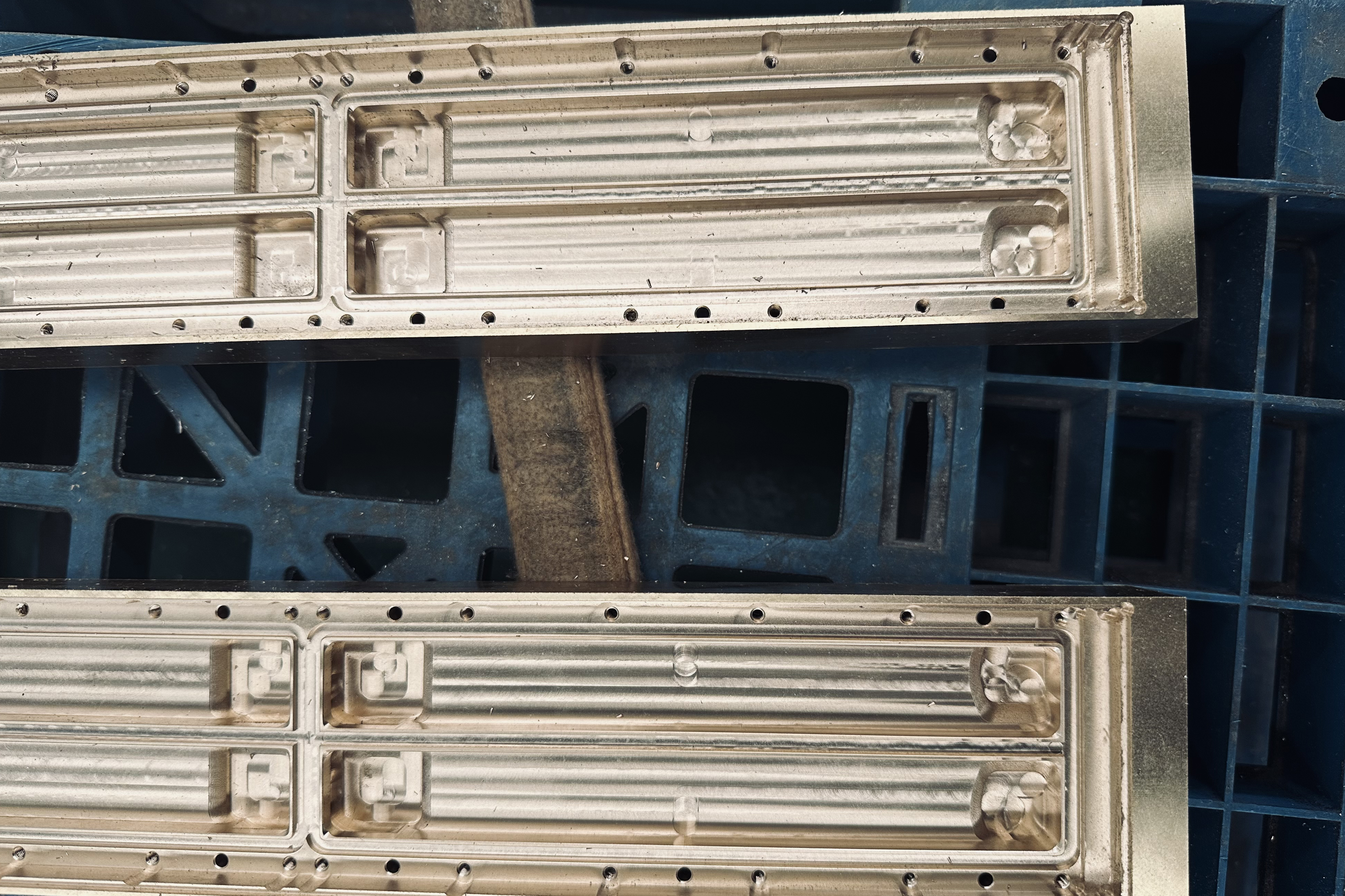

Durable Aluminium Board Fixings for Secure Installations

By:Admin

The company, known for its commitment to quality and innovative products, has been a prominent player in the industry for over a decade. With a strong focus on research and development, Aluminium Board Fixings has continuously invested in cutting-edge technology to provide customers with the best solutions for their construction needs.

The new range of fixings, which are designed to securely fasten aluminium boards to various surfaces, is a result of extensive research and testing. These fixings are engineered to provide a strong and reliable hold, while also offering ease of installation. With a variety of options available, including different sizes and designs, the new range of fixings from Aluminium Board Fixings is set to meet the diverse needs of construction professionals and DIY enthusiasts alike.

"We are thrilled to introduce our latest range of fixings, which we believe will set a new standard in the industry," said the spokesperson for Aluminium Board Fixings. "Our team has worked tirelessly to develop these innovative products, and we are confident that they will deliver exceptional performance and ease of use. We are excited to see the positive impact that these fixings will have on the construction industry."

