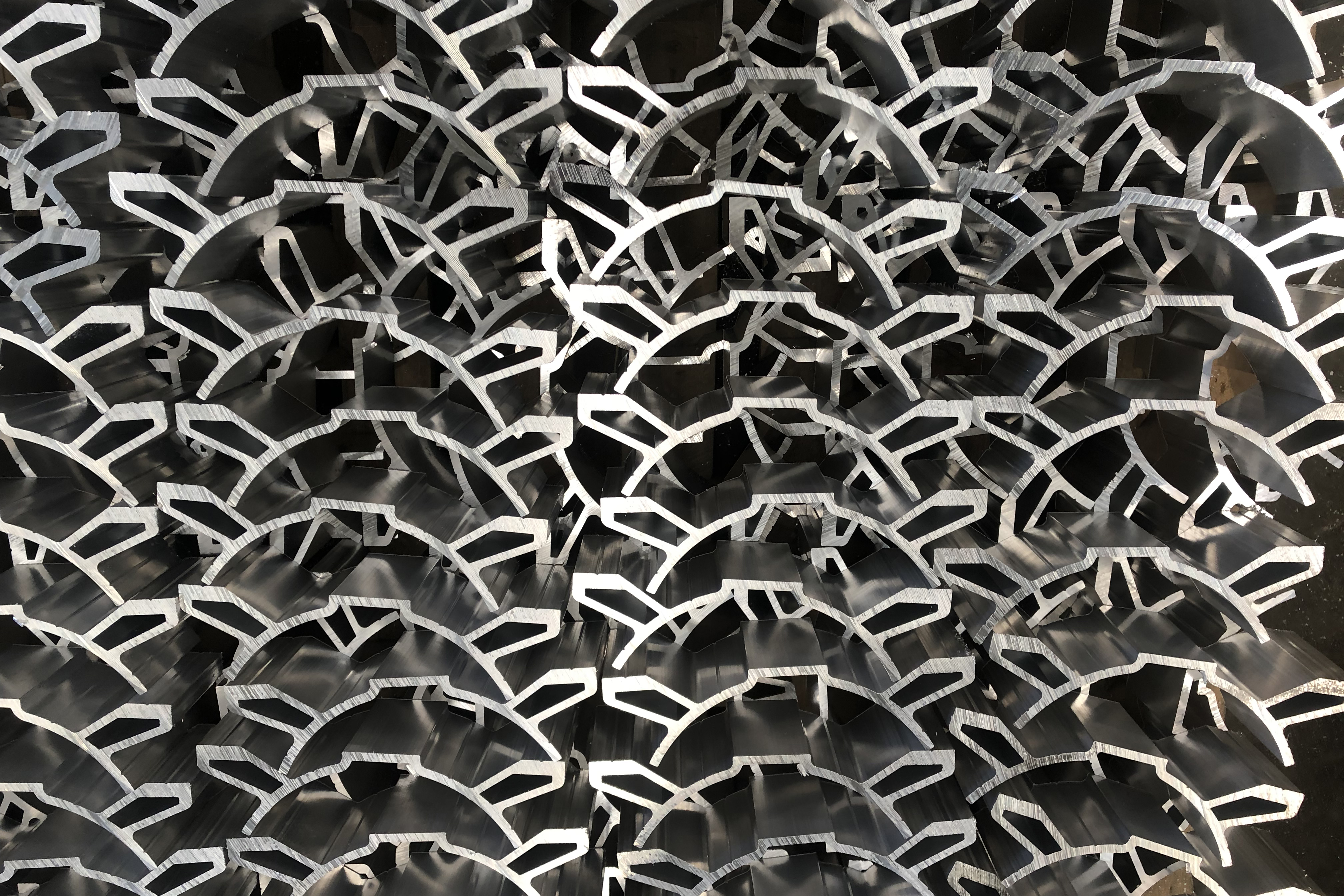

High-Quality Aluminum Alloy Profile for Various Applications

By:Admin

The company's dedication to quality and customer satisfaction has helped establish it as a trusted partner for businesses across the globe. With state-of-the-art manufacturing facilities and a team of experienced professionals, Aluminum Alloy Profile is committed to delivering superior products that meet the highest industry standards.

One of the key strengths of Aluminum Alloy Profile is its ability to offer customized solutions to meet the specific needs of its customers. Whether it's a unique shape, size, or alloy composition, the company has the expertise and capabilities to deliver tailor-made products that exceed expectations.

In addition to its focus on quality and customization, Aluminum Alloy Profile is also dedicated to sustainability and environmental responsibility. The company utilizes advanced manufacturing processes that minimize waste and reduce energy consumption, while also ensuring that its products are fully recyclable.

As a result of these efforts, Aluminum Alloy Profile has been recognized for its commitment to sustainability and has earned various certifications and accolades for its environmental stewardship.

