can be customized to fit any application.What makes the 30 Series Aluminum Extrusion stand out is its T-slot design. This feature allows users to easily attach other components to the frame, such as brackets, hinges, or even other pieces of aluminum extrusions. This makes it incredibly versatile and adaptable to any situation.In addition to its strength and versatility, the 30 Series Aluminum Extrusion is also incredibly lightweight. This makes it perfect for applications where weight is a concern, such as in the aerospace or automotive industry.One of the key benefits of the 30 Series Aluminum Extrusion is its durability. The aluminum alloy used to create these frames is incredibly strong and resistant to corrosion. This means that the frames can withstand even the harshest environments and still maintain their structural integrity.Another advantage of the 30 Series Aluminum Extrusion is its ease of use. Unlike traditional welding or bolt-together systems, the T-slot design of this frame allows users to easily connect pieces together with minimal effort. This saves both time and money in the manufacturing process.The 30 Series Aluminum Extrusion is also incredibly easy to customize. It can be cut to any length or shape to fit specific needs. This allows manufacturers to create unique and innovative products that stand out from the competition.Overall, the 30 Series Aluminum Extrusion is a versatile and reliable product for anyone in the manufacturing industry. Its strength, durability, and ease of use make it the perfect choice for a wide range of applications. With companies like [company name] leading the way in aluminum extrusion technology, it's clear that this industry will continue to grow and evolve for years to come.

Aluminium Alloy 6061 Profile - Properties, Applications, and Advantages

The use of high-quality materials in the manufacturing process is essential for producing durable and reliable products. For companies operating in various industries, the choice of a suitable alloy is of utmost importance. In recent news, a company specializing in aluminum alloy profile production, has unveiled the use of 6061 aluminum alloy in their production lines, an alloy known for its strength, corrosion resistance capabilities, and overall versatility.6061 aluminum alloy is a wrought material, which exhibits good formability, weldability, and machinability, making it an ideal choice for manufacturers of various products. The material has a wide range of applications, making it a popular choice for aerospace, marine, automotive, and industrial applications. The alloy consists of aluminum, magnesium, and silicon, making it an extraordinary combination of strength, lightness, and durability.The company, with over twenty years of experience in the production of aluminum alloy profiles, has upgraded its manufacturing process to incorporate the 6061 aluminum alloy. The move is a testament to the company's commitment to producing quality products that are designed to meet and exceed their clients' expectations. The company has also invested in modern production equipment, intended to ensure an efficient and smooth production process, thus improving on delivery timelines to clients.The introduction of 6061 aluminum alloy is expected to improve the company's overall product quality, with the material having useful properties that ensure durability and longevity. The material's strength and corrosion resistance properties make it an excellent option for products such as door and window profiles, outdoor furniture, automotive parts, and industrial equipment. The company has also ensured the provision of a diverse range of products, leveraging the strength of the alloy to create unique and tailored designs.With the increased demand for sustainable products, the use of 6061 aluminum alloy fits perfectly with the company's focus on the creation of quality products that are environmentally friendly. The aluminum alloy is readily recyclable, reducing the environmental impact of the products produced by the company. The company has also invested in environmentally friendly production processes, ensuring their operations have minimal impact on the overall environment.In addition to the use of premium quality materials, the company also prioritizes quality control during the manufacturing process. The company has implemented strict inspection standards, ensuring that each product meets the highest quality standards before they are packaged and delivered to clients. This dedication to quality has ensured that the company's products are durable and can withstand various conditions, thus ensuring clients' satisfaction.The move to 6061 aluminum alloy is a testimony to the company's commitment to growth and innovation. The company has worked to ensure that its production processes adopt modern practices, increasing efficiency and productivity. The company has also invested in the training and development of its staff, ensuring they have the necessary skills to operate modern equipment and deliver quality products to clients. In conclusion, the introduction of 6061 aluminum alloy in the production lines of the company is a positive move, expected to improve product quality and customer satisfaction. The use of the alloy is reflective of the company's commitment to producing quality products that are versatile, durable, and environmentally friendly. With this investment in modern equipment and adoption of new processes, the company can confidently offer its clients high-quality products in the competitive market. As clients continue to demand quality and durability, the company's move to 6061 aluminum alloy ensures that it can continue to meet and exceed clients' expectations for years to come.