In addition to their superior quality and performance, the new fixings from Aluminium Board Fixings also offer a sleek and modern design that enhances the overall appearance of the installed aluminium boards. This aesthetic appeal is a testament to the company's commitment to not only functionality but also style and aesthetics.

Aluminium Board Fixings is known for its dedication to customer satisfaction, and the new range of fixings is no exception. The company has ensured that the products are readily available and accessible to customers, with a wide distribution network and efficient customer support.

With the introduction of this new range of fixings, Aluminium Board Fixings has once again solidified its position as a leader in the construction and building materials industry. The company's commitment to innovation and quality has positioned it as a go-to choice for professionals and DIY enthusiasts seeking reliable and efficient fixings for their aluminium board installations.

The new fixings from Aluminium Board Fixings are now available for purchase, and the company encourages customers to experience the difference that these innovative products can make in their construction projects. Whether it's for commercial or residential applications, the new range of fixings is expected to make a significant impact in the industry, setting a new standard for quality and performance.

In conclusion, Aluminium Board Fixings has once again demonstrated its dedication to providing innovative and high-quality solutions for the construction industry. The introduction of the new range of fixings is a testament to the company's commitment to pushing the boundaries of what is possible in aluminium board installations. With their combination of superior performance, ease of installation, and sleek design, the new fixings from Aluminium Board Fixings are poised to make a lasting impression on the industry. Customers can expect nothing less than excellence when they choose Aluminium Board Fixings for their construction needs.

Company News & Blog

High-Quality 7075 Aircraft Aluminum: A Strong and Lightweight Option

[Your Company Name], a leading manufacturer of high-performance materials and products for the aerospace industry, has recently unveiled a groundbreaking innovation in aircraft manufacturing. The company has developed a new type of 7075 aircraft aluminum that promises to revolutionize the way aircraft are built and operated. This new material, which is now available for commercial use, is expected to significantly impact the aerospace industry and pave the way for more efficient and advanced aircraft designs.The new 7075 aircraft aluminum is a high-strength, heat-treatable alloy that is commonly used in aerospace applications. What sets this new material apart is its exceptional strength-to-weight ratio, corrosion resistance, and overall performance. It is widely known that the aerospace industry demands materials that can withstand extreme conditions and rigorous use, and this new 7075 aluminum meets those requirements and more.[Your Company Name] has been at the forefront of material innovation for over [number of years] years. By leveraging their expertise in metallurgy and materials engineering, the company has successfully developed this new 7075 aircraft aluminum to meet the increasing demands of the aerospace industry. This new material is the result of extensive research and development, confirming the company's commitment to pushing the boundaries of what is possible in aircraft manufacturing.The use of 7075 aluminum in aircraft construction offers several advantages. It is significantly lighter than traditional materials such as steel, which directly translates to fuel efficiency and reduced operating costs for airlines. Additionally, its exceptional strength properties allow for the design and construction of more robust and reliable aircraft structures. This means improved safety and performance for both commercial and military aircraft.In addition to its weight and strength characteristics, the new 7075 aluminum also boasts superior corrosion resistance. This is a critical factor for aircraft operating in diverse environments, from humid tropical regions to salt-laden coastal areas, as it ensures the longevity and durability of the aircraft. As a result, aircraft built with this new material will require less maintenance and have an extended service life, further contributing to cost savings for airlines and the aviation industry as a whole.Furthermore, the introduction of the 7075 aircraft aluminum opens up new possibilities for aircraft design and manufacturing. Its high formability and weldability allow for more intricate and complex aircraft components to be produced, leading to improved aerodynamics, performance, and efficiency. This may also enable the development of next-generation aircraft with advanced features and capabilities that were previously unattainable with conventional materials.The implementation of the new 7075 aluminum is not limited to commercial aircraft; it also has significant implications for military aviation. The material's exceptional strength and durability make it an ideal choice for military aircraft, where performance and reliability are of utmost importance. Its lightweight properties also offer strategic advantages, such as increased payload capacity and extended operational ranges for military missions.With the introduction of this new 7075 aircraft aluminum, [Your Company Name] aims to set a new standard for aircraft materials and contribute to the advancement of the aerospace industry. The company's dedication to innovation and excellence has positioned it as a trusted partner for aircraft manufacturers and operators worldwide. By providing cutting-edge materials like the new 7075 aluminum, [Your Company Name] continues to drive progress in aviation and meet the evolving needs of the aerospace market.In conclusion, the unveiling of the new 7075 aircraft aluminum by [Your Company Name] represents a significant milestone in aircraft manufacturing. This advanced material offers unparalleled strength, lightweight properties, and corrosion resistance, making it an ideal choice for modern aircraft construction. With its potential to improve fuel efficiency, enhance safety, and enable innovative aircraft designs, the new 7075 aluminum is poised to reshape the future of aviation. As [Your Company Name] continues to lead the way in material innovation, the aerospace industry can look forward to further advancements that will drive progress and elevate the standards for aircraft performance and reliability.