Furthermore, Aluminum Alloy Profile is continuously investing in research and development to further improve its products and processes. This commitment to innovation has allowed the company to stay ahead of the curve in an ever-evolving industry, and to consistently deliver cutting-edge solutions to its customers.

Recently, Aluminum Alloy Profile announced the launch of a new line of aluminum alloy profiles that are specifically designed for use in the aerospace industry. These profiles have been engineered to meet the stringent requirements of aerospace applications, including high strength-to-weight ratios and resistance to corrosion.

The introduction of this new product line underscores Aluminum Alloy Profile's ongoing commitment to expanding its offerings and addressing the needs of diverse industries. With its expertise and capabilities, the company is well positioned to serve as a reliable supplier for manufacturers in the aerospace sector.

In addition to its focus on aerospace applications, Aluminum Alloy Profile continues to serve a wide range of other industries, including automotive, construction, and consumer electronics. The company's diverse product portfolio and commitment to customization make it a preferred choice for businesses seeking high-quality aluminum alloy profiles.

Looking ahead, Aluminum Alloy Profile is poised for continued growth and success, as it remains dedicated to its core values of quality, innovation, and sustainability. By staying true to these principles, the company will continue to be a leading provider of aluminum products, meeting the evolving needs of its customers and industries around the world.

Company News & Blog

New Aluminum Extrusion Cutting Machine Launches, Offering Improved Efficiency and Precision

Aluminum Extrusion Cutting Machine (need remove brand name) Revolutionizing the Aluminum Processing IndustryAluminum extrusion has been a vital process in industries ranging from construction to automotive and aerospace. However, the process of cutting aluminum extrusions has often been problematic, with chipping and deformation being common issues. These problems are exacerbated when production demand is high, as is often the case in modern industrial enterprises. Thankfully, the Aluminum Extrusion Cutting Machine (need remove brand name) is poised to revolutionize this crucial process by providing a highly accurate, efficient, and reliable cutting solution.The Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution designed specifically for aluminum extrusions. This machine overcomes many of the challenges that traditional cutting methods have faced, such as chipping or deformation, by implementing advanced technology and a number of innovative features. With this machine, the cutting process is made much smoother, allowing for a more efficient and streamlined production process.Some of the key features that set this machine apart from others include its robust frame and precision cutting mechanism. The machine is made from high-grade aluminum alloy, which ensures its durability and longevity. Moreover, its cutting mechanism has been designed to minimize deformation and produce smooth and clean cuts every time. This feature is particularly important because it effectively eliminates the need for additional finishing processes, which can add to the production time and costs.The Aluminum Extrusion Cutting Machine (need remove brand name) also excels in terms of efficiency and precision. The machine is equipped with a highly accurate positioning system that ensures precise cuts each time. This system can be programmed to cut at specific lengths and angles, which enables manufacturers to produce custom parts quickly and with ease. Moreover, the machine's digital display makes it easy to adjust the cutting parameters as needed.One of the most impressive aspects of this machine is its speed. The Aluminum Extrusion Cutting Machine (need remove brand name) possesses a spindle speed of up to 20,000 rpm, which is significantly faster than most other cutting machines. This high speed allows for a much faster production process, reducing lead times and enabling manufacturers to keep up with growing demand.Of course, the true value of this machine is in its ability to deliver consistent results with every cut. The combination of precision, speed, and accuracy ensures that each cut is of the highest quality, allowing for seamless assembly and faster production times. This feature is particularly important in the manufacturing of complex applications, such as those found in the aerospace or automotive industries.In addition to its impressive features, the Aluminum Extrusion Cutting Machine (need remove brand name) is also highly customizable. The machine can be configured to meet the specific needs of individual manufacturers, with options such as dust collection, lubrication systems, and more. This level of customization ensures that manufacturers can tailor the machine to their specific requirements, producing higher quality results in less time.Finally, the machine's user-friendly design makes it easy to operate and maintain. The machine is equipped with a number of safety features, such as emergency stop buttons and an automatic lubrication system. The machine's digital control system makes it easy to adjust the cutting parameters, and its modular design allows for easy maintenance and repair.In conclusion, the Aluminum Extrusion Cutting Machine (need remove brand name) is an advanced cutting solution that is poised to revolutionize the aluminum extrusion industry. With its high precision, speed, and accuracy, it is equipped to handle the demands of modern industrial enterprises, delivering consistent and high-quality results every time. Its innovative features, user-friendly design, and extensive customization options make it an ideal choice for manufacturers looking to streamline their production processes and stay ahead of the competition.

