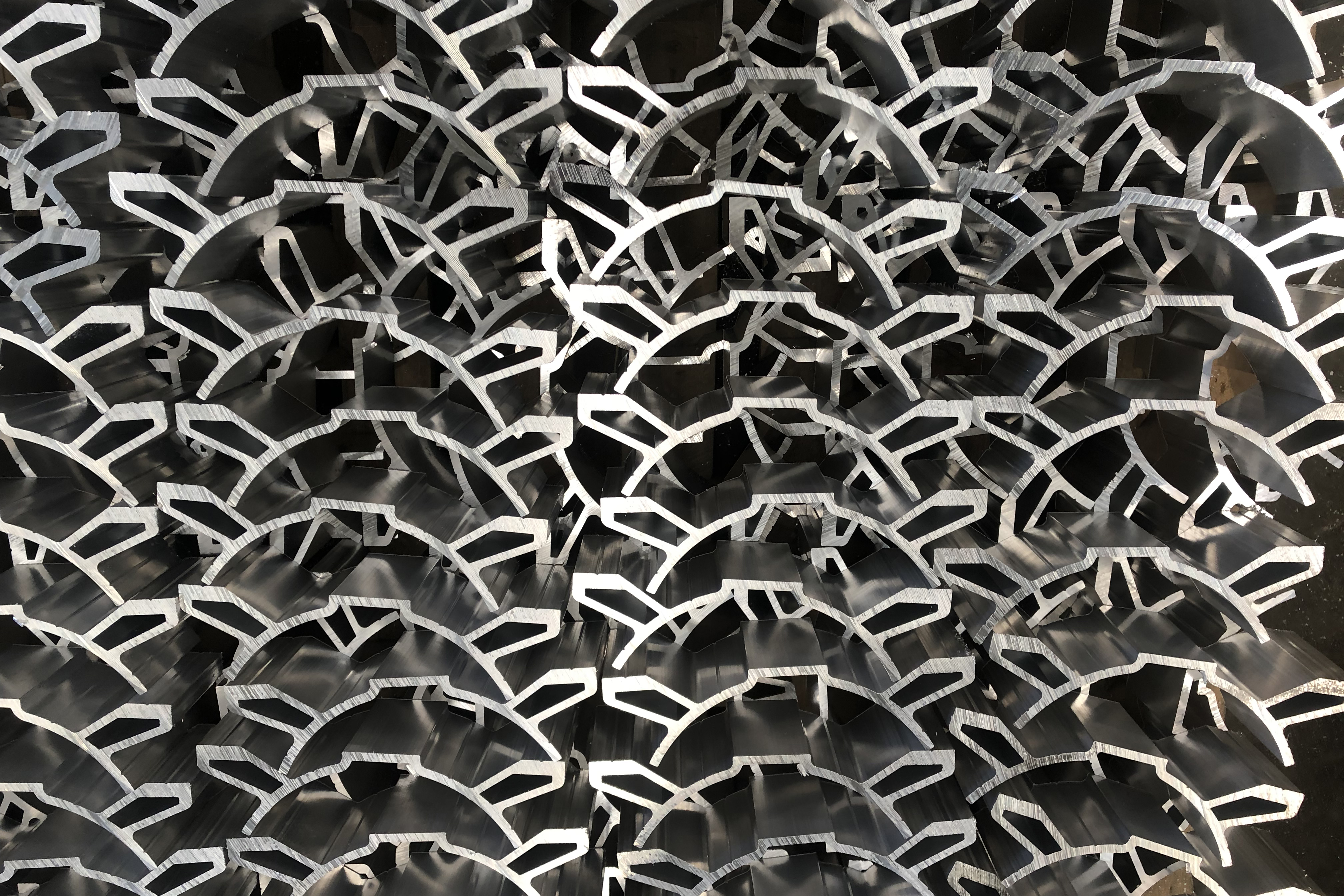

High-Quality Aluminium Pipe Extrusion for Various Applications

By:Admin

One of the leading providers of aluminium pipe extrusion services is {company name}, a renowned company with a long-standing reputation for excellence in the industry. With state-of-the-art facilities and a team of experienced professionals, {company name} has been at the forefront of aluminium pipe extrusion technology, providing high-quality products to customers across various sectors.

{Company name} utilizes advanced extrusion technology to produce aluminum pipes of various shapes, sizes, and specifications to meet the diverse needs of its clients. The company's extrusion process involves heating the aluminum billet to a specific temperature and then forcing it through a shaped opening, known as a die, using a hydraulic press, resulting in the formation of seamless aluminum pipes with precise dimensions and consistent quality.

