Discover the Strength and Durability of 7075 Aluminium Alloy Properties

By:Admin

Aluminium alloys are widely used in various industries due to their excellent properties, including high strength-to-weight ratio, corrosion resistance, and machinability. One of the most popular aluminium alloys is the 7075 alloy, known for its exceptional strength and toughness. In this article, we will explore the properties of the 7075 aluminium alloy and also introduce {} company, a leading manufacturer and supplier of high-quality aluminium products.

7075 aluminium alloy is an ultra-high strength material, with a yield strength of 73,000-78,000 psi (503-538 MPa). It contains zinc as the primary alloying element, which contributes to its high strength. In addition, small amounts of magnesium and copper are also added to enhance the alloy's strength and stress corrosion resistance. The 7075 alloy is heat treatable, which further improves its mechanical properties.

In terms of mechanical properties, 7075 aluminium alloy exhibits excellent strength and toughness. It has a tensile strength of 83,000-85,000 psi (572-586 MPa) and good resistance to fatigue, making it suitable for applications where high strength and durability are required. Additionally, the alloy has good machinability and responds well to various surface treatments, including anodizing and painting.

The corrosion resistance of 7075 aluminium alloy is also noteworthy. It has good resistance to general corrosion and provides excellent protection against corrosion in highly aggressive environments. This makes the alloy ideal for use in marine and aerospace applications, where exposure to moisture and salt can be significant.

{} company, a leading manufacturer and supplier of aluminium products, specializes in the production and distribution of high-quality aluminium alloys, including the 7075 alloy. With a strong focus on research and development, {} company has continuously improved its manufacturing processes to ensure the highest quality standards for its products.

As a customer-centric company, {} company is dedicated to providing tailored solutions to meet the specific needs of its clients. The company works closely with its customers to understand their requirements and offer personalized services, from alloy selection to product customization. With a strong emphasis on quality control, {} company ensures that its aluminium products meet the most stringent industry standards.

In addition to its manufacturing capabilities, {} company also has a strong commitment to sustainability and environmental responsibility. The company adheres to strict environmental regulations and actively seeks to minimize its environmental impact through responsible manufacturing practices and resource conservation.

Furthermore, {} company has a global presence, serving a diverse range of industries, including aerospace, automotive, marine, and defense. Its extensive distribution network and strategic partnerships allow the company to deliver its products to customers worldwide, ensuring timely and efficient service.

In conclusion, the 7075 aluminium alloy exhibits exceptional properties, making it a preferred material for various high-strength applications. With its outstanding mechanical properties and corrosion resistance, the 7075 alloy is widely used in critical industries such as aerospace and defense. As a reputable manufacturer and supplier of aluminium products, {} company plays a crucial role in supplying high-quality 7075 alloy products to meet the growing demand in the market. Through its dedication to quality, innovation, and sustainability, {} company continues to be a trusted partner for its customers, providing reliable solutions and superior products.