High-Quality Extruded Aluminum Tubing: A Comprehensive Overview

Title: Industry Leader Introduces Cutting-Edge 7075 Extruded Aluminum TubingIntroduction:In the ever-evolving landscape of aluminum alloys, industry leader (company name) is once again making waves with the introduction of its groundbreaking 7075 Extruded Aluminum Tubing. This innovative development in the aluminum industry has the potential to revolutionize various sectors that rely on high-performance materials, such as aerospace, automotive, and construction. With its exceptional strength-to-weight ratio and unmatched durability, this new product is set to redefine industry standards and push the boundaries of what is possible.Section 1: The Superiority of 7075 Extruded Aluminum Tubing(Company name) has long been known for its commitment to excellence and innovation. With the production of 7075 Extruded Aluminum Tubing, the company has once again raised the bar in terms of quality and performance. 1.1 Exceptional Strength-to-Weight Ratio7075 Extruded Aluminum Tubing boasts an impressive strength-to-weight ratio, making it ideal for applications where superior strength is necessary without adding unnecessary weight. This characteristic is particularly advantageous in the aerospace sector, where every ounce saved translates into increased fuel efficiency.1.2 Unmatched DurabilityThe durability of 7075 Extruded Aluminum Tubing surpasses that of other aluminum alloys. Its ability to withstand heavy loads, extreme temperatures, and corrosive environments makes it a top choice for applications in the automotive and construction industries. This tubing offers unparalleled resistance to oxidation, further enhancing its overall longevity.1.3 Versatility and CustomizabilityThe versatility of 7075 Extruded Aluminum Tubing allows for a wide range of applications, enabling various industries to benefit from its properties. The tubing can be easily shaped, bent, and formed to meet specific design requirements, making it a highly customizable solution for different projects.Section 2: Industry Applications2.1 Aerospace IndustryIn the highly demanding aerospace industry, where reliability and performance are crucial, 7075 Extruded Aluminum Tubing makes a remarkable impact. Its strength, durability, and lightweight properties make it an ideal choice for aircraft components such as landing gear, structural frames, and fuselage structures. The superior aerodynamic efficiency achieved through the use of this tubing leads to more fuel-efficient flights and reduced emissions.2.2 Automotive IndustryThe automotive industry is constantly seeking ways to enhance vehicle performance and fuel efficiency. 7075 Extruded Aluminum Tubing presents a significant solution to these challenges. Its capability to reduce a vehicle's overall weight while maintaining excellent strength allows for improved acceleration, increased payload capacity, and reduced fuel consumption. Additionally, its resistance to corrosion ensures longevity and enhances the safety of vital automotive components.2.3 Construction IndustryIn the construction industry, durability and load-bearing capacity are paramount. The introduction of 7075 Extruded Aluminum Tubing presents construction firms with a lightweight yet robust material for building façades, support structures, and framing systems. Its resistance to corrosive environments, combined with exceptional strength, makes it an ideal choice for both commercial and residential construction projects.Section 3: (Company Name) – Pioneers of Advanced Aluminum Solutions(Company name) has been at the forefront of the aluminum industry for (number of years) and has consistently led the way through its commitment to research and development. By leveraging their extensive expertise and cutting-edge manufacturing processes, the company has emerged as a pioneer of advanced aluminum solutions.With the introduction of 7075 Extruded Aluminum Tubing, (company name) is revolutionizing multiple industries by providing a superior alternative to conventional materials. This groundbreaking product demonstrates the company's dedication to pushing the boundaries of technological advancements and staying ahead of market demands.Conclusion:The unveiling of 7075 Extruded Aluminum Tubing marks yet another remarkable achievement by (company name), setting new benchmarks for strength, durability, and versatility in the aluminum industry. This innovative and high-performance product is poised to reshape the aerospace, automotive, and construction sectors. With superior characteristics such as a remarkable strength-to-weight ratio, unmatched durability, and exceptional customizability, 7075 Extruded Aluminum Tubing demonstrates the company's unwavering commitment to delivering advanced solutions that drive progress and transform industries.