In addition to the standard extrusion process, {company name} also offers customized solutions to meet the specific requirements of its customers. Whether it's a unique shape, special coating, or specific alloy, the company's technical expertise and flexible manufacturing capabilities allow for the production of tailor-made aluminum pipes that can withstand various operating conditions and environments.

Furthermore, {company name} is committed to sustainability and environmentally friendly practices. The company's extrusion process minimizes material waste and energy consumption, and it also utilizes recycled aluminum in its production, reducing its environmental footprint and contributing to a circular economy.

{Company name} takes pride in its rigorous quality control measures to ensure that its aluminum pipes meet industry standards and customer expectations. Through precision testing and inspection procedures, the company guarantees the structural integrity, durability, and overall performance of its products, providing peace of mind to its clients.

With a focus on innovation and continuous improvement, {company name} is constantly exploring new techniques and technologies to enhance its aluminium pipe extrusion capabilities. This dedication to research and development enables the company to stay ahead of industry trends and deliver cutting-edge solutions that drive the success of its customers' projects.

In conclusion, aluminium pipe extrusion plays a crucial role in the manufacturing and production processes of various industries, and {company name} stands out as a leading provider of high-quality aluminium pipes. With its advanced technology, customized solutions, commitment to sustainability, and dedication to excellence, {company name} continues to be a trusted partner for businesses seeking reliable and premium aluminium pipe extrusion services.

Company News & Blog

High-Quality 7020T6 Aluminum Extrusions for Various Applications

7020T6 Aluminum Extrusions - Revolutionizing the Aluminum IndustryThe aluminum industry has long been a cornerstone of manufacturing, providing essential materials for a wide range of products and applications. With the demand for lightweight, durable materials on the rise, the need for innovative aluminum solutions has never been greater. Enter 7020T6 aluminum extrusions, a game-changing product that is set to revolutionize the industry.{Company Name} is at the forefront of this revolution, leading the way in the production and development of 7020T6 aluminum extrusions. With a focus on precision engineering and advanced manufacturing techniques, {Company Name} is setting new standards for aluminum products. Their commitment to quality and innovation has made them a trusted partner for businesses across a wide range of industries, from aerospace and automotive to construction and consumer goods.So, what sets 7020T6 aluminum extrusions apart from traditional aluminum products? The answer lies in its unique composition and properties. 7020T6 aluminum is an alloy that is renowned for its exceptional strength, corrosion resistance, and weldability. This makes it the ideal choice for applications that require durability and longevity, such as aircraft components, structural frames, and automotive parts.In addition to its impressive mechanical properties, 7020T6 aluminum extrusions also offer significant weight savings compared to other materials. This makes them particularly valuable in industries where reducing weight is a priority, such as aerospace and transportation. By utilizing 7020T6 aluminum extrusions, businesses can improve fuel efficiency, increase payload capacity, and enhance overall performance.{Company Name}'s expertise in extrusion technology allows them to produce 7020T6 aluminum products in a wide range of shapes and sizes, providing solutions for even the most complex design requirements. Their state-of-the-art facilities and stringent quality control processes ensure that every extrusion meets the highest standards for precision and consistency.But the benefits of 7020T6 aluminum extrusions extend beyond their performance and versatility. This material is also highly sustainable, as aluminum is fully recyclable and retains its properties through multiple lifecycles. By choosing 7020T6 aluminum extrusions, businesses can reduce their environmental impact and contribute to a more sustainable future.As the global demand for advanced aluminum solutions continues to grow, {Company Name} is committed to staying at the forefront of innovation. They are constantly exploring new ways to enhance the performance and capabilities of 7020T6 aluminum extrusions, ensuring that their products remain at the cutting edge of the industry.In conclusion, 7020T6 aluminum extrusions represent a major advancement in the world of aluminum manufacturing. With their exceptional strength, lightweight nature, and environmental benefits, they are poised to transform a wide range of industries. {Company Name}'s dedication to quality and innovation has positioned them as a leader in this space, and their 7020T6 aluminum extrusions are setting new benchmarks for performance and reliability.For businesses seeking high-quality, reliable aluminum solutions, 7020T6 aluminum extrusions from {Company Name} are the clear choice. As the industry continues to evolve, {Company Name} will remain a driving force behind the advancement of aluminum technology, delivering cutting-edge solutions that meet the needs of today and tomorrow.