Enhancing Sustainability: The Rise in Aluminium Rail Extrusion Demand

Aluminium Rail Extrusion: A Strong Solution for Industrial NeedsIn the world of industrial engineering, finding the right materials is crucial. They can affect the product's quality, durability, and overall performance. And as the industry becomes more competitive, engineers need to keep up with the latest technological advancements to stay ahead. One material that has gained popularity in recent years is aluminium rail extrusion. This innovation is known for its strength, durability, and flexibility, making it a great choice for various industrial applications.Aluminium rail extrusion is the process of shaping aluminum into long, linear shapes with a consistent cross-section. The process involves heating up aluminum billets and forcing them through a die to produce the desired shape. This process provides many benefits, such as improved structural strength, better formability, and easier machining. Additionally, aluminium rail extrusion produces less waste, making it environmentally friendly.One company that provides high-quality aluminium rail extrusion is [Company Name]. They offer a wide range of extrusions that can be customized to meet specific customer needs. Their extrusions come in various shapes and sizes, making them suitable for many industrial applications, including transportation, building and construction, and automotive.The company has an advanced production facility with modern equipment and technology. Their extrusion lines can produce extrusions up to 600mm wide, 250mm high and 20m long. They also have the capability to produce complex extrusions with intricate designs. This flexibility allows them to meet the diverse needs of their clients.Apart from their production capabilities, [Company Name] also has a team of skilled engineers and technicians who work together to ensure the quality of their products. They follow strict quality standards throughout the production process, from choosing the right alloys to performing rigorous tests before shipping the extrusions to their customers. This dedication to quality has earned them a great reputation in the industry.Furthermore, the company's commitment to sustainability is admirable. They use recycled aluminum scrap in their production process, reducing their carbon footprint and conserving natural resources. They also have an in-house recycling facility, ensuring that any waste is properly disposed of.In terms of applications, aluminium rail extrusions have a wide range of uses in industrial engineering. One of the most common applications is in transportation, where lightweight yet strong materials are essential. Aluminium rail extrusions are ideal for building train carriages, bus frames, and even aircraft parts. Their excellent strength-to-weight ratio makes them an attractive option for these applications.Another application is in the building and construction industry. Aluminium rail extrusions are commonly used for window and door frames, roofing systems, and curtain walls. They provide excellent thermal insulation and weather resistance, making them suitable for any climate. Additionally, their ability to be customized allows architects and engineers to design structures with unique shapes and designs.Finally, automotive is a growing application for aluminium rail extrusions. They are used for engine frames, suspension systems, and even body structures. As the automotive industry moves towards electric vehicles, lightweight materials like aluminum rail extrusions will become more critical, as they will improve the vehicle's energy efficiency and range.In conclusion, aluminium rail extrusions are an excellent solution for various industrial needs. They offer many benefits, such as improved strength, flexibility, and sustainability. With companies like [Company Name] providing high-quality extrusions and exceptional customer service, engineers and manufacturers can trust this material to deliver the results they need.