Aluminum Components for Next-Generation Electric Vehicles

Aluminum For New Energy VehiclesThe automotive industry is undergoing a significant transformation, with a shift towards new energy vehicles (NEVs) becoming increasingly evident. As the demand for cleaner and more sustainable modes of transportation continues to rise, manufacturers are exploring innovative materials and technologies to drive the development of NEVs. One such material that is playing a crucial role in this evolution is aluminum.Aluminum is increasingly being integrated into the design and production of NEVs, thanks to its exceptional properties that make it an ideal choice for enhancing the performance and efficiency of these vehicles. Aluminum is lightweight, strong, and corrosion-resistant, making it a preferred material for reducing the overall weight of vehicles and improving their energy efficiency. Furthermore, aluminum is fully recyclable, aligning with the sustainability goals of the NEV industry.In this context, (remove brand name) is at the forefront of leveraging aluminum for the advancement of NEVs. As a leading manufacturer and supplier of aluminum products, (remove brand name) has been actively collaborating with NEV manufacturers to develop innovative solutions that meet the evolving needs of the industry.With a strong focus on research and development, (remove brand name) has introduced a range of aluminum products specifically tailored for NEVs. These products are designed to address the unique challenges and requirements of electric and hybrid vehicles, offering superior performance, durability, and sustainability.One such example is the use of high-strength aluminum alloys in the manufacturing of vehicle structures and components. By incorporating these alloys, NEV manufacturers can achieve significant weight savings without compromising on safety and structural integrity. This, in turn, contributes to extending the driving range and improving the overall efficiency of NEVs.Moreover, (remove brand name) has also developed aluminum solutions for the battery enclosures of NEVs. The use of aluminum in battery enclosures offers improved thermal management, enhanced safety, and better overall performance of the vehicle's power source. This contributes to the long-term reliability and durability of NEVs, while also supporting the efficient management of battery temperature and performance.In addition to its technical expertise, (remove brand name) has established a robust supply chain and manufacturing capabilities to meet the growing demand for aluminum in the NEV sector. With a commitment to quality and sustainability, (remove brand name) ensures that its aluminum products adhere to the highest industry standards, while also minimizing the environmental impact of their production and usage.As the NEV market continues to expand, the role of aluminum in driving innovation and progress in this industry is set to become even more significant. With its unparalleled advantages and versatility, aluminum is poised to play a pivotal role in shaping the future of transportation and advancing the development of sustainable mobility solutions.In conclusion, (remove brand name) is playing a crucial role in enabling the widespread adoption of aluminum in NEVs. Through its cutting-edge technology, manufacturing expertise, and focus on sustainability, (remove brand name) is well-positioned to support the evolving needs of the NEV industry and contribute to the realization of a cleaner and more sustainable transportation ecosystem. As the demand for NEVs continues to grow, the significance of aluminum in this sector is only expected to increase, further solidifying its position as a key enabler of the new era of mobility.

High-Quality 7020T6 Aluminum Extrusions for Various Applications

7020T6 Aluminum Extrusions - Revolutionizing the Aluminum IndustryThe aluminum industry has long been a cornerstone of manufacturing, providing essential materials for a wide range of products and applications. With the demand for lightweight, durable materials on the rise, the need for innovative aluminum solutions has never been greater. Enter 7020T6 aluminum extrusions, a game-changing product that is set to revolutionize the industry.{Company Name} is at the forefront of this revolution, leading the way in the production and development of 7020T6 aluminum extrusions. With a focus on precision engineering and advanced manufacturing techniques, {Company Name} is setting new standards for aluminum products. Their commitment to quality and innovation has made them a trusted partner for businesses across a wide range of industries, from aerospace and automotive to construction and consumer goods.So, what sets 7020T6 aluminum extrusions apart from traditional aluminum products? The answer lies in its unique composition and properties. 7020T6 aluminum is an alloy that is renowned for its exceptional strength, corrosion resistance, and weldability. This makes it the ideal choice for applications that require durability and longevity, such as aircraft components, structural frames, and automotive parts.In addition to its impressive mechanical properties, 7020T6 aluminum extrusions also offer significant weight savings compared to other materials. This makes them particularly valuable in industries where reducing weight is a priority, such as aerospace and transportation. By utilizing 7020T6 aluminum extrusions, businesses can improve fuel efficiency, increase payload capacity, and enhance overall performance.{Company Name}'s expertise in extrusion technology allows them to produce 7020T6 aluminum products in a wide range of shapes and sizes, providing solutions for even the most complex design requirements. Their state-of-the-art facilities and stringent quality control processes ensure that every extrusion meets the highest standards for precision and consistency.But the benefits of 7020T6 aluminum extrusions extend beyond their performance and versatility. This material is also highly sustainable, as aluminum is fully recyclable and retains its properties through multiple lifecycles. By choosing 7020T6 aluminum extrusions, businesses can reduce their environmental impact and contribute to a more sustainable future.As the global demand for advanced aluminum solutions continues to grow, {Company Name} is committed to staying at the forefront of innovation. They are constantly exploring new ways to enhance the performance and capabilities of 7020T6 aluminum extrusions, ensuring that their products remain at the cutting edge of the industry.In conclusion, 7020T6 aluminum extrusions represent a major advancement in the world of aluminum manufacturing. With their exceptional strength, lightweight nature, and environmental benefits, they are poised to transform a wide range of industries. {Company Name}'s dedication to quality and innovation has positioned them as a leader in this space, and their 7020T6 aluminum extrusions are setting new benchmarks for performance and reliability.For businesses seeking high-quality, reliable aluminum solutions, 7020T6 aluminum extrusions from {Company Name} are the clear choice. As the industry continues to evolve, {Company Name} will remain a driving force behind the advancement of aluminum technology, delivering cutting-edge solutions that meet the needs of today and tomorrow.