Company News & Blog

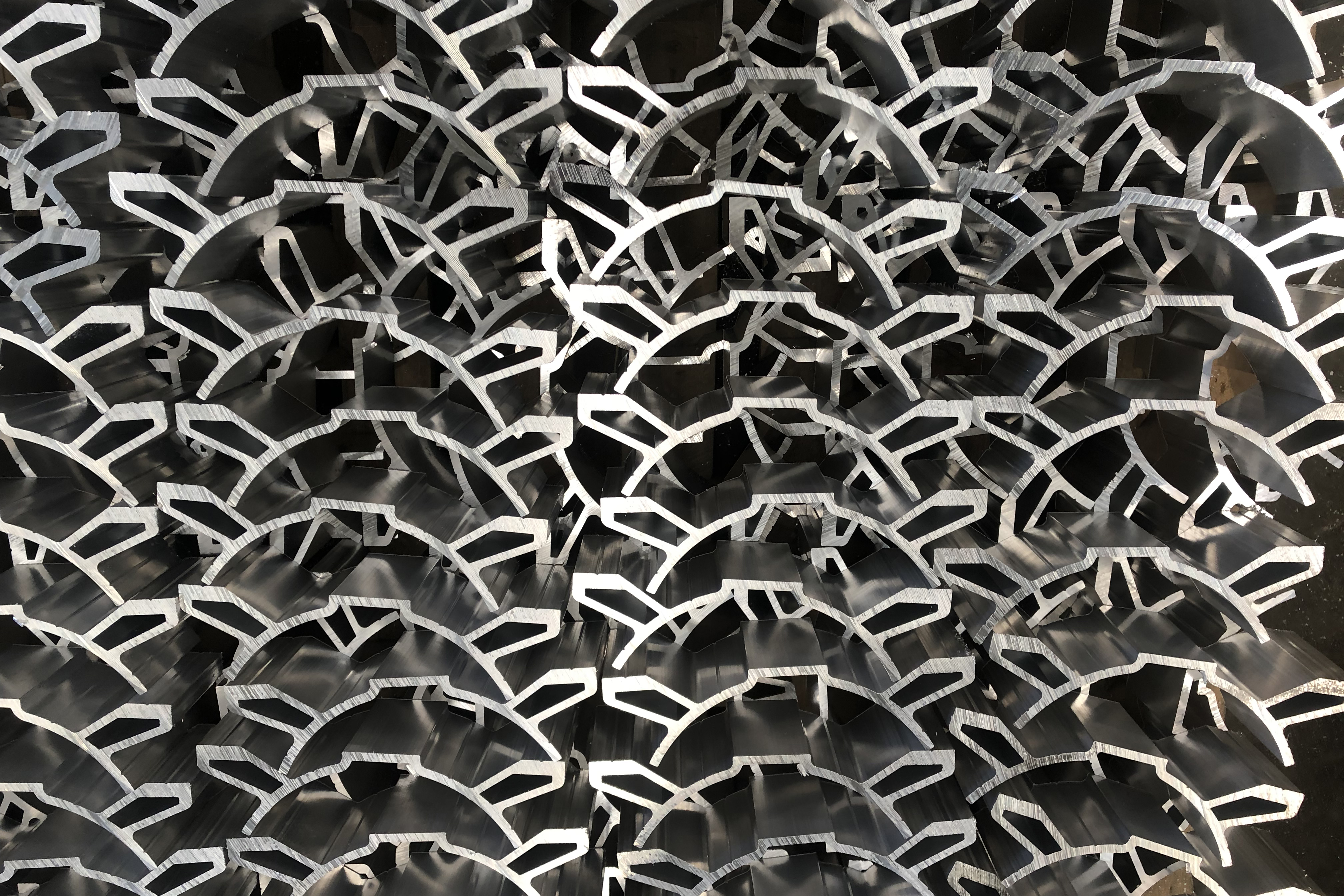

Different Types of Aluminum Sections: A Comprehensive Guide

Types Of Aluminum SectionsAluminum is a highly versatile metal that is widely used in the construction industry for its lightweight, durable, and corrosion-resistant properties. There are several different types of aluminum sections that are used for various applications in construction and other industries.One of the leading companies in the manufacturing and distribution of aluminum sections is {}. The company has been in the business for over 50 years and has established itself as a trusted supplier of high-quality aluminum products.One of the most commonly used types of aluminum sections is the rectangular tube. Rectangular tubes are widely used in various structural and architectural applications, thanks to their strength and versatility. These sections are often used in the construction of building frames, support beams, and even in the production of furniture and fixtures.Another popular type of aluminum section is the angle. Aluminum angles are L-shaped sections that are commonly used for corner and edge protection, as well as for structural support in construction projects. These sections are also used in the manufacturing of enclosures, frames, and brackets.Aluminum channels are another important type of aluminum section that are widely used in the construction industry. These sections are often used to create frames and supports for various structures, as well as for the installation of electrical wiring and cable management systems.In addition to these common types of aluminum sections, {} also offers a wide range of other specialty sections, including T-sections, Z-sections, and I-beams. These sections are often used in more specialized applications, such as in the construction of aircraft, automotive components, and marine structures.With a commitment to quality and customer satisfaction, {} is dedicated to providing a wide range of aluminum sections that meet the highest standards of performance and durability. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their products consistently meet the needs of their customers.In addition to supplying standard aluminum sections, {} also offers custom fabrication services to meet the specific requirements of their customers. Whether it's a unique shape, size, or finish, the company's skilled engineers and technicians can work closely with customers to create custom aluminum sections that meet their exact specifications.As a leader in the industry, {} is also committed to sustainability and environmental responsibility. The company's aluminum sections are manufactured using recycled materials, and they are fully recyclable at the end of their use. This commitment to sustainability helps reduce the environmental impact of the construction industry and promotes a more circular economy.In conclusion, aluminum sections are essential components in the construction industry, and {} continues to be a trusted supplier of high-quality aluminum products. With a wide range of standard and specialty sections, as well as custom fabrication services, the company is dedicated to meeting the diverse needs of its customers. With a focus on quality, sustainability, and customer satisfaction, {} is poised to remain a leader in the industry for years to come.