High-Strength Aluminum Alloy 7050 Gains Popularity in Aerospace Industry

Title: Advancements in Aluminum Alloys: Introducing the Cutting-Edge Aluminum Alloy 7050Introduction:In recent years, the demand for lightweight materials with exceptional strength and durability has been on the rise. This demand has led to immense research and development in the field of aluminum alloys, which are renowned for their low weight and high strength properties. Among the many aluminum alloys available, one particular alloy has caught the attention of industry experts and enthusiasts alike – Aluminum Alloy 7050 (brand name redacted). This cutting-edge alloy is set to revolutionize various sectors ranging from aerospace to automotive manufacturing. Let us delve into the intricacies of Aluminum Alloy 7050 and explore its potential applications.1. The Development and Composition of Aluminum Alloy 7050:Aluminum Alloy 7050 is a high-strength aluminum alloy primarily composed of aluminum, zinc, copper, and small amounts of other elements, such as magnesium and chromium. This unique composition leads to exceptional strength-to-weight ratio, excellent stress corrosion resistance, and remarkable toughness. The development of this alloy stems from the need to enhance structural integrity and reduce weight in various industries.2. Aerospace Applications of Aluminum Alloy 7050:One of the key sectors poised to benefit significantly from Aluminum Alloy 7050 is aerospace manufacturing. The alloy's exceptional strength properties make it an ideal choice for the construction of aircraft structural components, including fuselages, wings, and landing gear. By utilizing Aluminum Alloy 7050, aircraft manufacturers can significantly reduce weight without compromising on safety and structural integrity.Moreover, this alloy's improved fatigue resistance ensures enhanced durability, contributing to higher operational efficiency and cost-effectiveness. The aerospace industry will undoubtedly benefit from this pioneering alloy as it strives to develop more fuel-efficient and environmentally friendly aircraft.3. Automotive Applications of Aluminum Alloy 7050:The automotive industry is another sector that aims to capitalize on Aluminum Alloy 7050's unique properties. Lightweight materials are gaining increasing importance in the automotive sector due to their potential for reducing emissions and improving fuel efficiency. Aluminum Alloy 7050 presents automakers with the opportunity to achieve these objectives by replacing heavier steel components with its lightweight yet incredibly strong counterparts.Furthermore, this alloy exhibits exceptional formability, making it crucial for manufacturers during the fabrication process. The ability to shape and mold Aluminum Alloy 7050 into complex geometries opens up opportunities for innovation, allowing automotive designers to create lighter and more aerodynamic vehicles without compromising safety or structural integrity.4. Additional Industrial Applications:Apart from aerospace and automotive sectors, Aluminum Alloy 7050 has a wide range of potential industrial applications. These include the construction industry, where the alloy can be used to manufacture high-strength yet lightweight structural components, such as beams and columns. Additionally, its corrosion resistance properties make it well-suited for marine applications, including shipbuilding and offshore structures, where durability and weight reduction are essential factors.The oil and gas industry also stands to benefit from Aluminum Alloy 7050 as it provides a desirable alternative for various applications, including pipelines, pressure vessels, and drilling equipment. The alloy's excellent fatigue and stress corrosion resistance properties make it a reliable choice for withstanding harsh environments and prolonged exposure to corrosive substances.5. Conclusion:Aluminum Alloy 7050's emergence as a cutting-edge alloy has presented numerous possibilities for numerous industries, including aerospace, automotive, construction, marine, and oil and gas. Its exceptional strength-to-weight ratio, durability, and corrosion resistance make it an attractive choice for manufacturers aiming to reduce weight, improve fuel efficiency, and enhance structural integrity.As the demand for lightweight materials continues to increase, Aluminum Alloy 7050 will undoubtedly play a crucial role in shaping various industries and driving advancements in engineering and design. The future looks bright for this remarkable alloy, and we can expect to witness its growing applications across diverse sectors in the coming years.

Customizable T Slot Aluminum Frame for Your Projects

T Slot Aluminum Frame Revolutionizes the Manufacturing Industry with its Versatility and EfficiencyIn today's fast-paced and constantly evolving manufacturing industry, companies are always on the lookout for innovative solutions to improve their productivity and efficiency. One such solution that has been making waves in the industry is the T Slot Aluminum Frame, a revolutionary product that has redefined the way companies build their production lines and workstations.[Company Name] is one of the leading providers of T Slot Aluminum Frame solutions, offering a wide range of products to meet the diverse needs of its clients. With a focus on quality, durability, and versatility, [Company Name] has established itself as a trusted partner for companies looking to upgrade their manufacturing processes.The T Slot Aluminum Frame is a modular aluminum extrusion system that allows for easy and flexible construction of various structures such as workstations, machine frames, enclosures, and more. Its unique T Slot design enables users to easily connect and assemble different components without the need for welding or special tools, making it a cost-effective and time-efficient solution for a wide range of applications.One of the key advantages of the T Slot Aluminum Frame is its versatility. With a wide range of compatible accessories and fastening options, users can easily customize and adapt the frame to meet their specific needs. This flexibility allows for quick reconfiguration and expansion, enabling companies to make changes to their manufacturing setup as needed without having to invest in entirely new equipment.In addition to its versatility, the T Slot Aluminum Frame also offers exceptional strength and durability. Constructed from high-quality aluminum, the frame is capable of supporting heavy loads while maintaining its structural integrity. This makes it an ideal solution for demanding manufacturing environments where reliability is paramount.Furthermore, the T Slot Aluminum Frame excels in its ease of assembly and installation. The modular nature of the system simplifies the construction process, allowing companies to save valuable time and resources during setup. This also means that the frame can be easily disassembled and relocated, providing companies with added flexibility in their operations.With its numerous benefits, it is no surprise that the T Slot Aluminum Frame has become an increasingly popular choice for companies across various industries. From automotive and aerospace to electronics and packaging, the frame has proven to be a versatile and reliable solution for a wide range of applications.[Company Name] is dedicated to providing its clients with the highest quality T Slot Aluminum Frame solutions, backed by exceptional customer service and support. With a team of experienced professionals, the company works closely with its clients to understand their unique requirements and deliver tailored solutions that meet their needs.As the manufacturing industry continues to evolve, the T Slot Aluminum Frame has emerged as a game-changer, offering companies a flexible, efficient, and cost-effective solution for their production needs. With its versatility, strength, and ease of use, it has become a staple in modern manufacturing processes, empowering companies to optimize their operations and stay ahead of the competition.In conclusion, the T Slot Aluminum Frame has revolutionized the manufacturing industry by offering a versatile, efficient, and cost-effective solution for constructing workstations, machine frames, enclosures, and more. With [Company Name] leading the way in providing high-quality solutions, the T Slot Aluminum Frame has become a go-to choice for companies looking to optimize their manufacturing processes and stay competitive in today's fast-paced industry.