Discover the Benefits of Longer Aluminium Profiles for Your Project

[Company Name] Introduces Innovative Aluminium Profile Length to Support Various Industries[date][City, Country] - [Company Name], a leading provider of high-quality aluminium solutions, is proud to announce the launch of its latest product, the Aluminium Profile Length. With its exceptional versatility and durability, this groundbreaking product is set to revolutionize the manufacturing and construction industries.Known for its commitment to excellence, [Company Name] has always been at the forefront of delivering innovative solutions to meet the evolving needs of its customers. The Aluminium Profile Length is a testament to the company's dedication to providing superior products that drive growth and efficiency across various sectors.The Aluminium Profile Length is designed to address the common challenges faced by manufacturers and builders when it comes to fitting and adjusting aluminium profiles. With its adjustable length feature, the profile can be easily modified to meet specific project requirements, eliminating the need for complex and time-consuming manual modifications or custom orders.One of the key advantages of the Aluminium Profile Length is its enhanced durability. Crafted from high-grade aluminium alloy, it offers exceptional strength and resistance to wear and tear. This ensures that the profiles will withstand rigorous usage, particularly in applications where structural integrity is crucial.The versatility of the Aluminium Profile Length extends beyond its adjustable feature. Its lightweight nature makes it suitable for a wide range of applications, from industrial machinery and equipment to architectural designs and interior partitions. The profiles can effortlessly bear heavy loads while ensuring stability and safety, making them an ideal choice for various industries.Furthermore, [Company Name] strives to provide environmentally-friendly solutions, and the Aluminium Profile Length is no exception. The profiles are made from high-quality recycled aluminium, minimizing the environmental impact associated with the manufacturing process. This not only supports sustainable practices but also allows businesses to incorporate eco-friendly materials into their projects.To ensure seamless integration, [Company Name] offers a wide range of compatible accessories and connectors for the Aluminium Profile Length. This allows companies to create customized structures and systems according to their specific requirements, further expanding its range of applications.Commenting on the launch, [Company Name]'s CEO, [CEO's Name], emphasized the company's commitment to customer satisfaction and innovation. He stated, "Our Aluminium Profile Length is a game-changer in the industry. We have taken into account the evolving needs of our customers and developed a solution that offers unmatched versatility and durability. We are excited to see how this product will drive growth for our customers across various sectors."The Aluminium Profile Length has already attracted significant interest from manufacturers and construction companies alike. [Company Name] has received numerous pre-orders from both domestic and international clients, further solidifying its position as a trusted supplier of aluminium solutions.With its dedication to quality, innovation, and customer satisfaction, [Company Name] continues to push boundaries and exceed industry expectations. The launch of the Aluminium Profile Length reflects the company's commitment to delivering superior products that empower businesses across multiple sectors.About [Company Name]:[Company Name] is a market leader in providing innovative aluminium solutions for various industries. With a focus on quality and customer satisfaction, the company offers a wide range of high-grade aluminium products, including profiles, sheets, and extrusions. [Company Name] is committed to driving growth and efficiency by delivering superior products and fulfilling unique customer requirements.###Press Contact:[Company Name][Contact Name][Phone Number][Email Address]

Discover the Strength and Versatility of Aluminium Tensile

Aluminium Tensile, a global leader in innovative aluminum solutions, has recently made a significant impact in the industry with the introduction of their latest product line. This new line of aluminum products is set to revolutionize the way companies approach their manufacturing and construction projects, providing enhanced strength and durability for a wide range of applications.With a focus on sustainability and innovation, Aluminium Tensile has become a trusted partner for businesses looking to incorporate high-quality aluminum into their operations. The company's dedication to excellence and commitment to pushing the boundaries of what is possible in the industry has led to the development of this groundbreaking new product line.Aluminium Tensile offers a diverse range of aluminum products that are designed to meet the specific needs of their customers. From lightweight and versatile aluminum sheets to durable and corrosion-resistant aluminum bars, the company provides solutions for a wide range of industries, including aerospace, automotive, construction, and more. The introduction of their latest product line further demonstrates Aluminium Tensile's ability to deliver cutting-edge solutions that can make a real difference for their clients.One of the standout features of the new product line from Aluminium Tensile is its superior tensile strength. The company has leveraged advanced manufacturing techniques and state-of-the-art materials to create aluminum products that offer unparalleled strength and resilience. This makes them well-suited for use in demanding applications where durability and performance are paramount.In addition to their impressive tensile strength, the new product line from Aluminium Tensile also boasts exceptional corrosion resistance. This is a critical feature for many industries, particularly those operating in harsh or corrosive environments. The company's aluminum products are engineered to withstand the elements, ensuring longevity and reliability in even the most challenging conditions.Furthermore, Aluminium Tensile is committed to sustainability and environmental responsibility. The company's aluminum products are fully recyclable, making them an attractive option for businesses looking to minimize their environmental footprint. By choosing Aluminium Tensile's products, companies can not only benefit from the superior performance of aluminum but also contribute to a more sustainable future."We are thrilled to introduce our latest product line, which represents a significant leap forward for the industry," said a spokesperson for Aluminium Tensile. "The combination of exceptional tensile strength, corrosion resistance, and sustainability make our new aluminum products the ideal choice for a wide range of applications. We are excited to see the impact that these innovative solutions will have for our customers."As a global leader in the industry, Aluminium Tensile is known for its unwavering commitment to quality and customer satisfaction. The company's team of experts works closely with clients to understand their specific requirements and develop tailored solutions that meet their needs. With the introduction of their new product line, Aluminium Tensile is poised to further solidify its position as a preferred partner for businesses seeking high-performance aluminum solutions.In conclusion, Aluminium Tensile's latest product line represents a significant advancement in the industry, offering enhanced tensile strength, corrosion resistance, and sustainability. As a trusted partner for businesses around the world, the company continues to push the boundaries of what is possible with aluminum, delivering innovative solutions that make a real impact. With their latest offering, Aluminium Tensile is set to redefine the standards for aluminum performance and set a new benchmark for the industry.