Discover the Top Uses and Benefits of 7075 Sheet Aluminum" or "Unveiling the Key Features and Applications of 7075 Sheet Aluminum

In recent news, a new product is making waves in the manufacturing industry. The product in question is none other than 7075 sheet, an aluminum alloy sheet that has been garnering attention for its durability, strength, and light weight. Made by an industry-leading company (), the 7075 sheet offers a whole host of benefits that set it apart from other materials, such as steel and titanium.Let's take a closer look at what makes this product so special. For starters, the 7075 sheet is a high-strength alloy that is composed mainly of zinc, magnesium, and copper. It is known for its exceptional strength-to-weight ratio, which makes it an ideal material for various applications that require both strength and lightweight properties. As such, it has become a preferred choice in the aerospace and defense industries, where weight savings are a top priority.Moreover, the 7075 sheet is highly resistant to corrosion and stress cracking, making it a reliable option for harsh environments and extreme conditions. This quality has earned it widespread use in the marine industry, where it is used to manufacture boat components such as hulls, masts, and rigging. It is also used in the automotive industry to create parts for high-performance vehicles that require enhanced strength and durability.The company () that produces the 7075 sheet takes pride in its commitment to quality and precision. Their production process involves state-of-the-art technology and strict quality control measures to ensure that each sheet meets the highest standards. The result is a product that offers consistent mechanical properties and dimensionality, allowing for easy fabrication and assembly.The company's () dedication to innovation and product development has earned them a reputation for being at the forefront of the industry. They have invested heavily in research and development to create new and improved alloys that address the evolving needs of customers. Their expertise in the field and their focus on customer satisfaction have made them a trusted partner for businesses in various sectors.The benefits of the 7075 sheet do not stop there. It is also a highly machinable material, which means it can be easily cut, drilled, and formed to create components of different shapes and sizes. This makes it an economical option that offers greater flexibility and adaptability than other materials.To sum it up, the 7075 sheet is a game-changer in the manufacturing industry. Its superior strength, lightweight, durability, and resistance to corrosion make it an ideal choice for various applications in different sectors. The company () that produces it has proven itself to be a leader in the field, providing high-quality products and exceptional customer service. As businesses continue to demand more from their materials, the 7075 sheet is poised to become an even more valuable asset in the years to come.

Aluminum: An Essential Component for Hybrid Electric Vehicles (HEVs)

(title) Aluminum Innovations for Hybrid Electric Vehicles(Date)(News Organization)(Article)Hybrid Electric Vehicles (HEVs) have gained significant popularity over recent years as a more environmentally friendly alternative to traditional gasoline-powered vehicles. As the demand for HEVs continues to rise, automotive manufacturers are constantly seeking innovative solutions to enhance their performance, efficiency, and sustainability. One company that stands out in this endeavor is (remove brand name), a leading provider of cutting-edge aluminum technologies for the automotive industry.(Company Introduction)Founded in (year), (remove brand name) has established itself as a pioneer in the development and production of high-quality aluminum solutions for various industries. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible with aluminum, making it an ideal partner for automakers striving to optimize their HEV offerings.(Paragraph about the importance of lightweight materials in HEVs)In the context of HEVs, lightweight materials play a crucial role in improving overall vehicle efficiency and reducing emissions. Aluminum, being significantly lighter than traditional steel, offers substantial benefits to HEV manufacturers. By integrating lightweight aluminum components, automakers can achieve weight reduction without compromising the structural integrity and safety of the vehicles. Furthermore, the reduced weight allows for increased battery efficiency and improved overall performance.(Overview of aluminum innovations for HEVs)(remove brand name) has recently unveiled a range of innovative aluminum solutions specifically designed for HEVs. These advancements include but are not limited to:1. Aluminum Body-in-White (BIW) Structures: The company's advanced aluminum BIW structures provide a lightweight alternative to traditional steel frames without sacrificing safety. These structures offer exceptional strength, rigidity, and crashworthiness while significantly reducing the vehicle's overall weight.2. Aluminum Battery Enclosures: (remove brand name) has developed aluminum battery enclosures that effectively protect the HEV's battery pack and ensure its optimal performance. These enclosures offer excellent thermal management properties, preventing overheating and enhancing battery longevity.3. Aluminum Suspension Components: Incorporating aluminum suspension components allows for reduced unsprung weight, resulting in improved ride comfort and handling. Additionally, the lightweight nature of these components contributes to overall fuel efficiency and better energy recovery during regenerative braking.4. Aluminum Heat Exchangers: (remove brand name)'s aluminum heat exchangers provide efficient cooling solutions for HEVs. With their lightweight design and superior heat transfer capabilities, these exchangers ensure optimal thermal management while further reducing the vehicle's weight.(Another paragraph about the company's role in shaping the future of HEVs)By continuously investing in research and development, (remove brand name) is at the forefront of the aluminum revolution in the automotive industry. Their commitment to sustainability and innovation has positioned them as a key partner for automakers seeking to enhance the performance, efficiency, and overall appeal of HEVs. With their state-of-the-art aluminum solutions, (remove brand name) is contributing to the ongoing shift towards a greener and more sustainable transportation future.(Conclusion)As the global demand for HEVs continues to increase, companies like (remove brand name) play a vital role in shaping the future of automotive design. Through their groundbreaking aluminum innovations, they are enabling automakers to produce more energy-efficient and eco-friendly vehicles without compromising performance or safety. With the constant evolution of aluminum technologies, the possibilities for further advancements in HEVs are endless, and the future of sustainable transportation looks promising.