Durable and Lightweight Aluminum Extrusions Tube for Various Applications

Aluminum Extrusions Tube is a leading provider of aluminum extrusion products for a wide range of industries. The company has a strong focus on quality, innovation, and customer service, making it a trusted partner for businesses in need of aluminum extrusion solutions.With a state-of-the-art manufacturing facility and a team of experienced professionals, Aluminum Extrusions Tube has the capability to produce a diverse range of aluminum extrusion products, including tubes, channels, angles, and custom shapes. The company's extrusion process allows for the creation of complex shapes and designs, giving customers the flexibility to fulfill their specific project requirements.Aluminum Extrusions Tube is dedicated to providing high-quality products that meet or exceed industry standards. The company's commitment to excellence is evident in its rigorous quality control processes, which ensure that every product that leaves its facility is of the highest quality. With a focus on continuous improvement, Aluminum Extrusions Tube regularly invests in new technologies and processes to enhance its capabilities and maintain its competitive edge in the industry.In addition to its dedication to quality, Aluminum Extrusions Tube places a strong emphasis on innovation. The company's team of engineers and designers work closely with customers to develop custom solutions that meet their unique needs. Whether it's a complex extrusion design or a specific alloy requirement, Aluminum Extrusions Tube has the expertise and resources to deliver tailored solutions that add value to its customers' businesses.Customer service is at the core of Aluminum Extrusions Tube's business philosophy. The company's team is committed to providing exceptional support to its customers throughout the entire process, from initial consultation to final delivery. Aluminum Extrusions Tube understands the importance of meeting deadlines and aims to deliver products on time, every time.Beyond its commitment to excellence, innovation, and customer service, Aluminum Extrusions Tube also prioritizes environmental sustainability. The company has implemented eco-friendly practices in its manufacturing processes and is dedicated to reducing its environmental impact. Aluminum Extrusions Tube continuously seeks opportunities to improve its energy efficiency, reduce waste, and limit its carbon footprint.As a leading provider of aluminum extrusion products, Aluminum Extrusions Tube serves a diverse range of industries, including construction, automotive, aerospace, and consumer electronics. The company's products are used in a variety of applications, such as structural components, heat exchangers, and decorative trims, showcasing the versatility and adaptability of its aluminum extrusion solutions.In conclusion, Aluminum Extrusions Tube is a trusted partner for businesses in need of high-quality, innovative, and sustainable aluminum extrusion products. With a focus on quality, innovation, and customer service, the company is well-positioned to meet the diverse needs of its customers and exceed their expectations. Whether it's a standard extrusion or a custom solution, Aluminum Extrusions Tube has the expertise and capabilities to deliver reliable products that add value to its customers' projects and businesses.