High-Quality Aluminum Profile Cutter for Efficient Metal Work

Aluminum Profile Cutter Revolutionizes Cutting Process in the Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards automation and the use of advanced machinery to improve efficiency and productivity. One such innovation that has proven to be a game-changer in the industry is the Aluminum Profile Cutter, developed and manufactured by a leading company in the field of industrial equipment.The Aluminum Profile Cutter is a state-of-the-art cutting machine that is designed to streamline the process of cutting aluminum profiles with precision and accuracy. This revolutionary piece of equipment has been hailed as a game-changer in the industry, offering a level of efficiency and performance that was previously unattainable with traditional cutting methods.The company behind the Aluminum Profile Cutter has a long-standing reputation for delivering cutting-edge solutions for the manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation to provide its customers with the most advanced and reliable machinery on the market.The Aluminum Profile Cutter is the latest addition to the company's extensive range of industrial equipment, and it has quickly become a go-to solution for manufacturers looking to improve their cutting processes. By leveraging the latest technology and engineering expertise, the company has succeeded in creating a cutting machine that sets new standards for precision, speed, and reliability in the industry.One of the key features of the Aluminum Profile Cutter is its advanced cutting mechanism, which is capable of delivering highly precise cuts with minimal wastage. This not only helps manufacturers to optimize their material usage but also contributes to cost savings in the long run. Additionally, the machine's automated operation and intuitive controls have been designed to minimize human error and enhance overall safety in the workplace.Another notable advantage of the Aluminum Profile Cutter is its versatility, which allows it to accommodate a wide range of aluminum profiles with varying dimensions and complexities. This flexibility makes the machine suitable for a diverse set of manufacturing applications, including the production of aluminum frames, extrusions, and other custom profiles used in construction, automotive, and other industries.Furthermore, the company has prioritized the user experience in the design of the Aluminum Profile Cutter, ensuring that operators can easily set up and operate the machine with minimal training. This user-friendly approach has been well-received by manufacturers, as it helps to reduce downtime and increase overall productivity in their operations.The company's commitment to customer satisfaction is evident in its comprehensive after-sales support, which includes training, maintenance, and technical assistance to ensure that customers can maximize the benefits of the Aluminum Profile Cutter over its lifespan. This level of dedication has cemented the company's reputation as a trusted partner for manufacturers seeking cutting-edge solutions to meet their production needs.As the manufacturing industry continues to evolve, the Aluminum Profile Cutter stands out as a shining example of how innovation and technology can drive progress and efficiency. With its superior cutting capabilities, versatility, and user-friendly design, this cutting machine has become a valuable asset for manufacturers seeking to stay ahead in today's competitive market.In conclusion, the Aluminum Profile Cutter has set a new benchmark for cutting precision and efficiency in the manufacturing industry, thanks to the innovative engineering and customer-focused approach of the company behind it. As demand for high-quality aluminum profiles continues to rise, this cutting machine is expected to play a crucial role in shaping the future of manufacturing, driving productivity and profitability for businesses around the world.

Revolutionary Aluminum Frame Design Aims to Disrupt the Industry" can be rewritten as "Innovative Aluminum Frame Design Set to Revolutionize the Industry".