High-Quality Aluminum Profile Cutter for Efficient Metal Work

Aluminum Profile Cutter Revolutionizes Cutting Process in the Manufacturing IndustryIn recent years, the manufacturing industry has seen a significant shift towards automation and the use of advanced machinery to improve efficiency and productivity. One such innovation that has proven to be a game-changer in the industry is the Aluminum Profile Cutter, developed and manufactured by a leading company in the field of industrial equipment.The Aluminum Profile Cutter is a state-of-the-art cutting machine that is designed to streamline the process of cutting aluminum profiles with precision and accuracy. This revolutionary piece of equipment has been hailed as a game-changer in the industry, offering a level of efficiency and performance that was previously unattainable with traditional cutting methods.The company behind the Aluminum Profile Cutter has a long-standing reputation for delivering cutting-edge solutions for the manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation to provide its customers with the most advanced and reliable machinery on the market.The Aluminum Profile Cutter is the latest addition to the company's extensive range of industrial equipment, and it has quickly become a go-to solution for manufacturers looking to improve their cutting processes. By leveraging the latest technology and engineering expertise, the company has succeeded in creating a cutting machine that sets new standards for precision, speed, and reliability in the industry.One of the key features of the Aluminum Profile Cutter is its advanced cutting mechanism, which is capable of delivering highly precise cuts with minimal wastage. This not only helps manufacturers to optimize their material usage but also contributes to cost savings in the long run. Additionally, the machine's automated operation and intuitive controls have been designed to minimize human error and enhance overall safety in the workplace.Another notable advantage of the Aluminum Profile Cutter is its versatility, which allows it to accommodate a wide range of aluminum profiles with varying dimensions and complexities. This flexibility makes the machine suitable for a diverse set of manufacturing applications, including the production of aluminum frames, extrusions, and other custom profiles used in construction, automotive, and other industries.Furthermore, the company has prioritized the user experience in the design of the Aluminum Profile Cutter, ensuring that operators can easily set up and operate the machine with minimal training. This user-friendly approach has been well-received by manufacturers, as it helps to reduce downtime and increase overall productivity in their operations.The company's commitment to customer satisfaction is evident in its comprehensive after-sales support, which includes training, maintenance, and technical assistance to ensure that customers can maximize the benefits of the Aluminum Profile Cutter over its lifespan. This level of dedication has cemented the company's reputation as a trusted partner for manufacturers seeking cutting-edge solutions to meet their production needs.As the manufacturing industry continues to evolve, the Aluminum Profile Cutter stands out as a shining example of how innovation and technology can drive progress and efficiency. With its superior cutting capabilities, versatility, and user-friendly design, this cutting machine has become a valuable asset for manufacturers seeking to stay ahead in today's competitive market.In conclusion, the Aluminum Profile Cutter has set a new benchmark for cutting precision and efficiency in the manufacturing industry, thanks to the innovative engineering and customer-focused approach of the company behind it. As demand for high-quality aluminum profiles continues to rise, this cutting machine is expected to play a crucial role in shaping the future of manufacturing, driving productivity and profitability for businesses around the world.