Durable and lightweight aluminium frame construction: The future of building

Aluminium Frame Construction: The Future of Sustainable BuildingIn recent years, there has been a significant shift in the construction industry towards more sustainable and environmentally-friendly building materials. One of the materials that has gained popularity in the industry is aluminium, due to its numerous benefits such as its strength, durability, and recyclability. With the increasing demand for sustainable construction, more and more companies are turning to aluminium frame construction to meet these requirements.One of the leading advocates of aluminium frame construction is {Company Name}. Established in 1985, {Company Name} has been at the forefront of innovation in the construction industry, consistently providing high-quality and innovative solutions to meet the changing needs of the market. The company has built a solid reputation for its commitment to sustainability and has been a key player in promoting the use of aluminium in construction.Aluminium frame construction offers a number of advantages over traditional building materials. Firstly, aluminium is incredibly lightweight, yet strong, making it an ideal material for building structures that require both durability and flexibility. This means that buildings constructed using aluminium frames are not only more resistant to weather and natural disasters, but also easier and cheaper to transport and install.Additionally, aluminium is highly resistant to corrosion, which means that buildings constructed with aluminium frames require minimal maintenance over their lifespan. This not only reduces long-term costs for building owners, but also minimizes the environmental impact of construction by reducing the need for frequent replacements and repairs.Furthermore, aluminium is 100% recyclable, making it a much more sustainable choice compared to other building materials. This is in line with {Company Name}'s commitment to sustainability, as the company strives to minimize its environmental footprint and promote eco-friendly practices in the construction industry.{Company Name} has been at the forefront of promoting the use of aluminium frame construction by providing a range of innovative and high-quality aluminium products. The company offers a variety of aluminium framing systems that are designed to meet the specific needs of different building projects, from residential properties to commercial and industrial developments. Their expertise in aluminium construction has allowed them to work on a wide range of projects, from small-scale residential developments to large-scale commercial and industrial buildings.In addition to offering cutting-edge aluminium framing systems, {Company Name} also places a strong emphasis on providing excellent customer service and support. Their team of highly skilled and knowledgeable professionals are dedicated to working closely with clients to ensure that their specific requirements and preferences are met. {Company Name} prides itself on its ability to deliver customized solutions that are tailored to each client's needs, ensuring that every project is completed to the highest standard.With their strong focus on sustainability and innovation, {Company Name} is well-positioned to lead the way in promoting the use of aluminium frame construction in the construction industry. Their dedication to providing high-quality, sustainable solutions has earned them a reputation as a trusted and reliable partner for construction projects of all sizes.The use of aluminium frame construction is not only beneficial for the environment, but also offers a range of practical and economic advantages for building owners and developers. With the support of companies like {Company Name} that are committed to promoting sustainable building practices, the future of construction looks promising, as the industry continues to move towards more environmentally-friendly and innovative building materials.

High-Quality Aluminium Profile for CNC: A Complete Guide

Aluminium Profile For CNC Offers Precision and Reliability in Machining OperationsIn the world of manufacturing and machining, precision and reliability are essential factors for the success of any operation. With the increasing demand for high-quality CNC machining, the choice of materials is crucial in achieving the desired outcome. Aluminium profiles have emerged as a popular choice for CNC machining due to their excellent strength-to-weight ratio, corrosion resistance, and flexibility. One company that has been at the forefront of providing top-quality aluminium profiles for CNC machining is {}.{} has been a leading manufacturer and supplier of aluminium profiles for CNC machining for over two decades. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses in a wide range of industries, including automotive, aerospace, electronics, and construction.The company's aluminium profiles are designed to meet the exacting requirements of CNC machining operations. Made from high-quality aluminium alloys, the profiles offer exceptional strength, durability, and precision, making them the ideal choice for a variety of machining applications. Whether it's milling, drilling, tapping, or cutting, {}'s aluminium profiles provide the reliability and performance that manufacturers and machinists depend on.One of the key features of {}'s aluminium profiles is their versatility. Available in a wide range of sizes and shapes, the profiles can be customized to meet the specific requirements of different CNC machining operations. This versatility allows for greater flexibility in design and production, enabling businesses to optimize their machining processes for maximum efficiency and productivity.Furthermore, {}'s aluminium profiles are known for their excellent machinability. Their consistent and uniform composition ensures smooth and precise machining, while their corrosion resistance and thermal conductivity make them suitable for a variety of cutting fluids and cooling methods. This translates to longer tool life, lower operating costs, and higher overall productivity for businesses utilizing {}'s aluminium profiles for CNC machining.Another important aspect of {}'s aluminium profiles is their environmental friendliness. As a recyclable material, aluminium is favored by many businesses for its sustainability and eco-friendly properties. {} is committed to sustainable manufacturing practices, and their aluminium profiles are produced using energy-efficient processes and recycled materials, further enhancing their appeal to environmentally-conscious businesses.To complement their high-quality aluminium profiles, {} offers comprehensive technical support and customer service to ensure a seamless and successful CNC machining experience for their clients. From material selection to design assistance, the company's team of experts is dedicated to helping businesses achieve their machining goals with precision and confidence.As the demand for high-quality CNC machining continues to grow, the choice of materials becomes increasingly critical in determining the success of machining operations. {}'s aluminium profiles stand out as a reliable and versatile solution for businesses looking to achieve precision, efficiency, and cost-effectiveness in their CNC machining processes.In conclusion, {}'s aluminium profiles for CNC machining offer a winning combination of strength, precision, and reliability. With their exceptional machinability, versatility, and environmental friendliness, these profiles are setting a new standard for excellence in the machining industry. As businesses continue to seek high-quality materials for their CNC machining operations, {} remains a trusted partner, delivering top-quality aluminium profiles backed by technical expertise and outstanding customer support.