[Innovation in Aluminum Frame Design: Revolutionizing the Industry]Aluminum Frame Design (AFD), an industry-leading innovator in the field of lightweight construction, continues to push the boundaries with its groundbreaking designs. With a relentless focus on sustainability, efficiency, and durability, AFD is revolutionizing various industries by delivering state-of-the-art solutions that are reshaping the future of manufacturing.AFD's commitment to excellence can be traced back to its humble beginnings. Founded in {year} by visionary engineers, {Company Name} started its journey with the aim of transforming traditional manufacturing processes. By harnessing the power of aluminum, a lightweight yet robust material, AFD has been able to bring groundbreaking ideas to life.The secret behind AFD's success lies in its innovative aluminum frame construction techniques. By capitalizing on the unique properties of aluminum, the company has developed cutting-edge solutions that are not only stronger but also lighter than traditional frames made from materials like steel. The use of aluminum frames has significantly reduced the weight of various products, from automobiles to consumer electronics, making them more fuel-efficient and environmentally friendly.One of AFD's noteworthy achievements is its collaboration with the automotive industry. Over the years, the company has worked closely with leading car manufacturers to optimize vehicle design and enhance overall performance. By replacing conventional steel frames with aluminum ones, AFD has reduced the weight of cars, leading to improved fuel efficiency and reduced emissions. Additionally, the aluminum frames offer superior collision protection due to their high strength-to-weight ratio, ensuring the safety of passengers in case of accidents.Another industry where AFD's aluminum frame technology is making waves is in the aerospace sector. By partnering with aerospace giants, AFD has revolutionized aircraft manufacturing. The implementation of lightweight aluminum frames has not only reduced aircraft weight but also increased fuel efficiency. This breakthrough has had a significant impact on the aviation industry, leading to lower operational costs and reduced environmental impact.The benefits of AFD's aluminum frames extend beyond the automotive and aerospace industries. The company's innovative designs have influenced various sectors, including consumer electronics, architecture, and renewable energy. In consumer electronics, AFD's lightweight yet durable aluminum frames have made devices more portable, while maintaining structural integrity. In architecture, the use of aluminum frames has allowed for sleek and modern designs, enabling architects to create visually stunning structures with enhanced energy efficiency. In the renewable energy sector, AFD's aluminum frames have contributed to the development of lightweight solar panels, making them easier to install and transport.With sustainability at the forefront of its mission, AFD is committed to reducing the environmental impact of its manufacturing processes. Aluminum, being a highly recyclable material, aligns perfectly with the company's sustainability goals. AFD ensures that its production facilities adhere to strict environmental regulations and focuses on minimizing waste throughout the manufacturing process. By utilizing recycled aluminum and optimizing material consumption, AFD further contributes to a greener future.Looking ahead, AFD shows no signs of slowing down. The company is continuously investing in research and development to further enhance its aluminum frame designs. Collaborations with academic institutions and other industry leaders allow AFD to stay at the forefront of innovation, driving progress in lightweight construction techniques.In conclusion, Aluminum Frame Design (AFD) has emerged as a pioneer in the world of lightweight construction. Through its innovative aluminum frame designs, AFD has revolutionized various industries, from automotive to aerospace, consumer electronics to architecture. By reducing weight, increasing efficiency, and promoting sustainability, AFD's groundbreaking solutions are reshaping the future of manufacturing and contributing to a greener world.

Guide to Choosing the Right Thickness for Aluminium Profiles

Aluminium Profile Thickness: A Key Factor in Manufacturing ExcellenceAluminium profiles are an essential component in various industries, from construction to automotive and aerospace. The thickness of these profiles plays a crucial role in determining the strength, durability, and overall quality of the finished products. As a leading manufacturer of aluminium profiles, {Company Name} understands the importance of precise thickness control and its impact on the end products.{Company Name} has been a pioneer in the aluminium profile industry for over 20 years, specializing in the production of high-quality profiles for diverse applications. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company has built a reputation for excellence in delivering customised solutions to meet the unique requirements of its clients.One of the key factors that sets {Company Name} apart from its competitors is its commitment to maintaining strict control over the thickness of its aluminium profiles. The company utilises advanced technologies and precision equipment to ensure that every profile meets the exact thickness specifications required by the customer. This attention to detail not only guarantees the quality of the finished products but also ensures consistency and uniformity across large production runs.The thickness of aluminium profiles is critical in applications where structural integrity and load-bearing capacity are essential. For example, in the construction industry, aluminium profiles with precise thickness control are used in the fabrication of windows, doors, curtain walls, and other architectural elements. Similarly, in the automotive and aerospace sectors, the use of accurately manufactured aluminium profiles is vital for enhancing the performance and safety of vehicles and aircraft.{Company Name}'s dedication to maintaining optimal thickness control extends to its product development and testing processes. The company invests in research and development to innovate new alloys and manufacturing techniques that allow for greater flexibility in profile thickness while meeting the highest quality standards. Additionally, {Company Name} conducts rigorous quality testing to ensure that every profile meets or exceeds industry regulations and customer specifications.The company's capabilities in precision thickness control have earned it the trust of numerous clients across industries. Its commitment to delivering superior products has led to successful partnerships with some of the most renowned names in construction, automotive, and aerospace. With an unwavering focus on quality and customer satisfaction, {Company Name} has solidified its position as a preferred supplier of aluminium profiles.In addition to its dedication to product excellence, {Company Name} is also committed to sustainability and environmental responsibility. The company adheres to stringent eco-friendly practices in its manufacturing processes, ensuring that its aluminium profiles are produced with minimal impact on the environment. By prioritising sustainability, {Company Name} is not only contributing to a greener planet but also meeting the evolving demands of socially responsible industries.Looking ahead, {Company Name} aims to continue its trajectory of growth and innovation, leveraging its expertise in thickness control to expand its product offerings and target new markets. The company's dedication to excellence, coupled with its customer-centric approach, positions it as a reliable partner for companies seeking high-quality aluminium profiles for their applications.In conclusion, the thickness of aluminium profiles is a critical factor in determining the performance and durability of finished products across various industries. {Company Name}'s unwavering commitment to precision thickness control, combined with its dedication to quality, sustainability, and customer satisfaction, underscores its position as a leader in the aluminium profile manufacturing industry. As the company continues to innovate and expand its reach, it is poised to shape the future of aluminium profiles and set new benchmarks for excellence in the industry.