High-quality Aluminum Tubing Profiles for Various Applications

Extruded Aluminum Tubing Profiles are a significant component in many industries, playing a crucial role in the production of a wide range of products. From construction to automotive manufacturing, extruded aluminum tubing profiles are used in various applications due to their strength, durability, and versatility. These profiles are ideal for applications where lightweight, corrosion-resistant, and high-strength materials are required, making them a preferred choice in many industries.{} has been a leading manufacturer of extruded aluminum tubing profiles, providing high-quality products to meet the diverse needs of its customers. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, the company has been at the forefront of producing extruded aluminum tubing profiles that meet the highest industry standards.The company's expertise in producing extruded aluminum tubing profiles has been recognized by various industries, with its products being widely used in sectors such as construction, transportation, electrical, and industrial applications. With a commitment to continuous improvement and innovation, the company has been able to stay ahead of the competition, offering its customers the best-in-class products that meet their specific requirements.One of the key advantages of extruded aluminum tubing profiles is their versatility, allowing for a wide range of customization options to meet specific project requirements. {} has been able to leverage its expertise in extrusion technology to offer custom aluminum profiles, providing its customers with tailor-made solutions for their unique applications. Whether it's a complex geometric shape or a specific alloy requirement, the company has the capability to deliver custom extruded aluminum tubing profiles that meet the most demanding specifications.In addition to customization, {} also focuses on providing its customers with a comprehensive range of standard extruded aluminum tubing profiles. The company offers a diverse selection of standard shapes and sizes, catering to a broad spectrum of applications. Whether it's round, square, rectangular, or oval profiles, {} has a wide variety of options to choose from, ensuring that its customers have access to the right profiles for their projects.Furthermore, {} places a strong emphasis on quality and consistency in its manufacturing process, ensuring that every extruded aluminum tubing profile meets the highest standards of excellence. The company's stringent quality control measures and rigorous testing procedures guarantee that its products are reliable, durable, and performance-driven, meeting the stringent requirements of various industries.Moreover, {} is committed to sustainability and environmentally-friendly practices in its manufacturing processes. The company recognizes the importance of reducing its environmental footprint and has implemented innovative techniques to minimize waste and energy consumption in its production facilities. By prioritizing sustainability, {} aims to not only meet the present needs of its customers but also contribute to a greener and more sustainable future.As a customer-centric company, {} places great emphasis on providing exceptional service and support to its clients. With a dedicated team of professionals, the company offers technical assistance, product selection guidance, and timely delivery services, ensuring a seamless and hassle-free experience for its customers.Looking ahead, {} remains committed to innovation, quality, and customer satisfaction, aiming to strengthen its position as a leading manufacturer of extruded aluminum tubing profiles. With a focus on meeting the evolving needs of various industries and staying ahead of market trends, the company continues to invest in research and development, new technologies, and expanded capabilities to provide its customers with the best solutions for their projects.In conclusion, extruded aluminum tubing profiles play a crucial role in various industries, and {} has established itself as a trusted and reliable supplier of high-quality products. With a focus on customization, quality, sustainability, and customer satisfaction, the company is well-positioned to meet the diverse needs of its customers and contribute to the growth and success of the industries it serves.