Durable and Versatile Extruded Aluminum Material for Various Applications

Extruded Aluminum Material is a leading supplier of high-quality aluminum products that are used in a wide range of industries including construction, automotive, and aerospace. The company specializes in the extrusion of aluminum to create custom shapes and profiles that meet the specific needs of their clients. With a focus on innovation and precision, Extruded Aluminum Material has established itself as a trusted partner for businesses seeking reliable and high-performance aluminum products.The company’s commitment to delivering top-notch products is evident in their state-of-the-art manufacturing facilities, which are equipped with the latest technology and operated by a team of highly skilled professionals. This allows Extruded Aluminum Material to produce aluminum products that meet the highest standards of quality and performance. In addition, the company’s dedication to sustainability and environmental responsibility is reflected in their use of recycled aluminum in their manufacturing process, which helps to minimize their environmental impact and reduce their carbon footprint.Extruded Aluminum Material’s dedication to customer satisfaction is evident in their ability to provide custom solutions that meet the unique needs of their clients. By working closely with their customers, the company is able to develop innovative aluminum products that address specific challenges and deliver exceptional performance. Whether it’s creating custom extrusions for architectural applications or developing specialized aluminum components for the automotive industry, Extruded Aluminum Material has the expertise and resources to deliver superior solutions that exceed their clients’ expectations.In addition to their commitment to quality and innovation, Extruded Aluminum Material also places a strong emphasis on customer service. The company’s team of professionals is dedicated to providing exceptional support to their clients throughout the entire process, from initial consultation to product delivery. This level of personalized service sets Extruded Aluminum Material apart from other suppliers and has earned them a reputation for reliability and excellence in the industry.With a strong track record of delivering exceptional products and outstanding service, Extruded Aluminum Material has built a loyal and diverse customer base. From small businesses to large corporations, the company’s aluminum products are trusted by a wide range of clients who rely on them for their precision, performance, and durability. Whether it’s for architectural design, automotive manufacturing, or any other industry, Extruded Aluminum Material’s products have become essential components in a variety of applications.Looking ahead, Extruded Aluminum Material is poised to continue its success and remain at the forefront of the industry. The company’s ongoing commitment to innovation, quality, and customer service will ensure that they continue to meet the evolving needs of their clients and maintain their position as a leading supplier of aluminum products. With a focus on sustainability and a dedication to excellence, Extruded Aluminum Material is well-positioned to drive continued growth and success in the years to come.In conclusion, Extruded Aluminum Material is a trusted and reliable supplier of high-quality aluminum products, serving a diverse range of industries with precision, innovation, and superior customer service. With a dedication to excellence and a focus on sustainability, the company is well-positioned for continued success and growth in the future.