Improve Your Product Quality with Expert Extrusion Die Design

Extrusion Die Design: The Key to Efficient ManufacturingIn today's competitive manufacturing environment, companies are constantly striving for increased efficiency and productivity. One crucial factor in achieving these goals is the design of extrusion dies. These dies are used in the production of a wide range of products, from plastic pipes and tubing to metal profiles and rods. The design of these dies plays a critical role in the quality, consistency, and speed of the extrusion process.One company that has been at the forefront of extrusion die design is {}. With over 30 years of experience in the industry, {} has established itself as a leader in the design and manufacture of high-quality extrusion dies. The company's team of experienced engineers and designers work closely with customers to develop custom die designs that meet their specific requirements and production goals. By leveraging the latest technology and engineering practices, {} is able to deliver innovative die solutions that optimize the extrusion process and enhance overall manufacturing efficiency.The design of extrusion dies is a complex and intricate process that requires a deep understanding of material behavior, flow dynamics, and thermal management. {} excels in this area by utilizing advanced computer-aided design (CAD) software and simulation tools to model and analyze the extrusion process. This allows the company to fine-tune die designs and optimize critical parameters such as flow rates, temperature profiles, and material distribution. The result is a die design that maximizes material utilization, minimizes waste, and ensures consistent product quality.One of the key factors that sets {} apart in the industry is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay at the forefront of extrusion die technology. By staying abreast of the latest materials, processing techniques, and industry trends, {} is able to develop cutting-edge die designs that push the boundaries of what is possible in extrusion manufacturing. This commitment to innovation has earned {} a reputation as a trusted partner for companies looking to improve their extrusion processes and stay ahead of the competition.In addition to its technical expertise, {} also prides itself on its customer-centric approach to business. The company works closely with customers throughout the entire die design and manufacturing process, ensuring that their needs and expectations are met. From initial concept design to final production, {} collaborates with customers to deliver die solutions that are tailored to their unique requirements. This level of customer engagement and support sets {} apart as a true partner in helping companies achieve their manufacturing goals.As the manufacturing industry continues to evolve, the importance of extrusion die design will only grow. Companies that invest in high-quality, custom-designed die solutions stand to gain a significant competitive advantage. With its proven track record of innovation, technical expertise, and commitment to customer satisfaction, {} is well-positioned to continue leading the way in the field of extrusion die design.In conclusion, the design of extrusion dies is a critical factor in the success of modern manufacturing operations. With its wealth of experience, technical capabilities, and customer-focused approach, {} is a trusted partner for companies looking to optimize their extrusion processes. By leveraging cutting-edge design practices and a commitment to innovation, {} continues to set the standard for excellence in extrusion die design.