High-quality Aluminum Sign Extrusion for Your Signage Needs

Aluminum Sign Extrusion, a leading manufacturer of high-quality sign extrusions, has positioned itself as a reliable and innovative provider of aluminum extrusion products for the sign industry. The company, founded in 1998, has been committed to meeting the diverse needs of its customers with a wide range of products, from standard sign extrusions to custom-designed solutions.With a state-of-the-art facility and a team of experienced professionals, Aluminum Sign Extrusion has established itself as a trusted partner for sign manufacturers and businesses looking for durable and effective sign solutions. The company’s dedication to quality and customer satisfaction has earned it a strong reputation in the industry.One of the key products offered by Aluminum Sign Extrusion is its aluminum sign extrusions, which are designed to provide a lightweight and durable solution for a wide range of sign applications. The extrusions are available in various sizes and shapes, making them suitable for different types of signs, including channel letters, illuminated signs, and more.The company’s commitment to innovation has also led to the development of custom extrusion solutions, allowing customers to request specific designs and dimensions tailored to their unique sign requirements. This flexibility and customization capability set Aluminum Sign Extrusion apart from its competitors, as it can meet the exact specifications of its customers’ projects.Additionally, Aluminum Sign Extrusion offers a range of finishing options for its extrusions, including powder coating, anodizing, and custom colors. This ensures that customers have the flexibility to choose the finish that best suits their brand and design needs.Furthermore, the company prides itself on its dedication to sustainability and environmentally-friendly practices. Its extrusions are made from recyclable aluminum, and the company adheres to strict environmental standards in its manufacturing processes. This commitment to sustainability has made Aluminum Sign Extrusion a preferred choice for customers who prioritize eco-friendly solutions for their signage needs.In addition to its product offerings, Aluminum Sign Extrusion provides exceptional customer service and technical support to assist customers in choosing the right extrusion solutions for their projects. The company’s team of experts is available to provide guidance and expertise throughout the entire process, from initial design to delivery, ensuring a seamless and efficient experience for its customers.Aluminum Sign Extrusion’s success in the sign industry can also be attributed to its investment in cutting-edge technology and machinery, allowing for precision manufacturing and consistent quality in its extrusion products. The company’s manufacturing processes are continuously optimized to meet the evolving demands of the industry and deliver the highest standard of products to its customers.As a testament to its ongoing commitment to excellence, Aluminum Sign Extrusion has achieved various certifications and accolades, further solidifying its position as a leader in the sign extrusion market. Its dedication to quality and innovation has enabled the company to establish strong partnerships with leading sign manufacturers and businesses across the country.In conclusion, Aluminum Sign Extrusion has proven itself as a premier provider of aluminum sign extrusions, offering a comprehensive range of products, custom solutions, and exceptional customer support. With its unwavering dedication to quality, sustainability, and innovation, the company continues to set high standards in the sign industry and remains a trusted partner for businesses looking for reliable and high-performance sign extrusion solutions.

Durable and Versatile Aluminium Profile Pipe for Various Applications

Aluminium Profile Pipe: The Superior Solution for ConstructionIn the ever-evolving world of construction, the demand for high-quality and durable building materials is at an all-time high. Among the leading materials in the industry is Aluminium Profile Pipe, a versatile and reliable solution for a wide range of construction applications.The Aluminium Profile Pipe, offered by {company name}, is specifically designed to meet the needs of modern construction projects. With its unique combination of strength, lightness, and corrosion resistance, this innovative building material has become the go-to choice for architects, engineers, and contractors around the world.{Company name} has established itself as a leader in the production and distribution of Aluminium Profile Pipe, with a strong emphasis on quality and customer satisfaction. With state-of-the-art manufacturing facilities and a team of experienced professionals, the company is committed to delivering top-notch products that meet the highest industry standards.One of the key advantages of Aluminium Profile Pipe is its exceptional strength-to-weight ratio. This makes it an ideal choice for applications where structural integrity is essential, such as in the construction of high-rise buildings, bridges, and industrial facilities. Despite its impressive strength, Aluminium Profile Pipe is also remarkably lightweight, making it easier to handle and transport on the job site.Another significant benefit of Aluminium Profile Pipe is its resistance to corrosion. Unlike steel or iron, aluminium does not rust or deteriorate when exposed to moisture, making it an excellent choice for outdoor or high-humidity environments. This durability ensures that structures built with Aluminium Profile Pipe will stand the test of time, reducing the need for costly maintenance and repairs.The versatility of Aluminium Profile Pipe is yet another reason for its widespread popularity in the construction industry. This material can be easily customized and fabricated to meet the specific requirements of a project, allowing for greater flexibility and creativity in design. Whether it's for framing, support beams, or decorative elements, Aluminium Profile Pipe offers a wide range of possibilities for construction professionals.In addition to its physical properties, Aluminium Profile Pipe is also highly sustainable and environmentally friendly. Aluminium is fully recyclable, meaning that any scrap or waste material can be repurposed into new products, reducing the overall environmental footprint of a construction project.As the construction industry continues to embrace sustainable and energy-efficient building practices, Aluminium Profile Pipe is well-positioned to play a crucial role in the development of modern structures. Its ability to support green building initiatives and contribute to LEED certification makes it a material of choice for environmentally conscious builders and developers.With an unwavering commitment to quality and innovation, {company name} is dedicated to providing the construction industry with the best Aluminium Profile Pipe products on the market. As the demand for sustainable and durable building materials continues to grow, the company remains at the forefront, meeting the needs of its customers and contributing to the advancement of the construction industry.In conclusion, Aluminium Profile Pipe from {company name} is a superior solution for construction projects, offering unparalleled strength, durability, versatility, and sustainability. With its impressive range of capabilities and proven track record, it's no wonder that Aluminium Profile Pipe has become the material of choice for the modern builder.