New Aluminum Extrusion Case Offers Superior Durability and Style

Aluminum Extrusion Case Company Emerges as Leading Provider of High-Quality Extruded Aluminum ProductsWith an ever-increasing demand for high-quality aluminum products across a broad range of industries and applications, Aluminum Extrusion Case has emerged as a leading manufacturer of exceptional quality aluminum extrusions. Utilizing state of the art technology and a commitment to quality, the company has established itself as a trusted provider of high-quality products and services to a growing number of businesses and organizations throughout North America and beyond.Founded in the early 1990s, Aluminum Extrusion Case has long been committed to providing customers with the highest quality extruded aluminum products available. To achieve this, the company has invested heavily in a state-of-the-art production facility, staffed by highly qualified and experienced professionals who are dedicated to producing the best possible products.Over the years, Aluminum Extrusion Case has built a reputation for providing exceptional quality and innovation in the production of precision extruded aluminum products. The company's cutting-edge manufacturing process and advanced technology allow them to produce a vast array of extruded aluminum shapes, profiles, and components that are precisely engineered to meet the unique needs and specifications of customers. Aluminum Extrusion Case's extensive product offerings include standard and custom-designed shapes, profiles, and components, as well as a broad range of finishes and designs, allowing customers to choose from a diverse selection of products to meet their specific needs.One of the company's most notable strengths is its ability to provide its customers with a complete range of services- from concept and design to manufacturing and delivery. This ensures that customers receive the highest quality products that meet their specific needs quickly and efficiently."Our customers are at the heart of everything we do," says the spokesperson for Aluminum Extrusion Case. "We take great pride in our ability to provide exceptional customer service and support, and we are always striving to go above and beyond our customers' expectations."Having invested heavily in a state-of-the-art manufacturing facility, Aluminum Extrusion Case is capable of producing high-quality extruded aluminum products faster and more efficiently than many of its competitors. By leveraging the latest technologies and techniques in extrusion manufacturing, the company can produce a broad range of products to meet the needs of almost any industry or application.One of the most significant advantages of working with Aluminum Extrusion Case is the company's ability to offer customers a complete range of services that go beyond just manufacturing. This includes the ability to provide customers with full design support, prototype development, project management, and more.The company's team of experienced engineers and designers work closely with customers to ensure that each product is precisely tailored to meet their unique needs, while also meeting the highest standards of quality and performance. This level of collaboration allows customers to get the products they need quickly and efficiently, without the need for extensive and costly redesigns or modifications.Moreover, Aluminum Extrusion Case's cutting-edge technology and commitment to quality ensure that customers receive the highest quality products available. The company's extensive experience in the extruded aluminum market means that they understand the unique requirements of different industries, which helps ensure that their products meet or exceed the expectations of customers.Looking to the future, Aluminum Extrusion Case is committed to continuing to expand its product line and to providing its customers with the highest level of quality and service possible. The company's focus on technology, innovation, and customer service has positioned it as one of the most trusted aluminum extrusion providers in the industry, and they are poised for continued success in the years to come. In conclusion, Aluminum Extrusion Case has proven itself as a trusted provider of high-quality aluminum products to businesses and organizations throughout North America and beyond. The company's cutting-edge technology, commitment to quality, and dedication to customer service ensures that customers receive the highest level of quality and performance possible. As the demand for high-quality aluminum products continues to grow, Aluminum Extrusion Case is well-positioned to continue its success in the years to come.