Discover the Strength and Durability of 7075 Aluminium Alloy Properties

7075 Aluminium Alloy Properties and {} Company IntroductionAluminium alloys are widely used in various industries due to their excellent properties, including high strength-to-weight ratio, corrosion resistance, and machinability. One of the most popular aluminium alloys is the 7075 alloy, known for its exceptional strength and toughness. In this article, we will explore the properties of the 7075 aluminium alloy and also introduce {} company, a leading manufacturer and supplier of high-quality aluminium products.7075 aluminium alloy is an ultra-high strength material, with a yield strength of 73,000-78,000 psi (503-538 MPa). It contains zinc as the primary alloying element, which contributes to its high strength. In addition, small amounts of magnesium and copper are also added to enhance the alloy's strength and stress corrosion resistance. The 7075 alloy is heat treatable, which further improves its mechanical properties.In terms of mechanical properties, 7075 aluminium alloy exhibits excellent strength and toughness. It has a tensile strength of 83,000-85,000 psi (572-586 MPa) and good resistance to fatigue, making it suitable for applications where high strength and durability are required. Additionally, the alloy has good machinability and responds well to various surface treatments, including anodizing and painting.The corrosion resistance of 7075 aluminium alloy is also noteworthy. It has good resistance to general corrosion and provides excellent protection against corrosion in highly aggressive environments. This makes the alloy ideal for use in marine and aerospace applications, where exposure to moisture and salt can be significant.{} company, a leading manufacturer and supplier of aluminium products, specializes in the production and distribution of high-quality aluminium alloys, including the 7075 alloy. With a strong focus on research and development, {} company has continuously improved its manufacturing processes to ensure the highest quality standards for its products.As a customer-centric company, {} company is dedicated to providing tailored solutions to meet the specific needs of its clients. The company works closely with its customers to understand their requirements and offer personalized services, from alloy selection to product customization. With a strong emphasis on quality control, {} company ensures that its aluminium products meet the most stringent industry standards.In addition to its manufacturing capabilities, {} company also has a strong commitment to sustainability and environmental responsibility. The company adheres to strict environmental regulations and actively seeks to minimize its environmental impact through responsible manufacturing practices and resource conservation.Furthermore, {} company has a global presence, serving a diverse range of industries, including aerospace, automotive, marine, and defense. Its extensive distribution network and strategic partnerships allow the company to deliver its products to customers worldwide, ensuring timely and efficient service.In conclusion, the 7075 aluminium alloy exhibits exceptional properties, making it a preferred material for various high-strength applications. With its outstanding mechanical properties and corrosion resistance, the 7075 alloy is widely used in critical industries such as aerospace and defense. As a reputable manufacturer and supplier of aluminium products, {} company plays a crucial role in supplying high-quality 7075 alloy products to meet the growing demand in the market. Through its dedication to quality, innovation, and sustainability, {} company continues to be a trusted partner for its customers, providing reliable solutions and superior products.

High-Quality Aluminium Angle Profiles for Various Uses

Aluminium Angle Profiles have become increasingly popular in the construction and manufacturing industries due to their versatility and durability. These profiles are used in a variety of applications, including framing, support beams, and trim work. The demand for high-quality aluminium angle profiles has led to the rise of many manufacturers in the industry, including {company name}.{Company name} is a leading manufacturer of aluminium angle profiles, offering a wide range of profiles in various sizes and finishes. The company has established a reputation for producing high-quality products that meet the needs of the construction and manufacturing sectors. Their aluminium angle profiles are known for their strength, corrosion resistance, and long-lasting performance, making them the top choice for many industry professionals.One of the key reasons for the popularity of aluminium angle profiles is their lightweight nature. Aluminium is a lightweight metal, making it easy to handle and install compared to other materials like steel. This characteristic also makes it a cost-effective option for construction projects, as it reduces transportation and labor costs.In addition to their lightweight nature, aluminium angle profiles are also highly resistant to corrosion. This is particularly important in construction applications, where the profiles may be exposed to the elements. The corrosion resistance of aluminium ensures that the profiles maintain their structural integrity and appearance over time, making them a reliable choice for long-term use.Another advantage of aluminium angle profiles is their versatility. These profiles can be easily modified, cut, and shaped to fit specific project requirements. This flexibility allows for a wide range of design possibilities, making aluminium angle profiles a popular choice for architects and designers.{Company name} is committed to providing high-quality aluminium angle profiles that meet industry standards and customer expectations. The company utilizes advanced manufacturing processes and quality control measures to ensure that their products are of the highest standard. The profiles undergo rigorous testing and inspection to guarantee their structural integrity, surface finish, and dimensional accuracy.Furthermore, {company name} offers a range of surface finishes for their aluminium angle profiles, allowing customers to choose the right aesthetic for their projects. Whether it's a natural mill finish, anodized, or powder-coated finish, the company provides options to suit various design preferences.The company also places a strong emphasis on sustainability in their manufacturing processes. Aluminium is a highly recyclable material, and {company name} is committed to reducing waste and environmental impact. By utilizing recycled aluminium and minimizing material waste, the company is dedicated to contributing to a more sustainable future.{Company name}'s dedication to quality, versatility, and sustainability has made them a preferred supplier of aluminium angle profiles for many construction and manufacturing companies. Their profiles can be found in a wide range of applications, including commercial buildings, residential construction, industrial machinery, and more.As the demand for aluminium angle profiles continues to grow, {company name} remains at the forefront of the industry, providing innovative solutions and exceptional products to meet the evolving needs of their customers. With a focus on quality, reliability, and customer satisfaction, {company name} is poised to maintain its position as a leading manufacturer in the aluminium angle profile market.