Durable Aluminum Square Tubing Connectors for Various Applications

Aluminum Square Tubing Connectors have revolutionized the way in which various industries are able to create and assemble structures. These connectors, produced by {}, have become a staple in the construction, manufacturing, and DIY sectors due to their durability, versatility, and ease of use.{} specializes in the design and production of high-quality aluminum connectors that cater to the diverse needs of their customers. With a strong focus on innovation and customer satisfaction, the company has established itself as a leader in the industry, providing solutions that meet the demands of modern construction and design.The Aluminum Square Tubing Connectors offered by {} are designed to fit seamlessly with standard aluminum square tubing, providing a secure and reliable connection that is essential for a wide range of applications. This includes everything from building industrial structures, such as scaffolding and safety barriers, to creating custom furniture and displays for retail environments.One of the key advantages of using aluminum connectors is the material's inherent properties. Aluminum is lightweight, yet incredibly strong, making it an ideal choice for a wide range of construction projects. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor use, and it can be easily recycled, aligning with the increasing importance of sustainable practices in modern construction.The connectors produced by {} are available in a variety of configurations, including 2-way, 3-way, and 4-way connectors, as well as adjustable angle connectors. This flexibility allows for the creation of complex structures and designs without the need for specialized tools or welding equipment. The connectors are also available in a range of finishes, including clear anodized, black anodized, and powder-coated options, providing further customization for specific project requirements.In addition to their standard product offerings, {} also specializes in custom connector solutions, working closely with clients to develop bespoke connectors to meet their specific needs. This tailored approach sets {} apart from other manufacturers, allowing them to provide unique solutions that are tailored to each customer's requirements.The versatility of Aluminum Square Tubing Connectors extends beyond traditional construction applications. With the growing trend of DIY enthusiasts and makers, these connectors have also become popular for creating custom furniture, shelving, and display units. Their ease of use and durable construction make them an ideal choice for individuals looking to bring their design ideas to life without the need for specialized skills or equipment.In recent years, the construction industry has seen a shift towards modular and prefabricated building techniques, aimed at increasing efficiency and reducing construction timelines. Aluminum connectors have played a significant role in this shift, allowing for the rapid assembly and disassembly of structures while maintaining structural integrity. This has led to increased demand for high-quality connectors that can meet the rigors of modern construction practices, a demand that {} has consistently met.Looking ahead, {} is committed to furthering innovation in the field of aluminum connectors, with a focus on developing new products that can meet the evolving needs of their customers. With a dedication to quality, reliability, and excellent customer service, {} is poised to continue leading the way in the production of Aluminum Square Tubing Connectors, providing solutions that are essential for the construction and design industries.