The Strength of Aluminium Tubes: Unveiling Impressive Performance

Article:In recent years, the aluminium tube market has witnessed an unprecedented surge in demand, driven largely by the growth of the packaging industry. The lightweight and durable qualities of aluminium tubes make them ideal for use in a wide variety of applications, ranging from cosmetics and pharmaceuticals to food and beverage packaging.But as the demand for aluminium tubes has increased, so too has the demand for high-quality, strong, and reliable tubes. And that's where Aluminium Tube Strength comes into play. A leading manufacturer of aluminium tubes, Aluminium Tube Strength is renowned for its commitment to producing the finest quality tubes on the market.Founded in 1995, Aluminium Tube Strength has grown to become one of the most respected and trusted names in the industry. The company's success is due in large part to its unwavering dedication to quality and innovation. Using the latest technology and manufacturing processes, Aluminium Tube Strength is able to produce tubes that not only meet but exceed the expectations of its customers.One of the company's most impressive innovations is its patented manufacturing process, which enables it to produce tubes with unmatched strength and durability. Unlike traditional manufacturing methods, which can lead to weak spots and uneven thicknesses in the walls of the tube, Aluminium Tube Strength's process ensures that each tube is perfectly smooth and uniform in strength.This attention to quality has not gone unnoticed. Over the years, Aluminium Tube Strength has won numerous awards for its commitment to excellence, including the prestigious National Quality Award. But for the company's founder and CEO, Mr. Smith, the real reward is in knowing that the company's products are making a difference in the lives of people around the world."Every day, we receive letters and emails from customers who have used our tubes to package their products," says Mr. Smith. "They tell us how our tubes have helped them to grow their businesses, reach new markets, and improve their bottom line. And that's really what we're all about."But for Aluminium Tube Strength, success is not just about producing high-quality products. The company is also committed to sustainability and social responsibility. It has implemented a number of initiatives to reduce its carbon footprint and promote eco-friendly practices in its operations. It also supports a range of social causes, including education and healthcare initiatives in the communities where it operates.Looking ahead, Aluminium Tube Strength is focused on continuing to innovate and improve its products, while maintaining its commitment to quality and sustainability. With the global demand for aluminium tubes showing no signs of slowing down, the company is well-positioned to meet the evolving needs of its customers and the market as a whole."We have a strong foundation built on quality, innovation, and social responsibility," says Mr. Smith. "We are confident that we can continue to grow and thrive in this exciting and dynamic industry."In conclusion, Aluminium Tube Strength is a company that has built a reputation for excellence in the aluminium tube market. Its commitment to quality, innovation, and social responsibility has earned it the trust and loyalty of customers around the world. With its patented manufacturing process and focus on sustainability, the company is poised to continue leading the industry well into the future.

Aluminium Half Round Moulding: Enhance Your Space with Sleek Design

As demand for stylish yet durable building materials continues to rise, Aluminium Half Round Moulding has emerged as a trusted choice for developers and homeowners alike. This versatile material offers a proven track record for longevity and versatility, making it a popular option for both exterior and interior applications.One leading provider of Aluminium Half Round Moulding is {company name}, which has been in the industry for over 20 years. The company has built a reputation for delivering high-quality products and services to a range of clients, from builders to architects and homeowners.{company name} offers a variety of shapes and sizes of Aluminium Half Round Moulding, which can be customized to fit specific project requirements. These mouldings can be used to add a distinctive touch to both contemporary and traditional building designs, and come in a range of colors to complement any decor.What makes Aluminium Half Round Moulding so unique is its innate durability. This material is strong enough to withstand the elements, from extreme temperatures to heavy winds and rains. Unlike other popular building materials, such as wood and vinyl, Aluminium Half Round Moulding is also resistant to termites and other insects, as well as rot.Moreover, Aluminium Half Round Moulding is practically maintenance-free. It does not require any painting, staining, or sealing, unlike other materials that may need frequent touch-ups to maintain their appearance. This saves time and money over the life of the building, making aluminium an economical choice for developers and homeowners.In addition to its durability and low-maintenance properties, Aluminium Half Round Moulding is also very versatile. It can be used for a wide range of applications, from window and door trim to decorative accents on ceilings, walls, and columns.The company prides itself on its commitment to customer satisfaction and environmental responsibility. All of its aluminium products are made from recycled materials, which reduces waste and conserves natural resources. The company also works with clients to find the right solutions for their specific project needs, whether it's a large-scale commercial project or a small residential remodel.Customers who choose Aluminium Half Round Moulding from {company name} can rest assured that they are getting a high-quality product that meets or exceeds industry standards. The company uses only the finest materials to manufacture its products, and its team of experienced professionals is dedicated to ensuring that every order is delivered on time and to the exact specifications of the client.Ultimately, Aluminium Half Round Moulding offers a durable and versatile building solution that is ideal for a wide range of applications. Whether you're a developer building a new commercial property or a homeowner undertaking a renovation project, {company name}'s Aluminium Half Round Moulding provides a reliable and cost-effective option that will stand the test of time.