Ultimate Guide to Using V Slot Extrusion in Your DIY Projects

article:V Slot Extrusion: The Perfect Solution for Your Structural NeedsStructural framing is an essential aspect of various industries. Whether for building construction, manufacturing plants, or automotives, sturdy structural framing is necessary. Mechanisms that support and withstand loads drive these industries. With a focus on mechanical design, particular attention to the strength of members must be at the forefront of any project. Proper structural support ensures better quality and performance of any machine or building. One structural framing system that stands out is V Slot Extrusion. 4040 V Slot Extrusion (link to non-brand website) is a robust structural framing material system that incorporates a unique v-shaped slot feature. Thanks to its v-shaped slot, V Slot Extrusion allows for easy slide-in installation of T-slot nuts. It has pre-installed mounting shelves that make it easy to position different types of components, from door frames to work tables. V Slot Extrusion is made of aluminum, making it light and strong at the same time.V Slot Extrusion has a wide range of applications. It is perfect for designing structural frameworks, including machines, industrial work benches, camera sliders, 3D printers, and many more. Its flexibility makes it fit for numerous uses.Various companies have embraced V Slot Extrusion for its versatility. In one instance, a construction company used V Slot Extrusion to refurbish a hotel bar counter. They installed a customized bar that had a unique lighting and sound system, as well as several other hidden features. The construction company stated that V Slot Extrusion made it easier to install the various components into the bar counter easily. The finished job looked stunning, modern, and well structured, not to mention that it was sturdy enough to support the weight of the components.Another company that benefited from using V Slot Extrusion is a manufacturing plant that manufactures automobile parts. Their work table was made using V Slot Extrusion. The table had a unique design with extrusions as legs and beams supporting the work surface. The plant’s engineers stated that V Slot Extrusion provided additional mobility and streamline design, ensuring the table could support heavy equipment.The automotive industry is known for its complexity of machinery and the need to create efficient solutions that handle the pressure of daily operations. V Slot Extrusion has been the foundation of the manufacturing plant's automated process since 2017. The material is trustworthy and suits their needs perfectly. The V-slot configuration used for their work table offers the best ratio of weight to strength. As the table is moved around the plant, it can carry dense, heavy equipment, without any signs of wear or tear.V Slot Extrusion is also trending in the home DIY arena. Many homeowners are now discovering how V Slot Extrusion can create multi-purpose structures such as wardrobes, standing desks, or even home bar counters. The extrusions provide a sleek and finished look that is perfect for modern interior designs.Installing V Slot Extrusion is an easy process. It is available in different sizes and lengths, making it versatile to use. It has a pre-cut design that makes it convenient to work with. Moreover, attaching screws and nuts to V Slot Extrusion is a breeze, meaning it helps to save time while improving the efficiency of the project. A company spokesperson stated that V Slot Extrusion simplified their project design process, from the component selection phase to installation. As a result, it has reduced their construction time for their structural framework to only a quarter of what it used to be.In conclusion, V Slot Extrusion is the go-to solution for different structural framing needs. From industrial buildings to modern home DIY projects, V Slot Extrusion provides robust, flexible, and streamlined solutions that make any project stand out. Its versatility, lightweight, and strength are further evidence that it is the perfect solution for structural needs.