Cutting-edge Aluminum Extrusion Cutting Machine Makes Waves in the Latest News

Aluminum Extrusion Cutting Machine Enhances Precision and Efficiency in Manufacturing ProcessesIn today's rapidly advancing manufacturing industry, efficiency and precision are paramount for companies seeking to stay ahead of the competition. One such innovation that has become an integral part of the aluminum extrusion manufacturing process is the Aluminum Extrusion Cutting Machine (AECM). This cutting-edge technology has revolutionized the way aluminum extrusions are processed, significantly improving both accuracy and productivity.The AECM is a state-of-the-art machine that has gained popularity among manufacturers due to its ability to precisely cut aluminum extrusions with high efficiency. Equipped with advanced features and cutting-edge technology, this machine has transformed the aluminum extrusion industry by streamlining the manufacturing process and reducing production times.One of the key advantages of the AECM is its ability to provide precise cutting measurements, ensuring consistent and accurate results with every aluminum extrusion. This level of precision is especially crucial in industries like automotive, aerospace, construction, and electronics, where seamless integration and product quality are of utmost importance. The machine utilizes advanced algorithms and cutting techniques, guaranteeing optimal results and eliminating any potential defects or inaccuracies.Moreover, the AECM has the capability to handle a wide range of aluminum extrusion profiles, including complex shapes and intricate designs. This versatility allows manufacturers to meet the diverse requirements of various industries and cater to custom orders with ease. Additionally, the machine's adjustable cutting speeds and parameters enable manufacturers to maintain exceptional quality standards while improving productivity simultaneously.The AECM's advanced automation features contribute to further enhancing efficiency in the manufacturing process. With integrated software and computer-controlled systems, the machine can perform cutting operations with minimal human intervention. This reduction in manual labor not only improves production efficiency but also lowers the risk of errors or accidents, ensuring a safer working environment.Companies operating in the aluminum extrusion industry have recognized the immense benefits offered by the AECM and have begun incorporating this cutting-edge technology into their manufacturing processes. One such company is {} (company name), a leading manufacturer that specializes in aluminum extrusions. With a commitment to providing high-quality products and exceptional customer service, {} has embraced the AECM to enhance its production capabilities.By implementing the AECM, {} has experienced significant improvements in its manufacturing processes. The machine's precise cutting abilities have allowed {} to produce extrusions with unparalleled accuracy, meeting the exact specifications of its clients. Additionally, the increased automation and efficiency offered by the AECM have enabled {} to streamline its production line, resulting in reduced lead times and improved overall productivity.The adoption of the AECM by {} not only demonstrates the company's commitment to staying at the forefront of the aluminum extrusion industry but also highlights the positive impact this technology can have on the entire manufacturing sector. With the ability to enhance precision, efficiency, and overall production capabilities, the Aluminum Extrusion Cutting Machine has become an indispensable asset for companies seeking to thrive in a competitive market.In conclusion, the Aluminum Extrusion Cutting Machine has transformed the way aluminum extrusions are manufactured. With its advanced features, precise cutting abilities, and enhanced automation, this cutting-edge technology has revolutionized the industry, enabling manufacturers to achieve unparalleled accuracy, improved productivity, and customer satisfaction. As companies like {} continue to integrate the AECM into their operations, the future of aluminum extrusion manufacturing looks brighter than ever.

High-Quality Extruded Aluminum Rod: Latest News and Updates

Extruded Aluminum Rod: The Backbone of Modern IndustryIn today's rapidly evolving industrial landscape, the need for high-quality materials that can meet the demands of modern manufacturing processes has never been greater. Among these materials, extruded aluminum rod has emerged as a crucial component in a wide range of applications, playing a vital role in industries such as construction, automotive, aerospace, and consumer electronics.Extruded aluminum rod is a versatile and durable material that is widely used in the production of various components and products. It is created through a process known as extrusion, in which a cylindrical billet of aluminum is forced through a die to produce a uniform cross-section. This results in a product that has superior strength, excellent corrosion resistance, and a lightweight yet durable nature, making it ideal for a wide range of applications.One company at the forefront of producing high-quality extruded aluminum rod is {}. With a strong focus on innovation, quality, and customer satisfaction, {} has established itself as a leading supplier of aluminum products to industries across the globe. The company's state-of-the-art manufacturing facilities and cutting-edge technology allow them to produce extruded aluminum rod of the highest quality, meeting the stringent standards and specifications of their clients.With a strong commitment to sustainability and environmental responsibility, {} has also made significant investments in developing environmentally friendly processes for aluminum extrusion. This includes the use of recycled aluminum and the implementation of energy-efficient manufacturing practices, which not only reduce the environmental impact of production but also help to lower costs for their customers.The versatility of extruded aluminum rod is one of its key attributes, making it suitable for a wide range of applications across various industries. In the construction sector, it is used in the production of structural components, window and door frames, and curtain wall systems, thanks to its excellent strength-to-weight ratio and corrosion resistance. In the automotive industry, extruded aluminum rod is utilized in the manufacturing of components such as engine blocks, transmission cases, and structural support systems, where its lightweight properties and high strength are highly valued.Furthermore, the aerospace industry relies on extruded aluminum rod for its ability to provide lightweight yet durable solutions for aircraft components, fuel tanks, and structural sections. In the consumer electronics sector, the use of extruded aluminum rod is ubiquitous, with applications ranging from the production of smartphone frames and laptop casings to heat sinks and other electronic components.In addition to its physical properties, extruded aluminum rod also offers excellent thermal and electrical conductivity, making it an ideal material for heat transfer and electrical applications. This, coupled with its ability to be easily machined, welded, and anodized, further enhances its appeal across a wide spectrum of industries.With the global demand for extruded aluminum rod on the rise, {} has positioned itself as a reliable and forward-thinking supplier, dedicated to meeting the evolving needs of their customers. By continuously investing in research and development, as well as fostering partnerships with industry leaders, they are able to offer innovative solutions that push the boundaries of what is possible with aluminum extrusion.As the world transitions towards a more sustainable and resource-efficient future, the role of extruded aluminum rod in modern industry becomes increasingly indispensable. Its ability to deliver high performance, lightweight properties, and environmental sustainability makes it one of the most sought-after materials in the manufacturing sector. With companies like {} leading the way in the production of high-quality extruded aluminum rod, the future looks bright for this essential component of modern industry.