Aluminum Extrusion Association Reports Increase in Industry Demand

The Aluminum Extrusion Association (AEA) has recently announced its partnership with a leading aluminum extrusion company, to further promote the use of aluminum in various industries. The AEA, a non-profit trade association, aims to advance the use of aluminum extrusions in North America by providing a platform for education, networking, and advocacy.The company, known for their expertise in custom aluminum extrusions, has been a key player in the industry for many years. They have a strong focus on innovation, sustainability, and customer service, making them a perfect match for the AEA's mission to promote the benefits of aluminum extrusions.The partnership between the AEA and the company will focus on several key areas, including promoting the use of aluminum extrusions in various industries, raising awareness about the benefits of aluminum, and providing educational resources for manufacturers, engineers, and designers.One of the main objectives of the partnership is to highlight the sustainability of aluminum extrusions. Aluminum is a highly recyclable material, and the extrusion process itself is energy-efficient and produces minimal waste. By promoting the use of aluminum extrusions, the AEA and the company aim to support the transition towards more sustainable and environmentally friendly manufacturing processes.Additionally, the partnership will focus on showcasing the versatility and design flexibility of aluminum extrusions. With the ability to create complex shapes and profiles, aluminum extrusions can be utilized in a wide range of applications, from automotive and transportation to building and construction. By demonstrating the capabilities of aluminum extrusions, the AEA and the company hope to inspire more industries to consider aluminum as a viable and valuable material.Furthermore, the partnership will provide educational resources and support for manufacturers, engineers, and designers who are considering the use of aluminum extrusions in their products or projects. The AEA and the company will collaborate to develop and share best practices, design guidelines, and case studies to help professionals better understand and utilize the benefits of aluminum extrusions.In addition to the partnership with the company, the AEA is also working on several other initiatives to further promote the use of aluminum extrusions. These include advocacy efforts to address industry challenges and opportunities, networking events to connect professionals within the industry, and educational programs to provide training and knowledge sharing.Overall, the AEA's partnership with the leading aluminum extrusion company represents a significant step forward in promoting the benefits of aluminum extrusions in North America. By working together to raise awareness, showcase the sustainability and versatility of aluminum, and provide educational resources, the AEA and the company are contributing to the advancement of the aluminum extrusion industry and its impact on various sectors.As a result of their collaboration, the AEA and the company aim to inspire more manufacturers, engineers, and designers to consider the use of aluminum extrusions, ultimately contributing to the growth of a more sustainable and innovative manufacturing industry.

Discover the Benefits of Longer Aluminium Profiles for Your Project

[Company Name] Introduces Innovative Aluminium Profile Length to Support Various Industries[date][City, Country] - [Company Name], a leading provider of high-quality aluminium solutions, is proud to announce the launch of its latest product, the Aluminium Profile Length. With its exceptional versatility and durability, this groundbreaking product is set to revolutionize the manufacturing and construction industries.Known for its commitment to excellence, [Company Name] has always been at the forefront of delivering innovative solutions to meet the evolving needs of its customers. The Aluminium Profile Length is a testament to the company's dedication to providing superior products that drive growth and efficiency across various sectors.The Aluminium Profile Length is designed to address the common challenges faced by manufacturers and builders when it comes to fitting and adjusting aluminium profiles. With its adjustable length feature, the profile can be easily modified to meet specific project requirements, eliminating the need for complex and time-consuming manual modifications or custom orders.One of the key advantages of the Aluminium Profile Length is its enhanced durability. Crafted from high-grade aluminium alloy, it offers exceptional strength and resistance to wear and tear. This ensures that the profiles will withstand rigorous usage, particularly in applications where structural integrity is crucial.The versatility of the Aluminium Profile Length extends beyond its adjustable feature. Its lightweight nature makes it suitable for a wide range of applications, from industrial machinery and equipment to architectural designs and interior partitions. The profiles can effortlessly bear heavy loads while ensuring stability and safety, making them an ideal choice for various industries.Furthermore, [Company Name] strives to provide environmentally-friendly solutions, and the Aluminium Profile Length is no exception. The profiles are made from high-quality recycled aluminium, minimizing the environmental impact associated with the manufacturing process. This not only supports sustainable practices but also allows businesses to incorporate eco-friendly materials into their projects.To ensure seamless integration, [Company Name] offers a wide range of compatible accessories and connectors for the Aluminium Profile Length. This allows companies to create customized structures and systems according to their specific requirements, further expanding its range of applications.Commenting on the launch, [Company Name]'s CEO, [CEO's Name], emphasized the company's commitment to customer satisfaction and innovation. He stated, "Our Aluminium Profile Length is a game-changer in the industry. We have taken into account the evolving needs of our customers and developed a solution that offers unmatched versatility and durability. We are excited to see how this product will drive growth for our customers across various sectors."The Aluminium Profile Length has already attracted significant interest from manufacturers and construction companies alike. [Company Name] has received numerous pre-orders from both domestic and international clients, further solidifying its position as a trusted supplier of aluminium solutions.With its dedication to quality, innovation, and customer satisfaction, [Company Name] continues to push boundaries and exceed industry expectations. The launch of the Aluminium Profile Length reflects the company's commitment to delivering superior products that empower businesses across multiple sectors.About [Company Name]:[Company Name] is a market leader in providing innovative aluminium solutions for various industries. With a focus on quality and customer satisfaction, the company offers a wide range of high-grade aluminium products, including profiles, sheets, and extrusions. [Company Name] is committed to driving growth and efficiency by delivering superior products and fulfilling unique customer requirements.###Press Contact:[Company Name][Contact Name][Phone Number][Email Address]