Top Industrial Automation Solutions for Aluminum Production

Industrial Automation Aluminum (IAA) is a leading company in the field of industrial automation and aluminum solutions. With a focus on innovation and quality, IAA has been a key player in providing cutting-edge technology and products to various industries worldwide. Their commitment to excellence has made them a trusted partner for many businesses seeking reliable automation and aluminum solutions.IAA’s extensive product portfolio includes a wide range of automation equipment and aluminum products that cater to different industries such as automotive, aerospace, construction, and manufacturing. Their expertise in industrial automation allows them to provide customized solutions that meet the specific needs and requirements of their clients.One of the key strengths of IAA is their in-house design and engineering capabilities. With a team of highly skilled and experienced engineers, they can develop custom solutions that optimize production processes, improve efficiency, and reduce costs for their clients. This ability to tailor their products to meet the unique demands of various industries has set them apart from their competitors.In addition to their design and engineering capabilities, IAA is also known for its state-of-the-art manufacturing facilities. Equipped with advanced machinery and technology, IAA’s manufacturing plants ensure the highest quality standards are met for their products. This dedication to quality has earned them a strong reputation for reliability and performance in the industry.IAA's commitment to sustainability is another distinguishing factor. They prioritize environmentally friendly practices in their manufacturing processes, ensuring that their products have minimal impact on the environment. By incorporating sustainable practices into their operations, IAA not only contributes to a greener planet but also aligns with the growing demand for eco-friendly solutions in the industry.The company’s dedication to innovation is evident in their continuous investment in research and development. IAA is constantly exploring new technologies and methodologies to stay at the forefront of industrial automation and aluminum solutions. This proactive approach allows them to anticipate market trends and provide their clients with innovative products that give them a competitive edge.Furthermore, IAA’s commitment to customer satisfaction is unwavering. They prioritize building long-term relationships with their clients by providing exceptional service and support. Whether it's through product customization, technical assistance, or after-sales support, IAA goes the extra mile to ensure their clients’ needs are met and their expectations are exceeded.In line with their commitment to excellence, IAA has recently launched a new line of automation and aluminum products that are poised to make a significant impact in the industry. By leveraging their expertise in industrial automation and aluminum solutions, IAA’s new products are expected to offer enhanced performance, efficiency, and durability to their clients.With their strong reputation, commitment to innovation, sustainability, and customer satisfaction, IAA continues to be a driving force in the industrial automation and aluminum solutions market. As they set their sights on the future, IAA remains dedicated to delivering cutting-edge technology and products that empower businesses to thrive in a rapidly evolving industry.

High-Quality Aluminium Heat Sink Profiles for Efficient Thermal Management

Aluminium heat sink profiles are an essential component in numerous electronic devices and systems, providing efficient heat dissipation and thermal management. With the increasing demand for high-performance electronics, the need for high-quality aluminium heat sink profiles has never been greater.{Company Name}, a leading manufacturer of aluminium extrusion products, has been at the forefront of producing top-notch aluminium heat sink profiles for various industries. With years of experience and expertise in aluminium extrusion, the company is well-equipped to meet the growing demands for advanced thermal management solutions.The significance of aluminium heat sink profiles cannot be overstated, especially in the realm of electronics and technology. Electronic components, such as CPUs, GPUs, power transistors, and LED lighting systems, generate heat during operation. Without proper thermal management, these components can overheat, leading to reduced performance, shortened lifespan, and even system failure.{Company Name} understands the critical role of aluminium heat sink profiles in addressing thermal challenges. By utilizing high-quality aluminium alloys and state-of-the-art extrusion techniques, the company is able to produce heat sink profiles with excellent thermal conductivity, lightweight design, and exceptional durability. These profiles are engineered to effectively dissipate heat and maintain optimal operating temperatures for electronic devices and systems.In addition to their thermal properties, the aluminium heat sink profiles manufactured by {Company Name} are also designed with versatility and compatibility in mind. Whether it's for industrial machinery, automotive electronics, consumer electronics, or telecommunications equipment, the company offers a wide range of heat sink profiles to suit diverse applications.Furthermore, {Company Name} prides itself on its commitment to customization and design flexibility. The company works closely with its clients to understand their specific thermal management needs and provide tailored solutions. From custom profiles to intricate geometries and surface finishes, {Company Name} has the capability to deliver heat sink profiles that meet the exact requirements of each customer.With a focus on innovation and continuous improvement, {Company Name} has invested in advanced manufacturing technologies and quality assurance processes to ensure the highest level of product excellence. The company's dedication to precision engineering and strict adherence to industry standards have earned it a stellar reputation in the market.Looking ahead, the demand for aluminium heat sink profiles is projected to rise in tandem with the ongoing advancements in electronics and technology. As electronic devices become more powerful and compact, the need for efficient thermal management solutions will only intensify. {Company Name} is poised to play a pivotal role in meeting this demand, thanks to its cutting-edge capabilities and unwavering dedication to customer satisfaction.In conclusion, aluminium heat sink profiles are indispensable components for managing heat in electronic devices and systems. {Company Name} stands out as a premier manufacturer of high-quality aluminium heat sink profiles, offering customized solutions and superior performance. With its focus on innovation, quality, and customer-centric approach, {Company Name} is well-positioned to lead the way in delivering advanced thermal management solutions for the evolving needs of the electronics industry.