A Complete Catalog of Aircraft Aluminum Extrusion

Aircraft Aluminum Extrusion Catalog: Offering Top-notch Quality Extruded Aluminum ProductsAluminum extrusions play an essential role in the aviation industry as they serve as the backbone of various aircraft structures. They are used to create parts that are lightweight, durable, and have high stiffness and strength characteristics. That's why it's essential to choose a reliable supplier when it comes to aircraft aluminum extrusions solutions. And that is where the Aircraft Aluminum Extrusion Catalog comes in, providing high-quality extruded aluminum products to the aviation world.The Aircraft Aluminum Extrusion Catalog is a comprehensive guide to the vast range of extruded aluminum profiles, shapes, and sizes suitable for use in all aircraft models. The catalog provides a wide range of popular and reliable aluminum extrusion solutions to both new and existing aircraft OEMs, MROs, and aviation suppliers worldwide.The catalog, which has been a reliable source of information for aircraft engineers and designers for years, comes from a well-established manufacturer with decades of experience in the aviation industry. The company's expertise in providing high-quality aluminum aerospace solutions is unparalleled, guaranteeing its customers that all its provided products meet rigorous industry standards. Furthermore, the catalog has a well-designed layout, making it easy for customers to choose the appropriate aluminum extrusions solution to buy.The Aircraft Aluminum Extrusion Catalog contains a comprehensive list of extruded aluminum products, including standard, custom sections, and structural shapes. In the catalog, customers can find aluminum extruded profiles, bars, pipes, rods, channels, angles, and tubes, among other products. They can also get various custom-designed extrusions, including elliptical and rectangular profiles and unique forms.The extrusions catalog is regularly updated with new available aluminum extrusions designs developed for the aerospace industry. The company's dedicated team of engineers continually designs and manufactures products to meet customers' specific requirements. They are always working on innovative aluminum extrusion designs that focus on providing lightweight, durable, and efficient performances to meet any aviation requirements.The quality of the extruded aluminum products in the aircraft industry is vital. They must meet strict standards for use in critical applications such as airframes, landing gear, wing spars, engine support systems, and other critical parts. The extruded aluminum products in the Aircraft Aluminum Extrusion Catalog are tested to ensure they meet the industry requirements and are of top-notch quality.Another critical aspect of aviation aluminum extrusions is their finishing capabilities. The Aircraft Aluminum Extrusion Catalog provides a range of finishes, including anodizing, painting, and powder coating, among others. The finishes offer colors and aesthetics that match customers' specific requirements, including performance-enhancing options such as corrosion-resistant finishing. The aircraft extruded aluminum products provide solutions that maintain the highest level of aesthetics, performance, durability, and longevity.In conclusion, the Aircraft Aluminum Extrusion Catalog is an essential guide for any supplier looking for the best aluminum extruded solutions for their aviation customers. The variety of products, including custom-made solutions for specific customer requirements, ensures that the extruded aluminum profiles provided meet the exact needs of the aircraft industry.The Aerospace industry's requirements are continually evolving, and a reliable supplier must remain up-to-date and innovative to provide the best solution. With the Aircraft Aluminum Extrusion Catalog, customers can always have trust in the quality of the products provided and rely on the supplier's expertise in aviation aluminum extrusion solutions.

High-Quality Aluminium Extrusion: The Ultimate Guide for Your Project

30 30 Aluminium Extrusion: A Game-Changer in the IndustryWith the increasing demand for lightweight and durable materials in various industries, aluminium extrusion has become the go-to solution for many companies. The versatility and cost-effectiveness of aluminium extrusion make it a popular choice for a wide range of applications, from automotive and aerospace to construction and consumer goods.One company that has been at the forefront of aluminium extrusion technology is {}. With a history dating back to 1970, {} has established itself as a leading manufacturer of high-quality aluminium extrusion products. The company's state-of-the-art facilities and commitment to innovation have set them apart in the industry, making them a trusted partner for businesses around the world.One of {}'s flagship products is the 30 30 aluminium extrusion, which has been a game-changer in the industry. This particular profile offers a unique combination of strength, flexibility, and light weight, making it ideal for a wide range of applications. Whether it's for structural components in automotive manufacturing or precision frames for industrial machinery, the 30 30 aluminium extrusion has proven to be a versatile and reliable solution.One of the key advantages of the 30 30 aluminium extrusion is its high strength-to-weight ratio. This allows for the creation of lightweight yet sturdy components, reducing both material and transportation costs for businesses. Additionally, aluminium is highly resistant to corrosion, making it suitable for outdoor and harsh environments. This gives the 30 30 aluminium extrusion a longer lifespan compared to other materials, further adding to its cost-effectiveness.Another significant benefit of the 30 30 aluminium extrusion is its versatility in design and fabrication. With the ability to be easily shaped and formed, it offers designers and engineers the freedom to create complex and innovative products. Additionally, aluminium extrusion allows for high precision and tight tolerances, ensuring consistency and quality in the final products.In addition to its mechanical properties, the 30 30 aluminium extrusion also offers excellent thermal and electrical conductivity. This makes it suitable for applications that require heat dissipation or electrical grounding, further expanding its potential uses across various industries.{}'s dedication to quality and customer satisfaction has made the 30 30 aluminium extrusion a sought-after product in the market. With a focus on continuous improvement and research, they have been able to meet the evolving needs of their customers and stay ahead of the competition. Combined with their commitment to sustainable and environmentally friendly practices, {} has positioned themselves as a leader in the aluminium extrusion industry.The success of the 30 30 aluminium extrusion has not gone unnoticed, as it has garnered attention from businesses looking for reliable and cost-effective solutions. From small-scale enterprises to multinational corporations, the demand for this versatile profile continues to grow, further solidifying its position as a game-changer in the industry.In conclusion, the 30 30 aluminium extrusion has proven to be a game-changer in the industry, offering a combination of strength, flexibility, and cost-effectiveness that is unmatched by other materials. With {}'s expertise and commitment to innovation, the 30 30 aluminium extrusion has set a new standard for excellence in the aluminium extrusion industry. As businesses continue to seek reliable and versatile materials for their products, it's clear that the 30 30 aluminium extrusion will remain a top choice for years to come.