Explore the Benefits of 7075 T6 Alloy for Your Next Project

7075 T6 Alloy: The Future of Aerospace ManufacturingThe aerospace industry is constantly evolving and demanding materials that are lighter, stronger, and more durable than ever before. In response to this demand, a leading aerospace manufacturing company has announced the use of 7075 T6 alloy in their production process.The 7075 T6 alloy is a high-strength material that is widely used in the aerospace industry due to its exceptional strength-to-weight ratio and resistance to fatigue. This makes it an ideal choice for aircraft structures, where weight reduction and structural integrity are critical. In addition, the alloy also offers excellent corrosion resistance, making it suitable for use in harsh environmental conditions.The decision to integrate 7075 T6 alloy into their production process demonstrates the company’s commitment to implementing cutting-edge technologies and materials to stay ahead in the competitive aerospace industry. With this move, they are set to revolutionize the way aircraft components are manufactured, setting a new standard for performance and reliability.With the use of 7075 T6 alloy, the company aims to produce components that are not only lighter and more durable but also more cost-effective. By utilizing this high-strength material, they will be able to reduce the weight of their products, leading to improved fuel efficiency and overall performance of the aircraft. Furthermore, the exceptional strength and fatigue resistance of the alloy will contribute to longer service life and reduced maintenance costs, providing significant benefits to both the manufacturer and the end-user.In addition to the performance benefits, the company recognizes the environmental impact of aerospace manufacturing and the importance of sustainability. By incorporating 7075 T6 alloy into their production process, they are taking a step towards reducing the environmental footprint of their products. The lightweight nature of the alloy will contribute to lower fuel consumption, resulting in reduced emissions and environmental impact. Furthermore, the increased durability and longer service life of components made from this alloy will lead to fewer replacements and less material waste, ultimately contributing to a more sustainable aerospace industry.The company’s adoption of 7075 T6 alloy reflects their forward-thinking approach to manufacturing and commitment to innovation. By leveraging the properties of this advanced material, they are poised to deliver superior products that meet the ever-increasing demands of the aerospace industry. This move also solidifies their position as a leader in the field, setting a new standard for quality and performance in aerospace manufacturing.As the aerospace industry continues to advance, the use of advanced materials such as 7075 T6 alloy will play a crucial role in driving innovation and shaping the future of aircraft manufacturing. With its exceptional strength, durability, and environmental benefits, this alloy is set to redefine the standards for aerospace materials and pave the way for the next generation of aircraft components. The company’s integration of 7075 T6 alloy into their production process marks a significant milestone in the industry, signaling a new era of aerospace manufacturing that prioritizes performance, sustainability, and innovation.In conclusion, the adoption of 7075 T6 alloy by the leading aerospace manufacturing company represents a significant step forward for the industry. This advanced material promises to revolutionize the way aircraft components are manufactured, offering superior performance, durability, and environmental benefits. With this move, the company is set to establish a new standard for aerospace manufacturing, reaffirming their position as an industry leader and driving innovation in the field. As the aerospace industry continues to evolve, the integration of advanced materials such as 7075 T6 alloy will undoubtedly shape the future of aircraft manufacturing, leading to more efficient, sustainable, and high-performance aircraft that meet the demands of the modern era.