How to Choose the Best 5 Inch Aluminum Pipe for Your Needs

Title: New 5 Inch Aluminum Pipe Revolutionizes Industrial Piping SolutionsIntroduction: [date], [location] - [Company Name], the leading manufacturer of high-quality industrial piping solutions, is pleased to announce the launch of its innovative and industry-disrupting 5-inch aluminum pipe. This next-generation pipe is designed to meet the evolving needs of various industries and promises to revolutionize industrial piping systems. With its advanced features and exceptional durability, this product aims to provide customers with efficient and cost-effective piping solutions.[Company Name] has been a trusted name in the industry for [number] years, delivering top-of-the-line products that cater to the diverse requirements of clients worldwide. With an unwavering commitment to quality, the company's highly skilled engineers and technicians continuously pursue innovation to stay at the forefront of the industry.Product Features:The new 5-inch aluminum pipe presents a range of cutting-edge features that set it apart from traditional piping materials. The following features make it an ideal choice for industrial applications:1. Lightweight and Durable: The aluminum pipe is significantly lighter than traditional metal pipes, making it easier to handle and install. Despite its lightweight nature, the pipes are extremely durable, allowing them to withstand heavy pressure and extreme temperatures.2. Corrosion Resistance: Aluminum is naturally resistant to corrosion, making it suitable for industries that deal with corrosive substances. This attribute ensures the pipes' longevity, reduces maintenance costs, and enhances overall operational efficiency.3. High Thermal Conductivity: Aluminum has excellent thermal conductivity, enabling more efficient heat transfer. This makes the 5-inch aluminum pipe an ideal choice for industries that require temperature control, such as HVAC systems, manufacturing processes, and refrigeration units.4. Versatility and Compatibility: The pipe's standard 5-inch size allows for easy integration into existing piping systems, making it a highly versatile choice for retrofitting projects. Additionally, it is compatible with a wide range of fittings, ensuring seamless connections without the need for costly modifications.5. Sustainability: Aluminum is a recyclable material, aligning with the growing focus on sustainable practices. Choosing the 5-inch aluminum pipe helps industries reduce their carbon footprint and supports environmental responsibility.Industry Impact:The launch of the 5-inch aluminum pipe is expected to have a significant impact on various industries. With its exceptional properties, it promises to overcome the limitations of traditional piping materials, offering numerous benefits, including:1. Increased Efficiency: The lightweight design and improved thermal conductivity of the aluminum pipe contribute to more efficient operations, saving energy and reducing overall costs. Enhanced efficiency translates into higher productivity and improved bottom-line results for businesses.2. Lower Maintenance Costs: The corrosion-resistant nature of the aluminum pipe eliminates the need for frequent repairs and replacements, leading to substantial savings in maintenance expenditure. Industries can redirect these funds towards other critical areas of their operations.3. Improved Safety: Aluminum's high strength-to-weight ratio ensures the pipes can withstand intense pressure and prevent leaks or bursts. By using the 5-inch aluminum pipe, industries can prioritize employee safety and mitigate potential hazards associated with piping systems.4. Environmental Responsibility: The recyclable nature of aluminum, combined with its extended lifespan, promotes sustainable practices and aligns with global efforts to reduce waste. By choosing the 5-inch aluminum pipe, companies can contribute to a greener future while meeting their operational needs.Conclusion:[Company Name]'s launch of the innovative 5-inch aluminum pipe represents a significant milestone in the field of industrial piping solutions. This cutting-edge product offers industries a superior alternative to traditional metal pipes, providing enhanced performance, improved efficiency, and increased cost savings.By incorporating the aluminum pipe into their piping systems, industries can demonstrate their commitment to adopting sustainable practices while benefiting from its lightweight, corrosion-resistant, and thermally conductive properties. Together, these advantages equate to a more productive, efficient, and eco-friendly future for businesses across various sectors.[Company Name] remains committed to pioneering advancements in industrial piping solutions and strives to develop products that cater to ever-evolving industry needs. With their reputation for excellence, the company continues to present innovative solutions that revolutionize the way companies operate and further enhance their success.